Hi Everyone,

As mentioned in the Tutorial Project: Nº2 thread, several components will have their own thread, i.e. this one. This is mainly so there´s a generic thread on how to paint such componentes so anyone can use it as a guide without having to read through the whole main tutorial project.

You can see how these components look in the overall project by reading the main thread:

http://hardforum.com/showthread.php?t=1675489

First, I´m going to start with the optical drive.

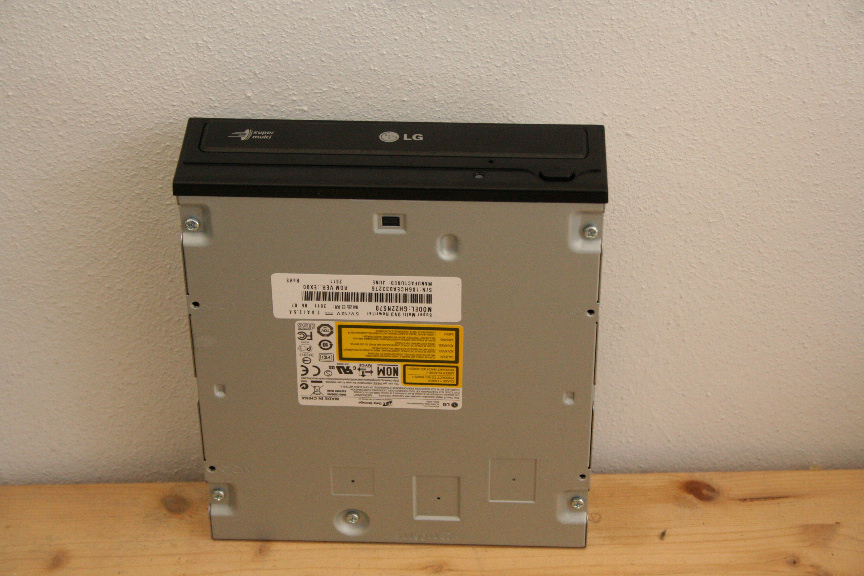

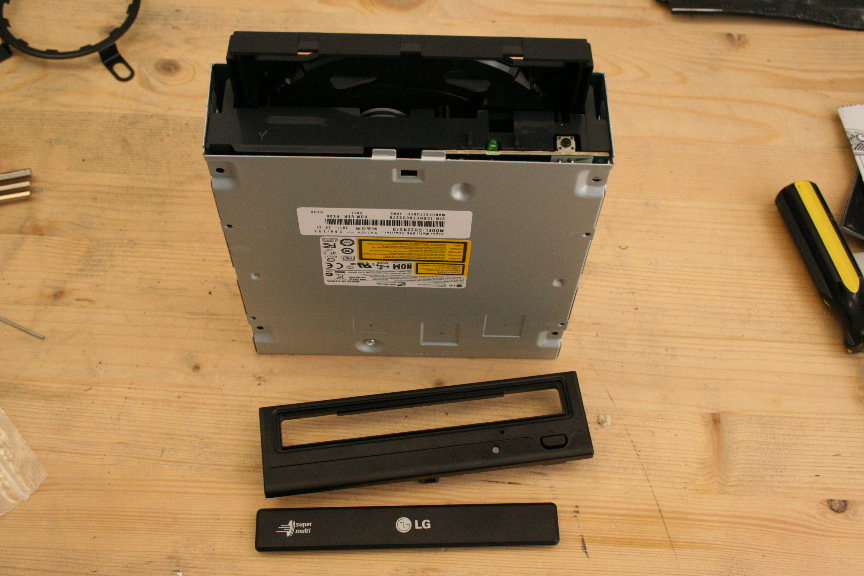

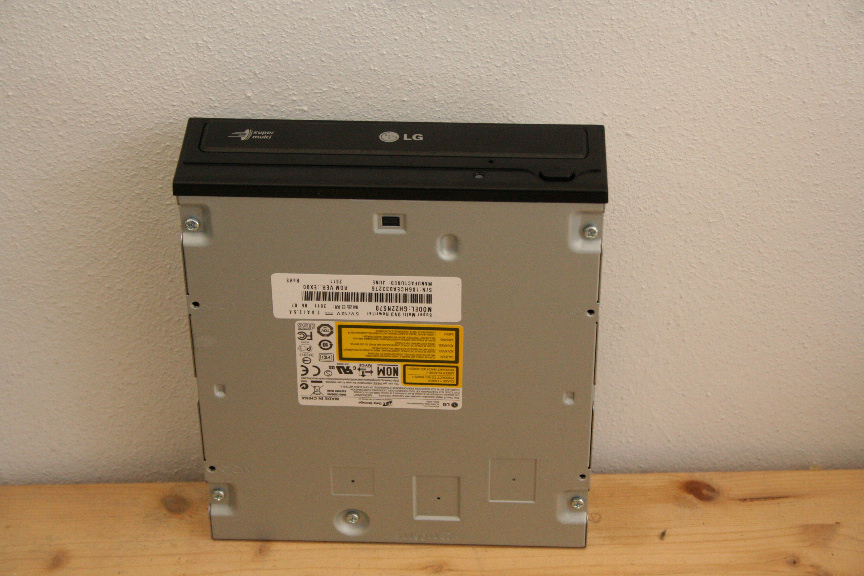

In this case I will be using an LG CD/DVD rewriter, but most common modern drives have the same mounting system so while there may be some differences, the concept remains the same.

