BrainEater

[H]ard|Gawd

- Joined

- Jul 21, 2004

- Messages

- 1,210

Woop !

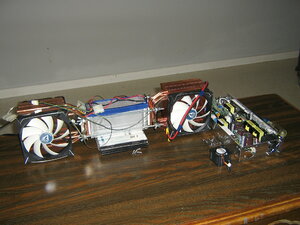

I did a test of my watercooling setup, d5 vario from a reservoir of my own design to dual socket 3647 cpu blocks.

Seems to work quite well, however I have some questions.

---

So a G1/4 watercooling fitting uses the o-ring to provide seal. The threads only provide 'compression' for the O-rings.Is there any reason NOT to use something like a medium strength threadlocker to keep things from unscrewing ?

--

Radiators :

I have to assume if you are using a radiator horizontally , barbs 'down' is bad.

I'm sure I'll think up a couple more dumb questions ,

TYIA all the same !

I did a test of my watercooling setup, d5 vario from a reservoir of my own design to dual socket 3647 cpu blocks.

Seems to work quite well, however I have some questions.

---

So a G1/4 watercooling fitting uses the o-ring to provide seal. The threads only provide 'compression' for the O-rings.Is there any reason NOT to use something like a medium strength threadlocker to keep things from unscrewing ?

--

Radiators :

I have to assume if you are using a radiator horizontally , barbs 'down' is bad.

I'm sure I'll think up a couple more dumb questions ,

TYIA all the same !

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)