Sponsored by:

AquaComputer

Watercool:

MIPS Computer GMBH

Corsair

This is my first real desktop mod, and it's been long in planning. Now that most of my components have arrived and some progress has been made I've decided to share what I've created so far.

The concept behind this case is to design a simple elegant case jam packed with technology, toys, and a powerful watercooling setup.

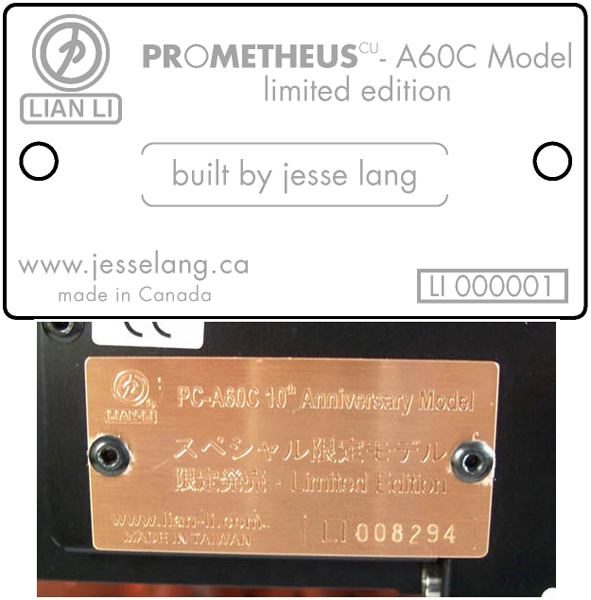

The idea for the design was directly inspired by the case I started with, a 10th Anniversary Lian-Li PC-a60c: *click for big*

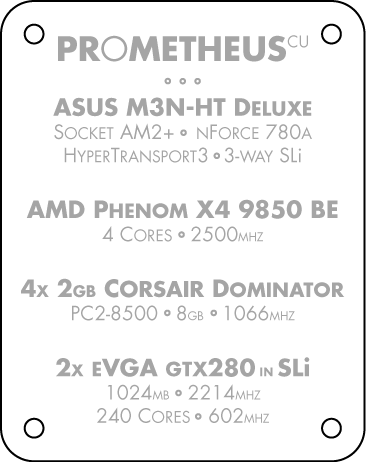

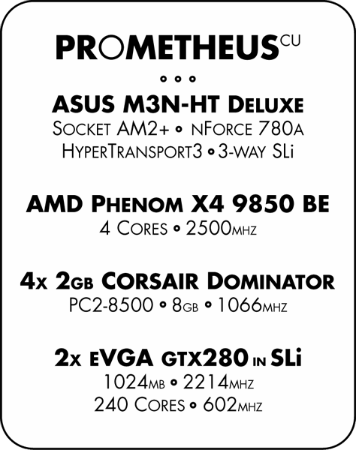

First I'll outline the system components I'll be using:

Main System

Lian-Li PC-A60C 10th Anniversary #294 of 300

Silverstone Strider 1200W Modular ATX

AMD Phenom X4 9850 BE Quad Core AM2 2.5GHZ

Corsair Dominator PC2-8500 5-5-5-15 8GB (4x2GB)

