Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DAN HSLP-48: A powerful sub 50mm heatsink

- Thread starter dondan

- Start date

Update:

I had a conversation with Noctua they told me, that four 6mm heatpipes is more than enough. As you can see the LP53 has only two heatpipes an work very well. They said it is better to have more surface what we get if we remove two pipes. So here is my updated design:

What I understand from this is that Noctua say that 4 heatpipes and more fin area will yeld better performance, correct?

Hotshot619

n00b

- Joined

- Oct 2, 2016

- Messages

- 35

Looking at the chart a page back I wonder if three 8mm heatpipes might be better than four 6mm pipes. If you happen to get on a call again with some engineers it might be a good question to ask. The difference would be a .5 mm increase in "Typical Flattened Height", an increase of only .3mm in total "Resulting Width" BUT, we would gain an increase of total "Max Power" by 37 Watts, gain more fin surface space for more dissipation of heat, and a theoretical maximum of 156 watts "Flatten Max Power" over the current designs maximum of 132 Watts. Just some food for though. Or maybe just two 8mm heat pipes taking inspiration from the LP53 since they state that their cooler can handle 100 Watts, but this chart would have you believe they can only manage 66 Watts with their 6mm heatpipes.

Last edited:

There is another chart (in the same site) write 6mm can handle to 65W.

Interesting. Bending of heatpipe loses about 10%performance : http://celsiainc.com/blog-how-does-bending-affect-heat-pipe-vapor-chamber-performance/

Interesting. Bending of heatpipe loses about 10%performance : http://celsiainc.com/blog-how-does-bending-affect-heat-pipe-vapor-chamber-performance/

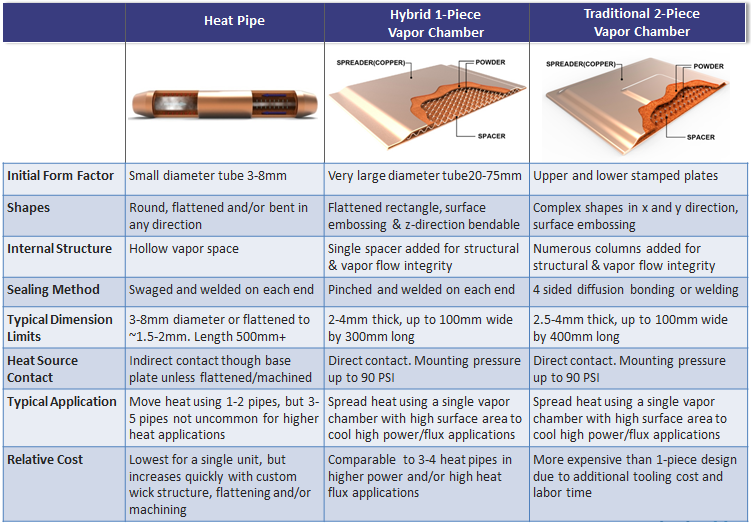

Source: Should I Use Heat Pipes or Vapor Chambers to Cool My Electronics ApplicationHeat pipes are probably a best choice if:

There’s plenty of air flow

You’ve got lots of room for fins

Nominal power densities are <25 w/cm2

Ambient temperatures are normal – let’s call this below 45oC

Cost is a key consideration – every penny counts!

A vapor chamber should be considered if:

Power densities are high – certainly by the time they hit 50 w/cm2

Reducing hot spot across the die is a key concern

Z-direction (height) is constrained, yet fin area needs to be increased

Atypical ambient temperatures and/or low air flow

Performance is a key consideration – every degree counts!

Last edited:

theGryphon

[H]ard|Gawd

- Joined

- Nov 21, 2011

- Messages

- 1,295

Hey dondan,

Good luck with your new project!

With the purpose of maximizing heat transfer while also maximizing surface area, you should really use 3 heatpipes at 8mm diameter: you would get more heat transferred per surface area lost for the heatpipes...

Along with that, you should use direct touch, which 8mm heatpipes would take better advantage of.

Good luck with your new project!

With the purpose of maximizing heat transfer while also maximizing surface area, you should really use 3 heatpipes at 8mm diameter: you would get more heat transferred per surface area lost for the heatpipes...

