Mr_Armageddon

Limp Gawd

- Joined

- Jun 3, 2009

- Messages

- 252

As mentioned, looks like a fantastic build.

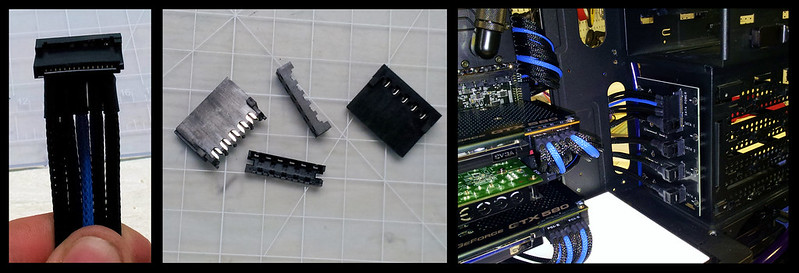

You ordered Aqua Computer and EK gear, but also went with the EVGA Hydro. Any particular reason for doing that instead of getting a separate block from either of those manufacturers?

The EVGA HydroCopper 2 was released at the same time as the other 580 editions. I didn't want to wait for EK to design a block for the 580, so I sprung with the EVGA one with the block pre-installed. Plus I really like the look of the full PCB covering Water Block. EK makes some great stuff, but at the time the HydroCopper was just more appealing.

I have never used anything from AquaComputer before, so this will be my first foray with their products. Reviews state that the Aquaeros 5 is a great fan controller, and the idea of having my pumps more quiet when performance is not needed is very appealing to me.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)