dave343

[H]ard|Gawd

- Joined

- Oct 17, 2000

- Messages

- 1,869

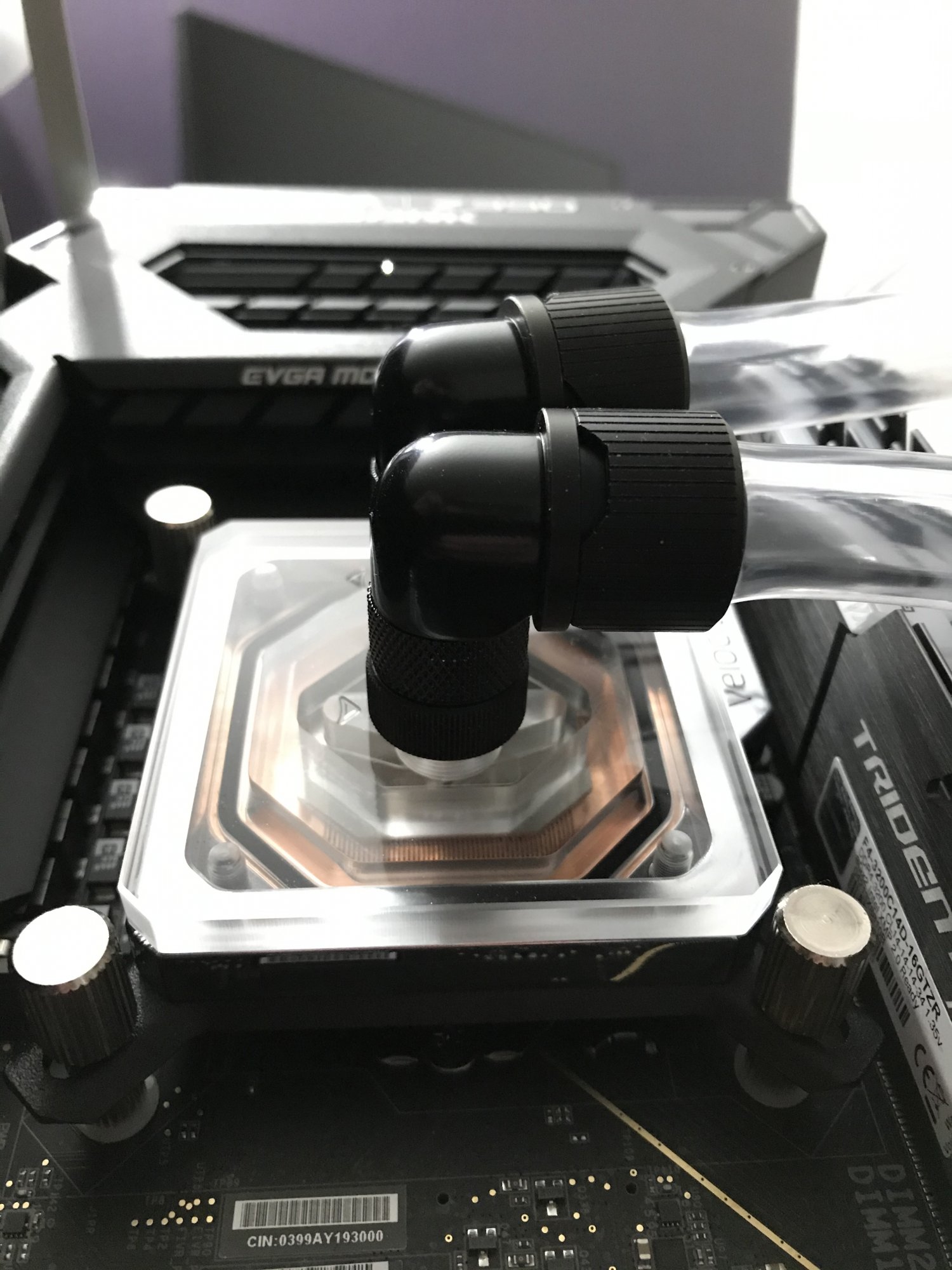