Along with that, you should use direct touch, which 8mm heatpipes would take better advantage of.

Heat carrying capacity in the heatpipes needs to be balanced against the conductivity of heat from heat pipes to the fins and then to the extremeties of the fins. Fewer heatpipes means more distance between them, and therefore the heat needs to be able to travel further within the fins.

For a given airflow rate, this might need the fins to be thicker, which as a percentage of airflow restriction might make a bigger difference than dropping from 4-3 heatpipes.

This is where the clever engineers in this field can make the calculations and then determine which is more optimal for our case and the fans that will be used.

Observationally, I can see that the LP53 has very thin fins, but with 2 heatpipes and a direct contact between the fins and the center copper block, it essentially is like having 3 heat sources with the maximum distance between heatsources of about 30mm.

The dan heatsink has a much thicker fin, I recall hearing 0.5mm fin thickness earlier in the thread, so the conductivity should be higher and therefore heat should be able to travel further through the fins for a given airflow rate. Is it too thick that it blocks airflow? Again up to the engineers making the calculations.

For a given airflow rate, this might need the fins to be thicker, which as a percentage of airflow restriction might make a bigger difference than dropping from 4-3 heatpipes.

This is where the clever engineers in this field can make the calculations and then determine which is more optimal for our case and the fans that will be used.

Observationally, I can see that the LP53 has very thin fins, but with 2 heatpipes and a direct contact between the fins and the center copper block, it essentially is like having 3 heat sources with the maximum distance between heatsources of about 30mm.

The dan heatsink has a much thicker fin, I recall hearing 0.5mm fin thickness earlier in the thread, so the conductivity should be higher and therefore heat should be able to travel further through the fins for a given airflow rate. Is it too thick that it blocks airflow? Again up to the engineers making the calculations.

RafaelMasiero

n00b

- Joined

- Dec 15, 2014

- Messages

- 4

dondan since your prototype seems similar to a hipotetical lower profile NH L12 and since you have been in contact with Noctua, it may prove interesting asking them about their results when they prototyped a lower NH L12, as described in this exchange in DAN A4-SFX's thread:

darksable

Noctua

darksable

what would you guys think about, rather than creating a taller L9i, creating a shorter NH-L12?

As I mentioned in my email to you guys, I'm actually using an NH-L12 in my small form factor case right now, after having removed both fans and jury-rigged the 120mm fan to be underneath the heatsink. If you want pictures of how this works, I'd be willing to take them for you. If the NH-L12 were shortened by 18mm, that height could mostly come from the heatpipes - at which point, a slim 120mm fan could be placed underneath the fins.

Noctua

Making an L12 that is less tall is something we tried in the past but we weren't happy with the results. The radius of the heatpipe bendings can influence the performance and it might also create compatibility issues with the mounting parts.

Making it that low makes it also difficult to fit a fan underneath without getting the problem you already noticed, that something is front of the fan and creates unwanted noises, let alone compatibility with VRM coolers and memory modules and a 120mm fan (even a slim one).

It will fit!I doesnßt know if anyone asked this before but will this cooler fit in a Sentry Case with 47mm mx cpu-cooler height ?

Or if not, can you make it possble ?

Julio Espinosa

Weaksauce

- Joined

- Feb 1, 2017

- Messages

- 71

Have you consider "ionic wind generators" or a Peltier thermoelectric cooler?

IDK if they are real-life-usable for cooling

IDK if they are real-life-usable for cooling

Have you consider "ionic wind generators" or a Peltier thermoelectric cooler?

IDK if they are real-life-usable for cooling

The ionic wind generators, while very very cool, have basically _zero_ static pressure, meaning that they simply aren't an option for heatsinks. I have seen a couple mods where the entire front panel was turned into one, though, and it makes for great airflow and a cool talking piece.

As for peltier coolers, there are huge problems with them in this form factor:

1) They draw stupid amounts of power; the properly powerful ones would easily draw as much power as the computer itself, and SFF power supplies would be way too heavily loaded.

