TN :

Yes (High flow doesn't cool unnecessary components)

Yes / No (Fittings aren't high flow, block design isn't low flow)

Yes (See point 1)

No (Good, relatively unrestrictive design for a chipset block, unless that is the GPU block....though aren't they the same?)

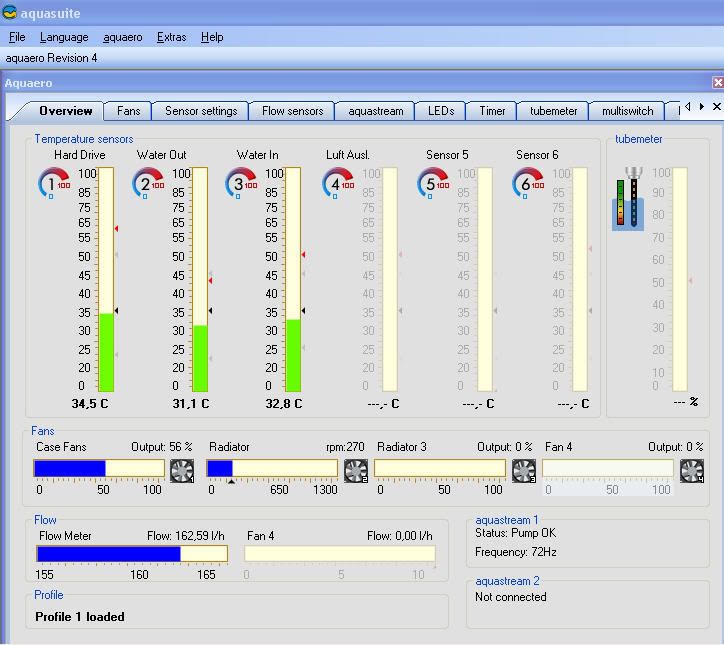

Actually they can be higher flowing blocks to cool RAM and VR's. Also many people use these blocks with DDC pumps and 6mm, 8mm, or 10mm tubing.

Remember that push-fits get a +1 over barbs in the Cathar overview of flow. Therefore 8mm tubing used with a push-fit is similar to a 10mm tube with barbs.

See point 1

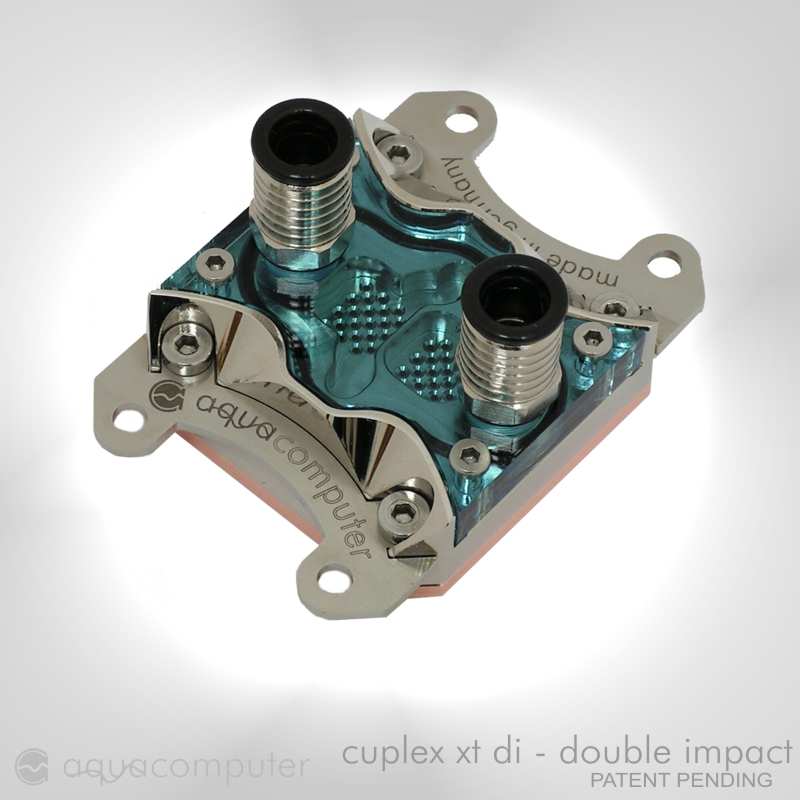

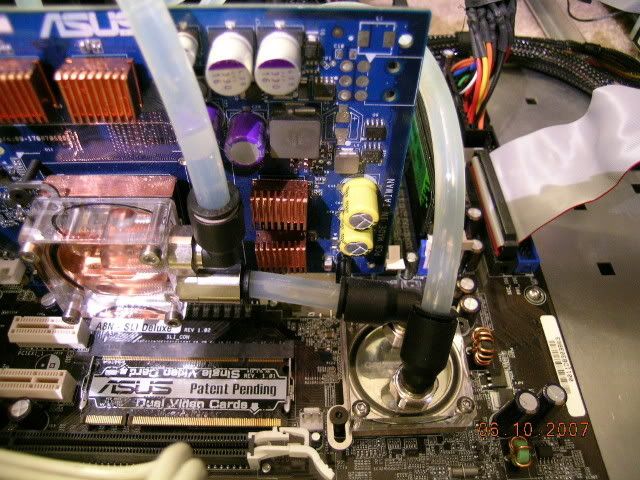

That block is being used as a chipset block. Some people, like me, also use them for GPU blocks. However, most people use the full cover or TwinPlex Pro design for their GPU's.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)