ASUS AM2+ M3N-HT Deluxe Mempipe 3-way SLI

2x EVGA E-geForce GTX 280 SSC 648MHZ 1024MB 2.322GHZ

Secondary System

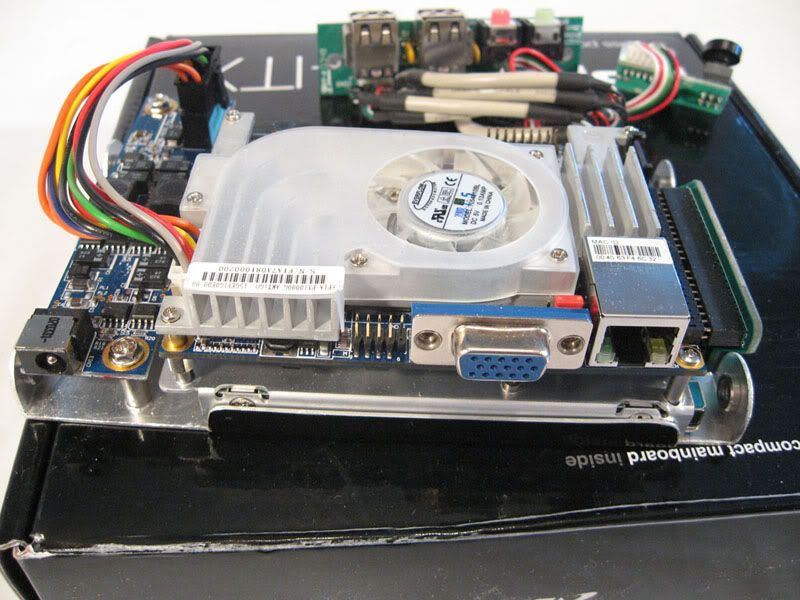

VIA ARTiGO Kit A1000 C7 1GHZ 1GB DDR2

OCZ 1GB DDR2 SODIMM PC2 PC-5400 667Mhz

Fujitsu 2.5" IDE 5400RPM 120GB

XDX 7" VGA Touch Screen TFT LCD 1024x768

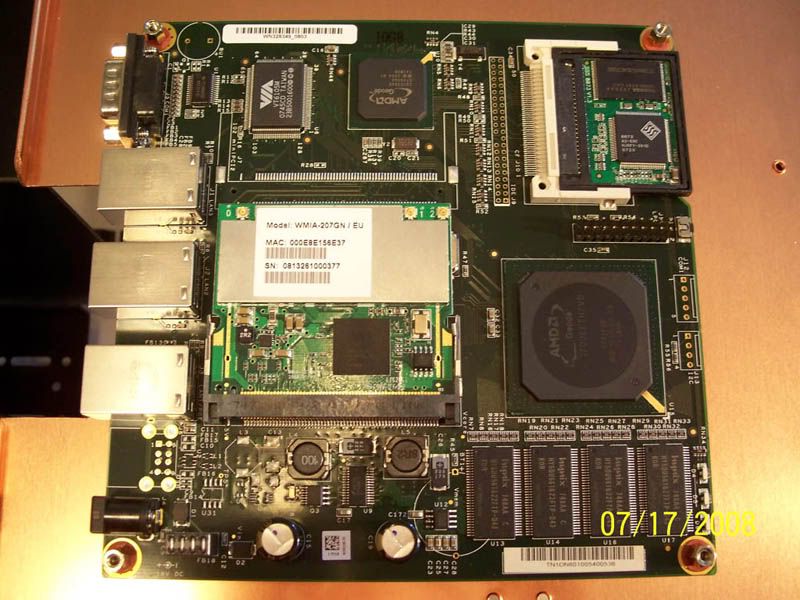

Router/Firewall

PCEngines ALIX.2C1 Kit 3x10/100LAN

SparkLAN WMIA-207GN WLAN 802.11n Mini PCI

1GB Type 6 Compact Flash

Storage/Media

Pioneer Slim 8X DVD+/-RW Slot Load

Slim CD/DVD-ROM to SATA Adapter

4x Hitachi 3.5" SATA 7200RPM 750GB

3x LaCie Neil Poulton eSATA 7200RPM 750GB External

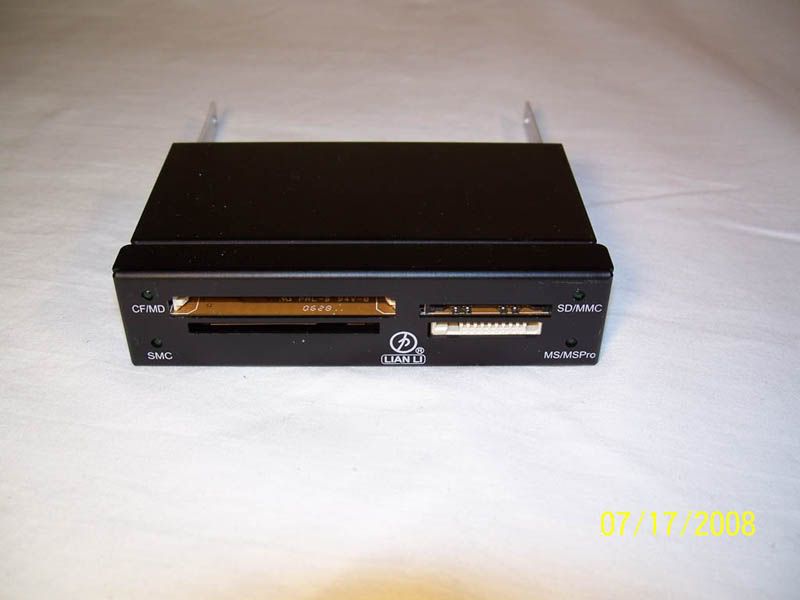

Lian-Li Aluminum 50-in-1 Card Reader

Additions

Mini Nova USB Bluetooth Adapter

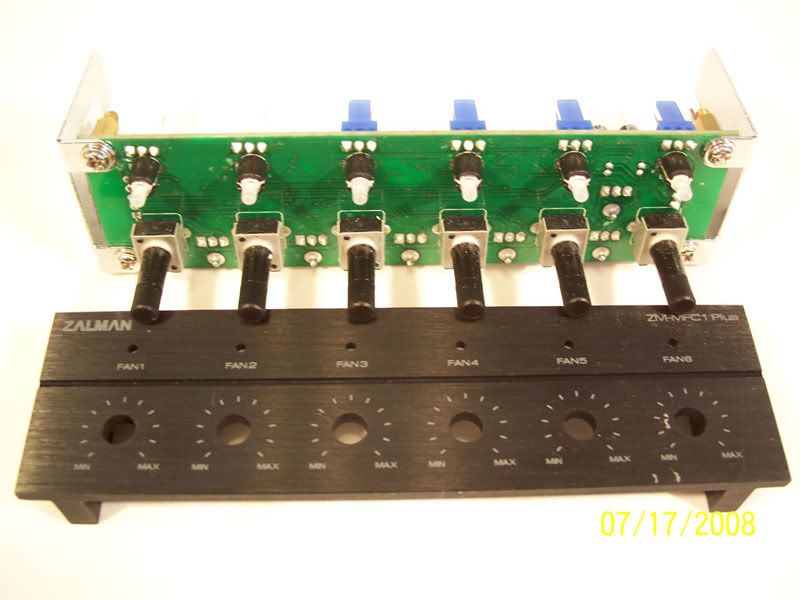