2) Although they do cool effectively, in order to do that, the "hot side" has to be allowed to get hot, but also needs significant amounts of cooling. Most peltier coolers powerful enough to do a good job of cooling a CPU require a heatsink like the Hyper 212 EVO.

They also pump a LOT of waste heat into the case because of that, meaning that even though your CPU would be nice and cool, in a small form factor case like this, your motherboard and M.2 drive would simply fry.

Good ideas, though, and innovation is always both welcome and a cool selling point for a cooler like this.

Maybe not useful for this cooler.

Edit: I was thinking if we replace aluminum fins/plates with this HiK plates (aluminum with heatpipes) will increase performance, but minimum thickness is more than 4 times of standard fins (0.4mm i think) and this will reduce the total number of them, then reducing the cooling surface and the performance. So copper fins are better solution.

Last edited:

dondan

[H]ard|Gawd

- Joined

- Apr 15, 2013

- Messages

- 1,751

Update:

This is a update full of bad news.

1.) Noctua refuse the project because they have no capacity and time for it

2.) Thermalright send me the price tag of it here are some numbers so you can see what we are talking about.

I made a calculation what will be the lowest price on Kickstarter including fix costs, import, german vat, kickstarter fees, with a profit of only 10€ for each heatsink:

So you see if you let produce from a competitor the price will be bad. With this pricetag the Kickstarter campaign will be a fail, because I have to sell 2000 units.

What will be the next steps:

- I asked Thermalright to lower the price and give me the price from every part of the heatsink so I can see why it is so expansive

- Contacting Cryorig or be quiet! maybe they can help me out.

This is a update full of bad news.

1.) Noctua refuse the project because they have no capacity and time for it

2.) Thermalright send me the price tag of it here are some numbers so you can see what we are talking about.

- Minimum Order Quantity (MOQ) = 2000 heatsinks

- Tooling fees = $35.000

- Price for the alu version = $50 + $17,50 tooling fees

- Price for the copper version = $85 + $17,50 tooling fees

I made a calculation what will be the lowest price on Kickstarter including fix costs, import, german vat, kickstarter fees, with a profit of only 10€ for each heatsink:

- Alu version: $100

- Copper version: $146

So you see if you let produce from a competitor the price will be bad. With this pricetag the Kickstarter campaign will be a fail, because I have to sell 2000 units.

What will be the next steps:

- I asked Thermalright to lower the price and give me the price from every part of the heatsink so I can see why it is so expansive

- Contacting Cryorig or be quiet! maybe they can help me out.

octagoncow

Limp Gawd

- Joined

- Aug 31, 2014

- Messages

- 131

Thanks for keeping us informed even if it's not really that good of news. I'm glad you're not giving up yet.

2.) Thermalright send me the price tag of it here are some numbers so you can see what we are talking about.

- Minimum Order Quantity (MOQ) = 2000 heatsinks

- Tooling fees = $35.000

- Price for the alu version = $50 + $17,50 tooling fees

- Price for the copper version = $85 + $17,50 tooling fees

I made a calculation what will be the lowest price on Kickstarter including fix costs, import, german vat, kickstarter fees, with a profit of only 10€ for each heatsink:

- Alu version: $100

- Copper version: $146

So you see if you let produce from a competitor the price will be bad. With this pricetag the Kickstarter campaign will be a fail, because I have to sell 2000 units.

1. $35k worth of tooling fees split between 2000 heatsinks is only a cost of $17.5 per heat sink. That's ~12% of the total cost of the copper heatsink, meh.

2. Would giving up on aluminum help reduce tooling costs?, it's looks like it'll be impossible to make a budget version of this heatsink, so cater to the no compromises crowd.

3. Timing the heatsink to launch with the next kickstarter campaign for your revision 2 alone should net you enough interest.

4. Owners of the Sentry case are also looking forward to this, with time your potential market is only going to continue to grow.

That said this news does make your tempered glass side panel seem much more appealing.

I think better to try with Scythe or EKL. There are so many other manufacturers, but is your choice.What will be the next steps:

- I asked Thermalright to lower the price and give me the price from every part of the heatsink so I can see why it is so expansive

- Contacting Cryorig or be quiet! maybe they can help me out.