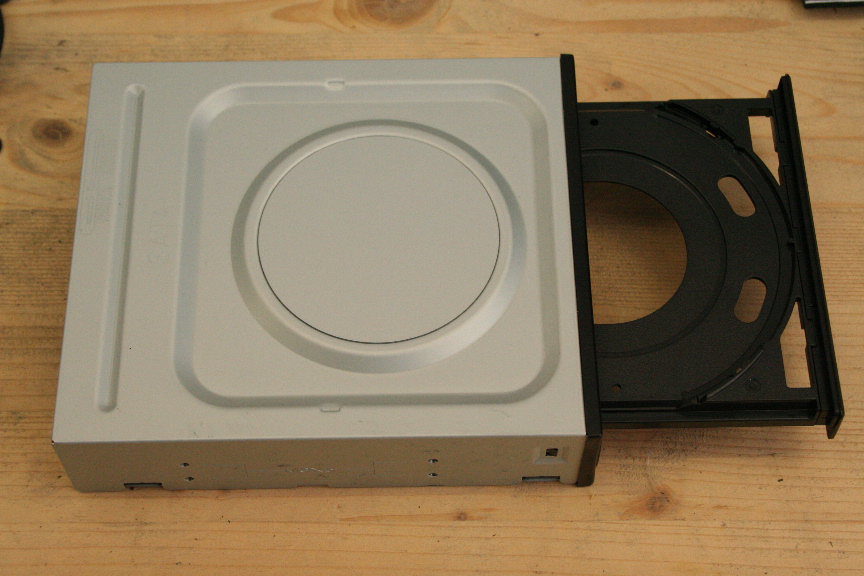

We need to open the bay, for that you can either open it when your pc is on and then leaving it open when you shut down and unmount it or you can put a pin in a small hole on the front of the bay which by pushing it in, it will eject the bay.

