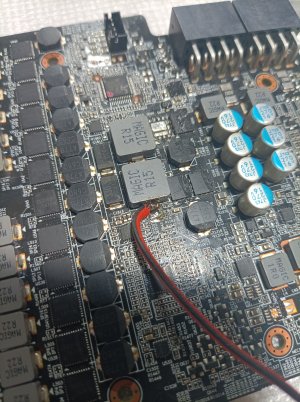

You can solder the wire to either end of any of the coils on that VRM. It doesn't really matter which end, or which one you choose, since they're all wired up together, and the coils don't have a meaningful effect if you're supplying a constant voltage.Well how I exactly I do that? Do I have to solder a wire if so on which coil, which side, to the coil with the complete mosfet or the one I removed, or both? Thank you.

Obviously, the other end of the wire should be connected to the positive terminal of the power supply, and you need to connect the negative terminal to the ground plane on the board. If your power supply has alligator clips, just the clip the negative terminal to the slot plate.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)