Good luck to find best for the success

Last edited:

dondan

[H]ard|Gawd

- Joined

- Apr 15, 2013

- Messages

- 1,751

The problem with other than Noctua and Thermalright is the fan. We need a company that already have a fan for it because tooling and development for a fan could be really expansive. A second option will be buying the fan from TH and make the heatsink from a differen company.

We DON'T need a company that already has a fan. we don't need a fan included. we can just buy a noctua a9x14-pwm ourselves or a prolimatech 12 slim or a thermalright ty-100.

try ZALMAN they have experience with copper coolers that are pretty nice.

try ZALMAN they have experience with copper coolers that are pretty nice.

XstreamHard

n00b

- Joined

- Jan 21, 2017

- Messages

- 60

You can't easily buy a TY-100 and nobody buys a heatsink that is designed for a fan you can't easily get. Buying it from Thermalright in larger quantities would be a good option though if they are up for it.

EKL might be a good idea for the heatsink itself since they are German.

EKL might be a good idea for the heatsink itself since they are German.

Julio Espinosa

Weaksauce

- Joined

- Feb 1, 2017

- Messages

- 71

I would pay that for the copper one, no problem, if it fits the A4 SFX and keeps an i7 7700k from throttling.

You could incluide it with the next shippment of the case. There would be more than 2,000 right?

You could incluide it with the next shippment of the case. There would be more than 2,000 right?

Hotshot619

n00b

- Joined

- Oct 2, 2016

- Messages

- 35

Hopefully some more shopping around for manufactures will yield better results. I honestly would have no issue buying the cooler with no fan as I already have a few I bought for my specific mods and plans for the A4. I don't know if most people would want to purchase a fan separately though. If you could manage to set up the cooler kickstarter with the A4 v2 launch that would for sure sell some as well as the people here who want a dedicated A4 or sentry cooler. Is there any downside to just trying to kickstart the cooler and if you don't back 2000+ it just wont be funded?

Including it with the case will increase its cost very significantly, and if its not universally compatible, will affect sales of the case.

The problem with 2000 units is this assumes that all units sell. Its so make or break with such a small profit margin.

If dan ends up selling all 2000, maximum profit for the effort is 20,000.

If he sells 1863 units, The earnings is $18,630, but he has to "buy" the remaining units for ($136x137) $18,632. Breaks even at 93% of the available quantity!

If we are less optimistic, say 'only' 1500 units sell, thats 15,000 earnings but a cost of $68,000!

So if dan only sells 1500, he has to cough up $58,000 for his heatsinks!

Or if he only sells 250, thats a cost of $235,500 to dan!

unlike the case, this just isnt going to sell anywhere near 2000 units, especially if it doesnt turn out to perform significantly better than the lp53, less than a third of the price. The only way this can happen is if he gets guaranteed sale of pretty much the MOQ.

As much as I would love to see this happen, there is just wayy too much risk for dan at this stage. Unless as mentioned above, there is minimal cost if the kickstarter doesnt reach moq

The problem with 2000 units is this assumes that all units sell. Its so make or break with such a small profit margin.

If dan ends up selling all 2000, maximum profit for the effort is 20,000.

If he sells 1863 units, The earnings is $18,630, but he has to "buy" the remaining units for ($136x137) $18,632. Breaks even at 93% of the available quantity!

If we are less optimistic, say 'only' 1500 units sell, thats 15,000 earnings but a cost of $68,000!

So if dan only sells 1500, he has to cough up $58,000 for his heatsinks!

Or if he only sells 250, thats a cost of $235,500 to dan!

unlike the case, this just isnt going to sell anywhere near 2000 units, especially if it doesnt turn out to perform significantly better than the lp53, less than a third of the price. The only way this can happen is if he gets guaranteed sale of pretty much the MOQ.

As much as I would love to see this happen, there is just wayy too much risk for dan at this stage. Unless as mentioned above, there is minimal cost if the kickstarter doesnt reach moq

Including it with the case will increase its cost very significantly, and if its not universally compatible, will affect sales of the case.

The problem with 2000 units is this assumes that all units sell. Its so make or break with such a small profit margin.

If dan ends up selling all 2000, maximum profit for the effort is 20,000.

