A few months back I started getting excited about Zen and Vega so I wanted to try something I've never done before. I began working on an ITX SFF case that would house a dGPU as well while keeping the volume as small as possible.

I began this project without knowing about the Sentry case, but decided to move forward instead because I both wanted to do some things differently and go through the experience of design to manufacture for myself.

I went to Michael's and bought some thick drawing board to first mock up a design in paper before translating it into CAD. These images are from the end of September and show the result of of the design I was able to achieve just sitting in my living room playing with dimensions and positions of components. You'll notice the mITX power supply I chose to use which later had to upgrade to a SFX when I realized I could only get it up to a maximum of 600W.

Once I had this portion complete, I started learning SketchUp so I could design the case and export it to the machine shop for their punch machine to manufacture. After I had the design complete in SketchUp, I added a placeholder for the SFX power supply as well as a USB 3.1 Type C 20-pin board and a wireless LED RGBW controller board. The plan is to install the custom RGB LED strips inside the case and have a custom front-panel RGB button.

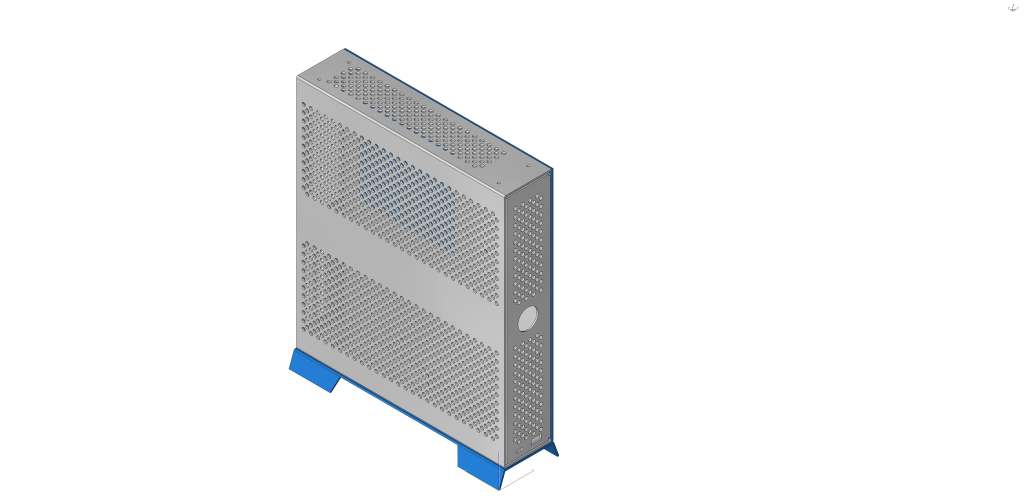

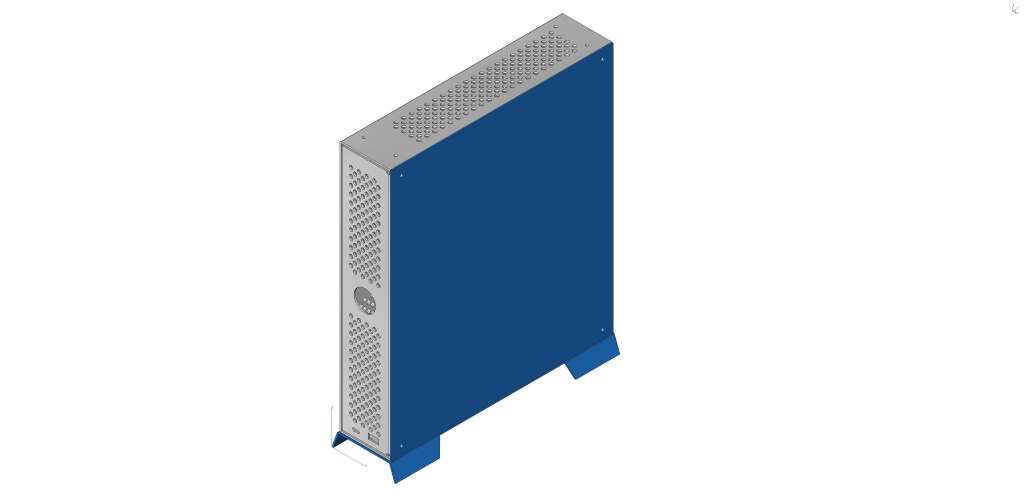

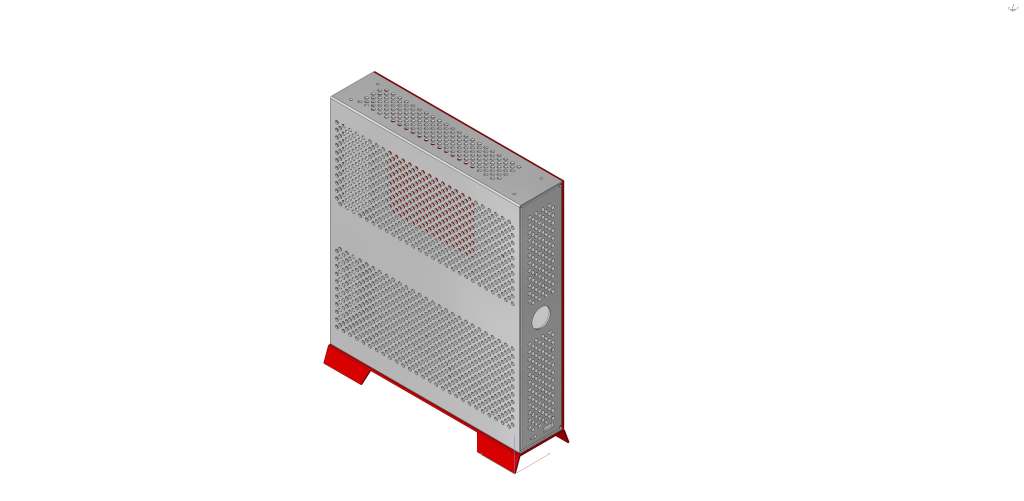

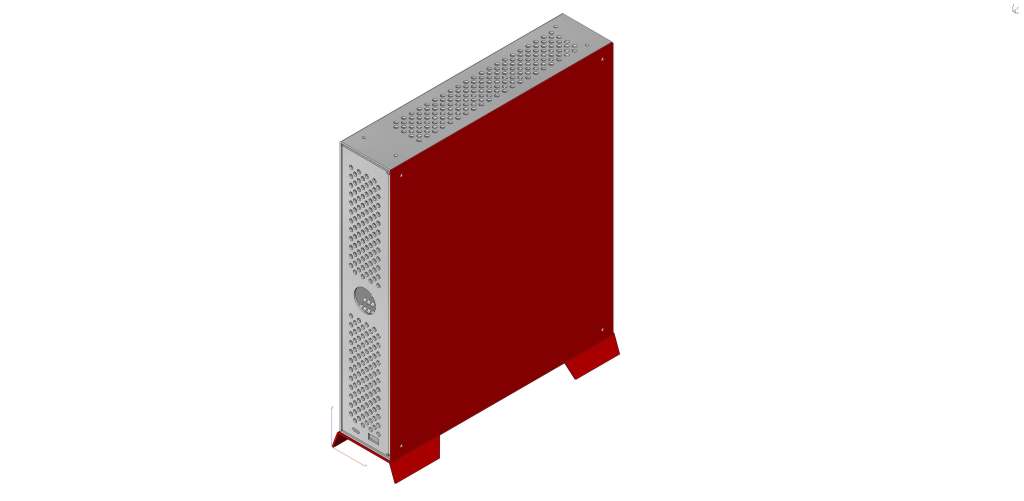

