greensabbath

n00b

- Joined

- Dec 5, 2005

- Messages

- 54

You are doing an excellent job.

Since you seem to be doing a lot of it throught he school, do they finance the supplies? The amount of aluminum you are using racks up quite fast, especially at that tickness. Does this double as a project in class?

Also, whats the concept behind the archetectual buildings that you had to do? Did everyone deal with the same platform to do a design on? Were you guys instructed to show more art and conceptulization rather than function?

Thank you and great questions.

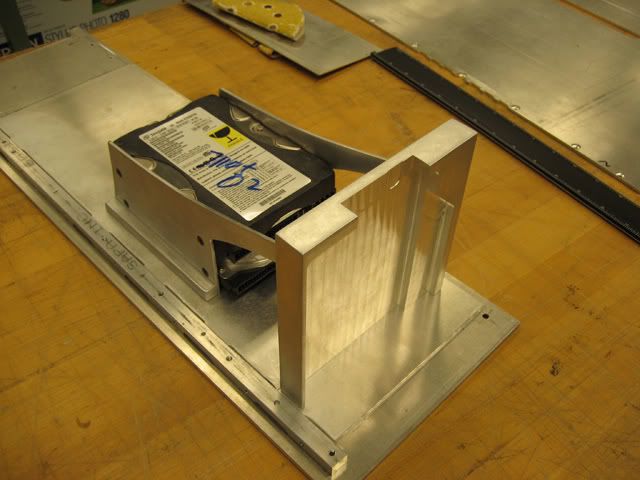

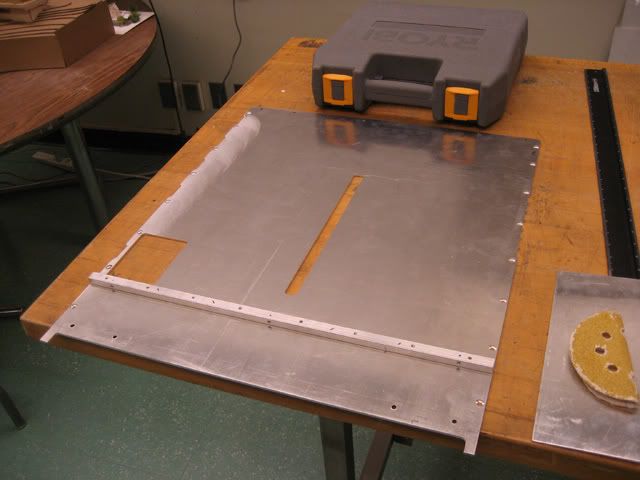

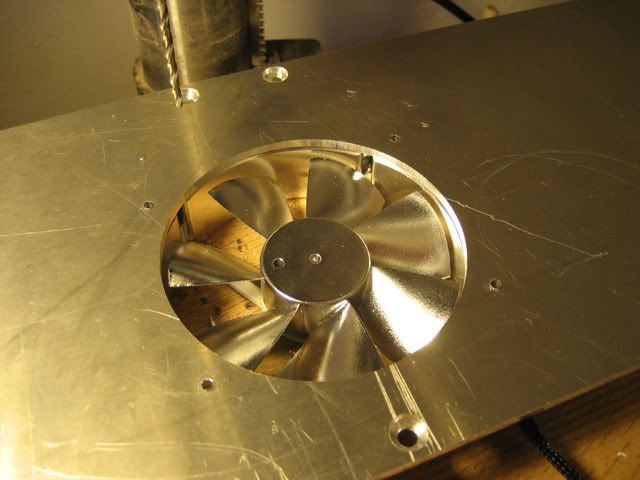

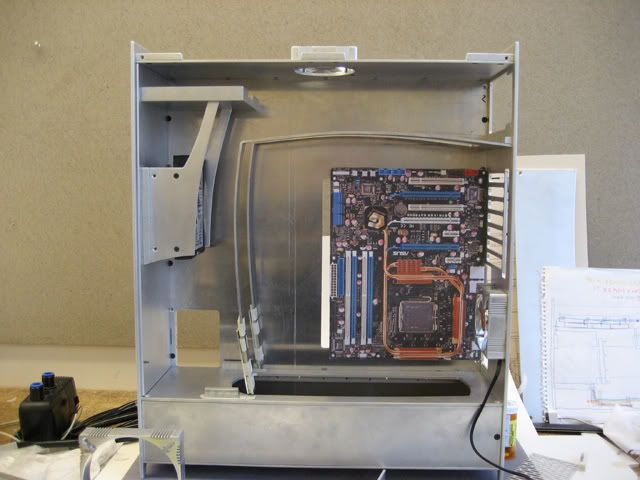

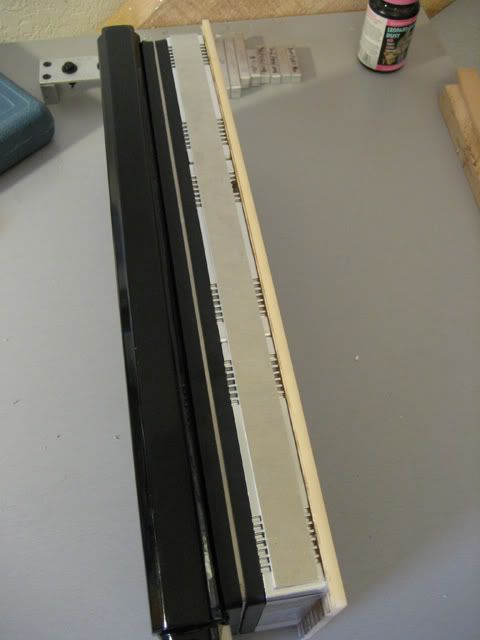

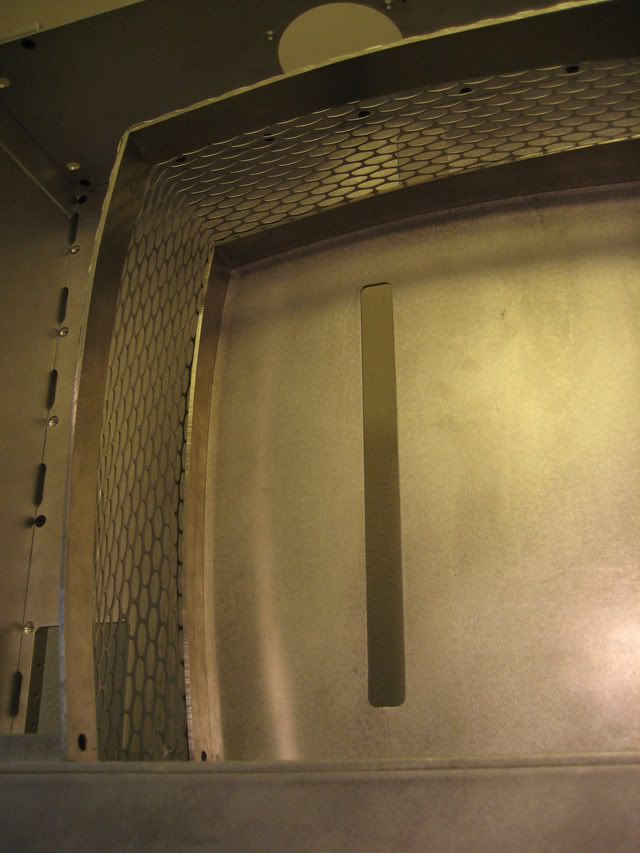

I wish they helped pay for supplies but they don't. My department (architecture) is actually pretty poor so they barely have enough money to get everyone in classes. The alu alone on this case has cost about 300 bucks so yeah it does add up rather quickly. It doesn't really double as a class project either but i work on it during class since I believe its more important.

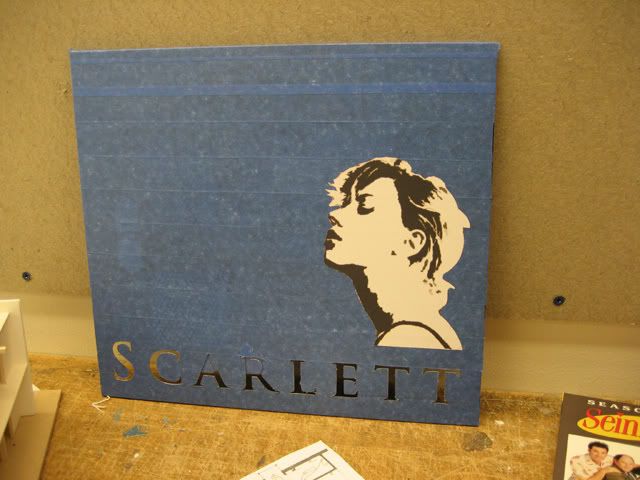

The concept behind that stupid house gave me a headache for the entire quarter. The "official" project was supposed to be a "biomorphic house" but my professor essentially does not teach. He showed up for a couple hours, painted some stuff, mumbled some words of wisdom, and went to a water polo game or something. He's a genious though and i guess its all part of his plan. We all had the same site but i chose the flatter part of the site (and essentially ignored it anyway) and we basically built whatever we wanted. Some people's were way more sculptural and a couple people's were much more practical. It just depened on your personality I guess.

Sorry these answers ended up so long. Updates coming soon.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)