michaLcoughliN

[H]ard|Gawd

- Joined

- Jan 13, 2007

- Messages

- 1,163

I finally go started on my mod. I will hopefully be done this mod within the next 2 months.

But here are some pics to get you started.

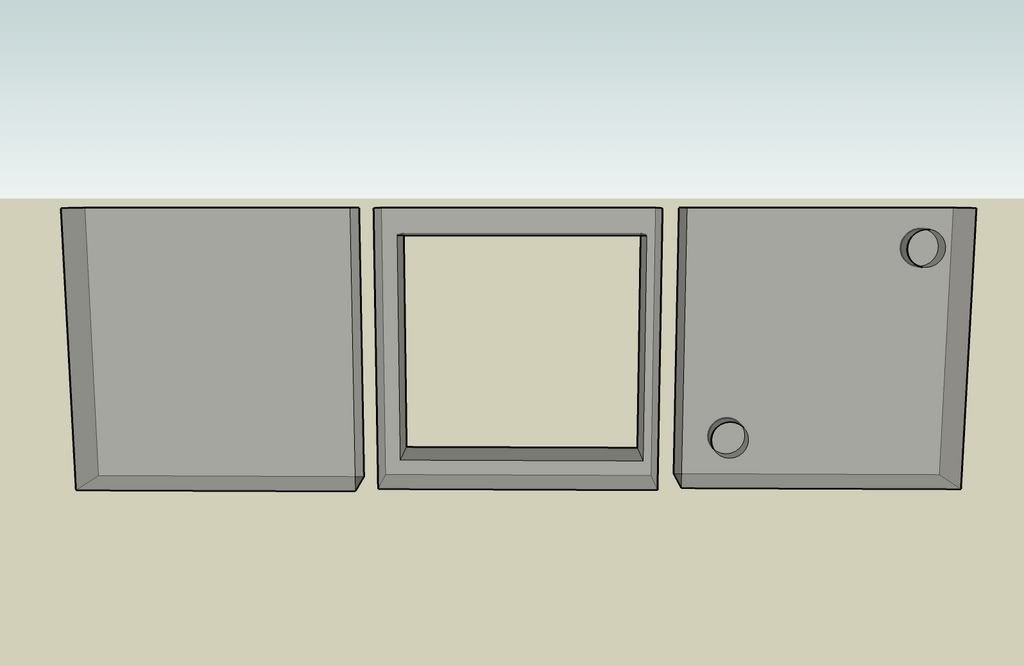