Zalman Plus Multi Fan Controller

Matrix Orbital GX Typhoon USB TRI-LED LCD 240x64

2xNexxtech mini 4 Port USB Hub

AquaComputer multiswitch USB 1.41

AquaComputer aquaero 4.00 USB

Air Cooling

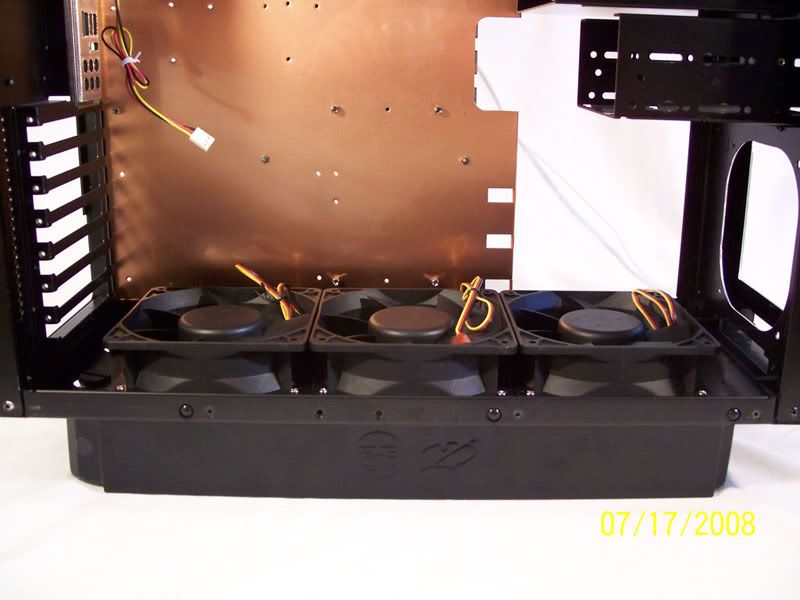

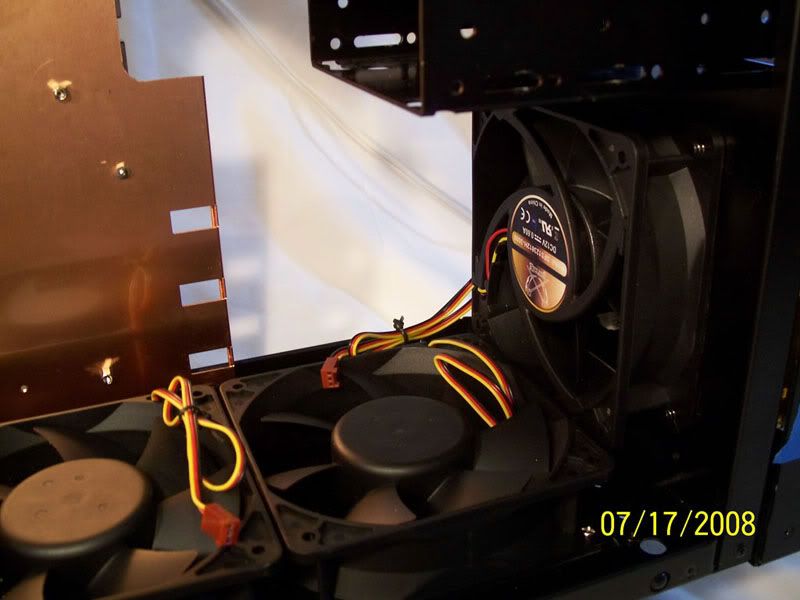

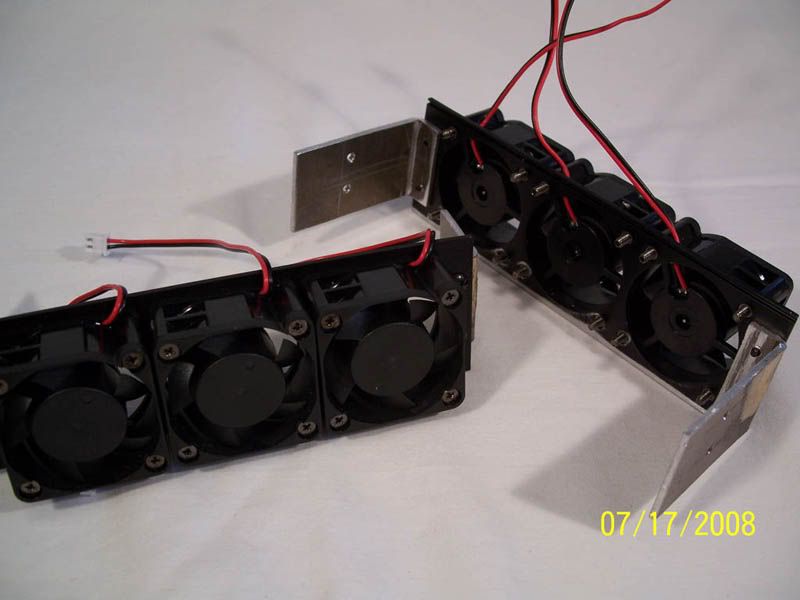

6xScythe Ultra Kaze 120mm x 25mm 133.60CFM

1xScythe Kama-Flex 80mm x 25mm 34.0CFM

9xScythe Mini Kaze Ultra 40mm x 20mm 4.86CFM

Watercooling

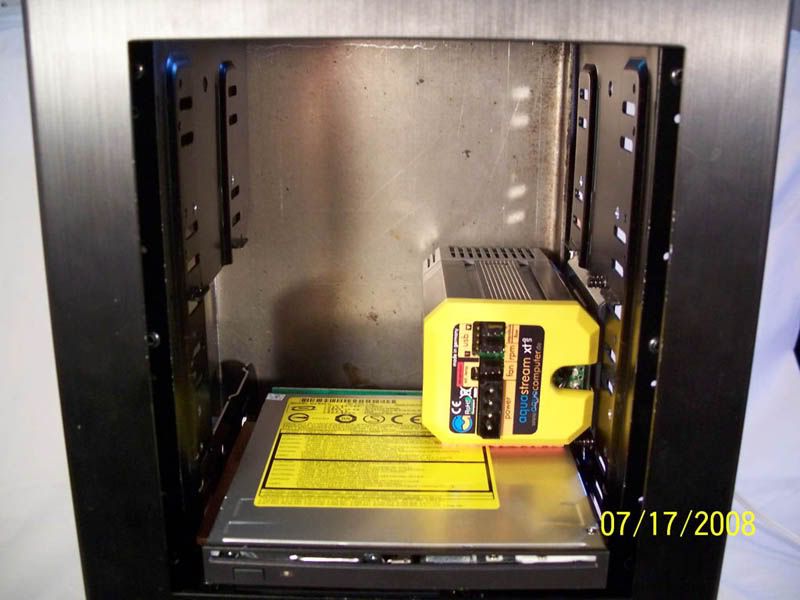

Aqua Computer Aquastream XT Ultra USB Eheim 12 V

Feser XChanger Triple 120mm Xtreme

D-TEK FuZion V2 Socket AM2 Waterblock

D-TEK FuZion v2 Quad Core Mid Chamber Insert

Mips Ram Freezer 4 Ram Waterblock Nickel Edition

2xAquaComputer G200 waterblock for GX280

AquaComputer Durchflusssensor (Flow Sensor)