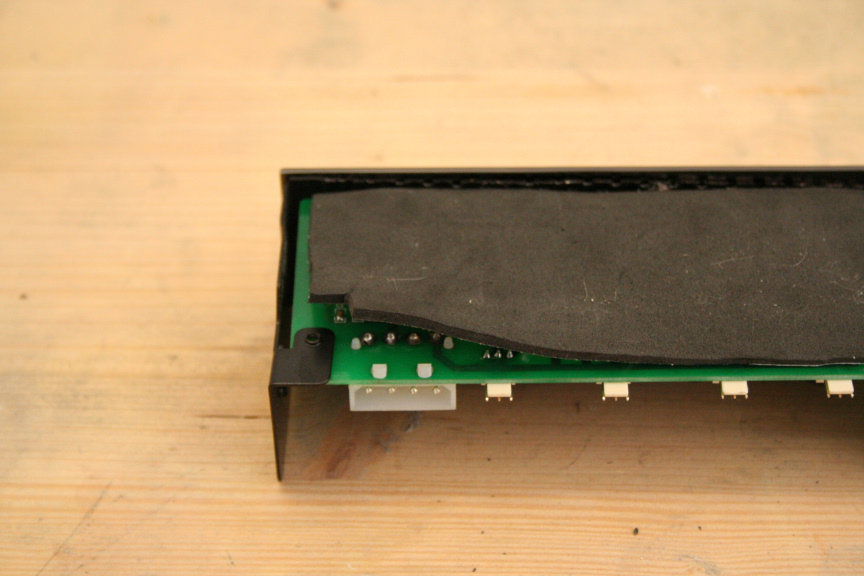

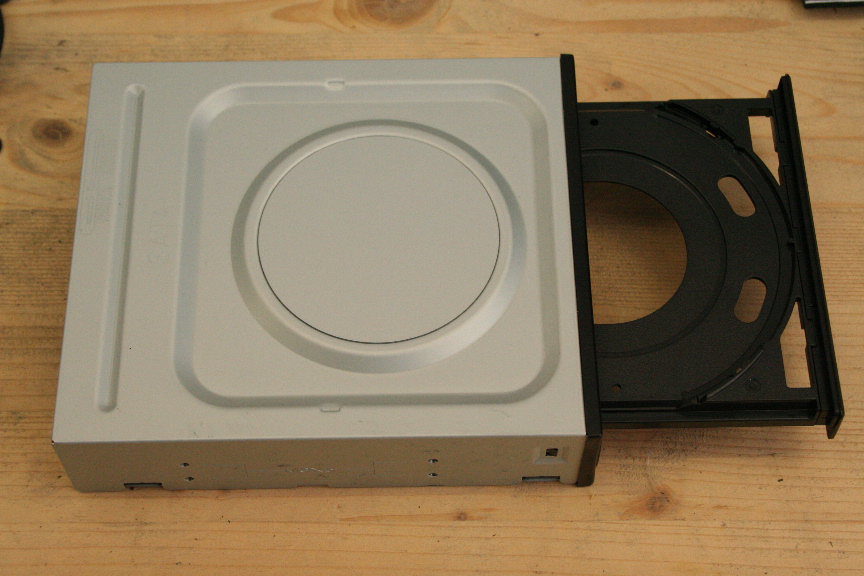

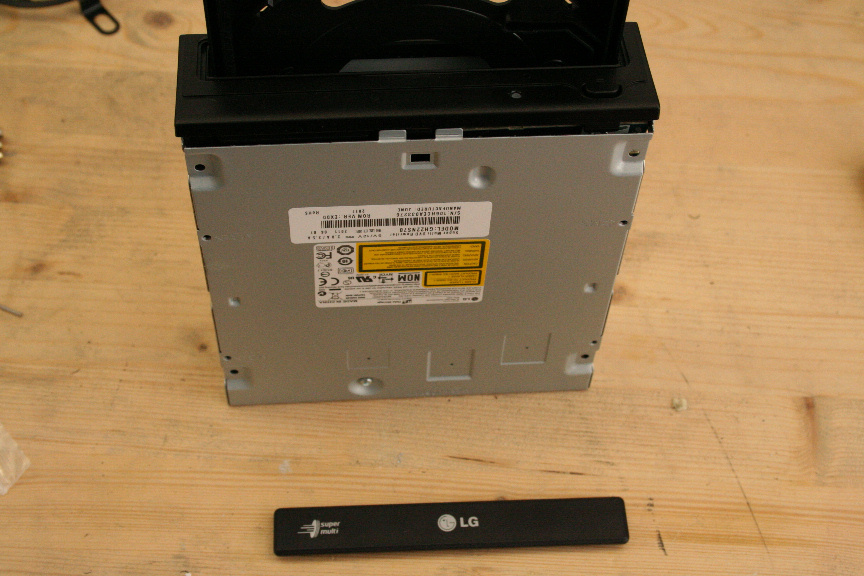

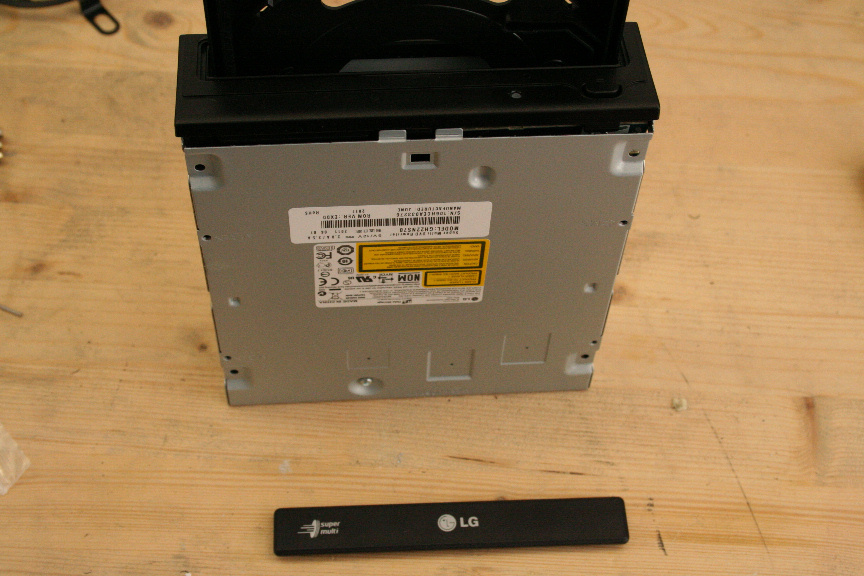

We now need to remove the bay mask, in this case it slides off upwards, again there may be some differences in your drive of choice but just be carefull, you don´t want to brake it.

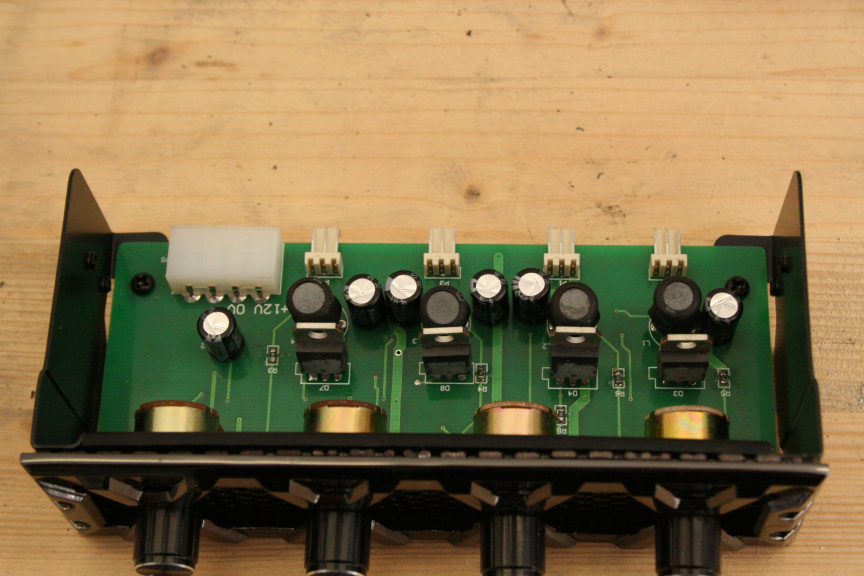

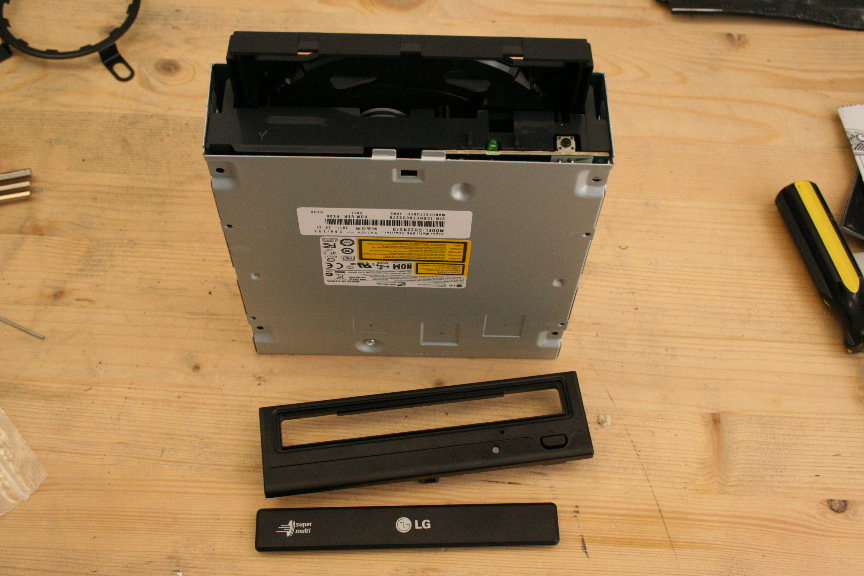

Now we need to remove the frontal, normally there are mounting clips on the sides and underneath which need to be pressed in in order to release it.

