SonDa5

Supreme [H]ardness

- Joined

- Aug 20, 2008

- Messages

- 7,437

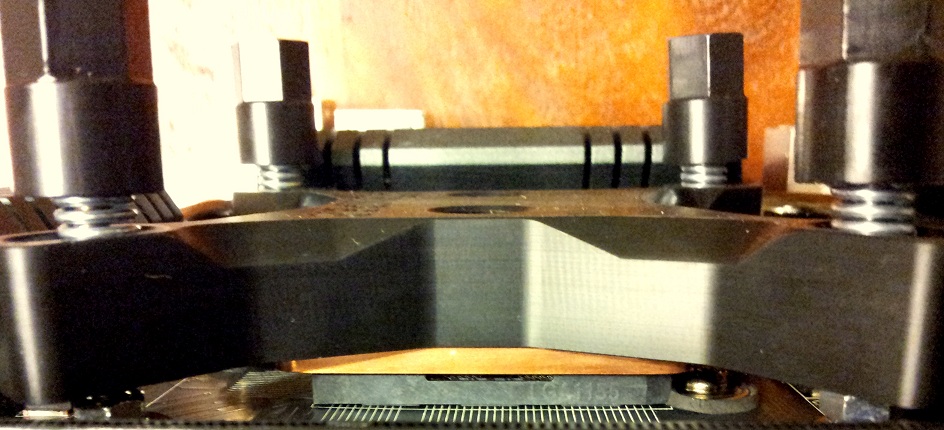

I got out of The LID.

Into the light.

Pure Razor IHS removal.