6xAquaComputer Rotary elbow adapter G1/4

AquaComputer aquaero/aquastream XT temperature sensor 70 cm

Danger Den Cooling System Fillport Black

Primochill Primoflex Pro LRT Black 1/2IN ID 3/4IN OD Tubing

20x Bitspower G1/4 High Flow 1/2IN Dark Nickel Plated Barb Fittings

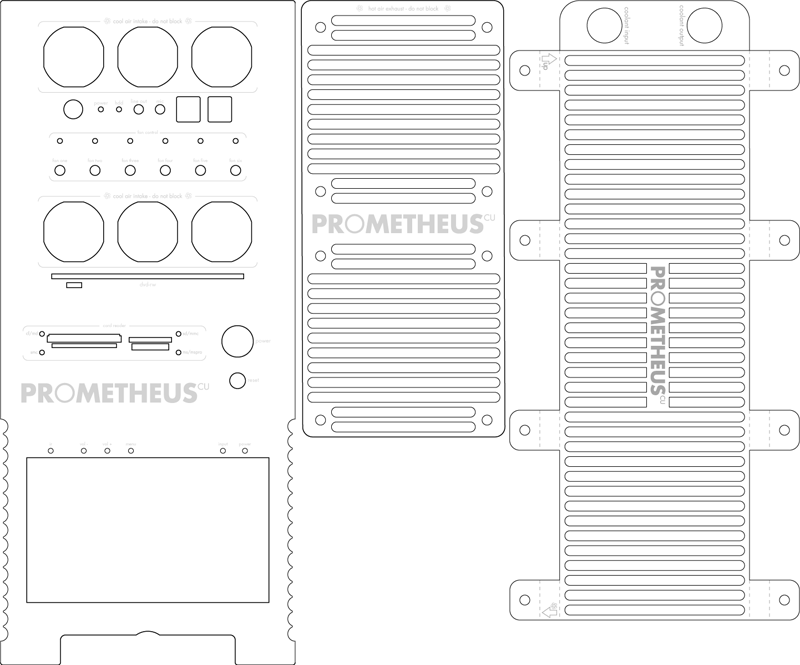

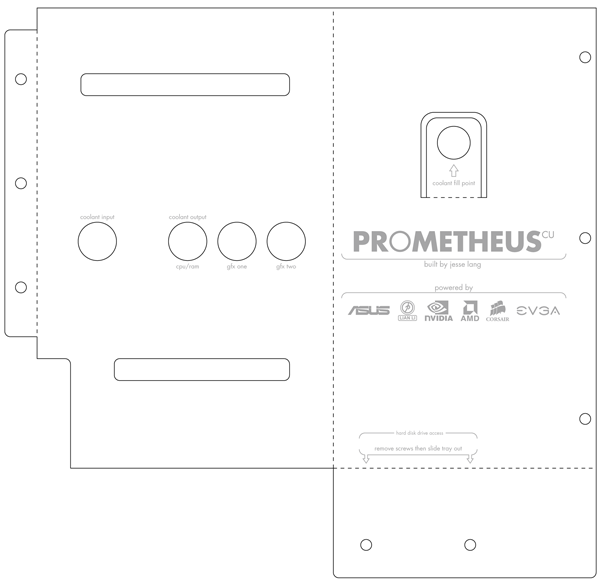

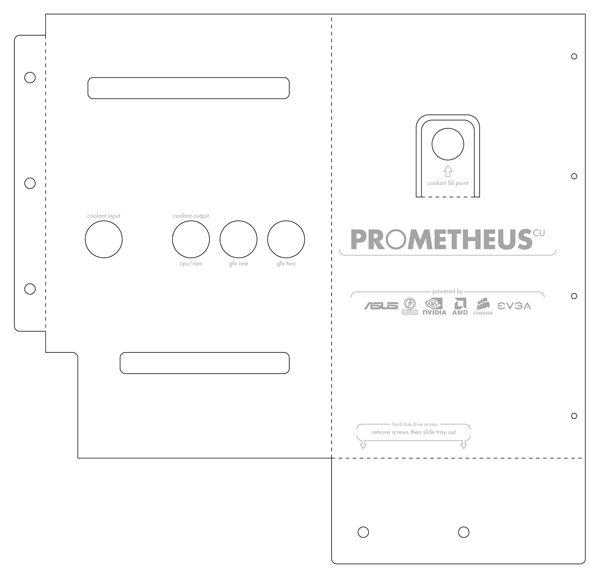

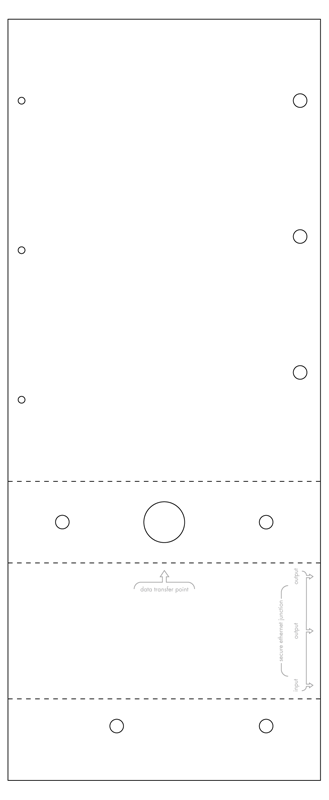