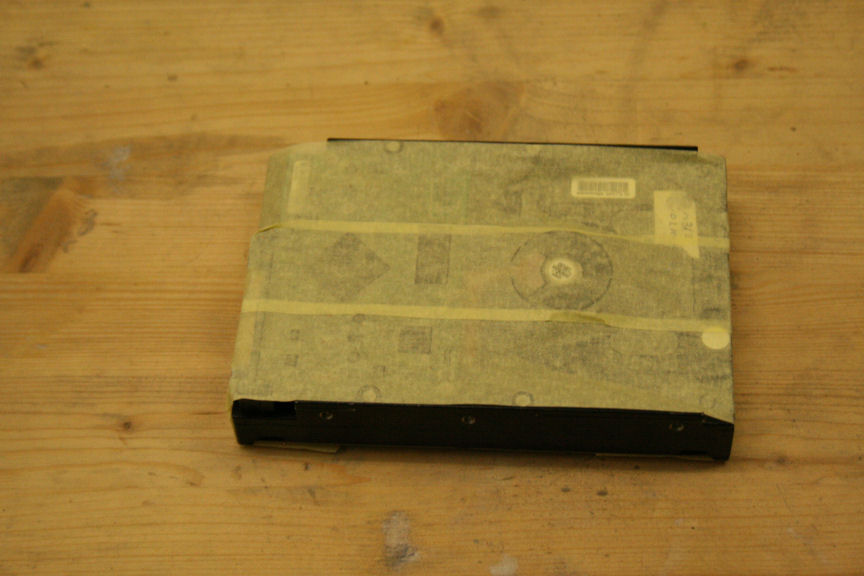

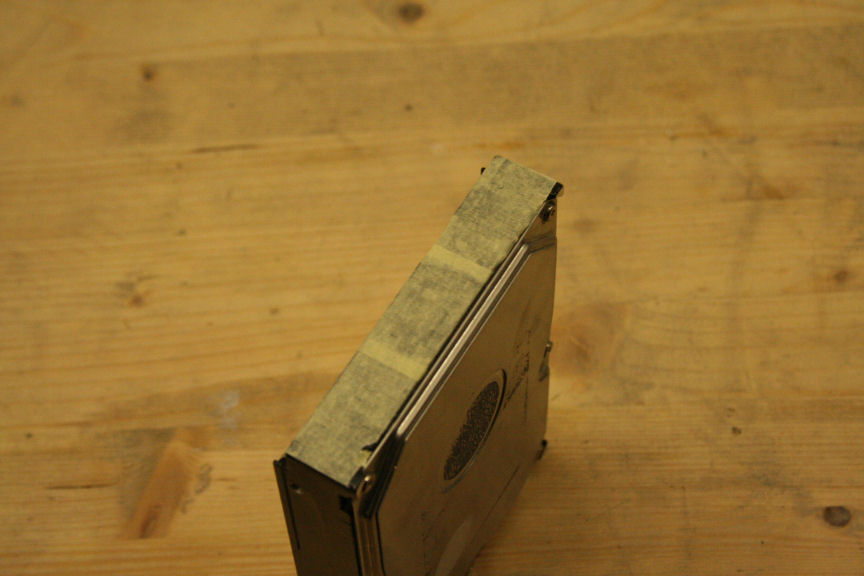

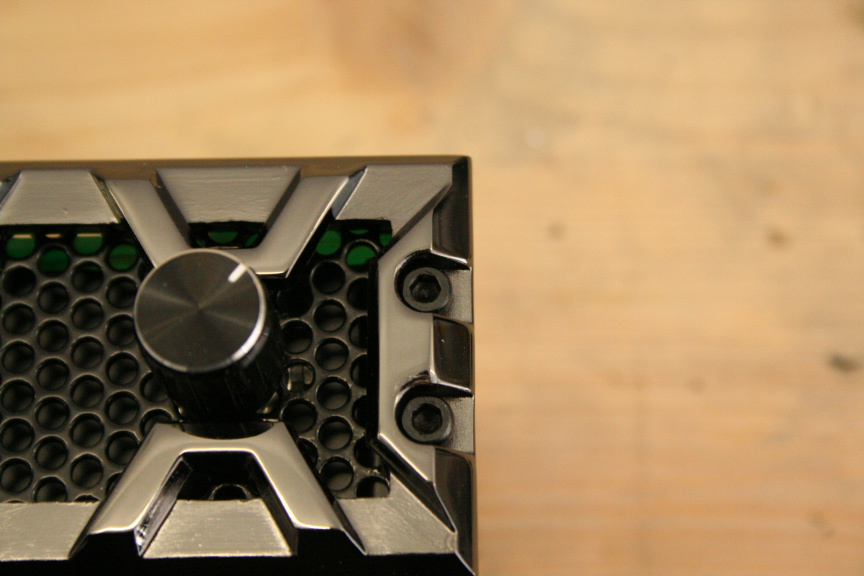

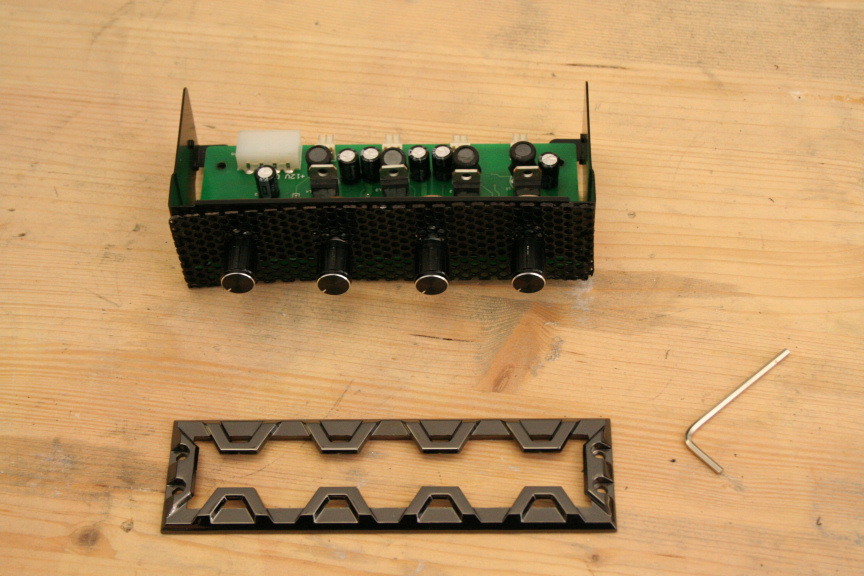

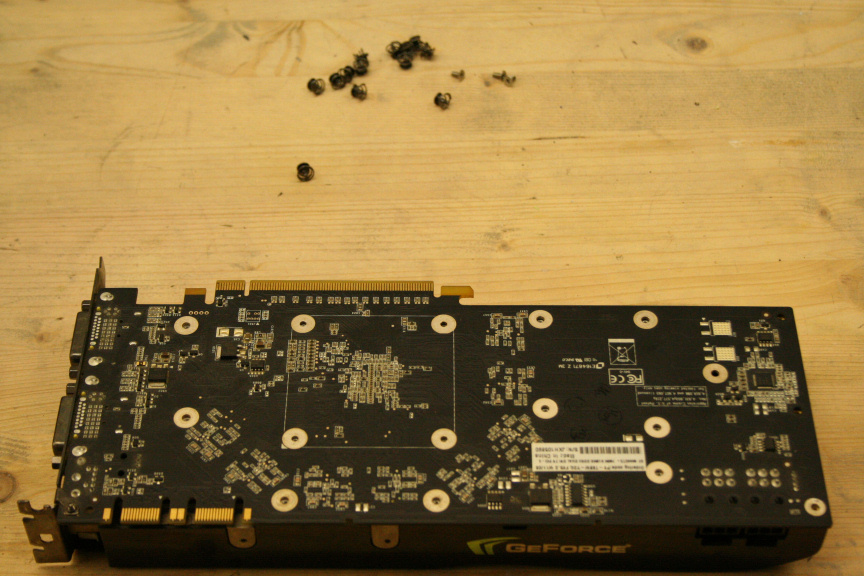

We remove the metal casing by taking off the 4-5 screws under the optical drive, once done you can take it apart easily, in most cases it will just slide off.

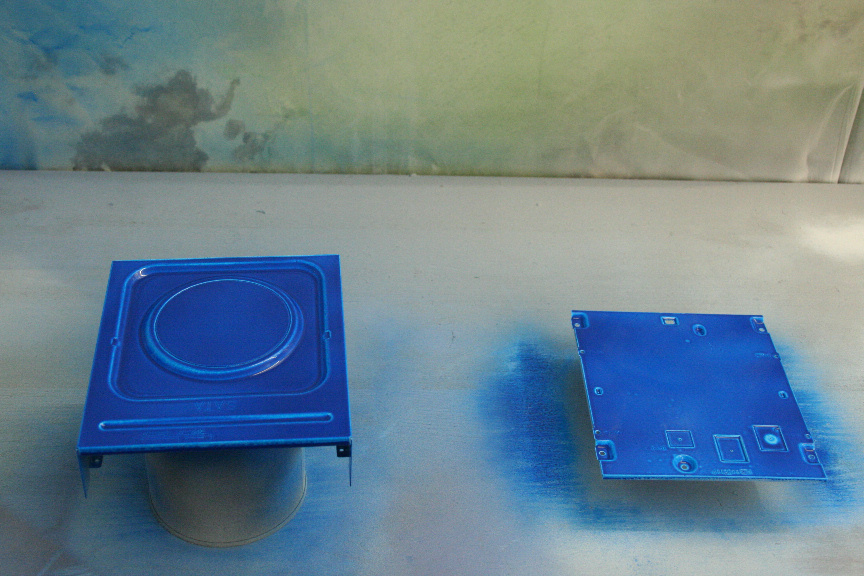

We proceed to sand down everything and clean it, remember to remove the stickers, normally I use distilled water but you