Well, what other materials do you want to print?

Wood: Kind of difficult since it has to grow from living things. Maybe if you want to glue sawdust together with a resin?

Paper: What's the point if you could?

Metal: That's what we really want, right? The melting point of steel is about 1370C. Aluminum is about 660C. Sure, you can use a powdered form - which is messy, but then you have to heat it until it fuses. That means an industrial laser or plasma arc. Hot and dangerous process. Not going to happen in your living room, and even if you do 3D print it, it's not as simple as that. There are many types of steel - carbon, stainless, alloys of all kinds, and same with aluminum. You won't ever see the strength from forging for certain, and because you're basically welding metal powder onto the resultant solid, the thermal variance is likely to cause varying placement of soft and brittle spots. Not all alloys could work with this kind of process, some melt at higher temperatures, and all have to be heat treated if you want to have any semblance of even hardness and temper, which means you'll need a kiln. You'd be better off with a milling machine.

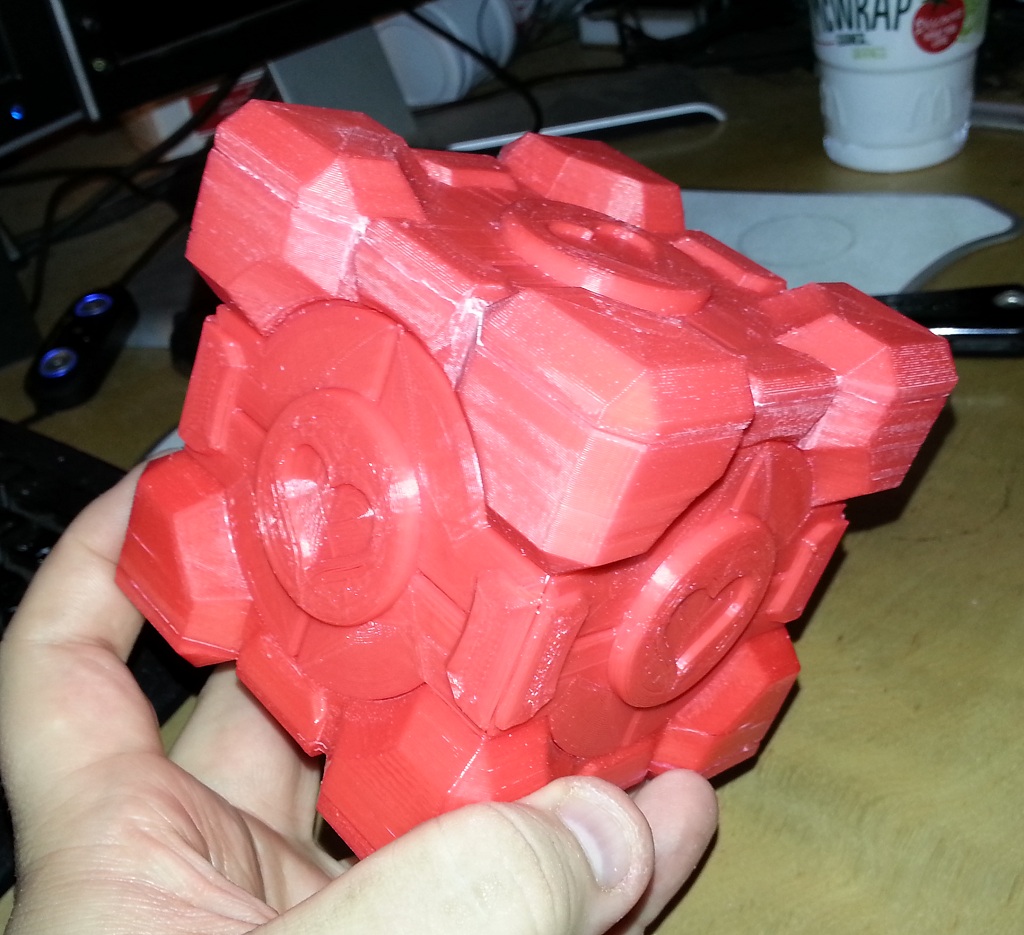

Now if they can find a way to effectively print carbon fiber cheaply that will change things, but right now it's not viable. That pretty much leaves plastic for the short term, along with all its shortcomings.

Bottom line: Give it some time. 3D printing is great for custom prototypes or one-of-a-kind small parts. The technology needs to advance before more sturdy stuff can be made with it.

There are other things, like MDF, other wood-like products, fiber, and as I noted before, food. And like you said, right now, it might not be viable, but that's right now, unless we all literally become retarded, progession in technology is gonna be going at a rather rapid rate. It good be that next year, carbon fiber would be able. And 5 years after that soft metals, and a couple after that steel. Can't look at it like it'll only be plastic.

What if they looked at it like that when they thought of printing. Oh, we got ink that we can slap on paper, who needs something sophisticated like a high powered electric printer that uses laser? Just foolishness.

Which is the mentality that this guys has (iirc, it's been a while since I read it)

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)