I’m just wondering and I’m sure it’s not a very intelligent question, but I got to know.

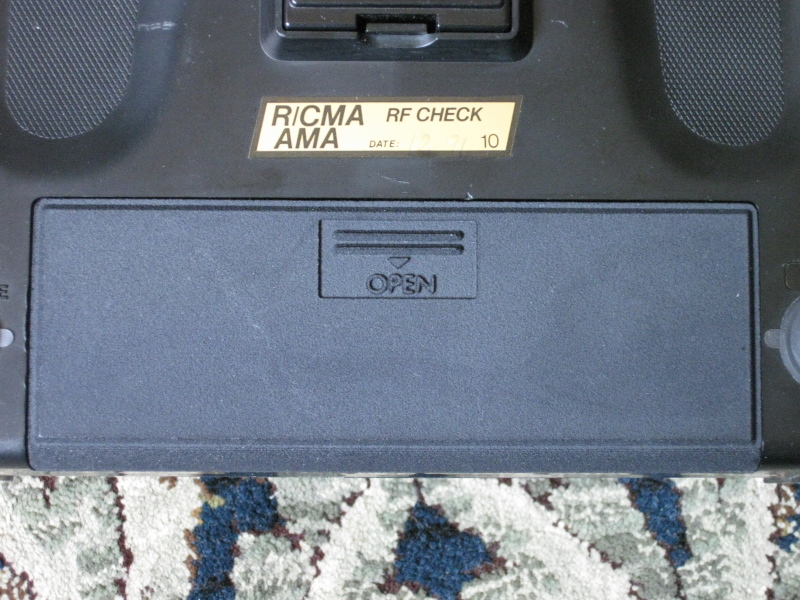

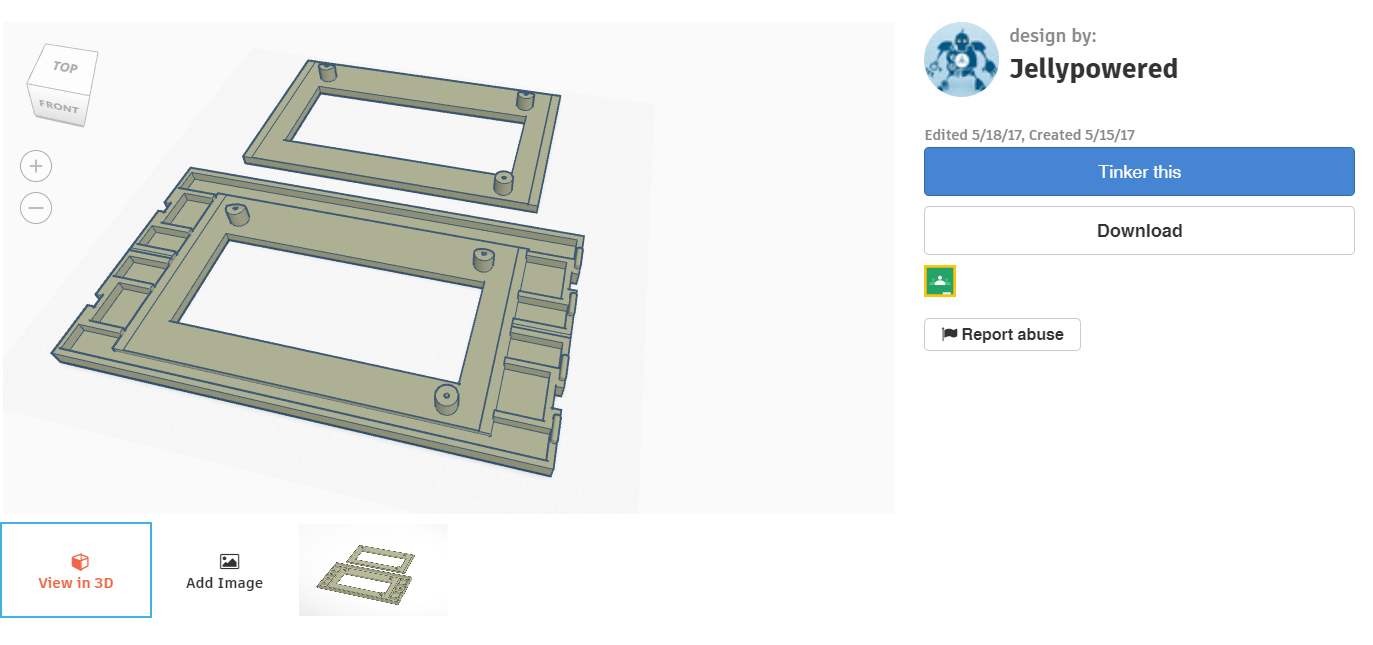

Hypothetical. If I have a part that breaks on some device and I want to replace it. How do you do that? Without having an existing print file?

Do you 3D scan it? I really do not understand.

I will be getting a printer in 2022. No doubt.

Hypothetical. If I have a part that breaks on some device and I want to replace it. How do you do that? Without having an existing print file?

Do you 3D scan it? I really do not understand.

I will be getting a printer in 2022. No doubt.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)