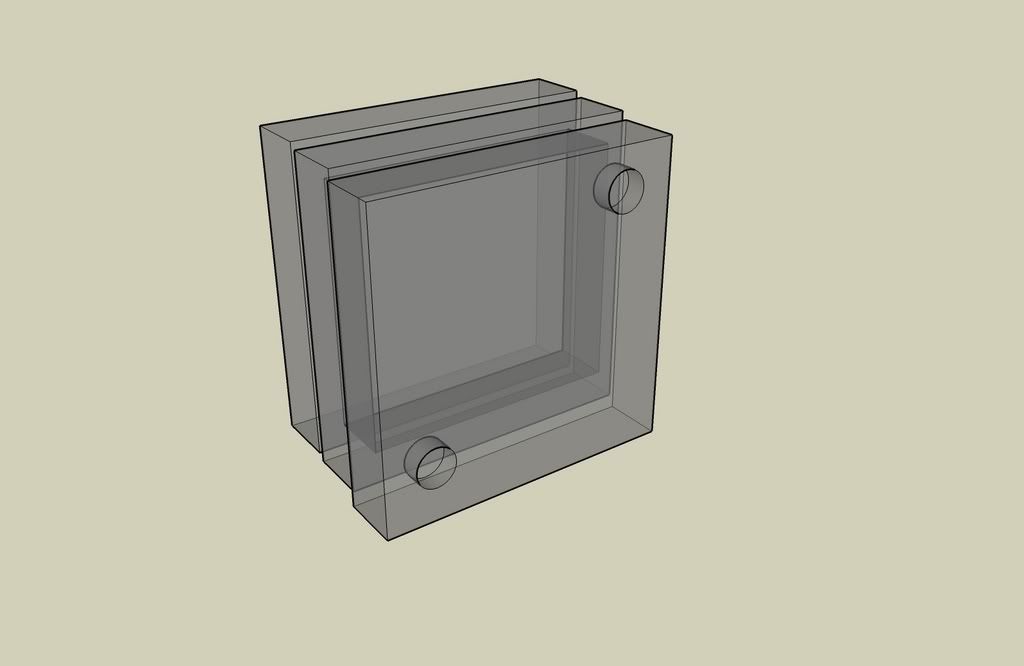

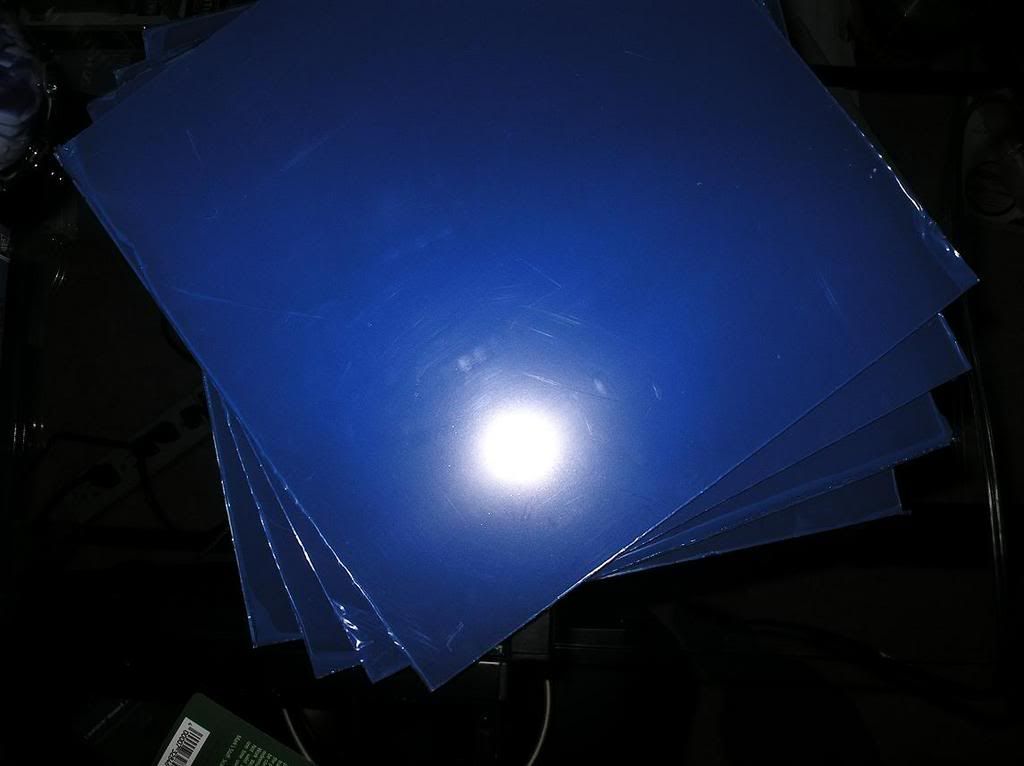

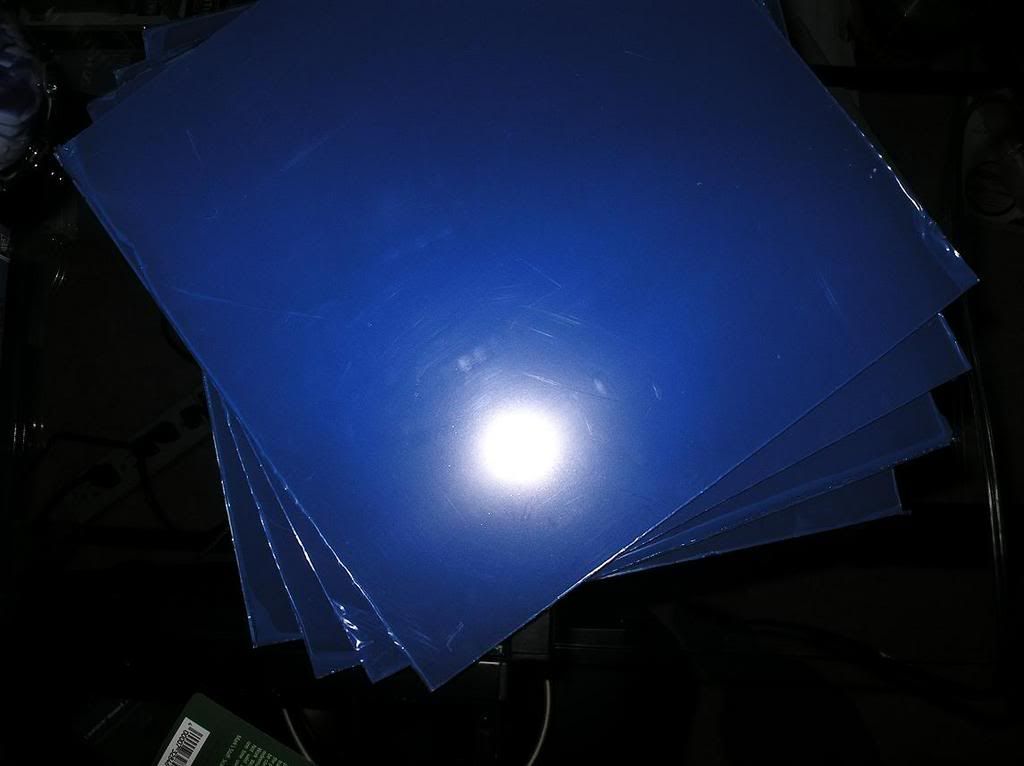

A basic cube design made from acrylic. making it 12x12 sheets by 1/4 thickness

Here are some pics.

