NightReaver

2[H]4U

- Joined

- Apr 20, 2017

- Messages

- 3,808

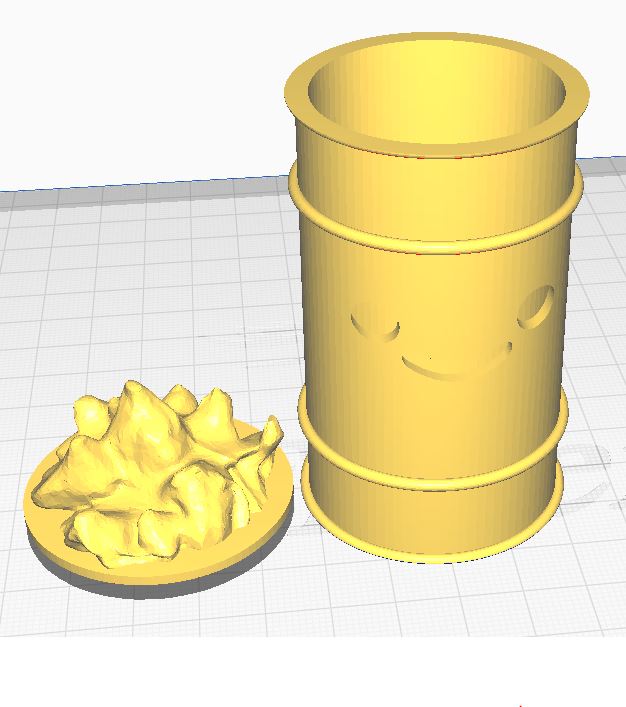

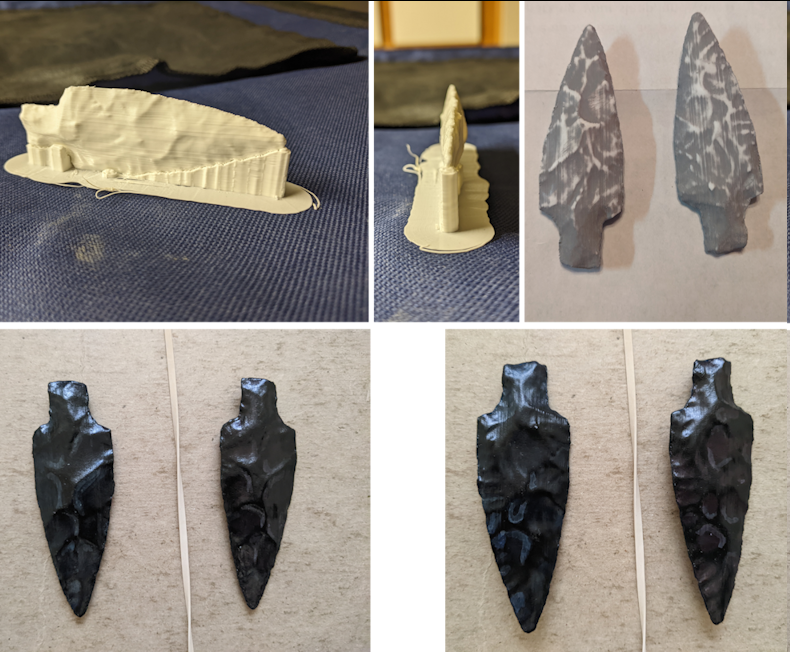

Lol, yeah you're right about that. The painting goes a long ways, too.Yeah.. I underestimated how much of a PITA it was to try to sand the top/backtop of the head.. not super noticeable until up close but I think smaller layers would have helped. So it goes.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)