may use other products like alcohol. If you use a different kind of product like window cleaner, make sure it´s not abrasive or you may damage the plastic.

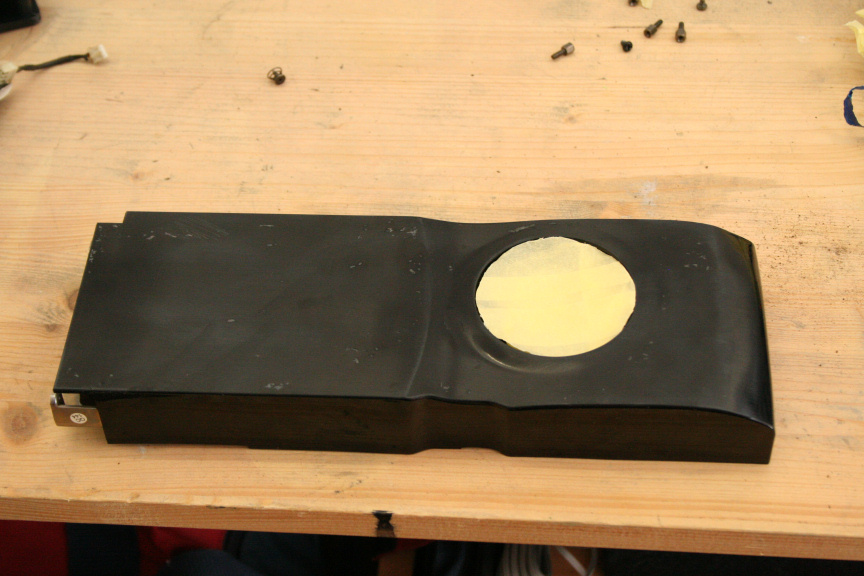

Once done and dry we proceed with the primer. For paint types and techniques please refer to the main project thread stated at the beggining of this thread.

Because I will be using a pearl effect finish, I need to aply a base color on top of the primer, if you´re using a normal, glossy, or metallic color you can ignore this step.