If he sells 1863 units, The earnings is $18,630, but he has to "buy" the remaining units for ($136x137) $18,632. Breaks even at 93% of the available quantity!

If we are less optimistic, say 'only' 1500 units sell, thats 15,000 earnings but a cost of $68,000!

So if dan only sells 1500, he has to cough up $58,000 for his heatsinks!

Or if he only sells 250, thats a cost of $235,500 to dan!

unlike the case, this just isnt going to sell anywhere near 2000 units, especially if it doesnt turn out to perform significantly better than the lp53, less than a third of the price. The only way this can happen is if he gets guaranteed sale of pretty much the MOQ.

As much as I would love to see this happen, there is just wayy too much risk for dan at this stage. Unless as mentioned above, there is minimal cost if the kickstarter doesnt reach moq

But that's the point of KickStarter, no? Set the target at 2,000 units * Cost per Unit. If there aren't enough backers the project fails with no losses. If there are enough backers then he's got the guaranteed level of profit required for his personal motivation.

Update:

This is a update full of bad news.

1.) Noctua refuse the project because they have no capacity and time for it

2.) Thermalright send me the price tag of it here are some numbers so you can see what we are talking about.

- Minimum Order Quantity (MOQ) = 2000 heatsinks

- Tooling fees = $35.000

- Price for the alu version = $50 + $17,50 tooling fees

- Price for the copper version = $85 + $17,50 tooling fees

I made a calculation what will be the lowest price on Kickstarter including fix costs, import, german vat, kickstarter fees, with a profit of only 10€ for each heatsink:

- Alu version: $100

- Copper version: $146

So you see if you let produce from a competitor the price will be bad. With this pricetag the Kickstarter campaign will be a fail, because I have to sell 2000 units.

What will be the next steps:

- I asked Thermalright to lower the price and give me the price from every part of the heatsink so I can see why it is so expansive

- Contacting Cryorig or be quiet! maybe they can help me out.

Seeing this, I think this project might be redundant before it comes to fruition:

If AM4 mini ITX boards come with Ryzen 5 launch, then considering bigger cooler mounting area on AM4, we might be able to mount dynatron vapor chamber radiators on top of it.

RosaJ has modded the 115x motherboard to test the performance of such radiator against other cooler and I believe performance difference was significant.

I believe that we might have outstanding combo with Ryzen 5 1400X which is 65W TDP and dynatroon T318 which is supposed to handle up to 165W TDP. The last part of this equation would be a fan that won't scream under load. I'll try to check if dimensions of AM4 vs narrow LGA2011 cooler areas match up...

dondan

[H]ard|Gawd

- Joined

- Apr 15, 2013

- Messages

- 1,751

But that's the point of KickStarter, no? Set the target at 2,000 units * Cost per Unit. If there aren't enough backers the project fails with no losses. If there are enough backers then he's got the guaranteed level of profit required for his personal motivation.

Yes but there is a lot of work and costs before I am in the situation starting the campaign.(protyping, testing, building the campaign, photoshooting, making a video s.o.) Currently I have the feeling that with this pricetag and MOQ the campaign will fail. With this feeling it is very hard going on to work on it and loseing life time. Also the profit for me will be very low.

SaperPL:

2011-3 narrow ilm = 56x94

AM4 = 56x90

Last edited:

Yeah, I know that the mounting holes will differ. I'm talking about the clearance area for the cooler. If the clearance area for AM4 is same or greater than narrow 2011-3, then making an adaptor plate to mount specific dynatron cooler like T318 on AM4 should be a problem and would be far cheaper and more likely successful than crowdfunding complete cooler with heatpipes.

Hotshot619

n00b

- Joined

- Oct 2, 2016

- Messages

- 35

I've been looking into possibly modifying a T318 for a 7700k LGA 1151 socket. Someone from the Sentry thread set up a R15 and was geting great cooling numbers. I was looking specifically at the Z270 Fatal1ty itx mother board and without having exact measurements it looks like if I (or anyone really) could make a bracket like this It could work. The difference of course being that instead of going from Narrow 2011 to normal 80x80 LGA2011 holes it would go to 75x75 LGA115x and you would then have to use flush screws and attach bolts on the backside of the motherboard. Also the original modder later mentioned that even if the Z height could be off (due to the large flat shape of the vapor chamber) you could just buy some copper shims to place on top of the IHS below the vapor chamber to correct any Z height issues (Imagine fitting those copper slices in between a bracket) (credit to SaperPL) . Could be an interesting and highly fruitful mod attempt. Any thoughts?

