MurderCityDevil

Gawd

- Joined

- Dec 6, 2007

- Messages

- 724

I'm drunk

Good lunk

we all need a bit of lunk from time to time

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

I'm drunk

Good lunk

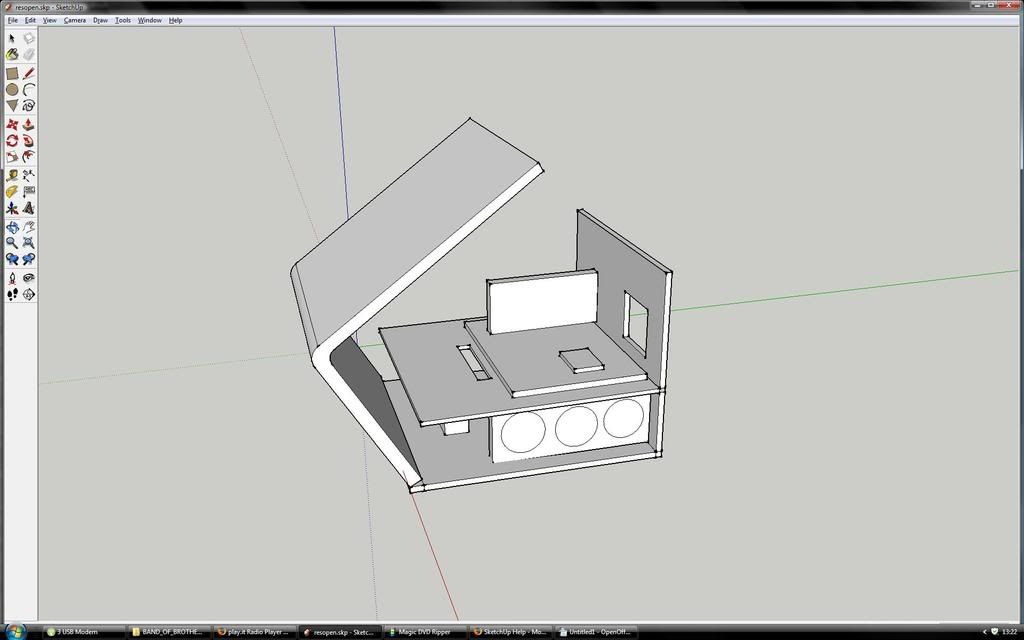

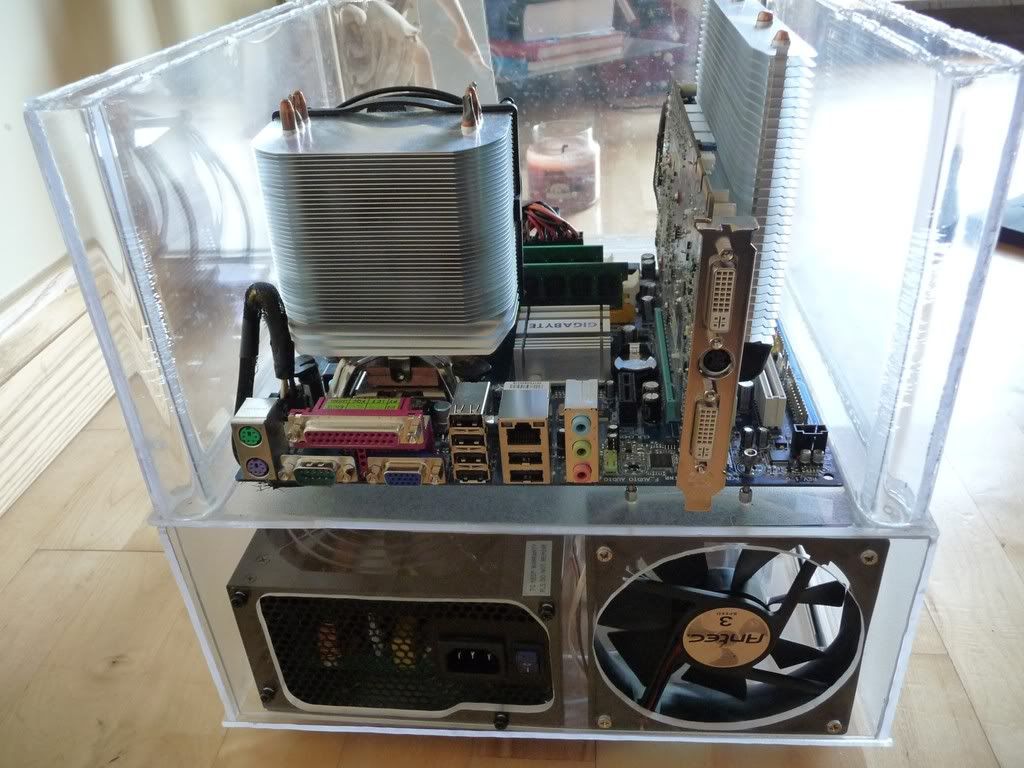

do you have any instructions on that toaster/bender mod thing?

I've been trying different ways of bending plexi, but without spending $200 on a professional bender, I always end up with massive amounts of bubbles in the plexiglass wherever I make bends.

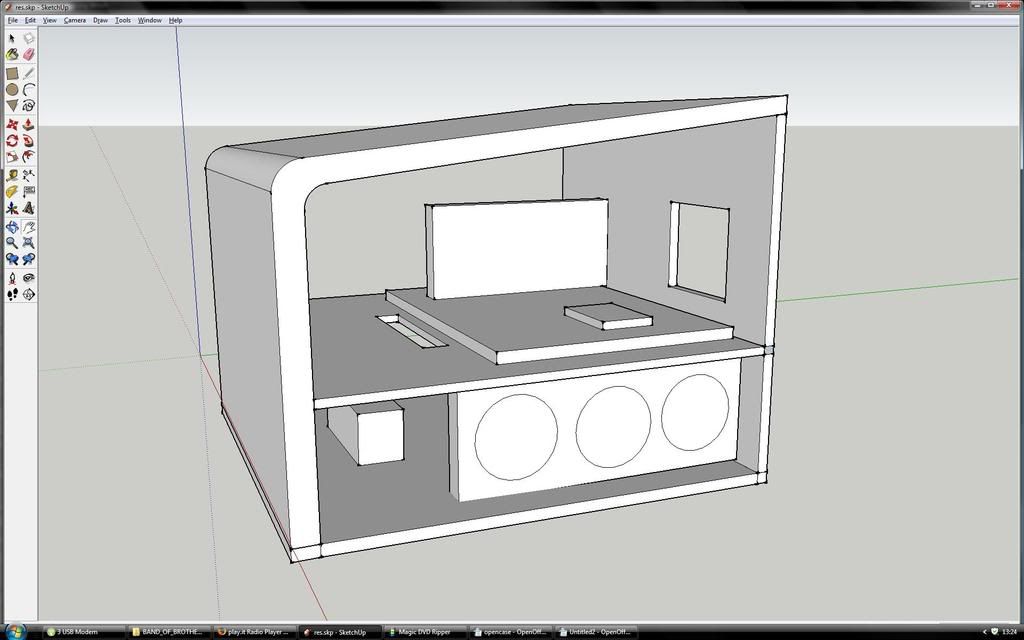

with the top section in place: