Hi everyone,

I wanted to share my ideas for a console style SFF aluminum case.

Background

My company designs and makes datacenter solutions for cold data storage, with a sheet metal workshop inhouse. After discovering the SFF community on Reddit, I pitched the idea to some friends (who are all gamers and LAN party enthusiasts), who had never heard of SFF before and were intrigued. I decided I wanted to make a small batch of cases for my friends to test the waters before possibly moving to mass production.

Preliminary Specs:

Changes 8/29/2017:

Changes 6/20/2017:

Changes 6/10/2017:

Changes 5/31/2017:

Upcoming:

I wanted to share my ideas for a console style SFF aluminum case.

Background

My company designs and makes datacenter solutions for cold data storage, with a sheet metal workshop inhouse. After discovering the SFF community on Reddit, I pitched the idea to some friends (who are all gamers and LAN party enthusiasts), who had never heard of SFF before and were intrigued. I decided I wanted to make a small batch of cases for my friends to test the waters before possibly moving to mass production.

Preliminary Specs:

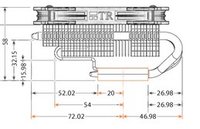

- Dimensions (H x W x D): 351x70x310, 7.6l

- CPU cooler clearance: up to 50mm

- GPU: Up to 305mm in length

- PSU: SFX(-L)

- Drives: 2x 2.5"

- Material: 1.58mm aluminum

Changes 8/29/2017:

- First prototype has been manufactured.

Changes 6/20/2017:

- Corners have been smoothened

Changes 6/10/2017:

- Vent holes have been redesigned for better airflow.

- Internal layout changed to allow for the included riser card.

- Cutout bracket added to support 92mm/120mm AIOs.

Changes 5/31/2017:

- Reduced volume from 8.1l to 7.6l.

- Additional vent holes added and density increased.

Upcoming:

- Design a stand for the case.

Manufacture a prototype.

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)