VanGoghComplex

2[H]4U

- Joined

- Apr 5, 2016

- Messages

- 2,286

I've moved this post from the Watercooling sub for visibility's sake.

Guys, I've got a big problem. My 7700K is relidded, having used superglue on the IHS edges as suggested by the maker of Rockit88's delid tool. The result is a lower Z-height on the IHS, and as a result, smaller gap between die and IHS internally. Win win, right?

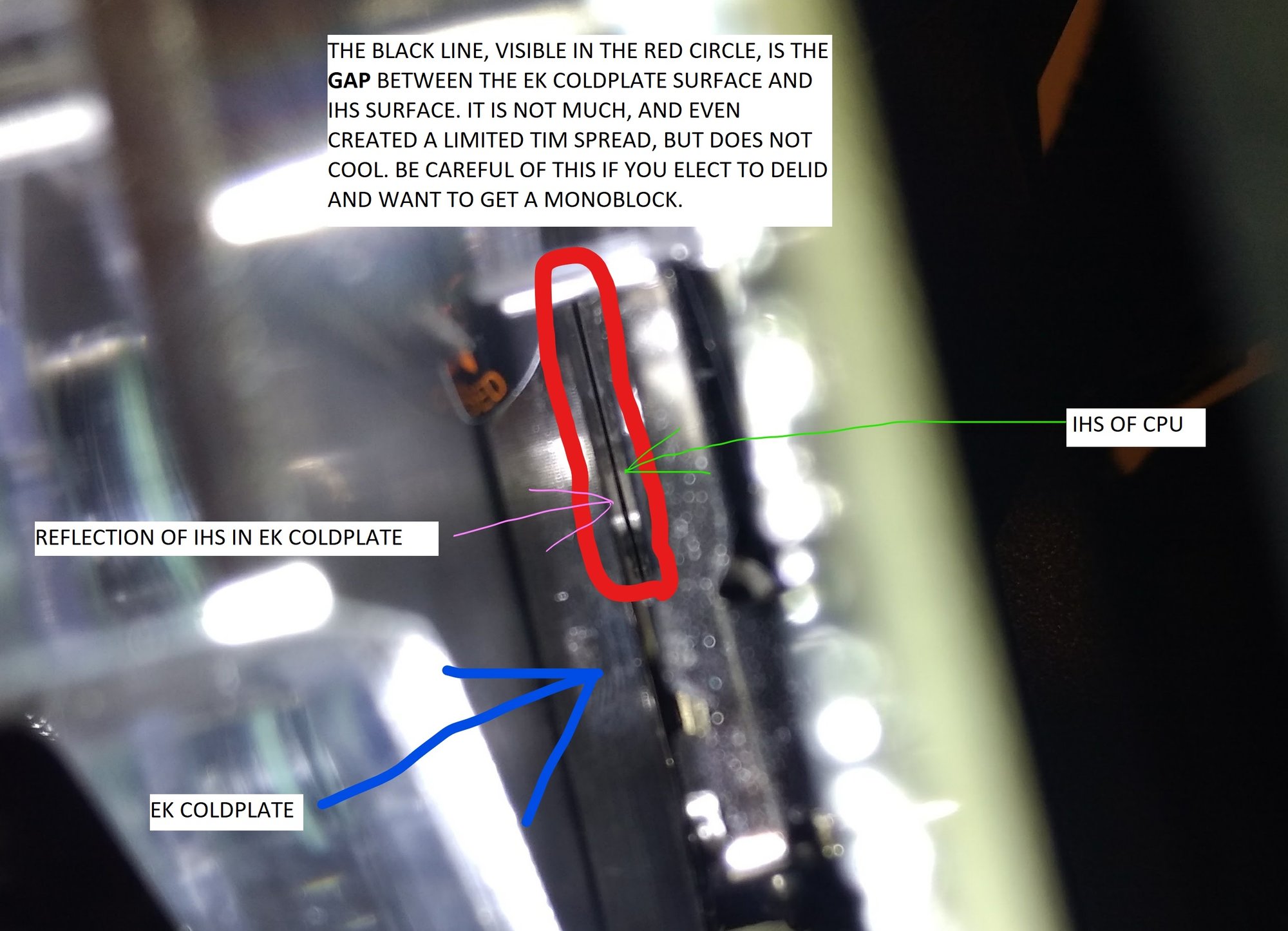

Except, it seems that EK's monoblock, which is NOT height adjustable, relies on the surface of the CPU IHS having at least a minimum Z-height. I've got it all replumbed, but looking between the card and block, I can SEE a gap. It's minor, but it's there. My temperatures are unacceptable.

The solution seems fairly obvious to me, though I hate it; delid and relid the CPU again, using RTV as typically suggested, and don't squeeze much on the relid bolt. I'll be sacrificing a larger gap between IHS and die to get rid of a gap between the EK monoblock coldplate and the IHS surface.

Is anyone else in this boat? How did you guys deal with this, if at all? I'm so bummed I can't check out the performance on my shiny new monoblock. ;_;

Guys, I've got a big problem. My 7700K is relidded, having used superglue on the IHS edges as suggested by the maker of Rockit88's delid tool. The result is a lower Z-height on the IHS, and as a result, smaller gap between die and IHS internally. Win win, right?

Except, it seems that EK's monoblock, which is NOT height adjustable, relies on the surface of the CPU IHS having at least a minimum Z-height. I've got it all replumbed, but looking between the card and block, I can SEE a gap. It's minor, but it's there. My temperatures are unacceptable.

The solution seems fairly obvious to me, though I hate it; delid and relid the CPU again, using RTV as typically suggested, and don't squeeze much on the relid bolt. I'll be sacrificing a larger gap between IHS and die to get rid of a gap between the EK monoblock coldplate and the IHS surface.

Is anyone else in this boat? How did you guys deal with this, if at all? I'm so bummed I can't check out the performance on my shiny new monoblock. ;_;

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)