At this point, I had decided to make the dGPU face "up" so the fans would be oriented in the same way the CPU fans were. This way, I could configure the case in either a vertical or horizontal configuration and not have to worry about airflow. Another change I made was to allow the case to be mounted to the stand on either the "top" or the "bottom" face so that the user could decide which way they wanted the vent panel to face.

I added a 4mm panel without vents to provide strength as well as a cover for the "mounting" panel so you can easily access the underside of the mainboard as well as the SSDs.

At this point I sent the design to the machine shop who immediately threw it back to me because SketchUp's IGS format converter did a lousy job of converting SketchUp's surface format. At this point, I purchased ViaCAD Pro and remodeled the entire case from scratch so I could send the case file to the machine shop.

As far as the power button, I decided I wanted something much different than usual. I started by looking at Alibaba to find what buttons manufacturers offer that also provide LED lighting. I stumbled upon Piezo switches that seemed to provide me with something unique. Piezo switches have no moving parts (similar to capacitive switches but without a power requirement). After ordering a sample, the LEDs were fine, but the button operation was momentary only - you cannot "hold" the switch in the off position. Therefore, this button style wouldn't work and I started running out of time to have these by the end of the year. Below is a picture of the sample Piezo switch I ordered.

I eventually settled for a standard button in a similar style with RGB LEDs.