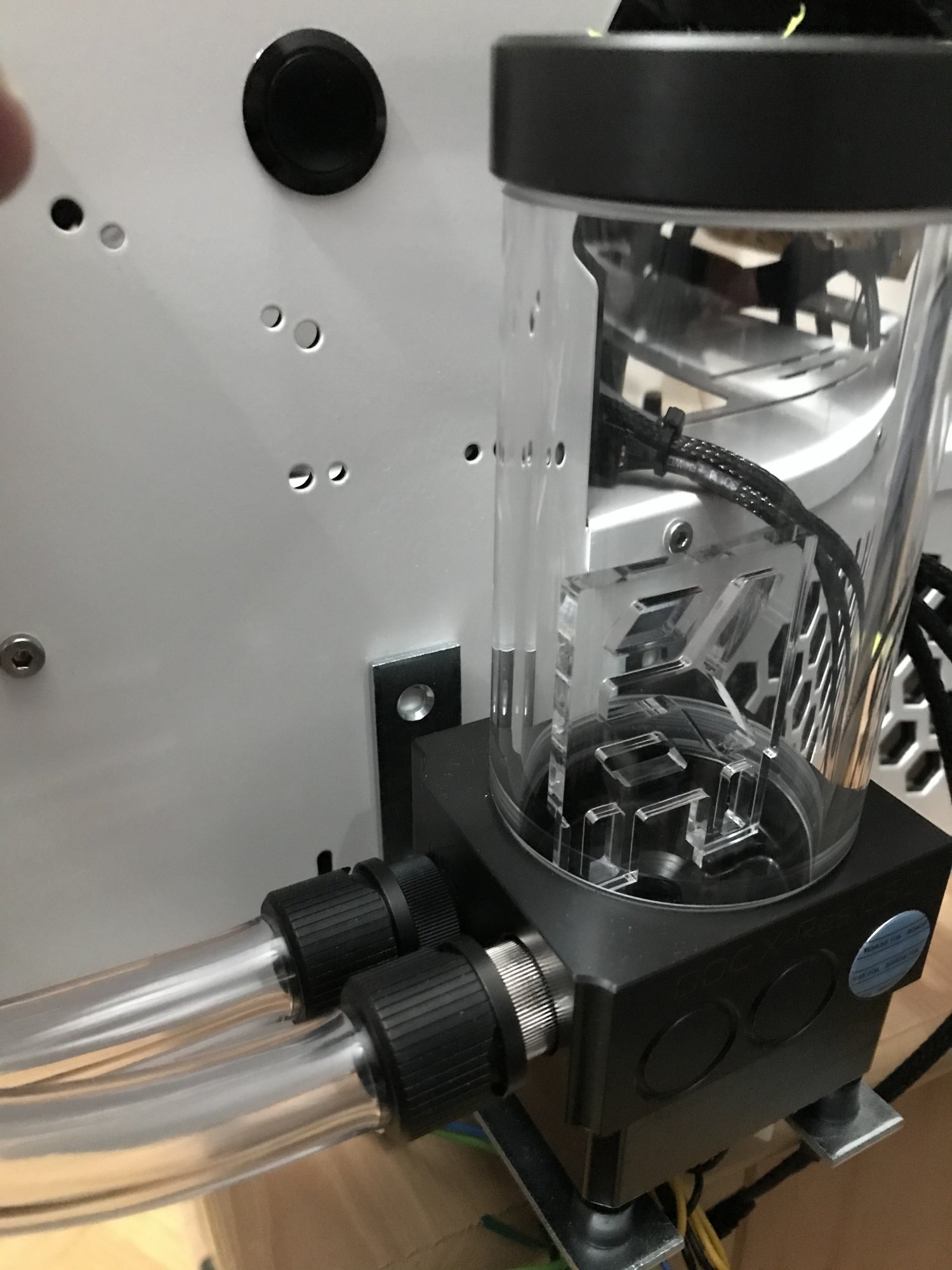

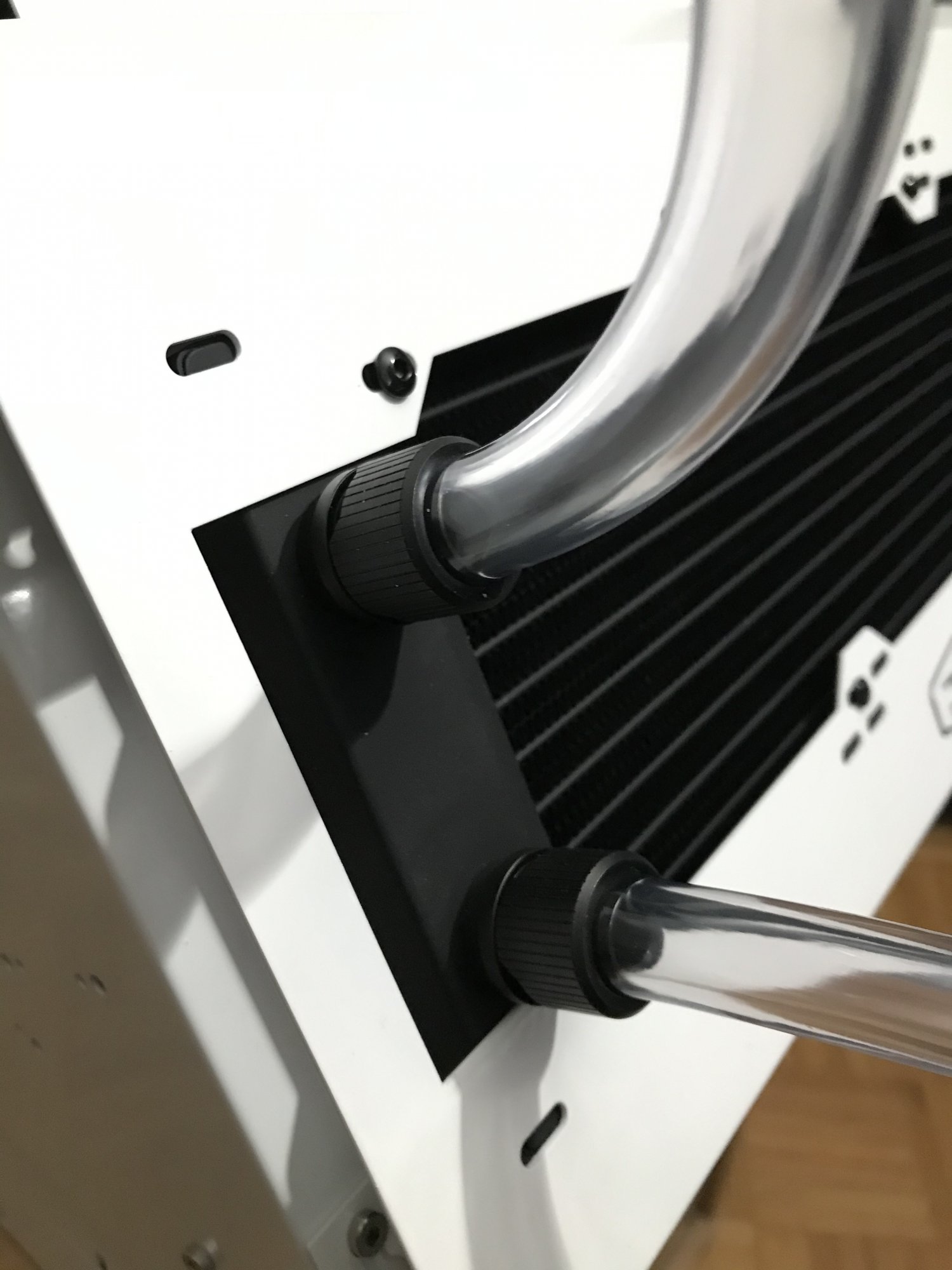

