dave343

[H]ard|Gawd

- Joined

- Oct 17, 2000

- Messages

- 1,869

While I’m using the system yesterday for a few hours I kept looking at the tank, and notice it’s getting slightly lower. But whatever... I chalked it up to bubbles making there way through the system, which I've read happens so ok. Fast forward a few more hours, it's midnight, I check on the system and now the tank is 2/3 full... hmm, must have been a big bubble right? yes, that must be it  ... well, I still didn’t check, I just went to bed.

... well, I still didn’t check, I just went to bed.

Well, woke up this morning to a 1/3 full tank. Pulled the panel off and sure enough there’s water on the bottom of the case, but thankfully limited to the front and since all the metal is perforated it just made its way down to the desk.

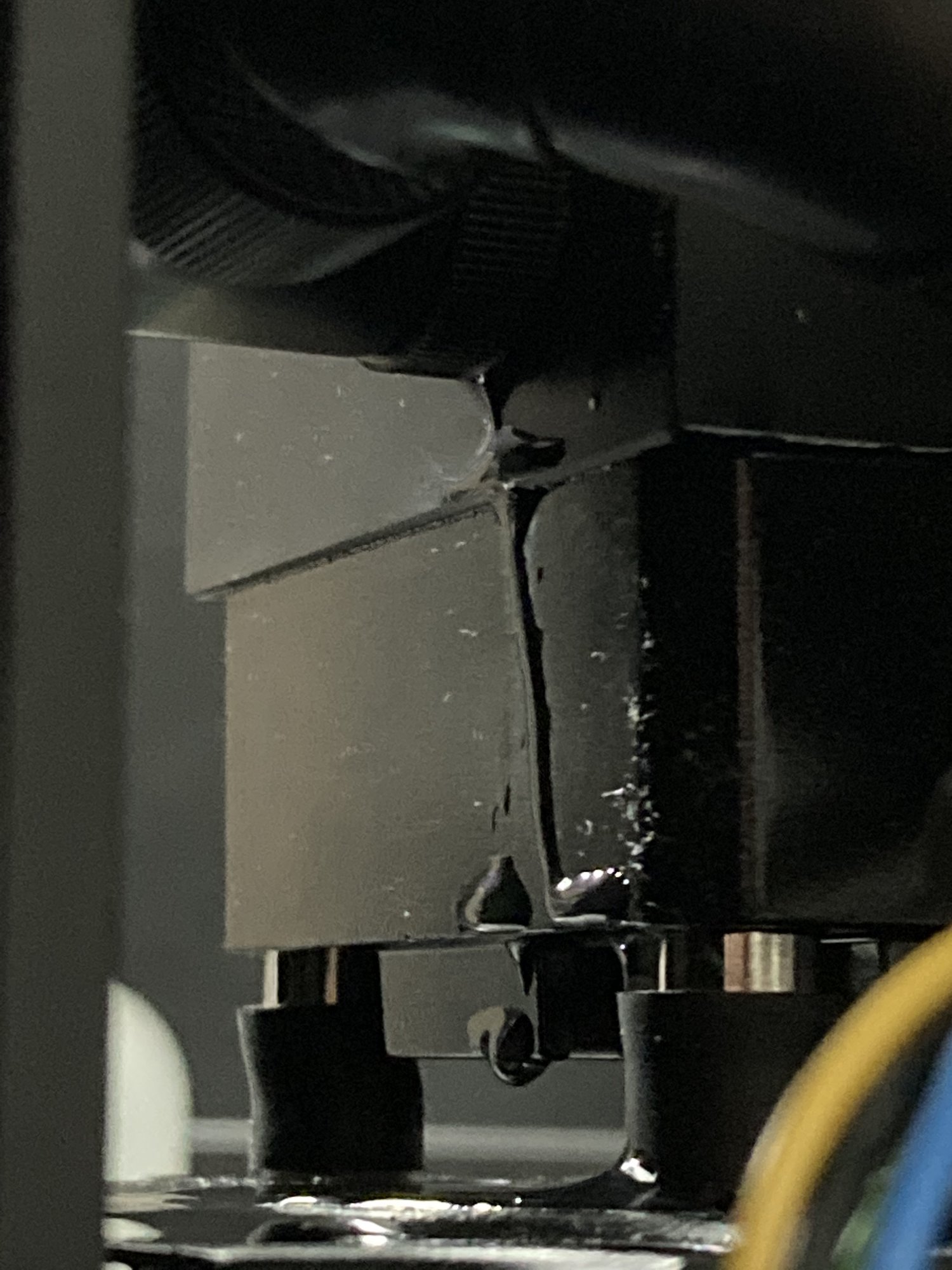

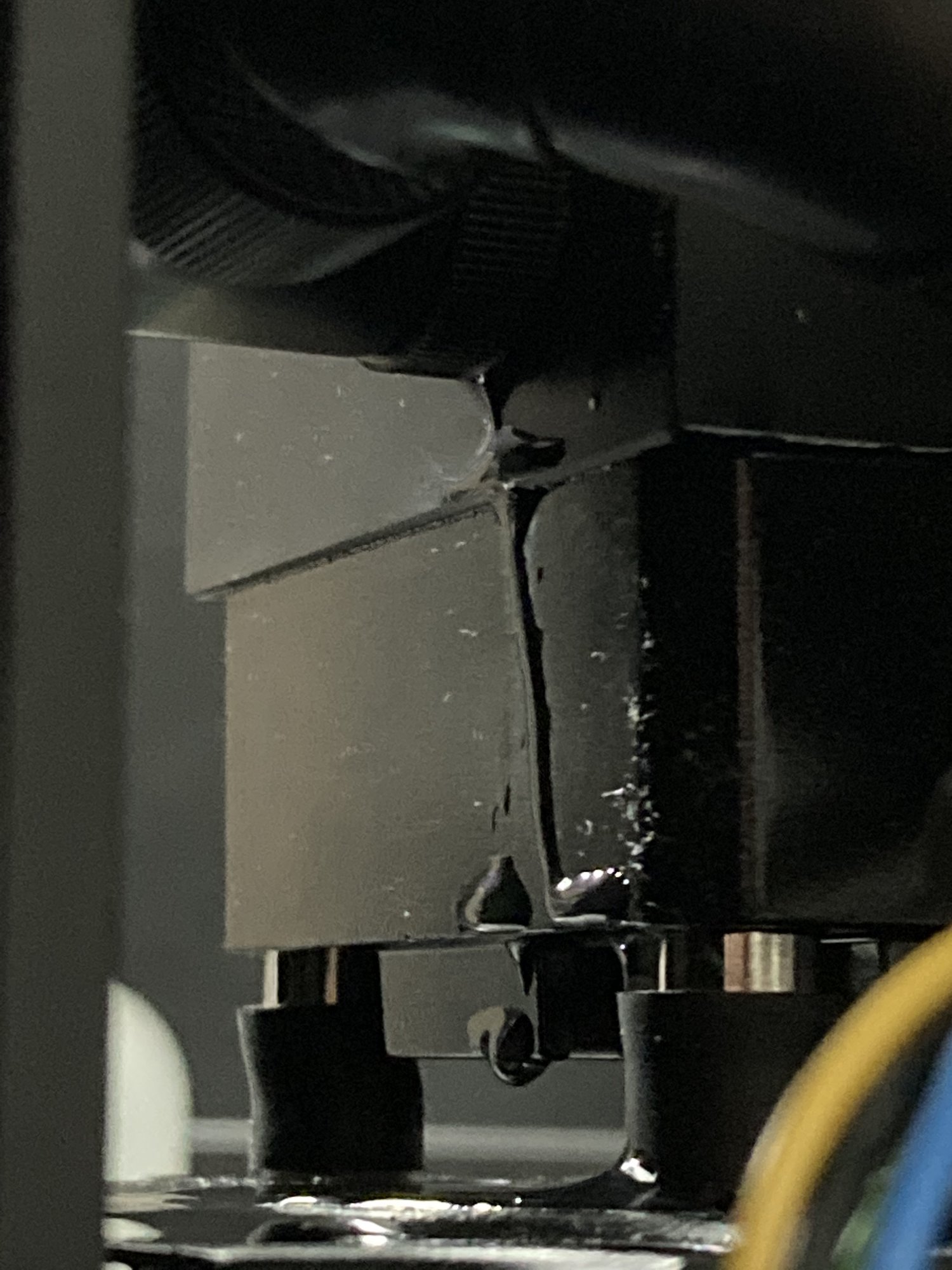

Yikes... so thankfully is isn’t leaking from a fitting or bend. The leak is on the back where I have the drain port hooked up. The EK DDC 140 res/pump has 3 ports, the main IN came with this silver fitting which recedes into the port. The OUT didn’t, and the other IN where I have the drain hooked up, just had a plug which receded into the port making it flush. So both the OUT and the drain 2nd IN I used fittings which don’t recede all the way into those ports... only the main IN I’m using the provided silver EK fitting. The drain port and the OUT I’m using 8mm extenders, m-f, that screwed in ok but stopped when the ports holes are smaller than the diameter of the extender fitting. I hope that explains it ok. I've attached a picture where you can see both the IN and OUT beside each other and the IN has the provided EK fitting that receeds into it's port, where the OUT I used a 8mm extender. On the back of the pump, the 2nd IN is the 2nd 8mm extender and that one is leaking. See pics.

