I put in my Xigmatek s1823 cooler that I got, I was getting better temps then with the stock cooler but there was a 10 degree diffrence between the hottest and coolest cores so I thought I did something wrong. I took it off,cleaned the heatsink and cpu with alchohol and put as5 on it and I got worse temps then before. For the last hour or two I tried everyway I could think of putting the as5 on and I still get bad temps. I dont know what to do about it. Is there something I'm not doing or something wrong with the heatsink? Thanks.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Horrible Temps Xigmatek Q6600

- Thread starter webbed

- Start date

Applying thermal paste is hell. I remember my hands having scratches and toilet paper covered in the stuff was everywhere. I learned that less is more in terms of the stuff. Just keep trying, youll get it right. Just keep the amount low

Which is why you buy something like AS5 or MX-2 that comes in a nice little syringe type thingy. Scratches and toilet paper? You just put a little dab on the CPU and that's it.

To the OP, when locking the push pins down, make sure to go in a diagonal from the first corner. That's the only thing I could think of as not doing so might cause uneven mounting.

arctic silver's website recommends applying it this way:

http://www.arcticsilver.com/pdf/appinstruct/as5/ins_as5_intel_quad_wcap.pdf

I had horrible temps with my stock cooler, but i upgraded to a zalman cnps9700 and it works fantastically. Im not sure how that HSF connects to the motherboard, but if it has those push in feet, those can be a pain sometimes to get connected well.

http://www.arcticsilver.com/pdf/appinstruct/as5/ins_as5_intel_quad_wcap.pdf

I had horrible temps with my stock cooler, but i upgraded to a zalman cnps9700 and it works fantastically. Im not sure how that HSF connects to the motherboard, but if it has those push in feet, those can be a pain sometimes to get connected well.

I just tried the line across again. Thats how I had it the first time. I also tried pushing the pins in diagonaly and that didn't help. The temps in the bios just kept going up until I turned it off. I looked at the heatsink bottom and it looks like the cpu idented parts of the heatpipe. Could that be a problem or is that normal?

Old Hippie

Supreme [H]ardness

- Joined

- Oct 31, 2005

- Messages

- 6,013

I looked at the heatsink bottom and it looks like the cpu idented parts of the heatpipe.

No, that's the "signature" of this design. The heatpipes are in direct contact with the chip. They have to have a flat bottom.

You need to change those push pins to a bolt down assembly. I saw some guy over at the Extreme forums ( I think that's where it was), and he contacted the manfg. to bitch about the pins, and they're sending him a bolt down kit for free.

Nice customer service!

Riccochet

Fully [H]

- Joined

- Apr 11, 2007

- Messages

- 29,906

You could try lapping your proc and heatsink base. I'd also recommend a bolt-down kit.

Personally, I don't like those AS5 instructions. I usually place a then line (like the one they showed in the pdf file) on the heat sink. Place my index finger in a plastic baggy (zip lock or similar) and smooth out the AS5 to the entire surface for the heatsink. This process will not only allow full coverage of the heatsink, but also removes excess AS5.

In your case though, I think your pins aren't staying locked down. order the bolt on kit.

In your case though, I think your pins aren't staying locked down. order the bolt on kit.

Riccochet

Fully [H]

- Joined

- Apr 11, 2007

- Messages

- 29,906

I use the grain of rice method typically, other times I spread it all over the proc then use a credit card to scrape away all but a thin transparent film of it. Literally transparent. I only do that with lapped procs though as I know they are flat.

Less is more when it comes to AS5. It's an interface material, anything more than an extremely thin coat of it turns it into an insulator.

Less is more when it comes to AS5. It's an interface material, anything more than an extremely thin coat of it turns it into an insulator.

tuksonrider

Gawd

- Joined

- Sep 29, 2007

- Messages

- 814

The AS method of applying TIM doesn't work too well with the HDT Xig uses. Xig recommends manually spreading the TIM on the HSF, then installing it. Just remember, less is more when it comes to TIM applications. Also, cover your finger with a sandwich baggie so that you don't contanimate the TIM with oils.

When I applied TIm, I used a slightly different method.

Now, this LOOKS like a lot, but it really isn't (though definately more than a single rice grain). I'm using IC Diamond 7 Carat TIM. It's thicker than most TIMS, but the results I'm getting are great.

If I was to redo it, I would use a little SHORTER line, and the outside lines a little cloer to the center of the HSF, than right down the center of the heatpipes.