Last edited:

As an Amazon Associate, HardForum may earn from qualifying purchases.

I would quickly fund this in full copper, but 2000 units seems like it would be impossible to reach - especially when considering that this wouldn't work in other cases like the Node 202 or Sentry.

The denser the fins are, the louder it will be, so I don't think it is so smart to go so dense.

The denser the fins are, the louder it will be, so I don't think it is so smart to go so dense.

Last edited:

Yeah, 2000 units is quite a lot, but considering the tooling and precision required for such product is reasonable. I obviously would love to have Sentry & A4-SFX -optimized cooler, but I don't think we can do much over asking manufacturers to make a Frankenstein product out of different cooler/fans and mountings they are already making.

I would quickly fund this in full copper, but 2000 units seems like it would be impossible to reach - especially when considering that this wouldn't work in other cases like the Node 202 or Sentry.

The denser the fins are, the louder it will be, so I don't think it is so smart to go so dense.

Wait, what?

The Sentry is a 48mm max cooler height and the Node 202 is 56. Why wouldn't it work in those cases?

I, for one, wouldn't hesitate to buy one of these for my Sentry if it turned out to be a better, quieter performer.

Definitely talk to Zalman, dondan!

The Zalman CNPS 2X was used in the original Steam Machine prototypes to surprisingly great effect. (To that matter, it's actually one of the few low profile coolers which I think none of us have tested yet, isn't it?)

We did tests on CNPS-2X after getting it back from RMA. It's actually only good for low wattage cpu's, I think.

It's the quietest cooler I've ever tested, but at the same time load temps on 65W skylake are terrible in comparison to box cooler and noctua NH-L9i.

It might've been one of the reasons why Steam Machine prototype was not received that well by the people who got it, apart from cooling on GPU side.

It's the quietest cooler I've ever tested, but at the same time load temps on 65W skylake are terrible in comparison to box cooler and noctua NH-L9i.

It might've been one of the reasons why Steam Machine prototype was not received that well by the people who got it, apart from cooling on GPU side.

Wrong thread, but hey, gorgeous setup!

Jonas Mellkvist

Limp Gawd

- Joined

- Dec 18, 2016

- Messages

- 159

I still think a 150$ price tag is reasonable (if the cooler can handle 95W no problem). I think you should really do some sort of polling or something to get an estimate of how many people would be willing to pay that much.

I would buy that cooler in Copper if it perform as Dan sayed.

But im also a entusist but i think the most are that buy this Case

A Vapor-Chamber is not necessary because of the tiny surface of the CPU plate. Furthermore I have to pay patent license for it if I have it correct in my mind.

I think you should get a sample from the people who make vapor chambers. Nvidia and AMD choose vapor chamber for their 250W video cards which use more power and have less space for heatsinking than a CPU.

Price for the alu version = $50 + $17,50 tooling fees

- I asked Thermalright to lower the price and give me the price from every part of the heatsink so I can see why it is so expansive

I would also like to know what is the cost of this 1080ti heatsink:

https://videocardz.com/67049/nvidia-geforce-gtx-1080-ti-taken-apart

Last edited:

It`s a bit different cooler (GTX1080ti is without shroud), but for reference: cooler for ZOTAC GTX580I would also like to know what is the cost of this 1080ti heatsink

For CPU with bare die (removed IHS and die guard) i think is possible modding with vapor chamber: 56*56*3mm

Last edited:

richiegore

Limp Gawd

- Joined

- Feb 1, 2017

- Messages

- 322

I would think that dynatron heatsink, with taller copper fins than the t318 for better cooling capacity would be ideal. It just needs to be compatible with AM4 and Intel's sockets and have a better way of mounting fans. Have you connected them?

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)