boocake

Limp Gawd

- Joined

- Jul 11, 2015

- Messages

- 170

Hello all!

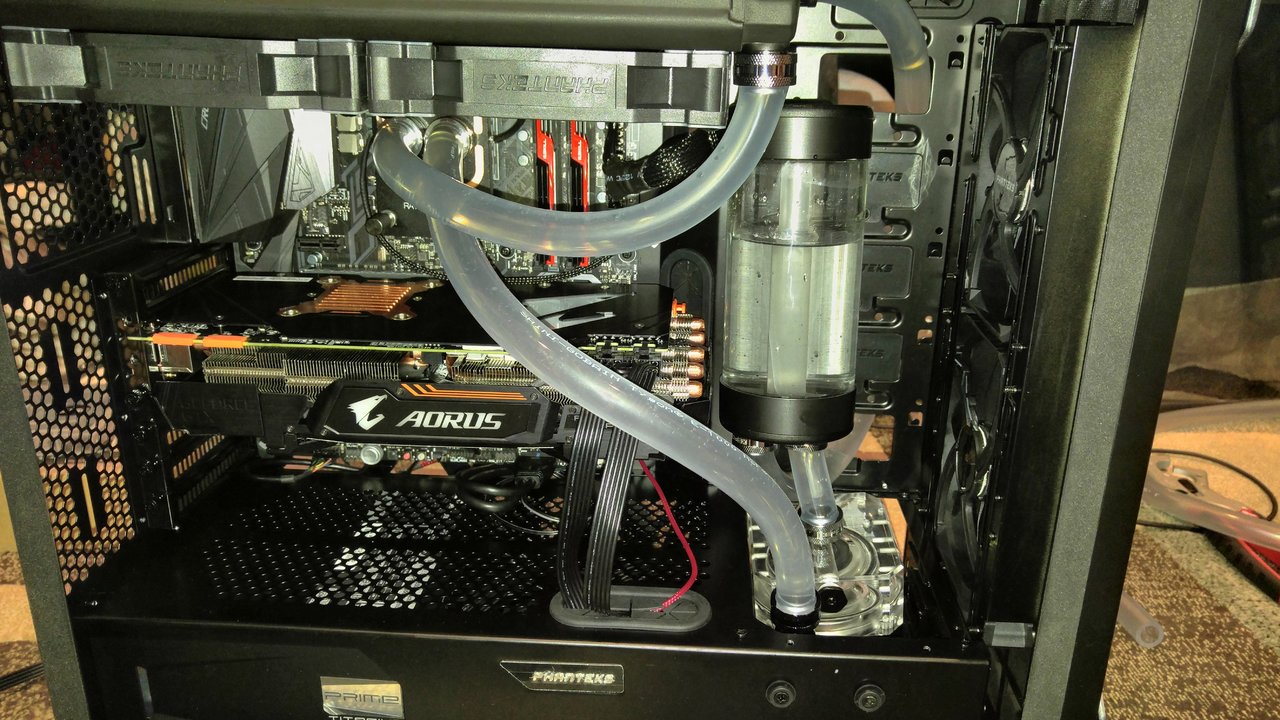

Been carousing this forum for quite a bit (going through the sticky threads, some recent threads from other newbies) trying to absorb as much as possible. I'm looking to build a new rig, but for the first time in decades, wanted to kind of 'evolve' from the air / AIO coolers that made me lazy.

Not going to lie - I'm absolutely terrified about screwing up my first custom loop! In any case, I went ahead and ordered parts that are shipping from performance-pcs. I guess my question is- is there anything else that I should be looking to also get? The case I'm looking to use to build my first custom loop is a mean:it 4pm cube case (https://www.newegg.com/Product/Product.aspx?Item=9SIACUC57H2439)

For now, I'd like to get my feet wet by doing just the CPU. Maybe down the line, when I get enough courage, I'll start adding my GPU to the mix- but taking baby steps for now!

XSPC DDC Photon 170 Tube Reservoir

XSPC Raystorm Pro CPU Waterblock - AMD w/ G1/4" to 1/2" ID, 3/4" OD Chrome Compression Fittings

Tygon E-1000 1/2" ID (3/4" OD) "Plasticizer Free" Tubing - Clear (6 feet)

XSPC D5-Vario Series 12 VDC D5 Water Pumps - With Speed Control and Housing and Swiftech MCP655 Series Housing (Acrylic) DarkSide Gentle Typhoon Performance Radiator Fan - 2150rpm, 68cfm - Black Edition (3x)

EK-CoolStream XE 360 (Triple)

Been carousing this forum for quite a bit (going through the sticky threads, some recent threads from other newbies) trying to absorb as much as possible. I'm looking to build a new rig, but for the first time in decades, wanted to kind of 'evolve' from the air / AIO coolers that made me lazy.

Not going to lie - I'm absolutely terrified about screwing up my first custom loop! In any case, I went ahead and ordered parts that are shipping from performance-pcs. I guess my question is- is there anything else that I should be looking to also get? The case I'm looking to use to build my first custom loop is a mean:it 4pm cube case (https://www.newegg.com/Product/Product.aspx?Item=9SIACUC57H2439)

For now, I'd like to get my feet wet by doing just the CPU. Maybe down the line, when I get enough courage, I'll start adding my GPU to the mix- but taking baby steps for now!

XSPC DDC Photon 170 Tube Reservoir

XSPC Raystorm Pro CPU Waterblock - AMD w/ G1/4" to 1/2" ID, 3/4" OD Chrome Compression Fittings

Tygon E-1000 1/2" ID (3/4" OD) "Plasticizer Free" Tubing - Clear (6 feet)

XSPC D5-Vario Series 12 VDC D5 Water Pumps - With Speed Control and Housing and Swiftech MCP655 Series Housing (Acrylic) DarkSide Gentle Typhoon Performance Radiator Fan - 2150rpm, 68cfm - Black Edition (3x)

EK-CoolStream XE 360 (Triple)

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)