reaper7534!

Limp Gawd

- Joined

- Feb 13, 2016

- Messages

- 132

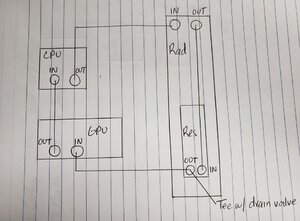

Having a issue where my loop isn't draining. I ran a similar setup on my P5 case and the drain was lower than the radiator and res and it drained almost completely ( had drain port on bottom of rad ). The new setup has both inlet and outlet on top of rad. Am I not draining because my drain is not below the radiator ? My res will empty and I'm not sure how much of the rad empties, but the lines and blocks look pretty full. I've tried to illustrate what levels each component is at ( drain does not extend past radiator ). Where would the ideal place to install a drain ? Explanation would be nice since I don't understand this whole gravity thing.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)