UPDATE: Custom D5 Pump Mount

I made some progress, but it seems the list left to be done grew!

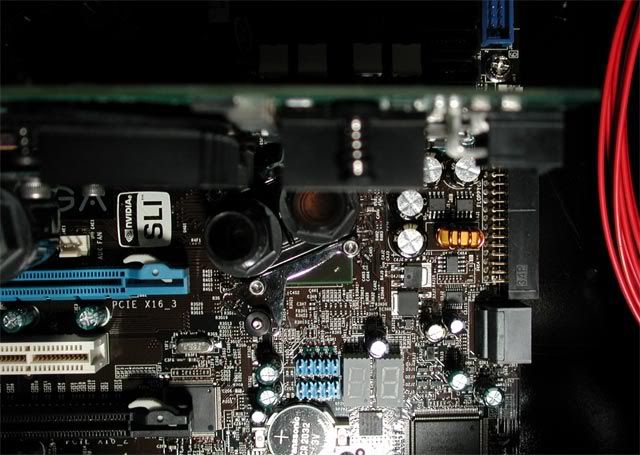

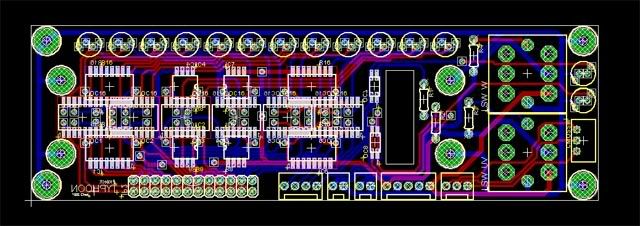

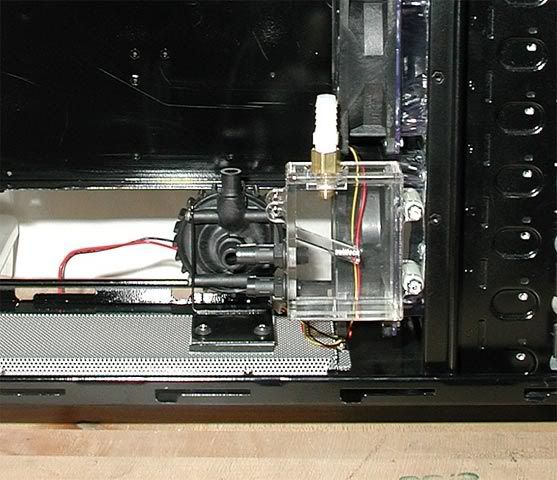

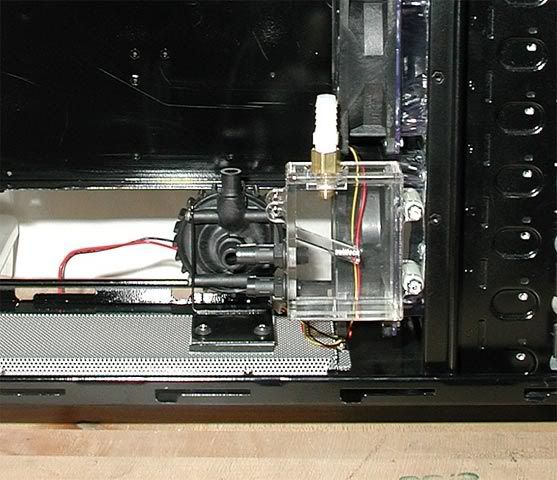

This is a previous picture showing how the pump was mounted before...

The problem with it not aligning with the res is now fixed (hopefully) by the shorter brass res fitting. The next problem I realized is that even if the pump could move all the way to the right against the fan, the outlet would run right into the longer 8800 graphics card, (I don't have one yet, but I might in the future). The solution would be to rotate the pump 90 degrees and run the outlet tube to the left.