The acrylic has been scored part 1

making sure measurements are perfecto

Part 2 making the acrylic into a 12x12 sheet.. scoring once more

Now the 12x12 sheets x 8(sheets)

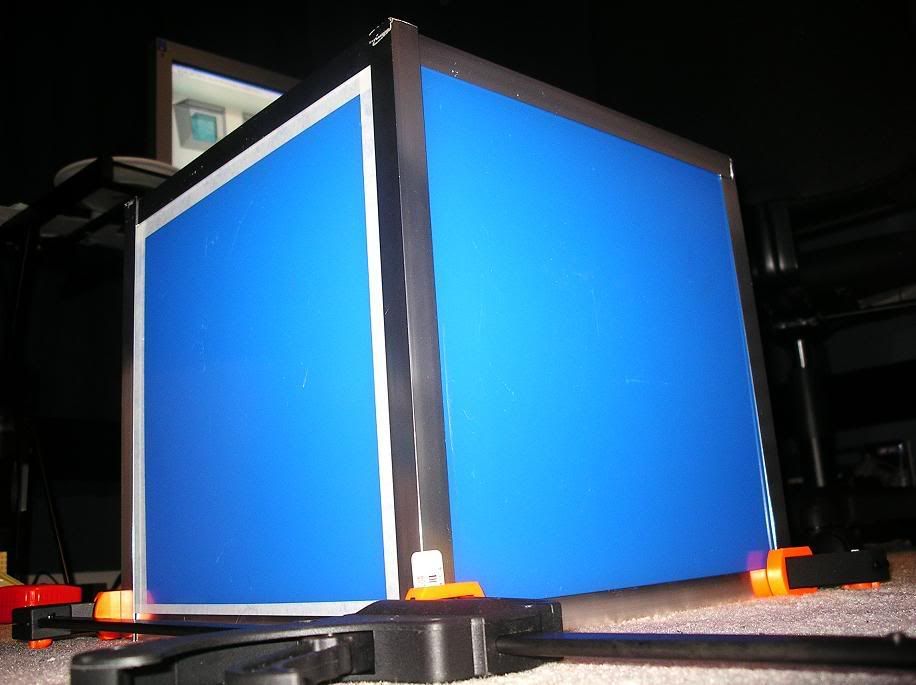

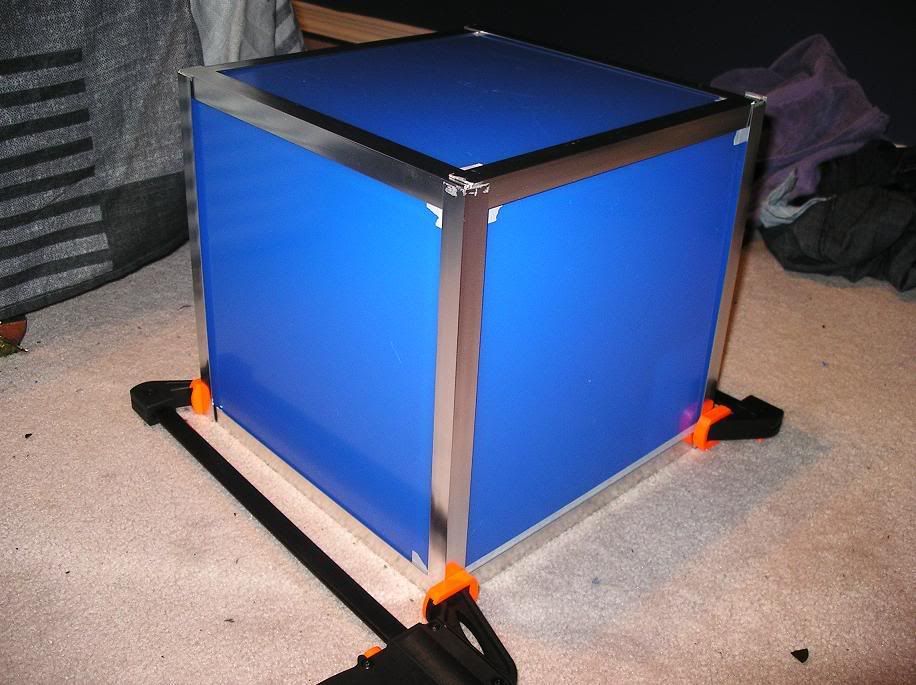

Just setting it up to see what it will look like

I will be using L brackets alongst the part where the plexi meets up. all way round. So home depot sells them in 8 ft pieces..had to cut and then sand down the rough edges with good old dremel + drum bit

A total of 12 pieces

Completed task..

Completed task..

That is all for now more to come later on Keep tuned [H] forum

Keep tuned [H] forum

But here are some pics to get you started.

A basic cube design made from acrylic. making it 12x12 sheets by 1/4 thickness

Here are some pics.

The acrylic has been scored part 1

making sure measurements are perfecto

Part 2 making the acrylic into a 12x12 sheet.. scoring once more

Now the 12x12 sheets x 8(sheets)

Just setting it up to see what it will look like

I will be using L brackets alongst the part where the plexi meets up. all way round. So home depot sells them in 8 ft pieces..had to cut and then sand down the rough edges with good old dremel + drum bit

A total of 12 pieces

That is all for now more to come later on

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)