The dents are normal as the copper tubing is soft. I'm also using TR 775 Bolt-thru kit ($5 from sidwindercomputers.com)

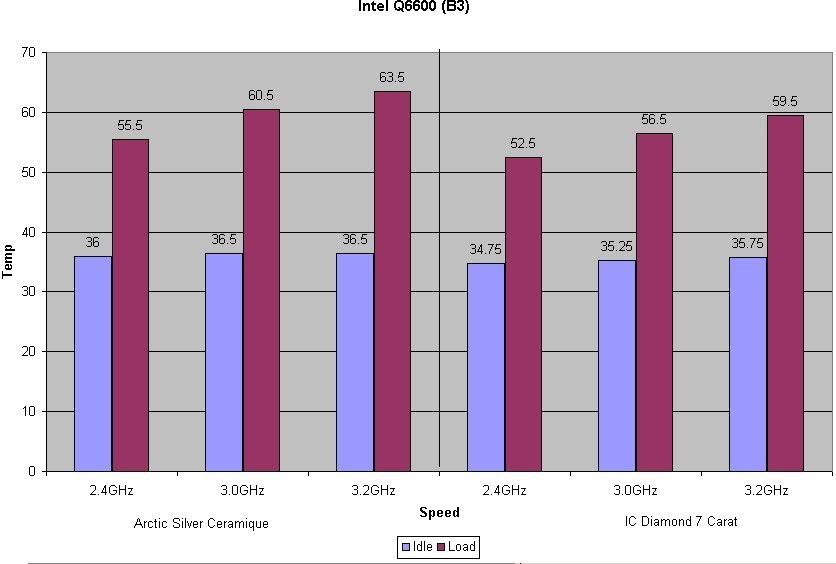

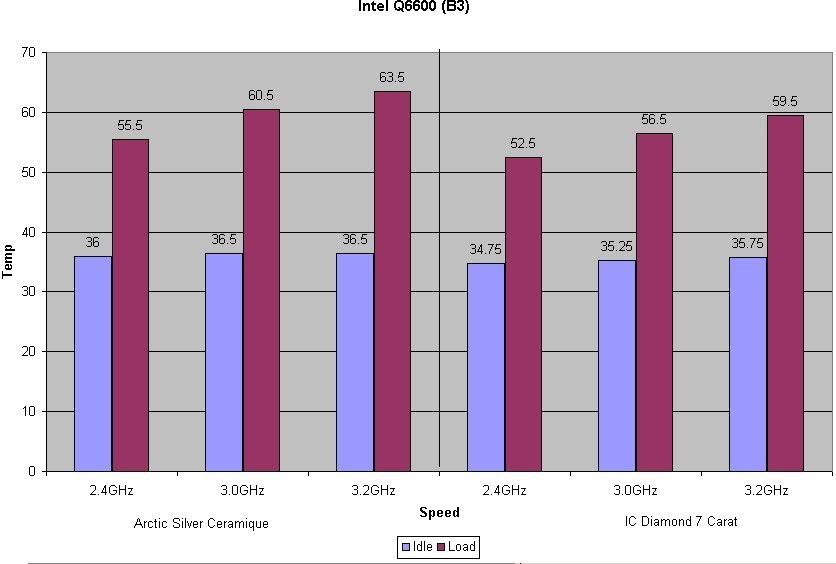

Here are my temps comparing ASC vs IC7 (Q6600 B3) @ Ambient Room Temp of 21C throughout the ENTIRE test.

When I applied TIm, I used a slightly different method.

Now, this LOOKS like a lot, but it really isn't (though definately more than a single rice grain). I'm using IC Diamond 7 Carat TIM. It's thicker than most TIMS, but the results I'm getting are great.

If I was to redo it, I would use a little SHORTER line, and the outside lines a little cloer to the center of the HSF, than right down the center of the heatpipes.

The dents are normal as the copper tubing is soft. I'm also using TR 775 Bolt-thru kit ($5 from sidwindercomputers.com)

Here are my temps comparing ASC vs IC7 (Q6600 B3) @ Ambient Room Temp of 21C throughout the ENTIRE test.

The AS method of applying TIM doesn't work too well with the HDT Xig uses. Xig recommends manually spreading the TIM on the HSF

I've been looking at the Kingwin version and from my reading, I understand that with HDT style coolers it is indeed better to pre-apply the thermal compound to the heatsink itself. With just the usual dot on the processor there isn't enough compound to fill the voids around the heatpipes once you clamp it down.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)