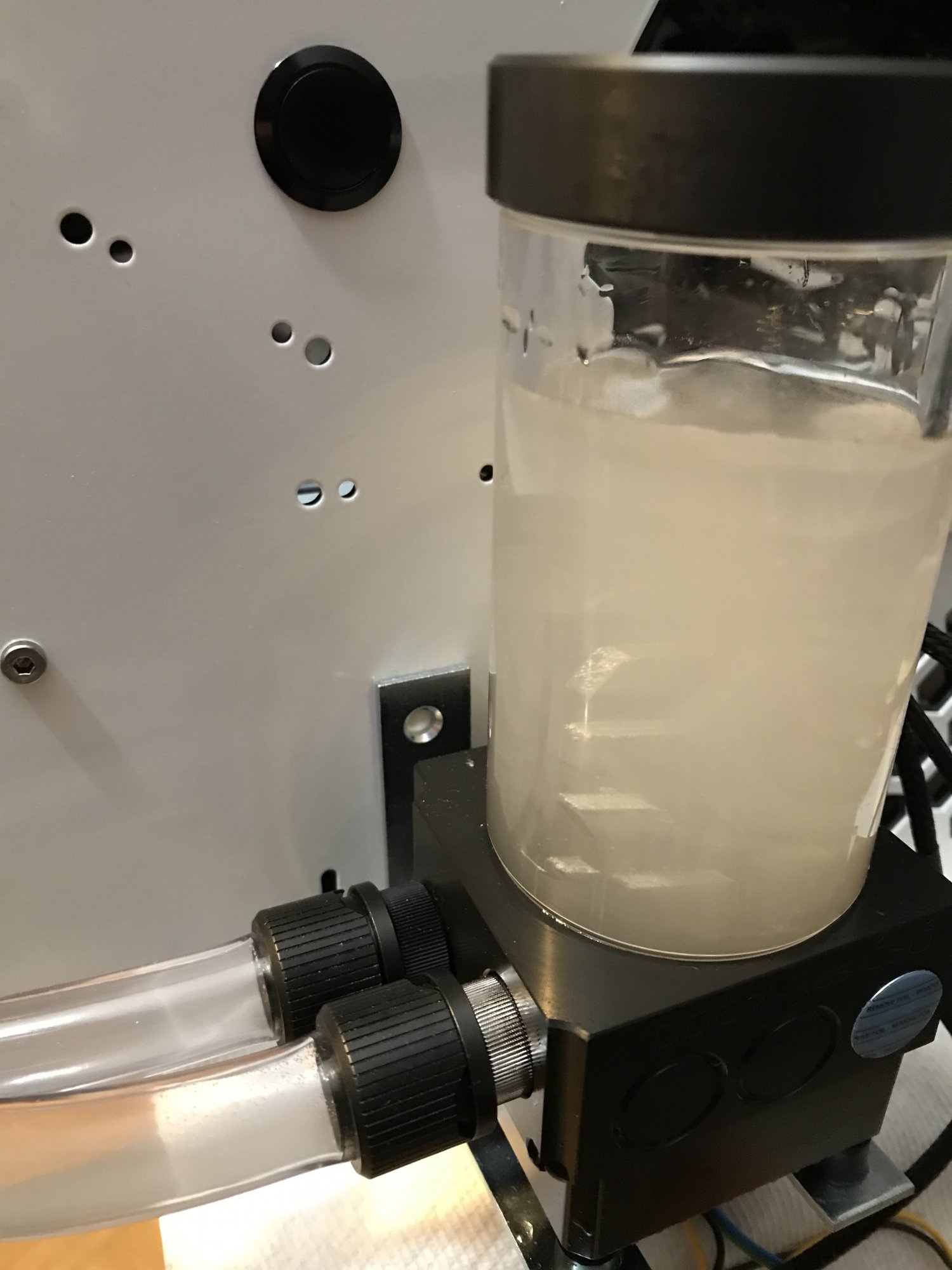

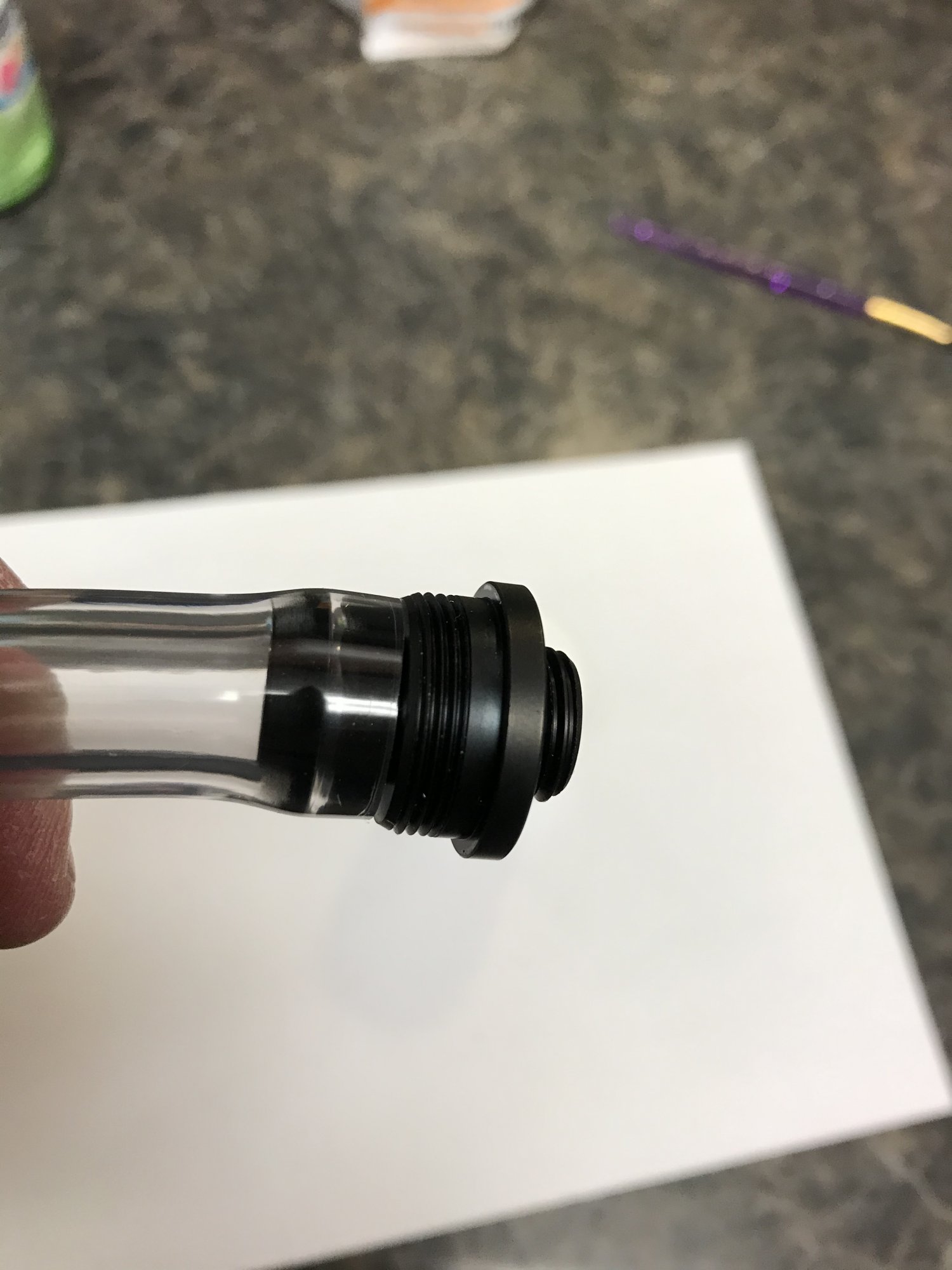

