- Joined

- May 18, 1997

- Messages

- 55,598

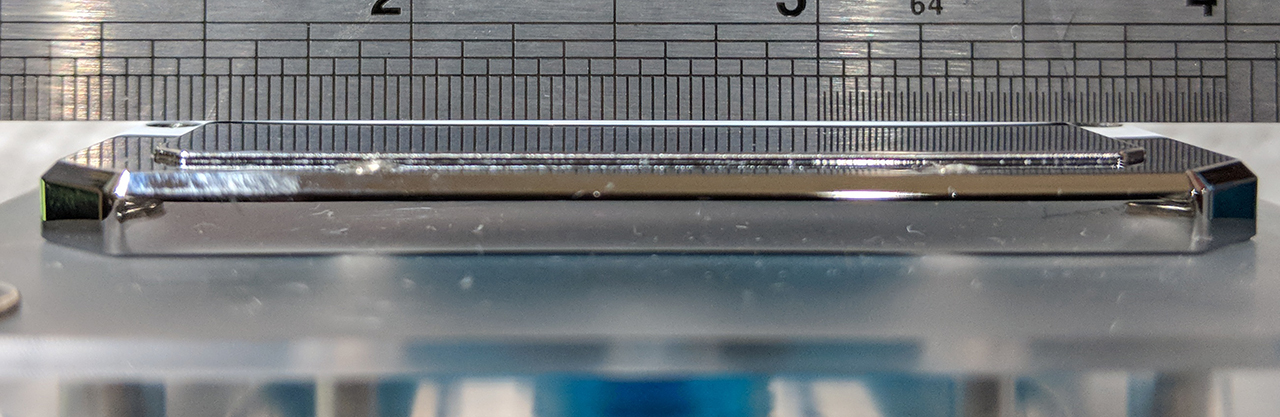

AMD Ryzen Threadripper TIM Application

AMD's Threadripper has shown to be a very different CPU in all sorts of ways and this includes how you install the Thermal Interface Material as well should you be pushing your Threadripper's clocks beyond factory defaults. We show you what techniques we have found to give us the best temperatures when overclocking.

If you like our content, please consider supporting HardOCP through Patreon for as little as $1 a month.

AMD's Threadripper has shown to be a very different CPU in all sorts of ways and this includes how you install the Thermal Interface Material as well should you be pushing your Threadripper's clocks beyond factory defaults. We show you what techniques we have found to give us the best temperatures when overclocking.

If you like our content, please consider supporting HardOCP through Patreon for as little as $1 a month.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)