StandartBlitz

n00b

- Joined

- Jul 29, 2021

- Messages

- 60

I have a Gainward GTX 770 Phantom with heavy static artifacts and already tried reflowing it which didn't help. Then I inspected the solder connections of the RAM chips and found one that was particularly stretched - fixing it also did not work.

Now have a useless graphics card liying around and would like to know whether the GPU is still good and the RAM / board bad or vice versa so I don't throw away potentially good parts.

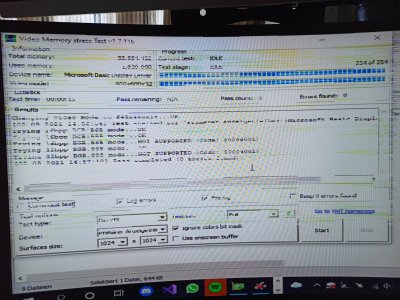

GPU - Z gives no readings for vmem and video memory stress test can't recognize any errors.

Are there any other diagnostic tools or ways to narrow down the problem without replacing all the RAM - Chips?

diagnostic tools or ways to narrow down the problem without replacing all the RAM - Chips?

Now have a useless graphics card liying around and would like to know whether the GPU is still good and the RAM / board bad or vice versa so I don't throw away potentially good parts.

GPU - Z gives no readings for vmem and video memory stress test can't recognize any errors.

Are there any other

diagnostic tools or ways to narrow down the problem without replacing all the RAM - Chips?

diagnostic tools or ways to narrow down the problem without replacing all the RAM - Chips?![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)