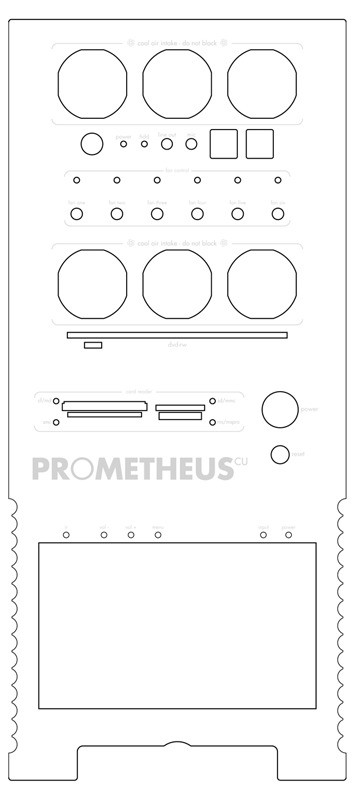

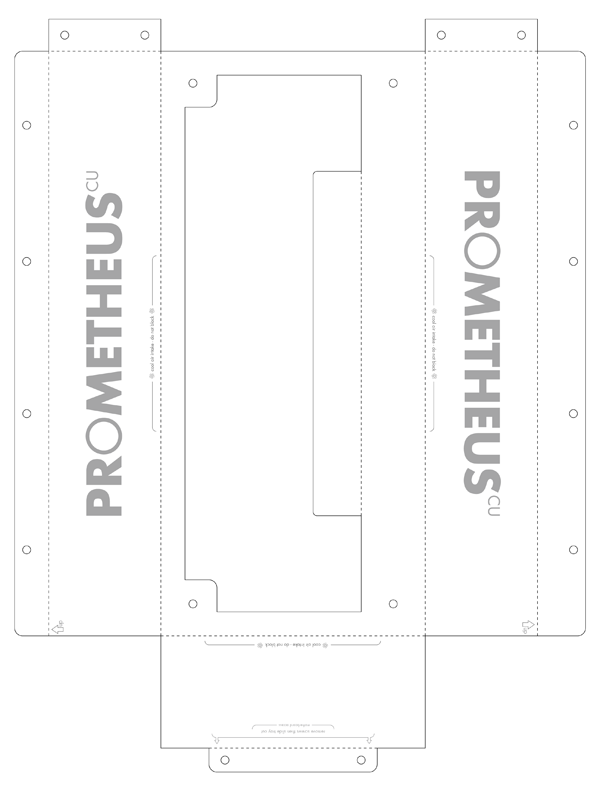

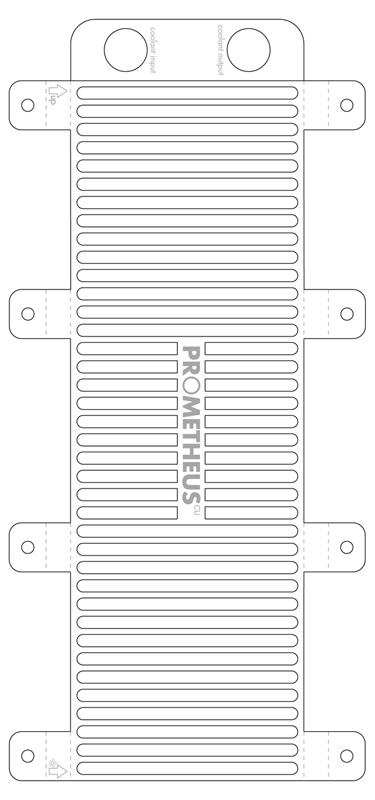

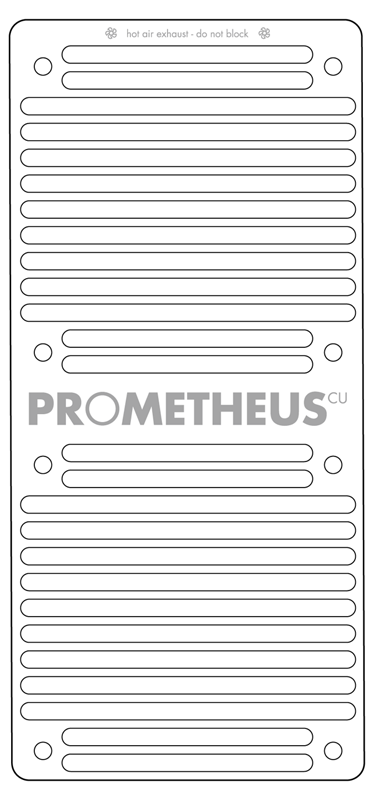

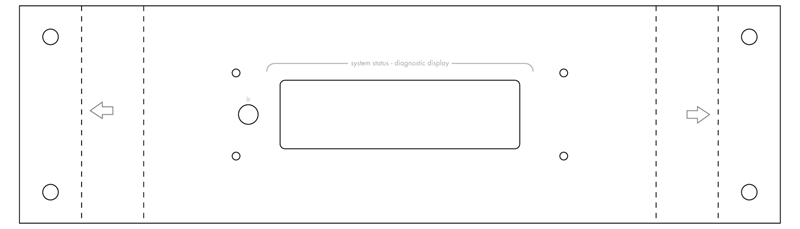

Here is a rough concept of the design plans: *click for big*

Rough Designs for the front panel, top panel, and dive bay enclosure panel

Now onto part pictures: *click for big*

AMD Phenom 9850 BE

Asus M3N-HT

SilverStone Strider St1200 1200Watt

Corsair Dominator RAM