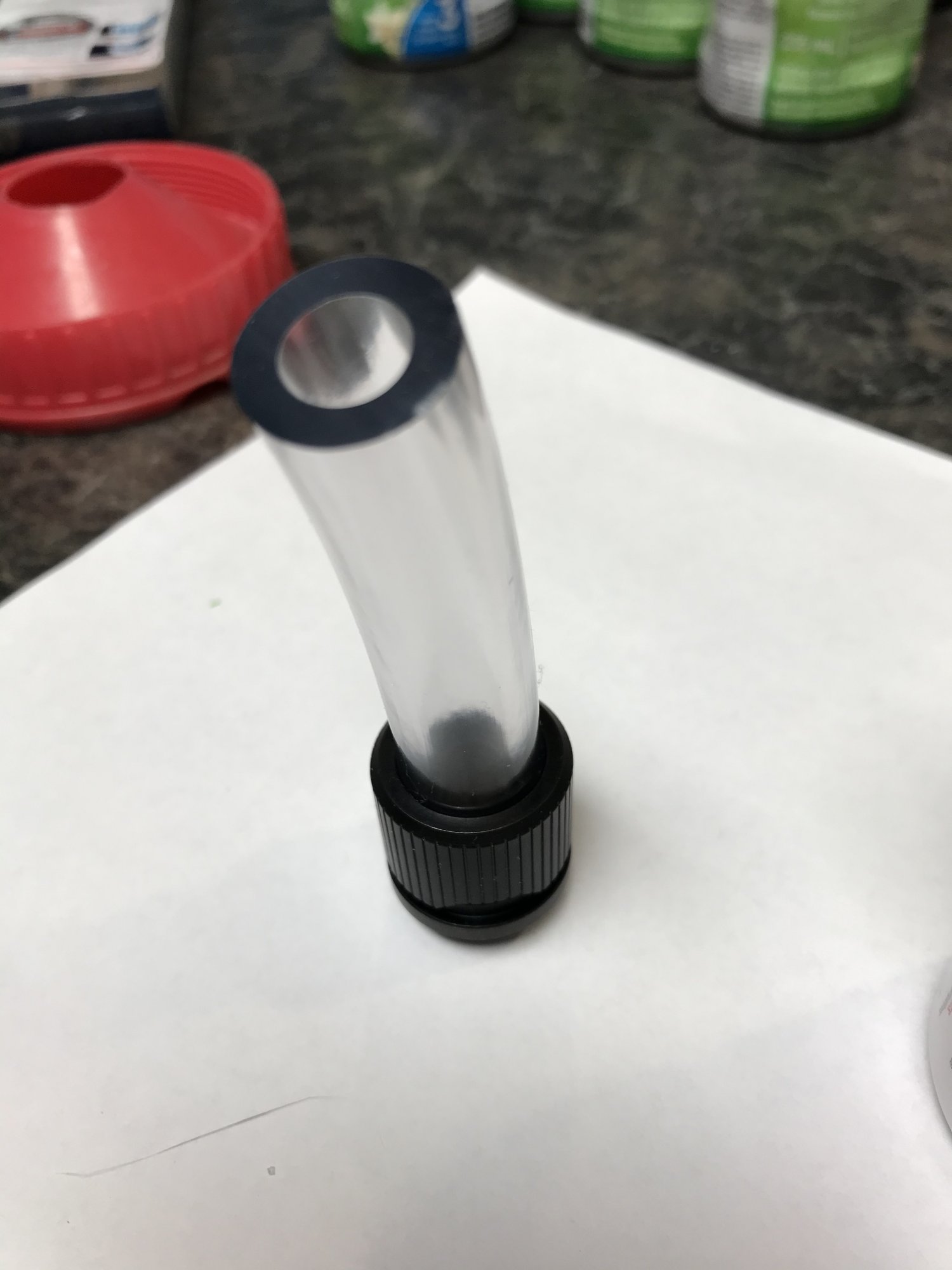

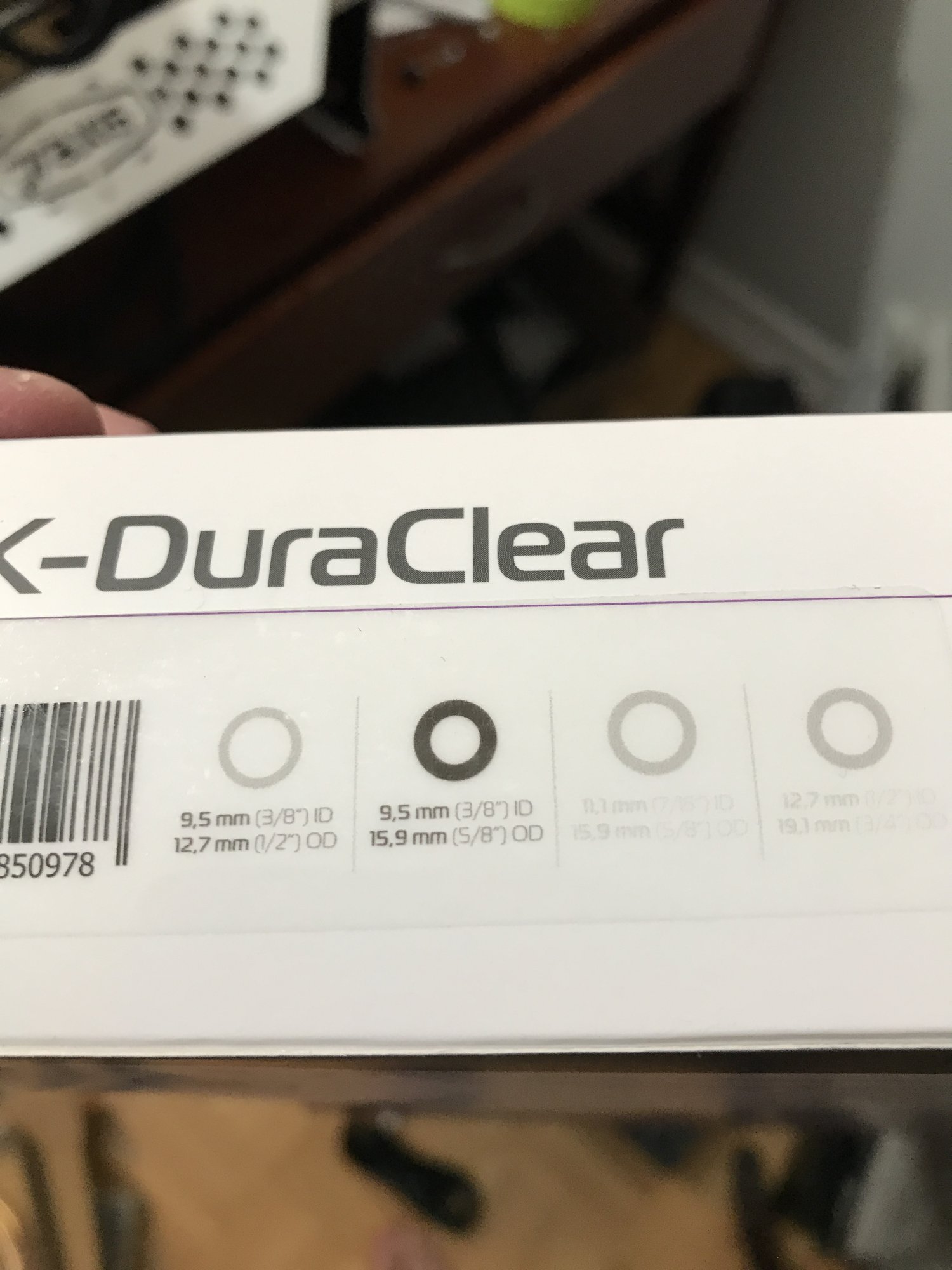