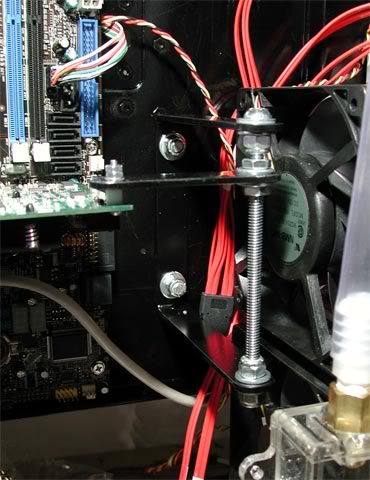

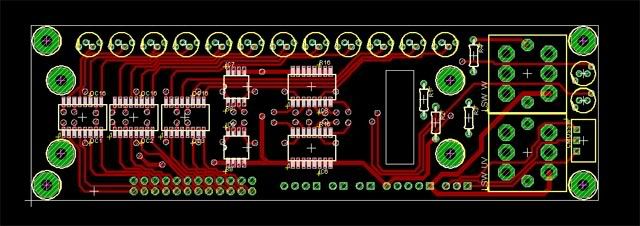

Well, here's how the pump looks now mounted in its new mount. With the shortened res fitting, the pump moved the right and opened up enough room for the outlet tube to route horizontally toward the PSU. The red arrow points to the gap where it would route. Now the problem is: that gap's a little too tight for 1/2" ID tubing to make the bend. I need to find a way to put a threaded 90 degree elbow on the end of that outlet barb. Hmmm... Anyone have any suggestions?...

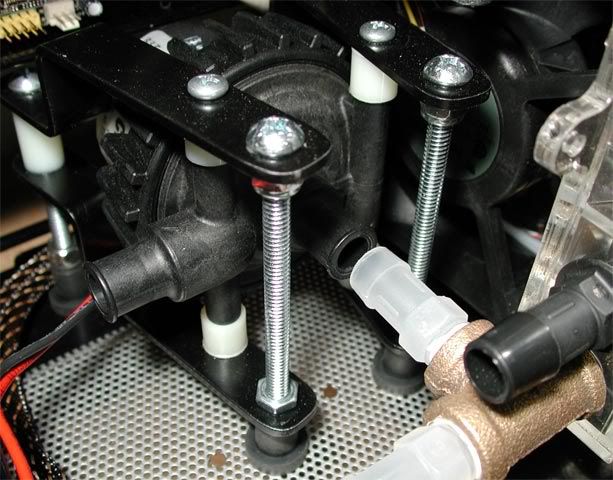

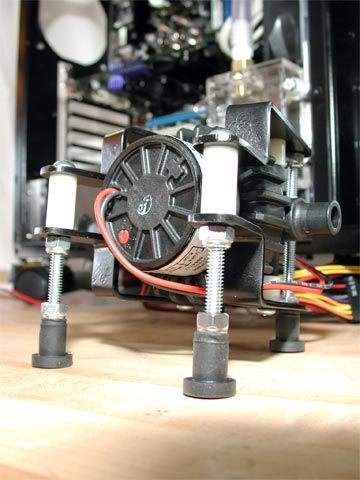

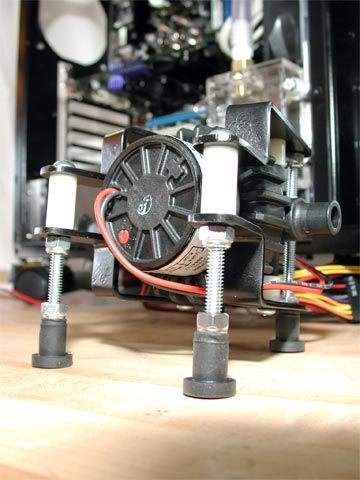

This time, the pump is not bolted to the case. Instead, it just sits in there which makes it easier to line the pump up with the res...