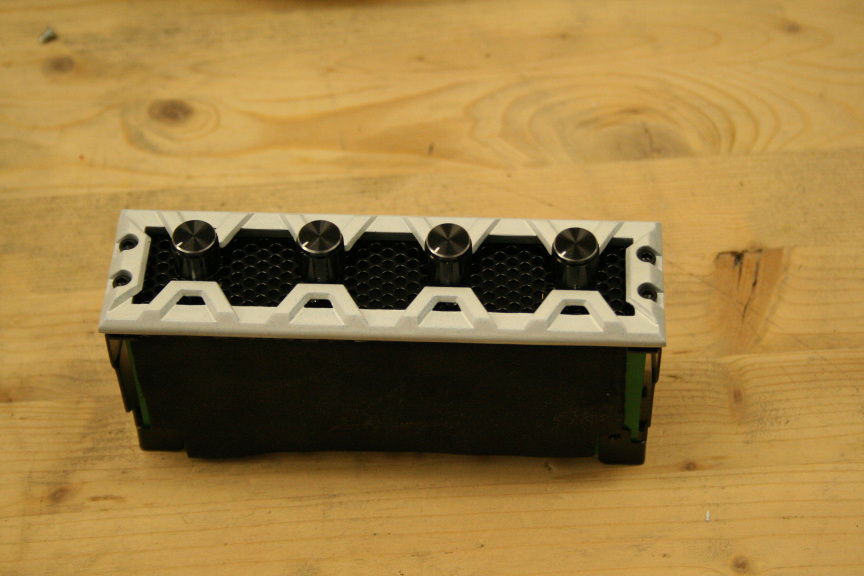

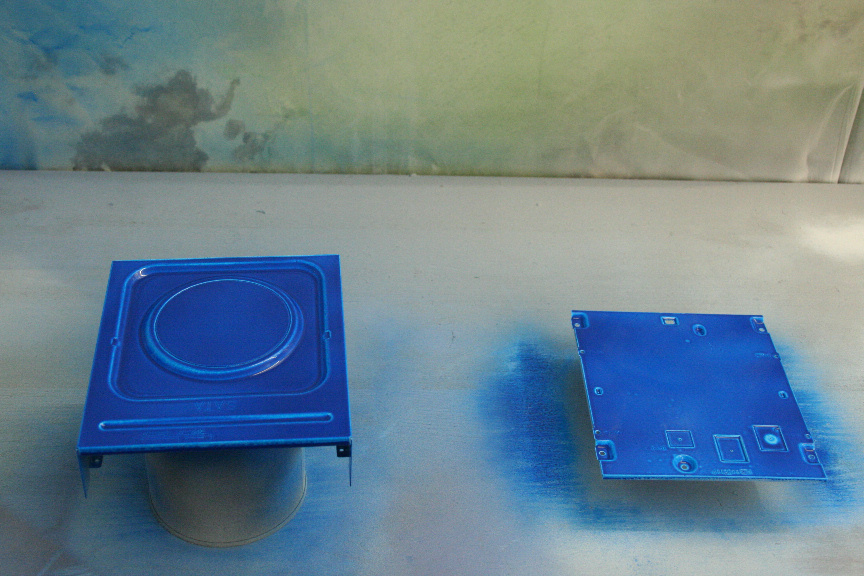

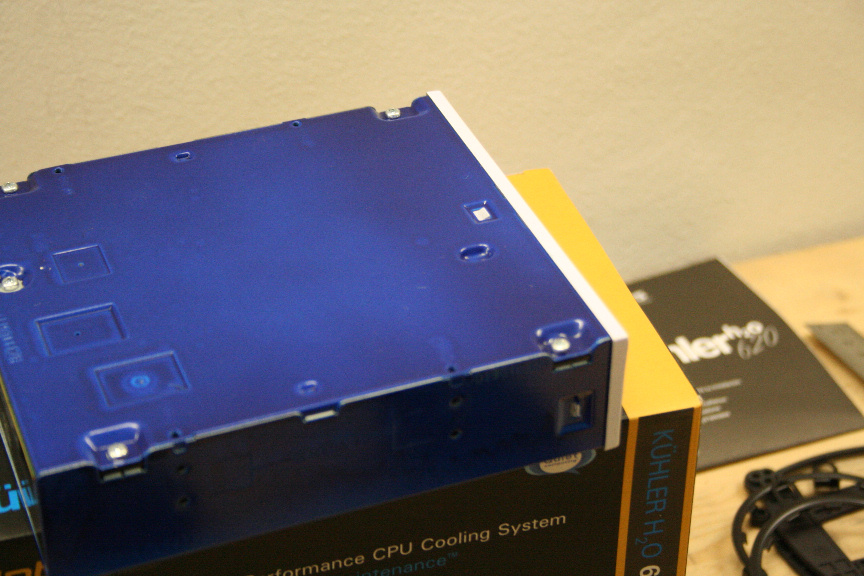

The first coat of pearl blue.

