boocake

Limp Gawd

- Joined

- Jul 11, 2015

- Messages

- 170

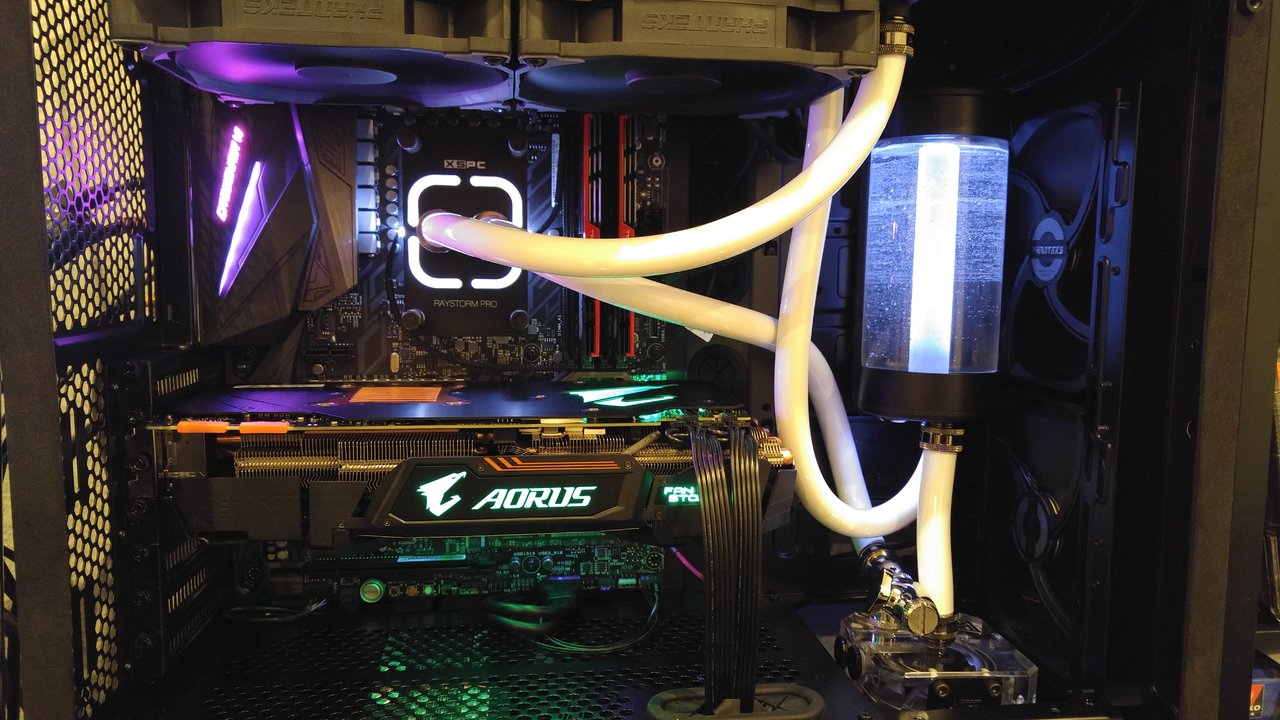

Air bubbles - Just have to run it for a couple of days. Big bubbles will go soon, micro bubbles take a while. Up to 3 days or so for those to disappear depending on your pump power.

- Run the system whilst holding the case. Tip it from side to side to let trapped bubbles release. Remember they like to gather at high points. Make sure you don't tip so far that the pump sucks in air in the reservoir.

- Varying the pump speed from low to high also helps.

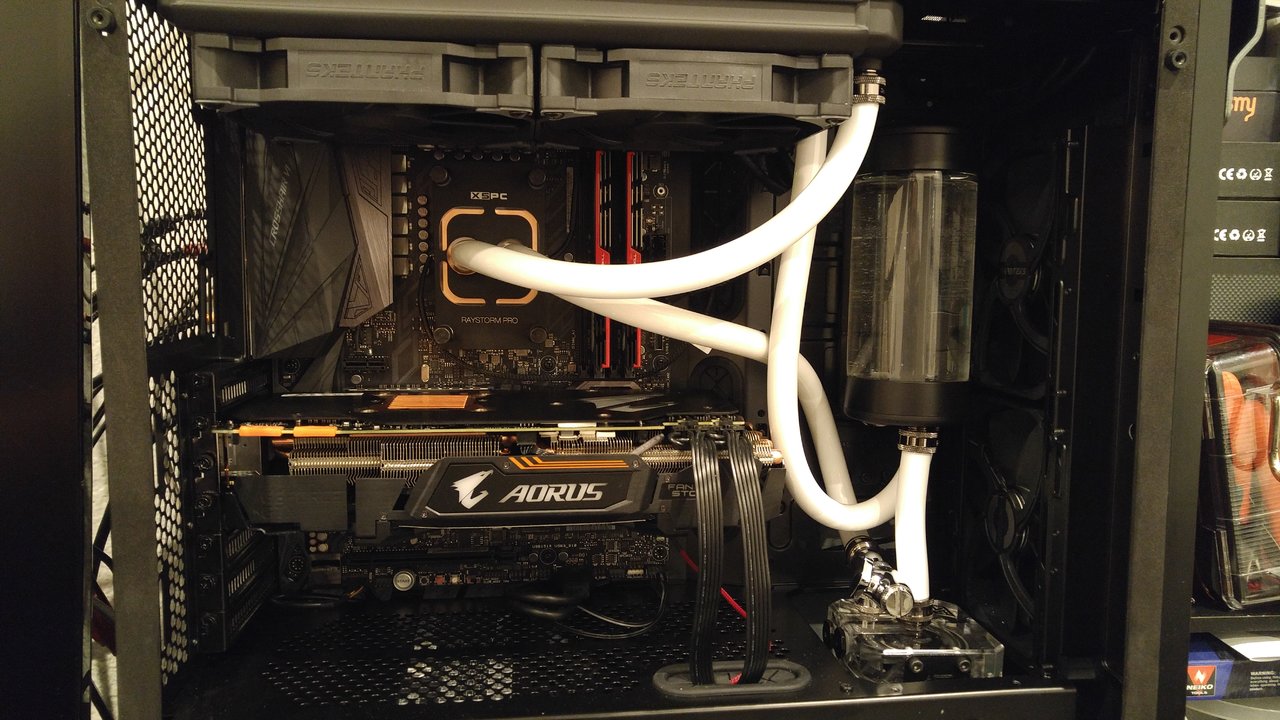

If you think that's tight.... check this out

Wow, that is super clean! As for my pump speed, I've got it plugged into the CH6's water pump pins near the bottom right of the motherboard. I think it's set on Auto, would like to see if I can adjust accordingly software-wise, but I think I'd have to go into the BIOS for that. I haven't bothered installing too much bloat from Asus on my setup.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)