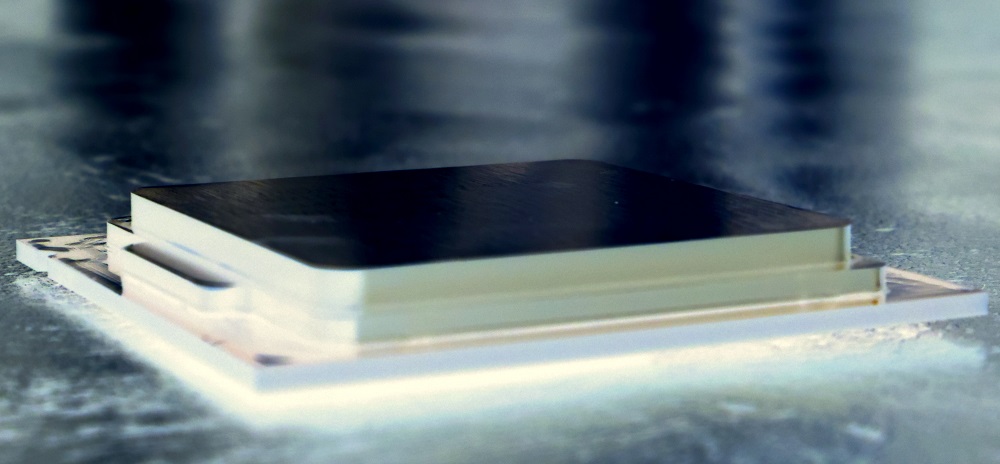

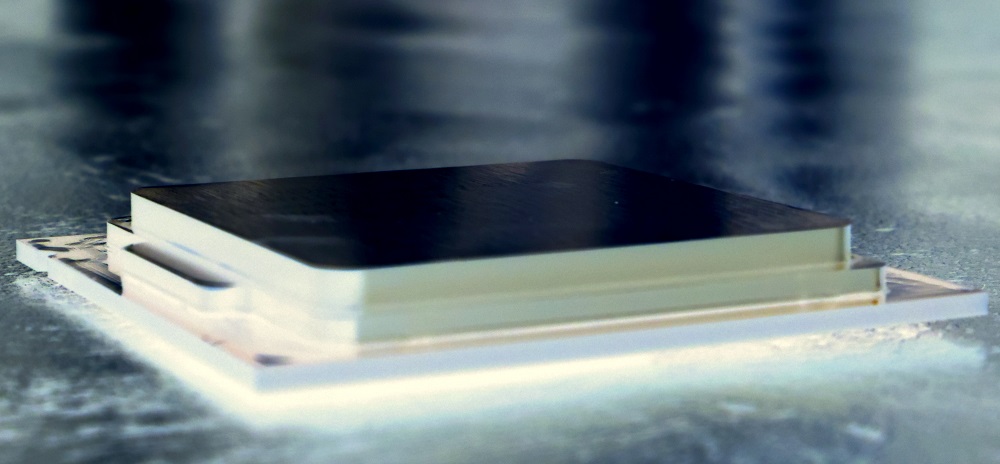

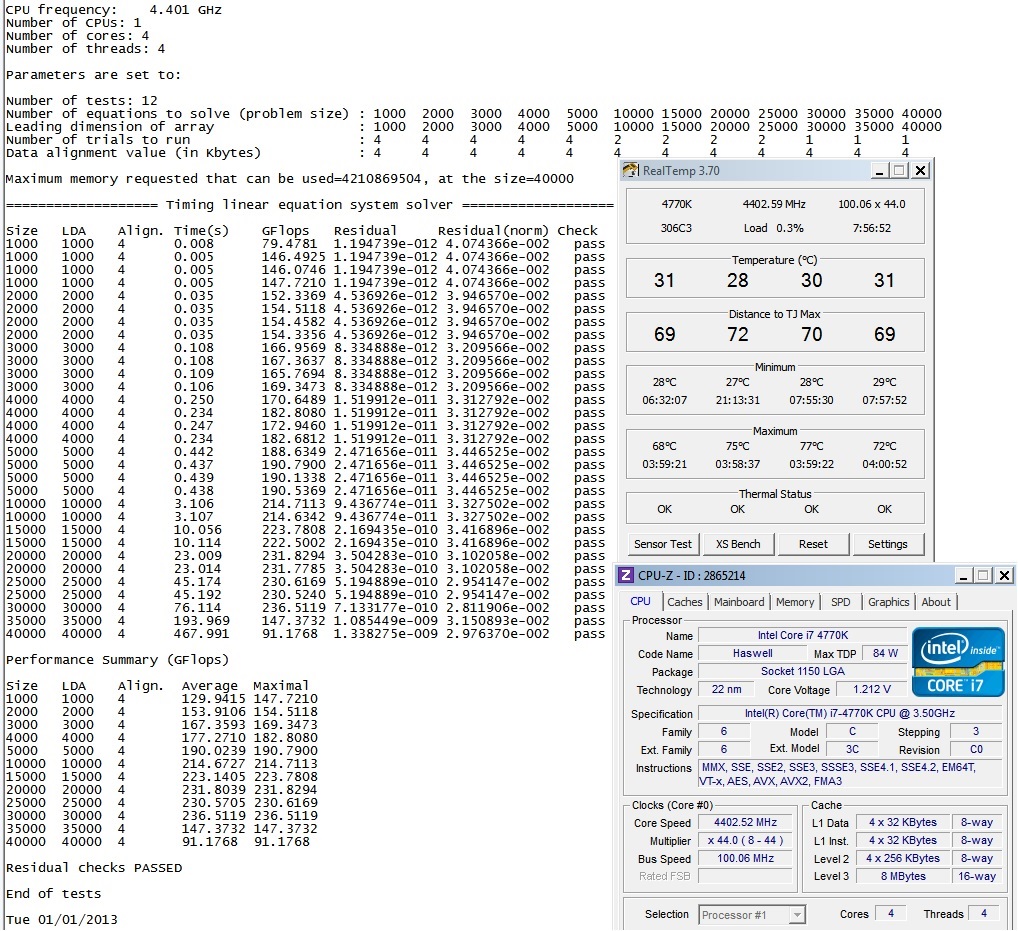

Delidded no IHS direct core mount.