After the machine shop asked me to make a few tweaks, I modified the base to simply have 4 angled feet so I could get a prototype done, but I'll probably modify the base again before making the final product.

Specs

Internal Dimensions: 304mm x 68mm x 350mm (7.23L)

External Dimensions: Unknown (will depend on metal thickness)

1 x standard ITX motherboard mount

1 x PCIe dGPU with maximum length of ~304mm

4 x 2.5 drive mounts (if I decide to make adapter plates they could be stacked to support up to 16 drives without a dGPU)

1 x SFF Power Supply (Using Lian Li 750W to mock up mount plate)

1 x USB 3.1 Type C connector (front panel)

1 x USB 3.0 Type A connector (front panel)

1 x Wireless LED controller with phone app to adjust RGB color

No optical drives

For a lot of the parts I had to order them in quantity so it is possible that I will be making these for sale at some point. I'll be updating this thread as I make progress. Currently I'm waiting on the machine shop to make the first prototype which should be done by the first of the year. BTW, the prototype will be done in aluminum which I plan to use unless it proves too weak to support the weight of the components. I will then finish off the main portion of the case by blasting the aluminum to have a "macbook"-like finish and I'll paint the thick side panel and base a bold color.

I began this project without knowing about the Sentry case, but decided to move forward instead because I both wanted to do some things differently and go through the experience of design to manufacture for myself.

I went to Michael's and bought some thick drawing board to first mock up a design in paper before translating it into CAD. These images are from the end of September and show the result of of the design I was able to achieve just sitting in my living room playing with dimensions and positions of components. You'll notice the mITX power supply I chose to use which later had to upgrade to a SFX when I realized I could only get it up to a maximum of 600W.

Once I had this portion complete, I started learning SketchUp so I could design the case and export it to the machine shop for their punch machine to manufacture. After I had the design complete in SketchUp, I added a placeholder for the SFX power supply as well as a USB 3.1 Type C 20-pin board and a wireless LED RGBW controller board. The plan is to install the custom RGB LED strips inside the case and have a custom front-panel RGB button.

At this point, I had decided to make the dGPU face "up" so the fans would be oriented in the same way the CPU fans were. This way, I could configure the case in either a vertical or horizontal configuration and not have to worry about airflow. Another change I made was to allow the case to be mounted to the stand on either the "top" or the "bottom" face so that the user could decide which way they wanted the vent panel to face.

I added a 4mm panel without vents to provide strength as well as a cover for the "mounting" panel so you can easily access the underside of the mainboard as well as the SSDs.

At this point I sent the design to the machine shop who immediately threw it back to me because SketchUp's IGS format converter did a lousy job of converting SketchUp's surface format. At this point, I purchased ViaCAD Pro and remodeled the entire case from scratch so I could send the case file to the machine shop.

As far as the power button, I decided I wanted something much different than usual. I started by looking at Alibaba to find what buttons manufacturers offer that also provide LED lighting. I stumbled upon Piezo switches that seemed to provide me with something unique. Piezo switches have no moving parts (similar to capacitive switches but without a power requirement). After ordering a sample, the LEDs were fine, but the button operation was momentary only - you cannot "hold" the switch in the off position. Therefore, this button style wouldn't work and I started running out of time to have these by the end of the year. Below is a picture of the sample Piezo switch I ordered.

I eventually settled for a standard button in a similar style with RGB LEDs.

After the machine shop asked me to make a few tweaks, I modified the base to simply have 4 angled feet so I could get a prototype done, but I'll probably modify the base again before making the final product.

Specs

Internal Dimensions: 304mm x 68mm x 350mm (7.23L)

External Dimensions: Unknown (will depend on metal thickness)

1 x standard ITX motherboard mount

1 x PCIe dGPU with maximum length of ~304mm

4 x 2.5 drive mounts (if I decide to make adapter plates they could be stacked to support up to 16 drives without a dGPU)

1 x SFF Power Supply (Using Lian Li 750W to mock up mount plate)

1 x USB 3.1 Type C connector (front panel)

1 x USB 3.0 Type A connector (front panel)

1 x Wireless LED controller with phone app to adjust RGB color

No optical drives

For a lot of the parts I had to order them in quantity so it is possible that I will be making these for sale at some point. I'll be updating this thread as I make progress. Currently I'm waiting on the machine shop to make the first prototype which should be done by the first of the year. BTW, the prototype will be done in aluminum which I plan to use unless it proves too weak to support the weight of the components. I will then finish off the main portion of the case by blasting the aluminum to have a "macbook"-like finish and I'll paint the thick side panel and base a bold color.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)