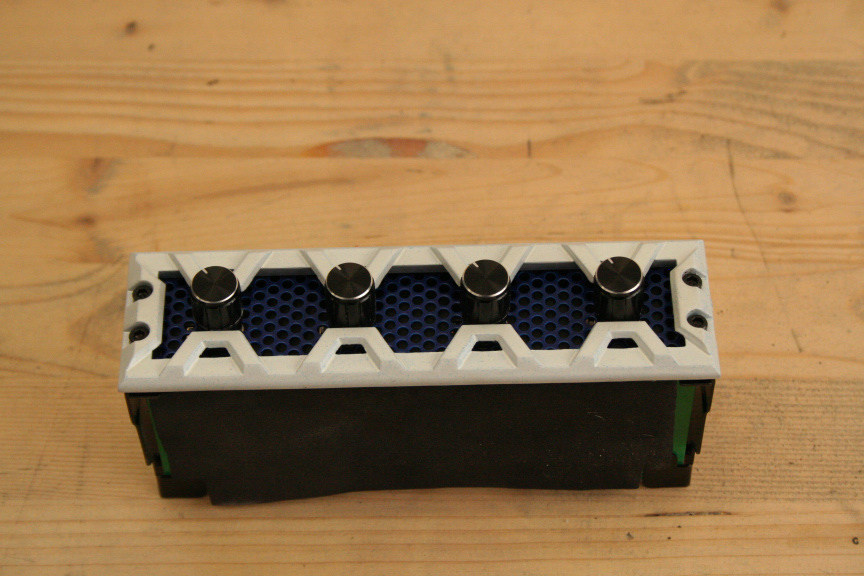

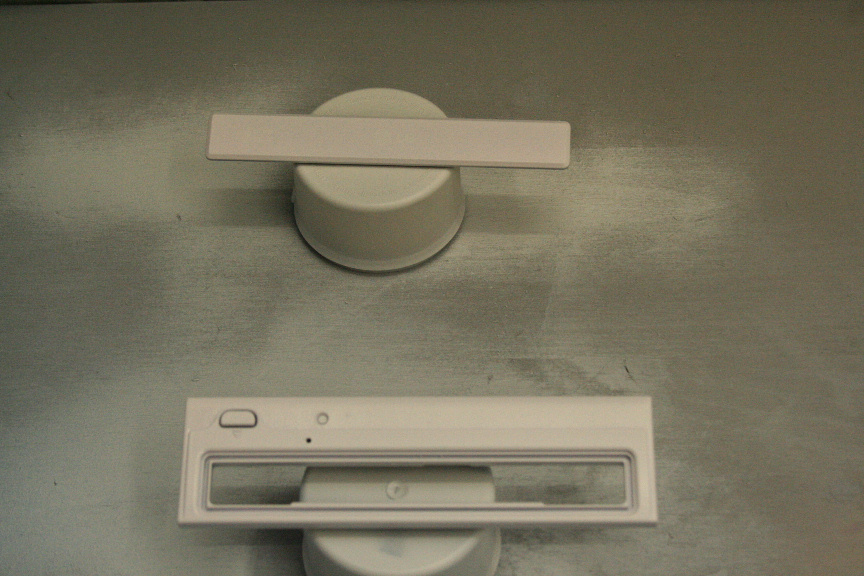

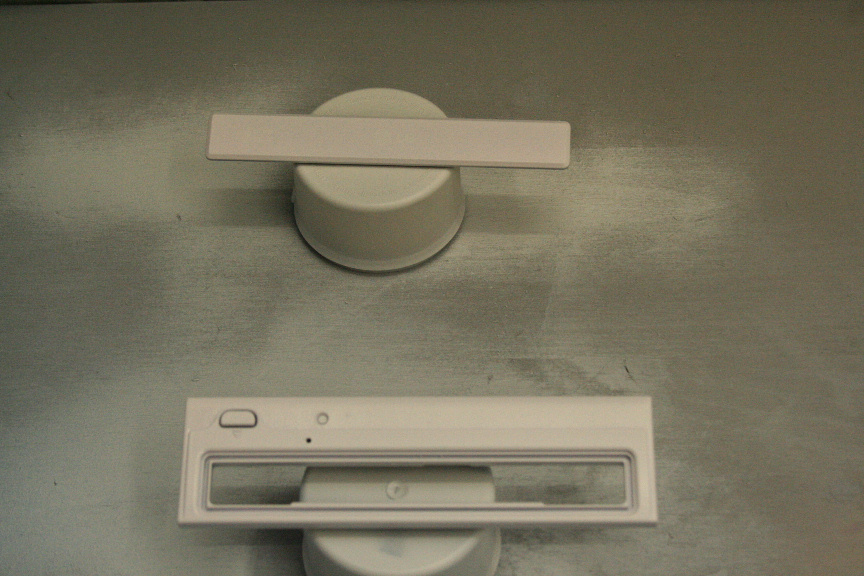

First coat of pearl white on the frontal.

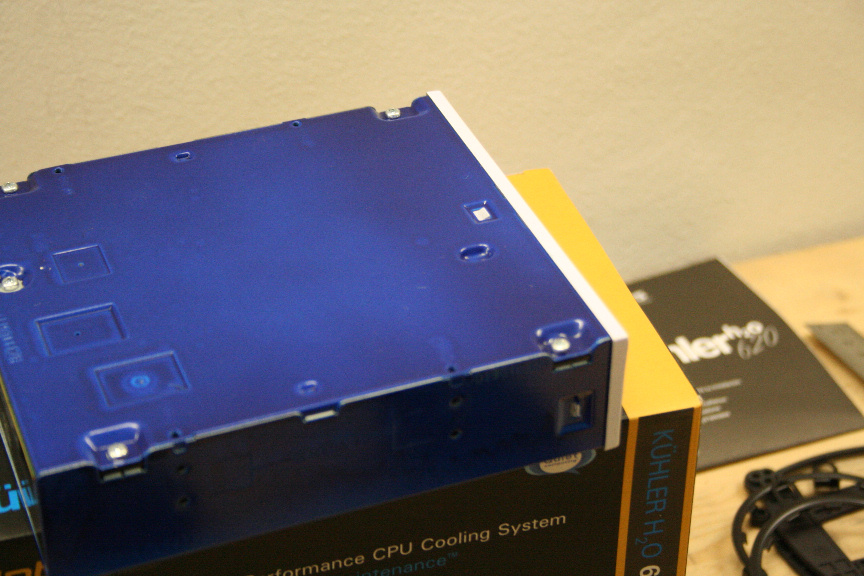

Once dry, we aply a coat of clear lacquer and leave it to cure for 24h

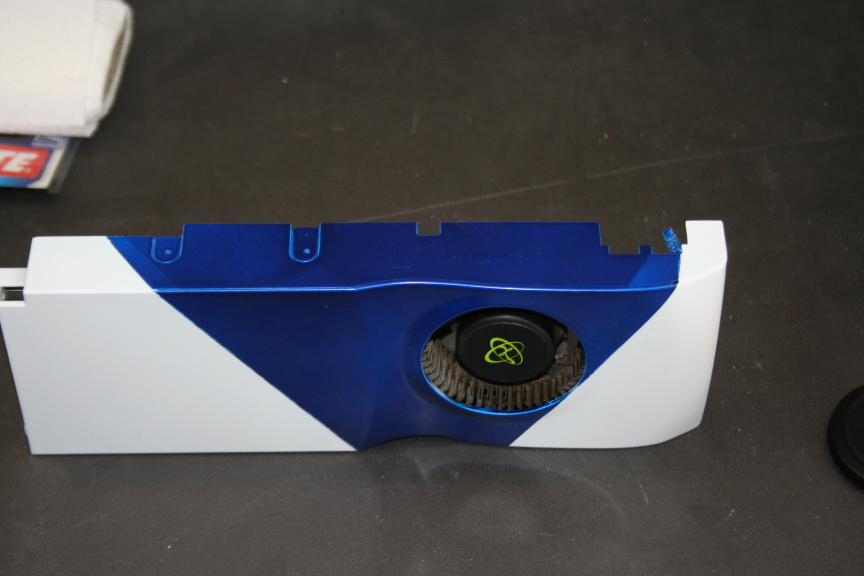

Now it´s all ready to put it back togueter, and here we go, our finished optical drive, ready to be mounted in the tower.