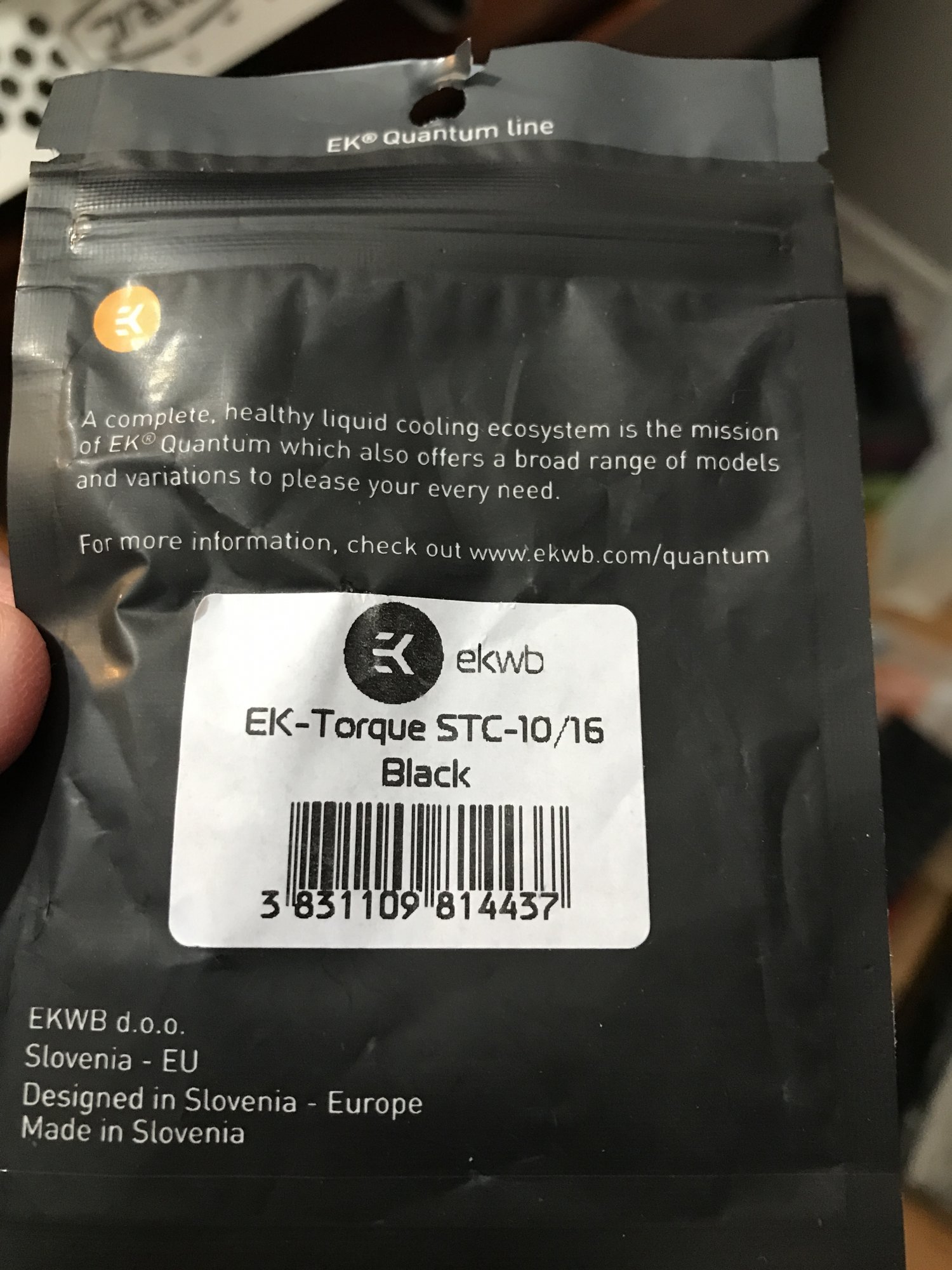

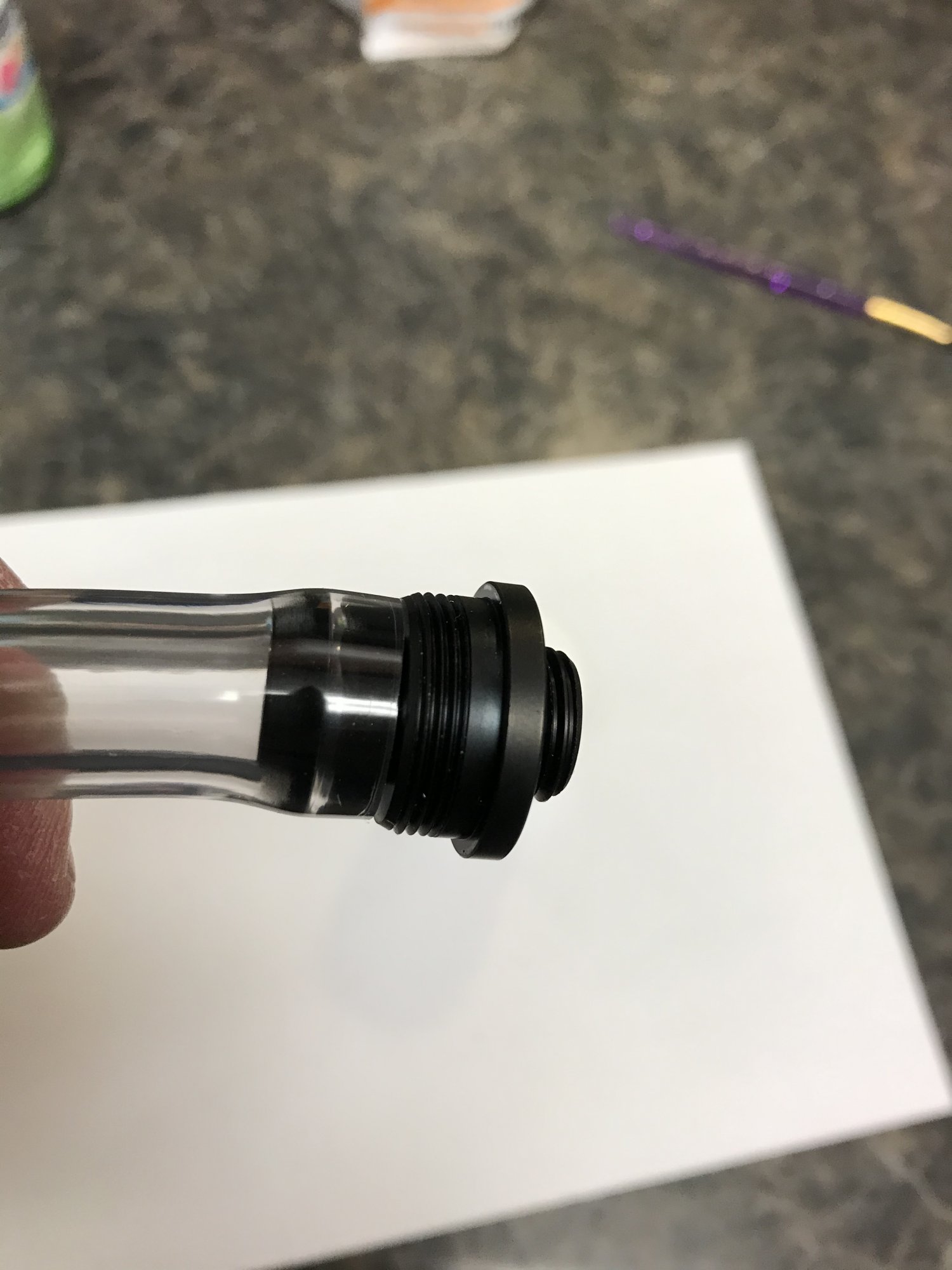