The 120mm Fans

The MO TyphoonGX tri-colour

The Linksys WIFI-n card for bypassing the emedded firewall

I'm sorry I diddn't take any progess pics so-far but I'll be doing so from here on out.

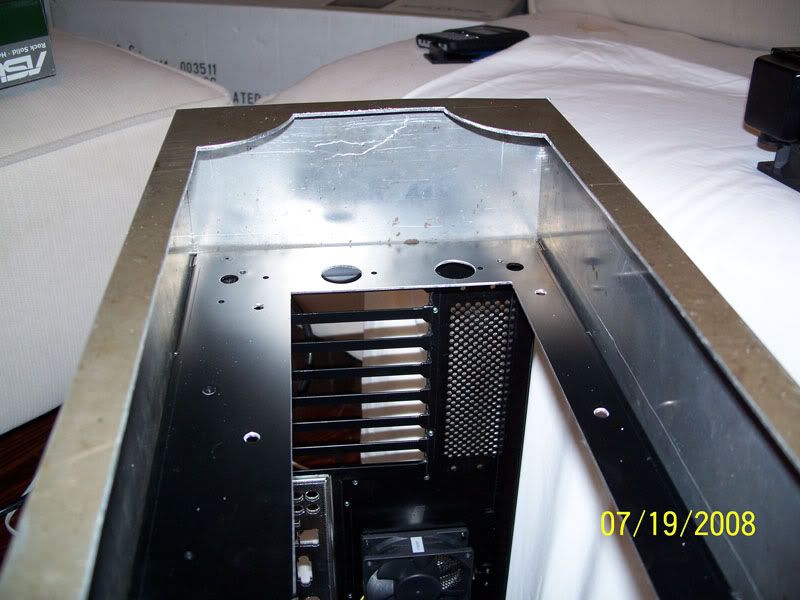

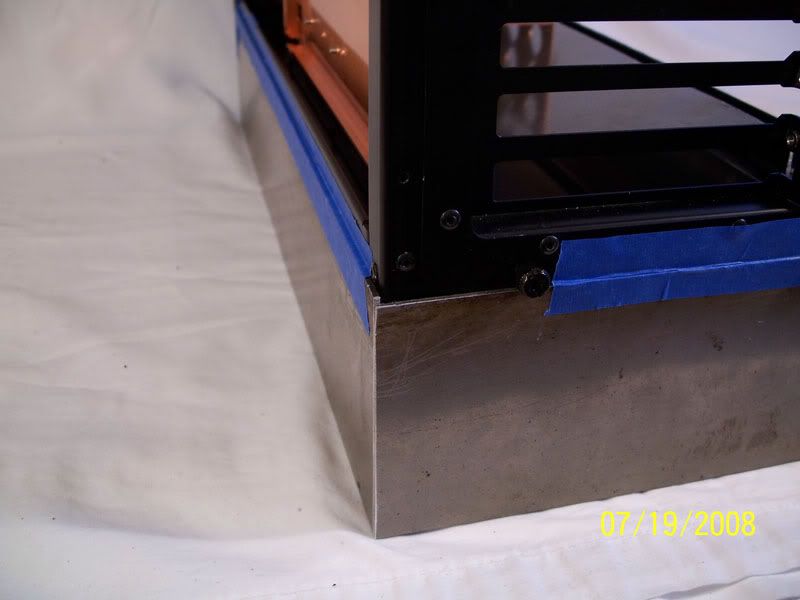

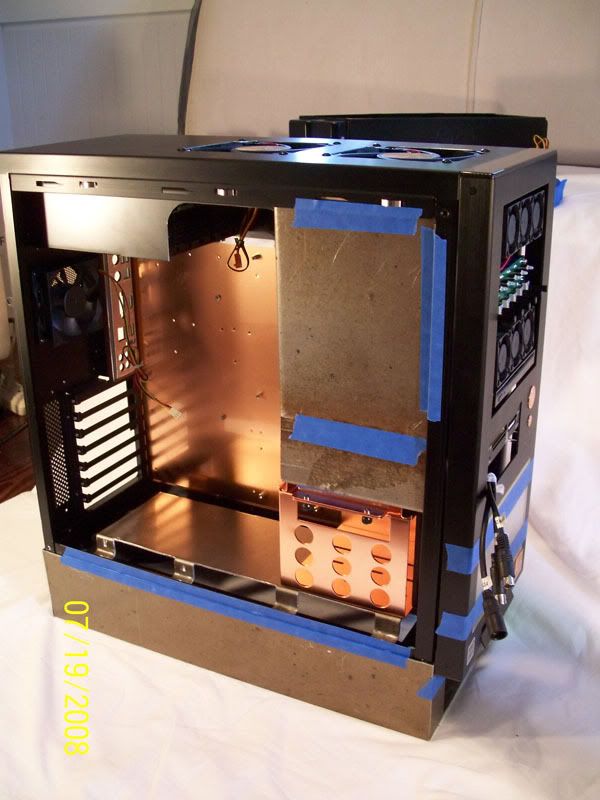

After a few hours with the dremel and jigsaw... then many more with a set of hand files I turned my lian-li case into the below:

