Blazestorm

Supreme [H]ardness

- Joined

- Jan 17, 2007

- Messages

- 6,940

Looks amazing, glad the microfibers worked for you... amazing material

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Don't those tubing guides increase your risk of a short?

I love the water cooling distributor block. It has a slight Matrix/Star Trek Borg look to it. Very cool.

Its almost sad to see it just about finished, Updates were always fun, but I'm sure you are already planning your next build, despite saying this build was for many PC's to come.

I hope you post here every time it is published!

Are your modded crossflow fans for sale? PM me a price.

When constructing this case, I didn't want any metal framework detracting from the look, so here's how the acrylic panels will fit together:

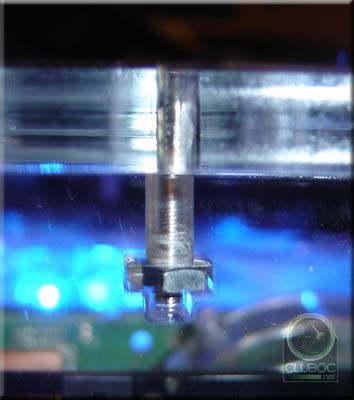

There are (clear) acrylic blocks fitted at all corners with these brass expansion threaded inserts, erm, inserted in to them.

The one on the left is the flush type, the other type flange. I've chosen flush type, M5 threads as I'll have M5 screws holding it all together. Which brings me to an other question of purely aesthetics, what type of screws should I use? I'm thinking cap heads (more hex shapes!), but countersunk to be flush, round caphead or bolts? I can't decide at the moment, consensus?

As I said before, the case parts should arrive in the near future. It will all be undrilled so I'll have fun putting it all together before I even get any components in it.

One question - how did you mount these "brass expansion threaded" things in acrylic blocks? Using glue? or just tidy sqeeze?

Thanks guys!

...

3. The only way this would have been possible is to use really thick panels or use smaller inserts. For example, say the insert requires a 6mm drilled hole, you need some 'meat' left on the piece to make it strong so it won't crack outwards. Also, when you drill the edge of acrylic, it can expand outwards due to the heat if your not carefull. When you screw into the inserts they too expand slightly and bite into the acrylic, increasing the risk of it cracking. It is possible to do it, but I opted for the less risky option!

Another way to press in those brass inserts is to press them into the pre-drilled hole with a soldering iron. A conical tip fits neatly into the resess in the insert and the heat softens the acrylic, they go in very easily.