Next post will be the hard drive.

As mentioned in the Tutorial Project: Nº2 thread, several components will have their own thread, i.e. this one. This is mainly so there´s a generic thread on how to paint such componentes so anyone can use it as a guide without having to read through the whole main tutorial project.

You can see how these components look in the overall project by reading the main thread:

http://hardforum.com/showthread.php?t=1675489

First, I´m going to start with the optical drive.

In this case I will be using an LG CD/DVD rewriter, but most common modern drives have the same mounting system so while there may be some differences, the concept remains the same.

We need to open the bay, for that you can either open it when your pc is on and then leaving it open when you shut down and unmount it or you can put a pin in a small hole on the front of the bay which by pushing it in, it will eject the bay.

We now need to remove the bay mask, in this case it slides off upwards, again there may be some differences in your drive of choice but just be carefull, you don´t want to brake it.

Now we need to remove the frontal, normally there are mounting clips on the sides and underneath which need to be pressed in in order to release it.

We remove the metal casing by taking off the 4-5 screws under the optical drive, once done you can take it apart easily, in most cases it will just slide off.

We proceed to sand down everything and clean it, remember to remove the stickers, normally I use distilled water but you may use other products like alcohol. If you use a different kind of product like window cleaner, make sure it´s not abrasive or you may damage the plastic.

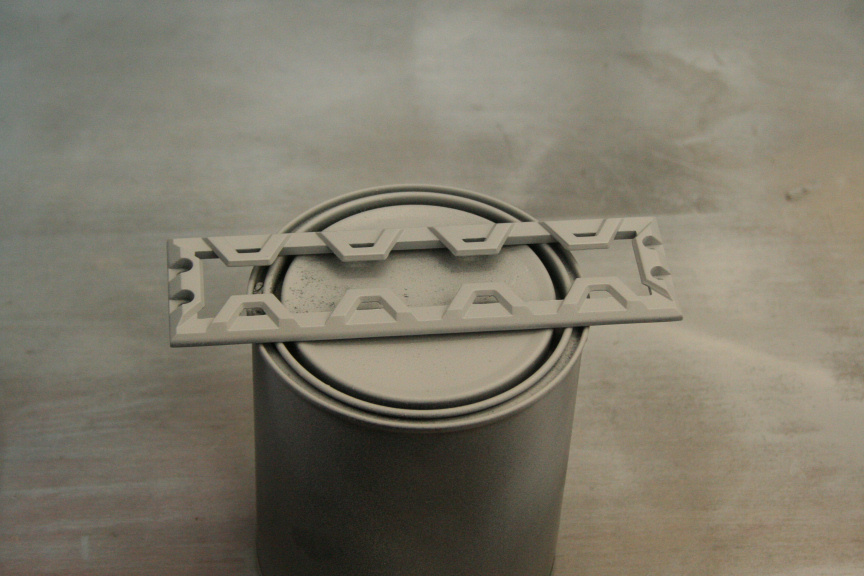

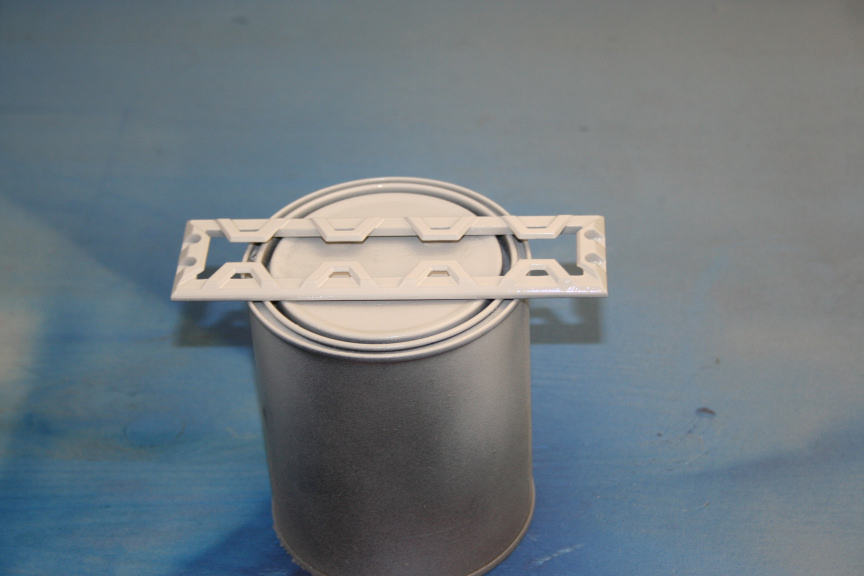

Once done and dry we proceed with the primer. For paint types and techniques please refer to the main project thread stated at the beggining of this thread.

Because I will be using a pearl effect finish, I need to aply a base color on top of the primer, if you´re using a normal, glossy, or metallic color you can ignore this step.

The first coat of pearl blue.

First coat of pearl white on the frontal.

Once dry, we aply a coat of clear lacquer and leave it to cure for 24h

Now it´s all ready to put it back togueter, and here we go, our finished optical drive, ready to be mounted in the tower.

Next post will be the hard drive.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)