The details:

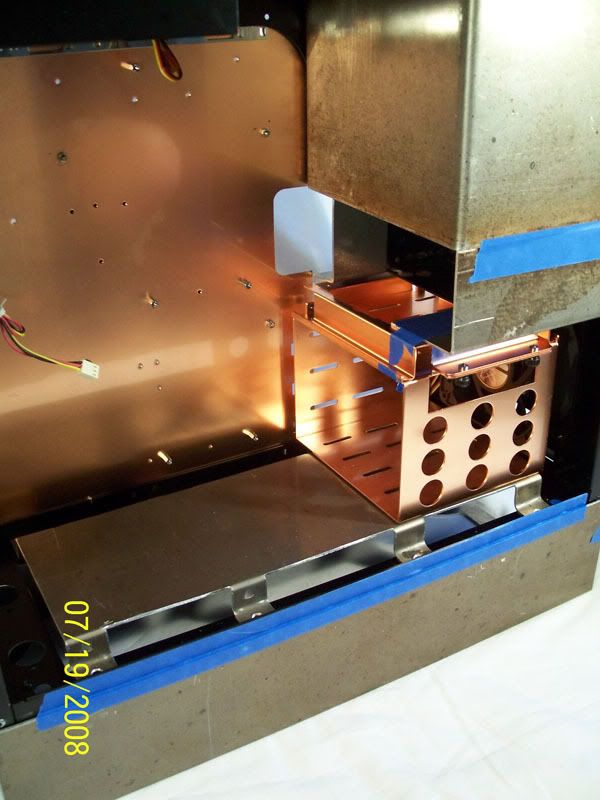

First I cut out some material from the drive bay area

I then mounted the Alix 2c1 embedded linux firewall after installing the mini-PCI wifi-n card and the 1GB compact flash