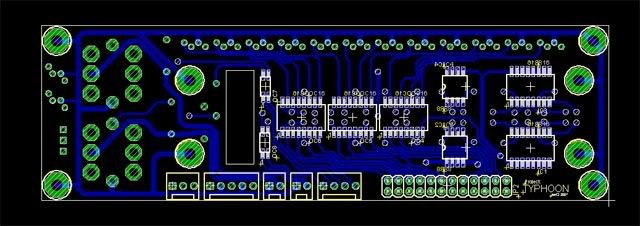

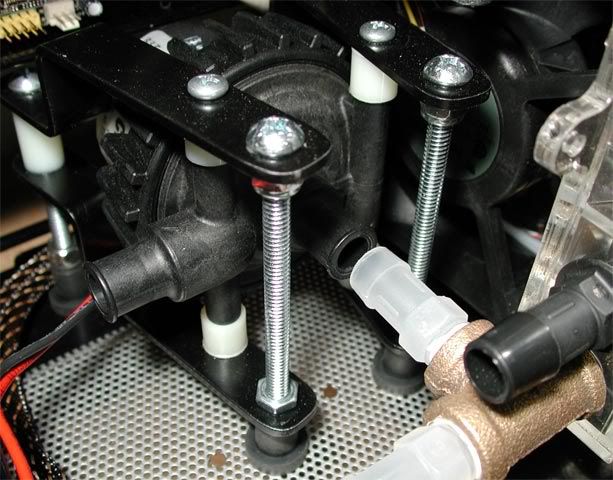

How it looks from the back side. The rear legs can be adjusted up/down for inlet barb alignment...

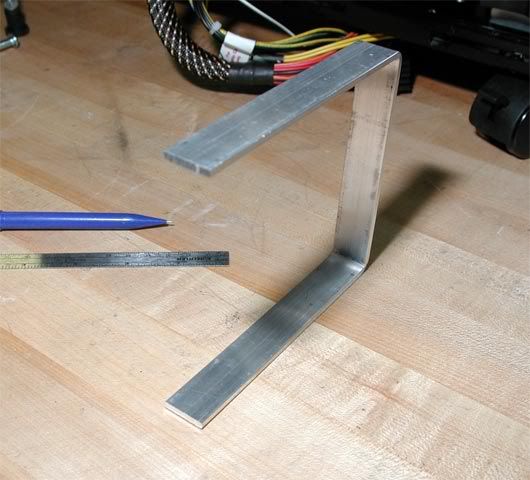

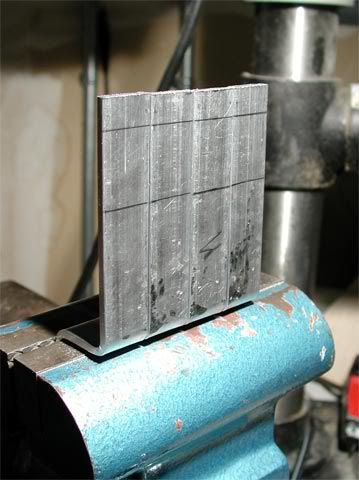

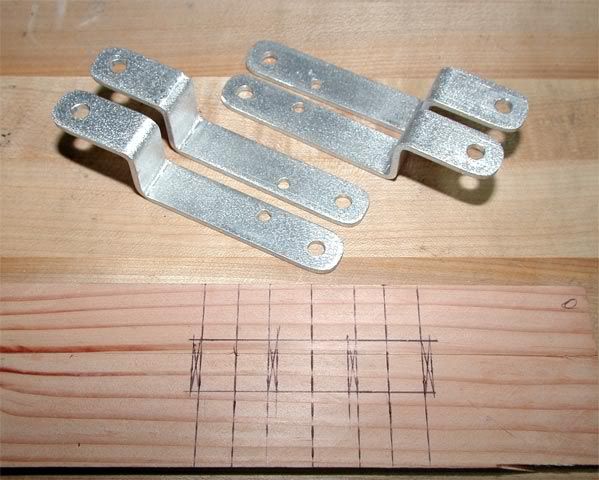

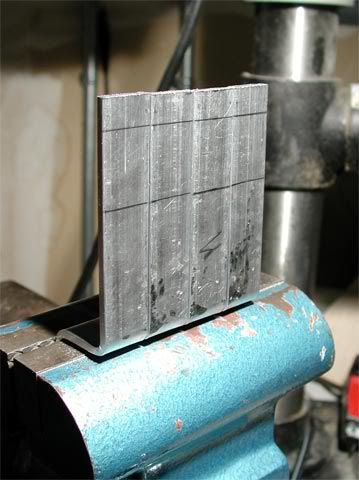

And some pics of the making in progress. Actually each piece was bent individually, then placed altogether and "tweaked" until they were the same...

