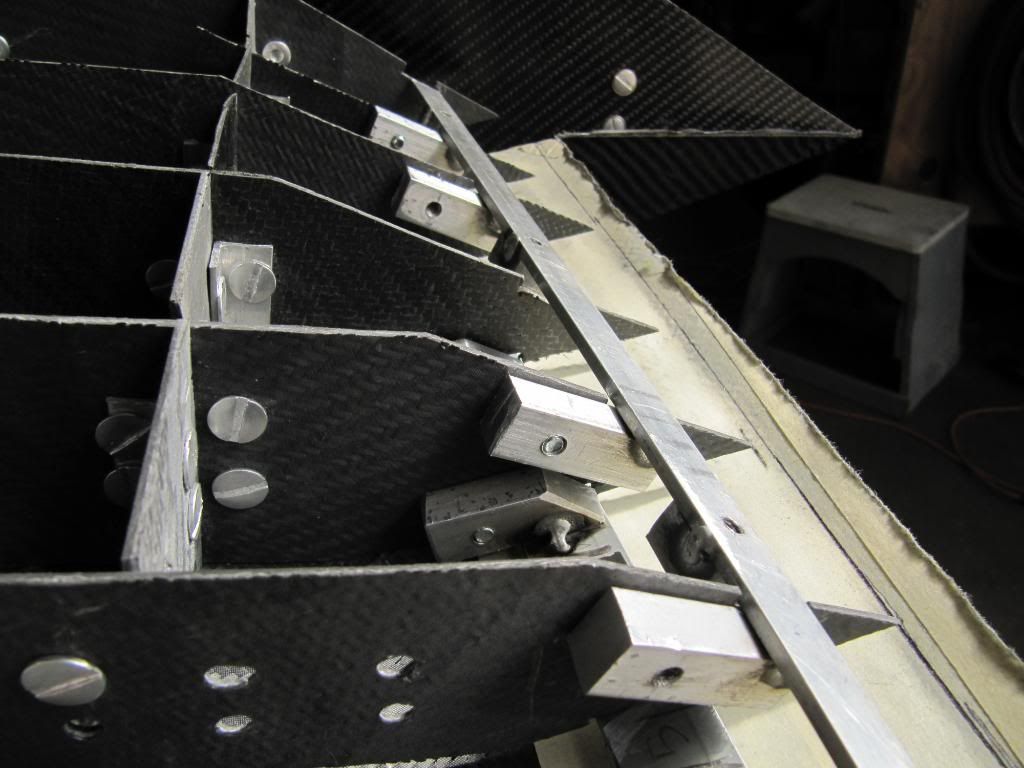

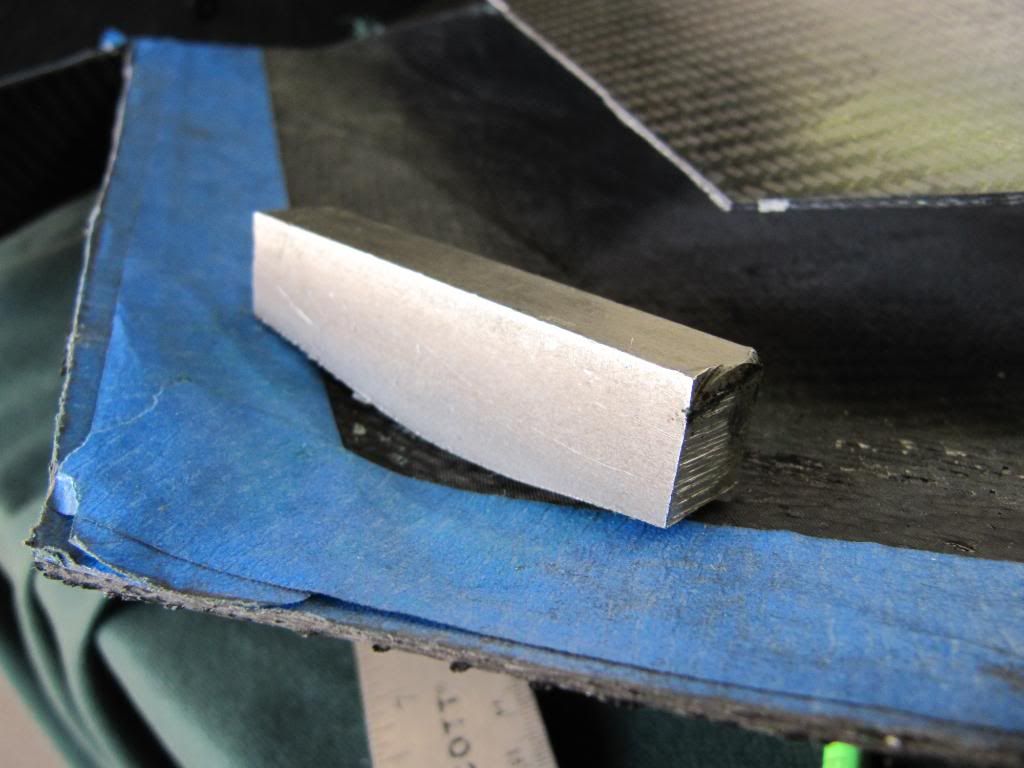

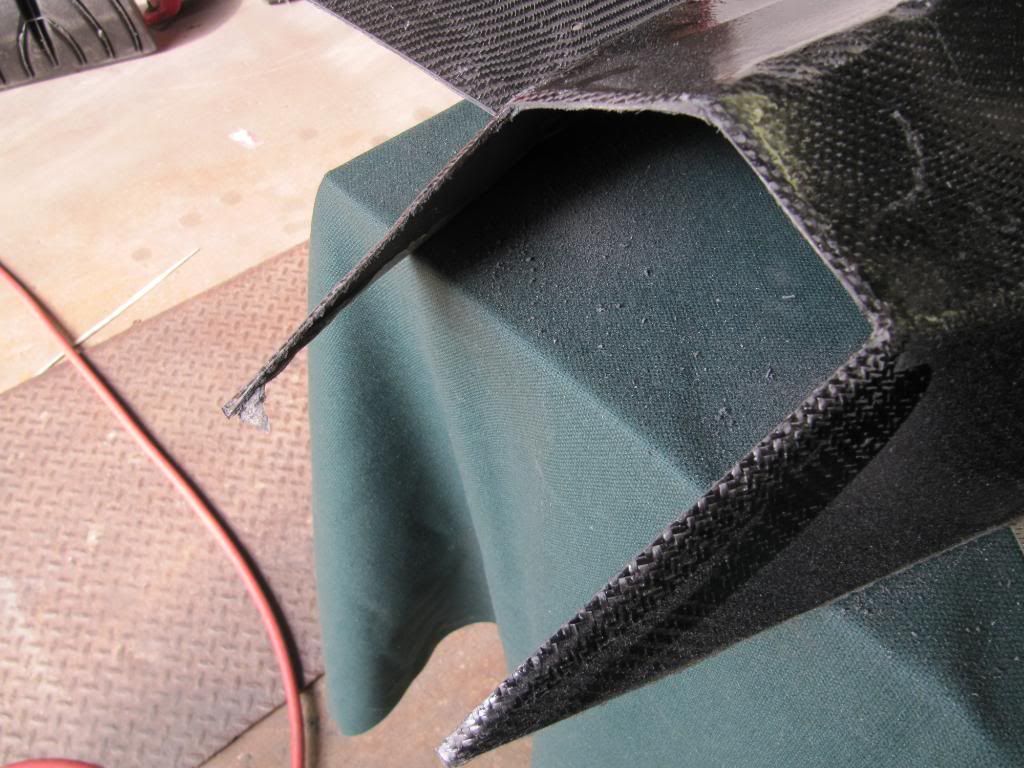

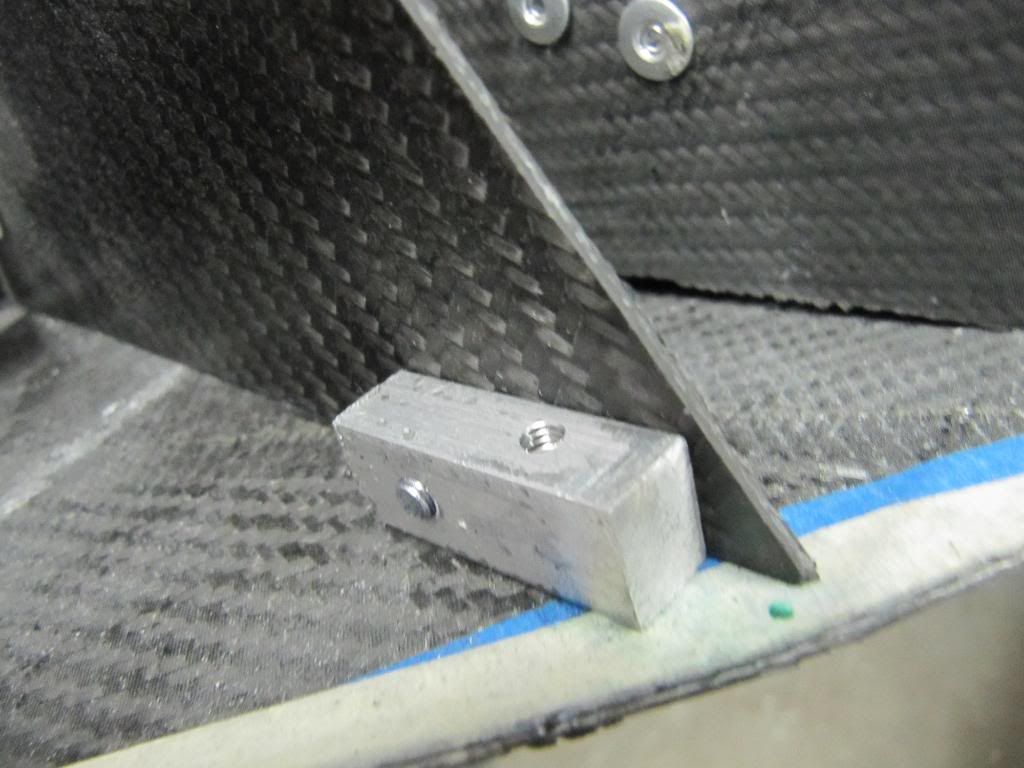

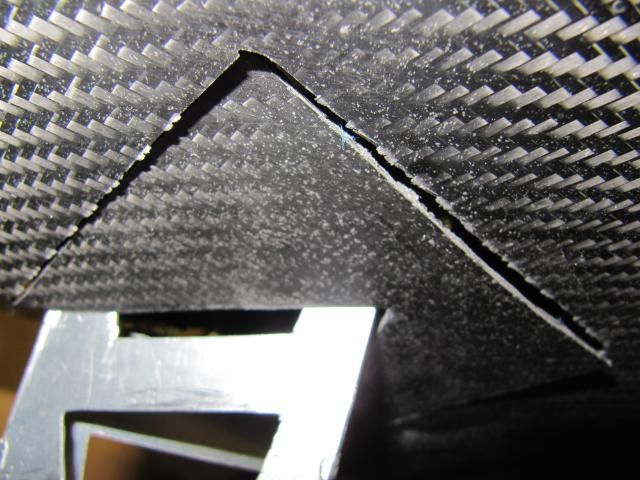

I was going to suggest a layer or 2 of clearcoat over the cf pieces..but I'm too late. One of my friends wraps auto interior and exterior pieces in CF so I know the amount of attention to detail this takes. Nice write up.

If you got some good advice on polishing CF, I would like to hear it. Thanks I try my best in my tutorial write ups. In my regular post, I just try and be myself. Thanks for the support.

I want to see the finished product man!

Me and you both.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)