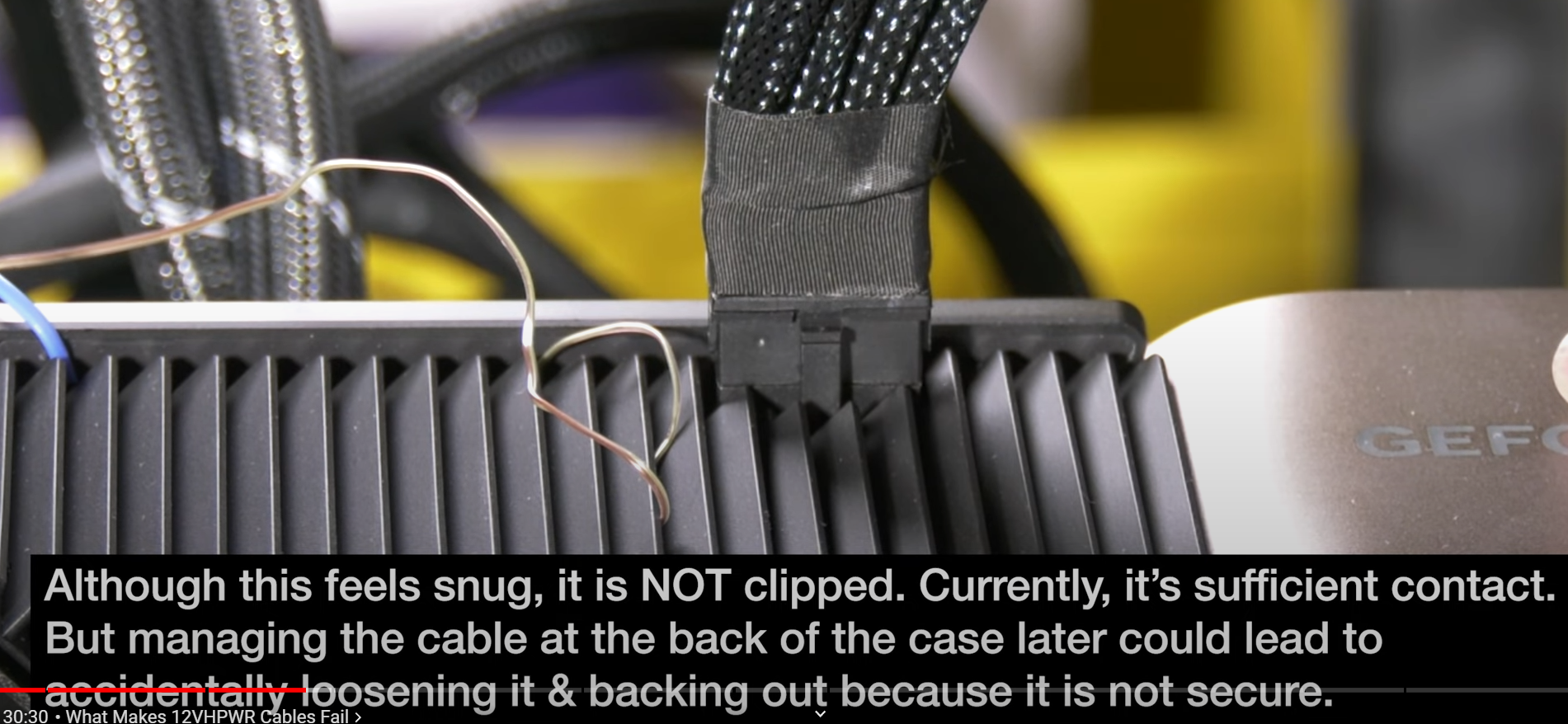

Is it mostly user error… yesThat man is most likely going to drop that case real quick once he watches that GN video.

Is it a mostly bad design… also yes

50/50 chance a lawsuit could go forward

100% chance the lawyers laugh their way to the bank and nothing comes of it.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)