When I was looking at PPCS and my local Dazmodes, I tried looking for fitting a that would recede into those OUT and 2nd IN ports, just like the provided EK silver fitting, but everything just listed as diameter size. Even under reservoir fittings I couldn’t see anything.

Well, woke up this morning to a 1/3 full tank. Pulled the panel off and sure enough there’s water on the bottom of the case, but thankfully limited to the front and since all the metal is perforated it just made its way down to the desk.

Yikes... so thankfully is isn’t leaking from a fitting or bend. The leak is on the back where I have the drain port hooked up. The EK DDC 140 res/pump has 3 ports, the main IN came with this silver fitting which recedes into the port. The OUT didn’t, and the other IN where I have the drain hooked up, just had a plug which receded into the port making it flush. So both the OUT and the drain 2nd IN I used fittings which don’t recede all the way into those ports... only the main IN I’m using the provided silver EK fitting. The drain port and the OUT I’m using 8mm extenders, m-f, that screwed in ok but stopped when the ports holes are smaller than the diameter of the extender fitting. I hope that explains it ok. I've attached a picture where you can see both the IN and OUT beside each other and the IN has the provided EK fitting that receeds into it's port, where the OUT I used a 8mm extender. On the back of the pump, the 2nd IN is the 2nd 8mm extender and that one is leaking. See pics.

When I was looking at PPCS and my local Dazmodes, I tried looking for fitting a that would recede into those OUT and 2nd IN ports, just like the provided EK silver fitting, but everything just listed as diameter size. Even under reservoir fittings I couldn’t see anything.

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)