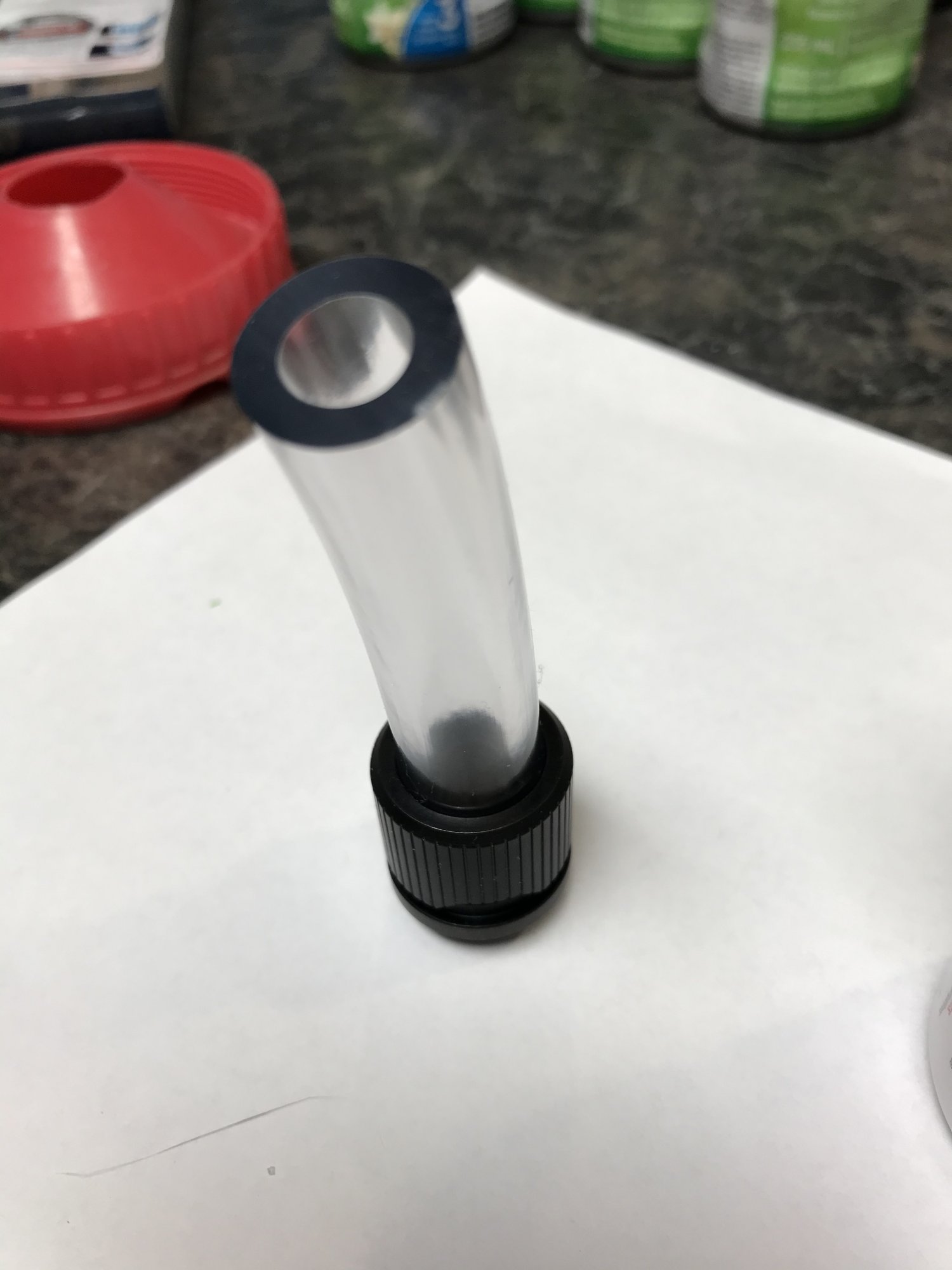

Hey guys, getting my first loop together, i thought I had ordered the right fittings and tube but the tubing is super tight to get onto the conpression fitting.