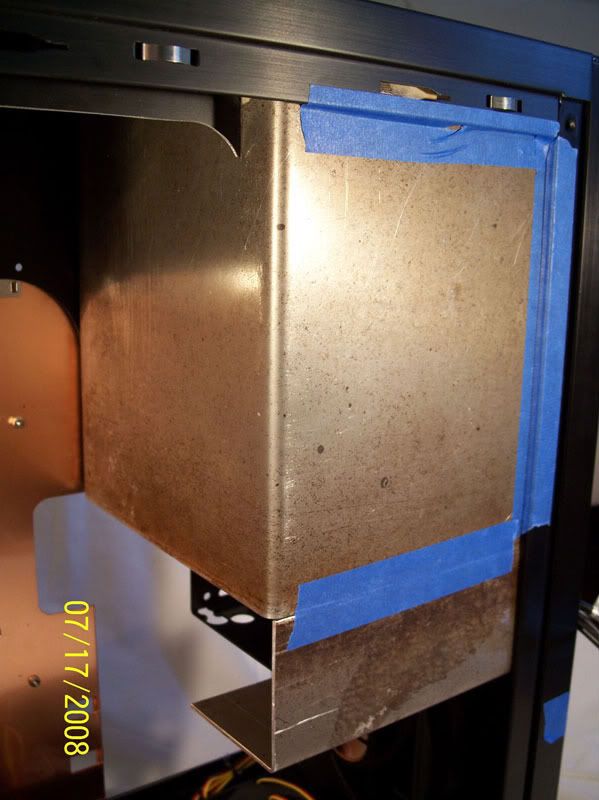

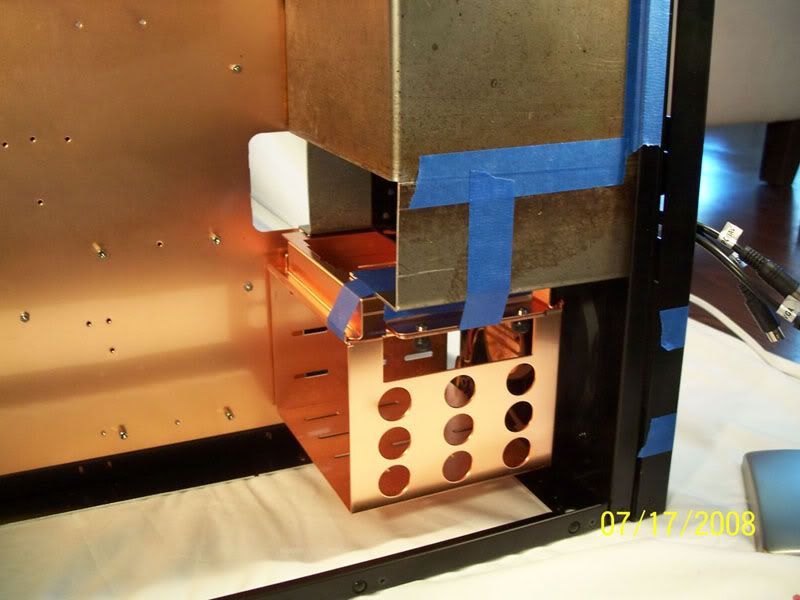

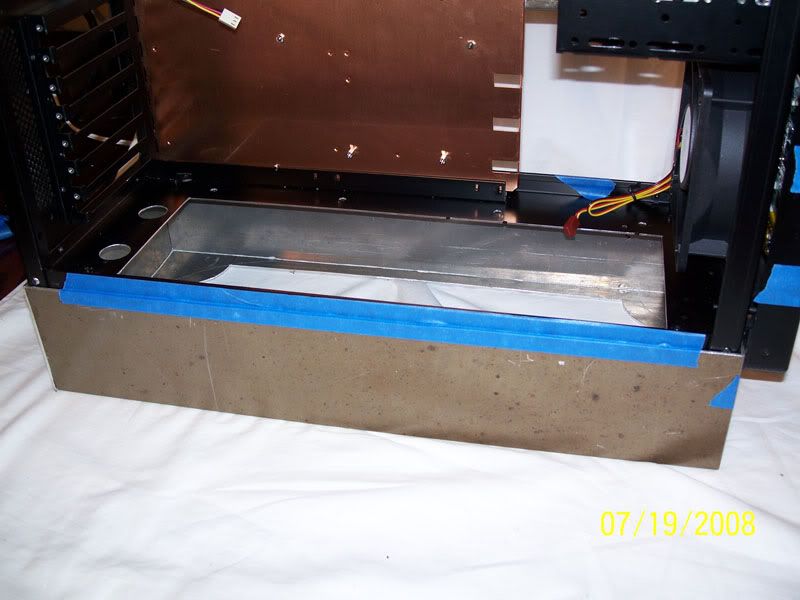

A cutout was made to allow space for the lan ports on the motherboard tray. Also a box was cut from the drive bay to allow for the pump to be mounted.

I haven't yet built the pieces that will guide the airflow; but i have installed the fans that will cool the Alix board.

1/4inch slots will be milled on the panel and dividers will be constructed to guide the air out the slots. Until then, this is how it stands.

Here is the Pump

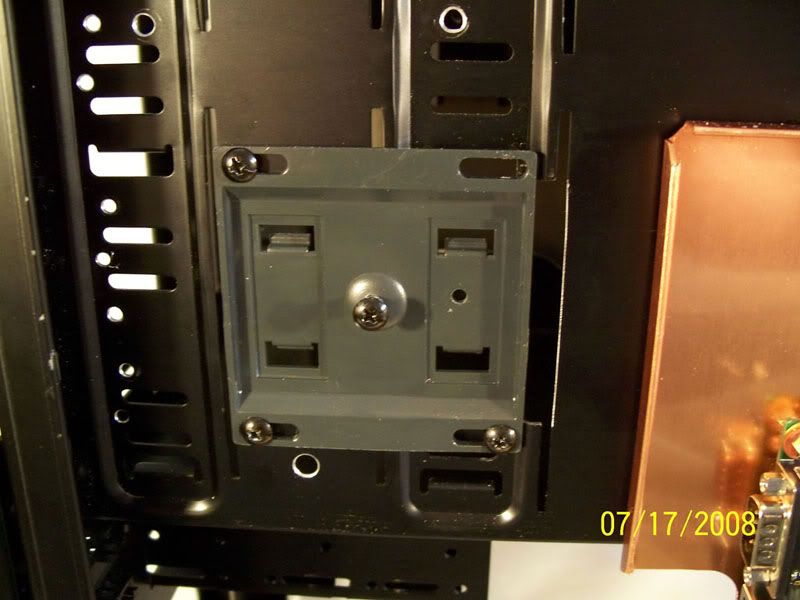

And the mounting bracket put into place

Two 120mm fan holes were cut from the top of the case

A large rectangle was removed from the front panel to make space for the 7" touch panel LCD

I then built another temporary bracket to hold the PSU in place. This too will be replaced with a CNC machined bracket.

After cutting a piece of copper plate that will 'compression' fit into place. I used double sided foam tape to afix the slot load dvd-rw.

I then installed the slim-DVD to SATA adapter.

The drive is then squished into place, and holds suprisingly well

Then the pump is mounted to the bracket, this foam is also temporary and will be replaced with black neoprene

We then come to the Pico-ITX unit that will live in the drive bay

Here is is installed

I then cut apart the Corsair Dominator fan assembly and made some temporary mounting brackets, the final brackets will be CNCd as well.

The zalman fan controller that I'll be using

Here is the fan contoller installed

The final fan assembly and some glamour shots

I also got a Lian-Li card reader, it will be stripped of its case by the end of this mod

Hello All-

As many of you know, last year, Jesse was forced to place this project, as well as many others, on hold while he was called to head overseas to consult for work. While overseas, Jesse fell ill of e. coli poisoning. Unfortunately, Jesse Lang passed away before he was able to resume his project, leaving millions of people on the forums wondering where has Jesse gone?. I was contacted by his lawyer, who notified me of his death and informed me that Jesse had specified that I take over his project and complete his creation.

My name is Tobias, I, like Jesse, am a Canadian modder that has always had a passion tweaking computers, I am not a stranger to basking in the glow of computer monitors, even as a child. Thats why, when presented with the opportunity, I was very excited to take part in the development of PROMETHEUSCU. Jesse was a technologist, and it became evident very soon after I met him that he had a gift. A gift for taking something mundane, something you would not even look twice at, and reinventing it in a way that would blow any persons mind. I was fortunate enough to get to know him, and later became his apprentice in the User Experience Design world. He introduced me to the idea being to align my interests, technology and creativity, into a possible career path. Jesse was, and will forever be a huge influence in my life. It would truly be the least I could do to fulfil his request and rebuild PROMETHEUSCU in his honor. Unfortunately, over the past two years in storage, various parts of PROMETHEUSCU have been either lost or pulled for other projects. It is my intention to fulfil Jesses wish of completing PROMETHEUSCU by building upon the remnants of the case and original design plans.

I wish to humbly request that you, the community, would follow me in my quest to honour Jesse's memory through the completion of one of his last great works.

If anyone has any questions or concerns please feel free to contact me via PM.

Best regards,

Tobias

Last edited by a moderator:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)