Zarathustra[H]

Extremely [H]

- Joined

- Oct 29, 2000

- Messages

- 38,878

Ahh, thats what I thought. I did feel I remembered goofy for the E's, due to die orientation.

How you like that sheet? I wanna replace the Gelid I'm using under and over the lid, but havent decided if I wanna go back to the CLU or try something else.

I haven't deflowered it yet in my current setup, but I used it once before when I had the rare 180mm maingear cooler in my system, and as I recall the temps were much better with the indigo Extreme than with AS5.

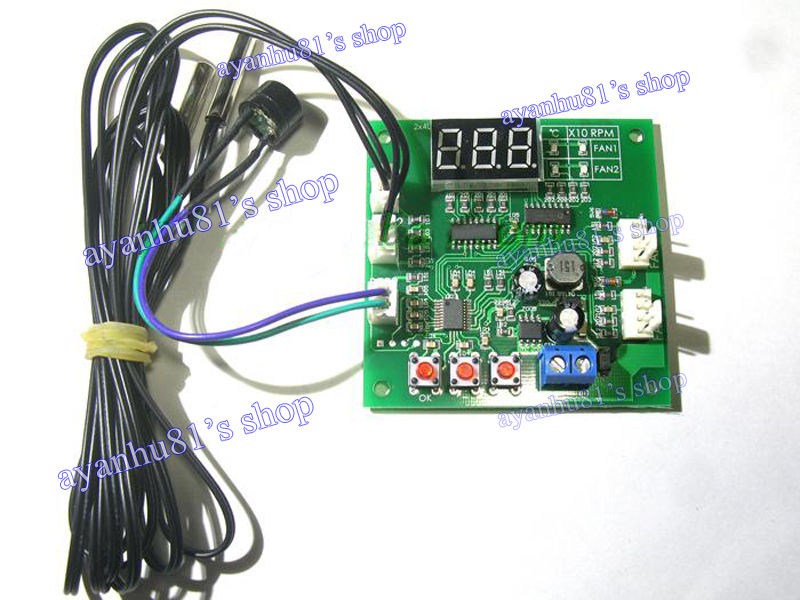

The main benefit seems to be that while complicated to install, it minimizes the importance of getting a good mount. You might get equivalent or better performance from some other pastes if you have an absolutely dead on perfect mount, but the indigo extreme seems to take the mount more or less out of the equation, as long as you follow their directions precisely. (you have to reflow it in a horizontal orientation, and follow their detailed instructions for what to look for on the temp chart. If you don't it won't work right.

For my GPU I didn't use the included EK paste, and instead went with the Thermal Grizzly Kryonaut paste as it reviews the best out of all the non-conductive pastes.

Oh, and another note. The sheets are application specific, so you have to buy them for the specific CPU you want to use them on. They wouldn't work under the lid.

Since you have delidded it already, Have you considered going direct die like in the old days? I wonder if typical CPU block would mount correctly, or if the spacing would be all wrong.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)