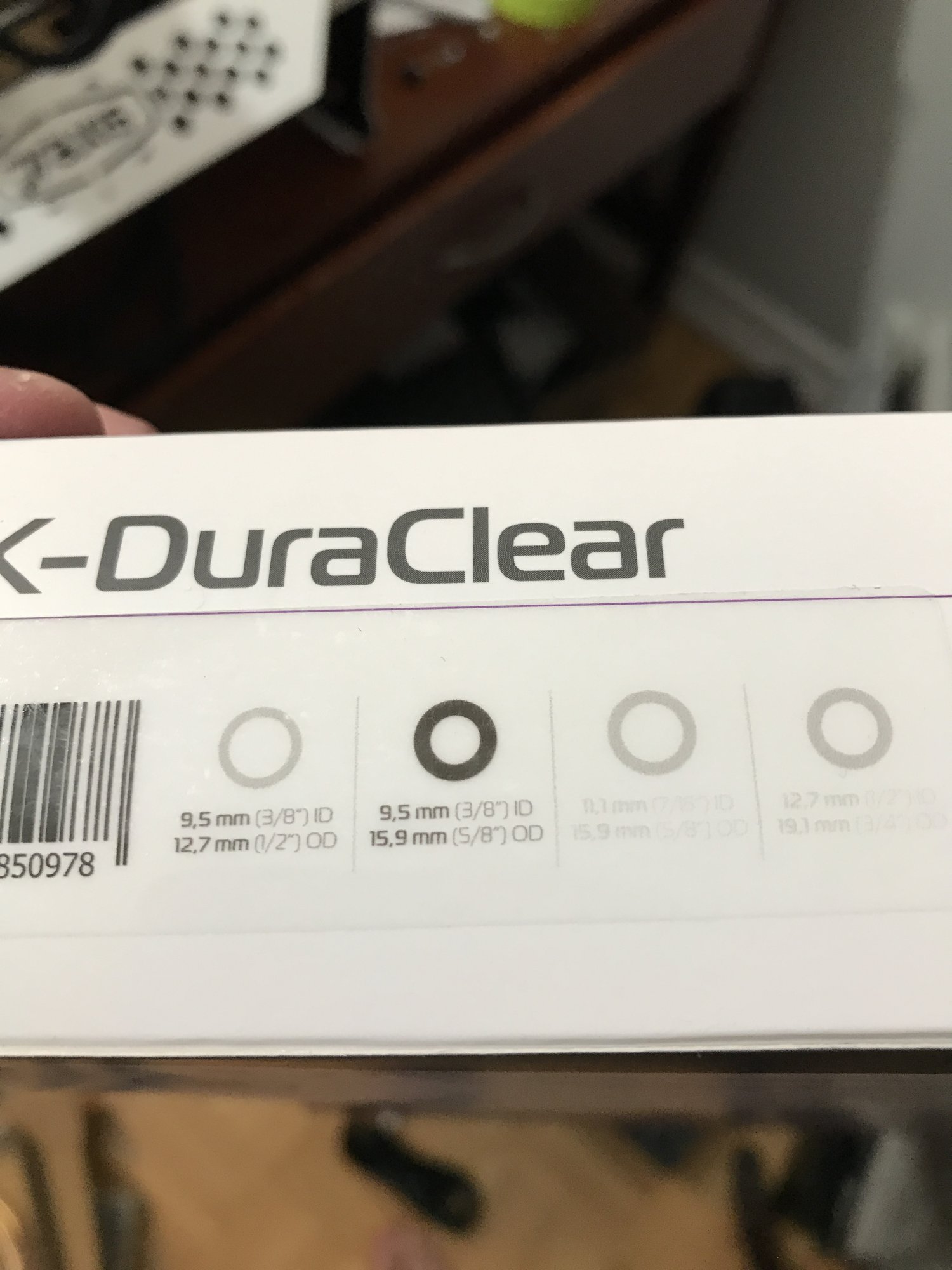

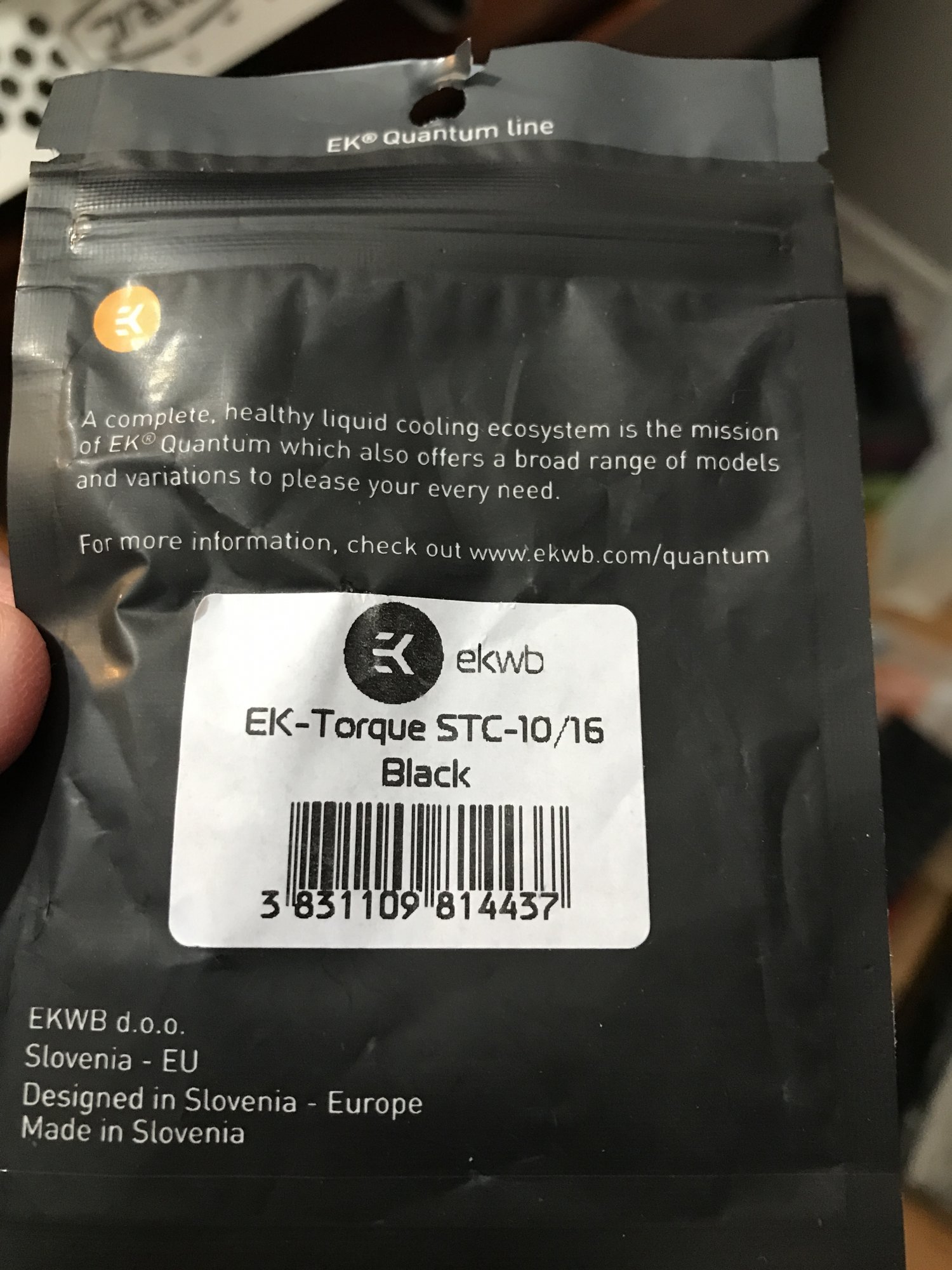

I ordered EK Torque STC 10/16 (5/8) fittings, and for my soft tube, I bought 10/16 3/8 ID 5/8 OD soft tubbing. But it just seems really tight to get onto the fitting, like i really have to twist to get it on. See pics. Thanks for any help.

I ordered EK Torque STC 10/16 (5/8) fittings, and for my soft tube, I bought 10/16 3/8 ID 5/8 OD soft tubbing. But it just seems really tight to get onto the fitting, like i really have to twist to get it on. See pics. Thanks for any help.

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)