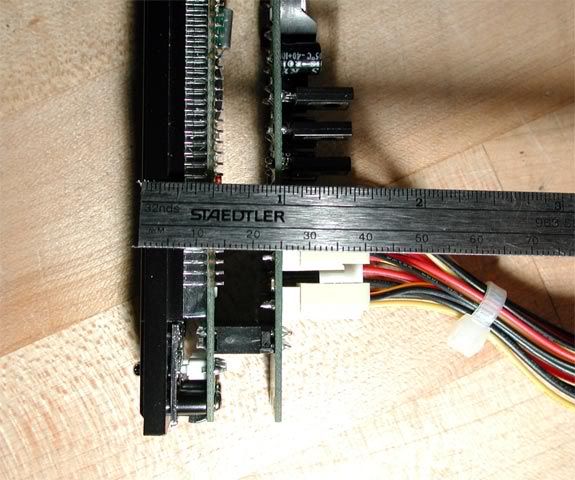

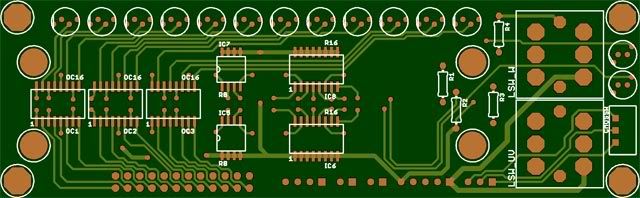

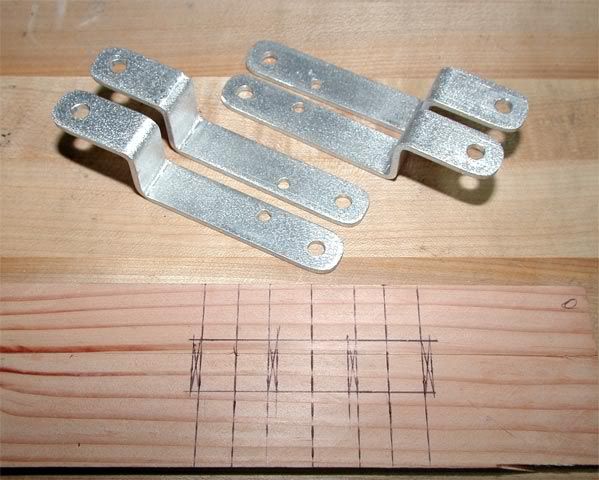

The pieces were measured and bent off one template for consistency. Here they are power sanded and ready for paint...

The feet are 1/4-20 "well nuts" which should keep any pump vibrations away from the case...

More to come...

I made some progress, but it seems the list left to be done grew!

This is a previous picture showing how the pump was mounted before...

The problem with it not aligning with the res is now fixed (hopefully) by the shorter brass res fitting. The next problem I realized is that even if the pump could move all the way to the right against the fan, the outlet would run right into the longer 8800 graphics card, (I don't have one yet, but I might in the future). The solution would be to rotate the pump 90 degrees and run the outlet tube to the left.

Well, here's how the pump looks now mounted in its new mount. With the shortened res fitting, the pump moved the right and opened up enough room for the outlet tube to route horizontally toward the PSU. The red arrow points to the gap where it would route. Now the problem is: that gap's a little too tight for 1/2" ID tubing to make the bend. I need to find a way to put a threaded 90 degree elbow on the end of that outlet barb. Hmmm... Anyone have any suggestions?...

This time, the pump is not bolted to the case. Instead, it just sits in there which makes it easier to line the pump up with the res...

How it looks from the back side. The rear legs can be adjusted up/down for inlet barb alignment...

And some pics of the making in progress. Actually each piece was bent individually, then placed altogether and "tweaked" until they were the same...

The pieces were measured and bent off one template for consistency. Here they are power sanded and ready for paint...

The feet are 1/4-20 "well nuts" which should keep any pump vibrations away from the case...

More to come...

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)