Same water cooling as before.

Same BIOS settings as before.

Coolaboratory Liquid Pro TIM between DIE and Block.

http://valid.canardpc.com/2865214

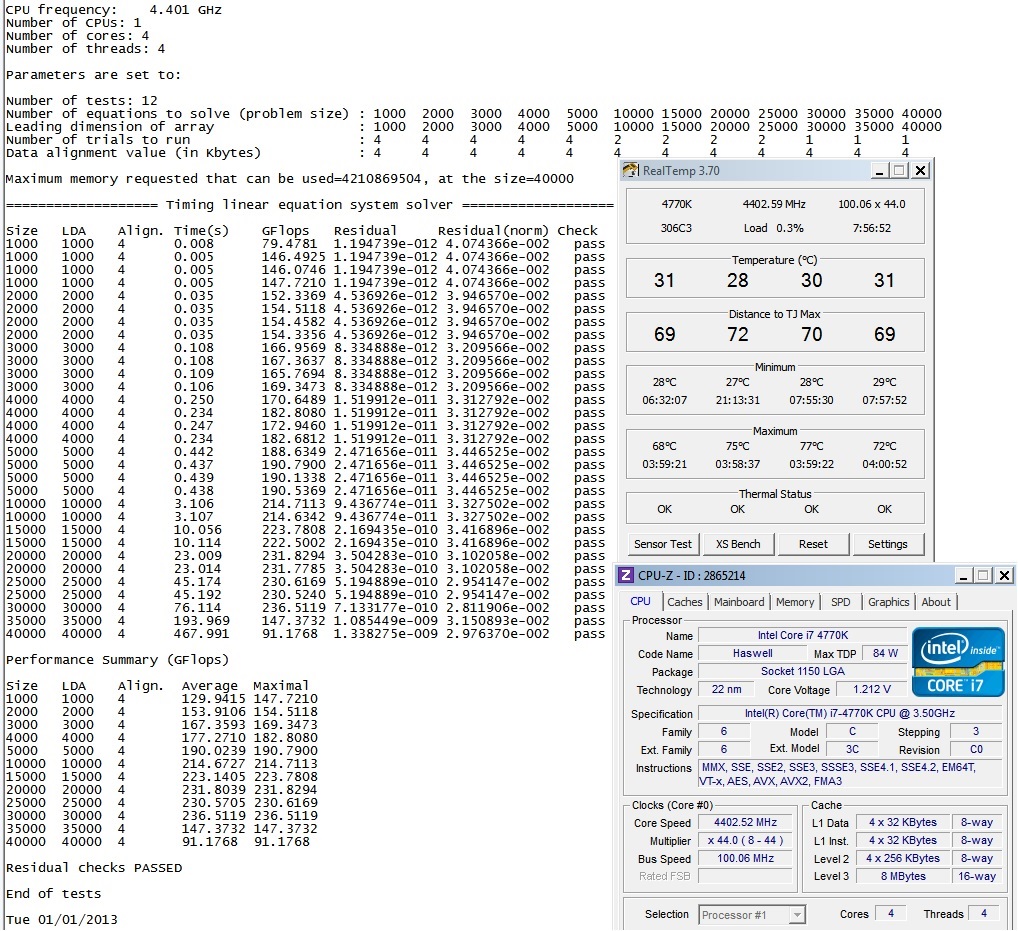

Process Gflop performance is up!

With ambient temps taken into consideration temps dropped at least 29C per core!

Also important to note that during the before delid test a 100C TDP heat was topping out and the CPU slows down a little by itself to keep from heating up. So max operation temps were never seen for the before delid test.

Conclusion:

Delidding was a big win for my hot 4770k.

Currently gaming at 4.7GHZ and temps max out at 50C range on each core.

Into the light.

Pure Razor IHS removal.

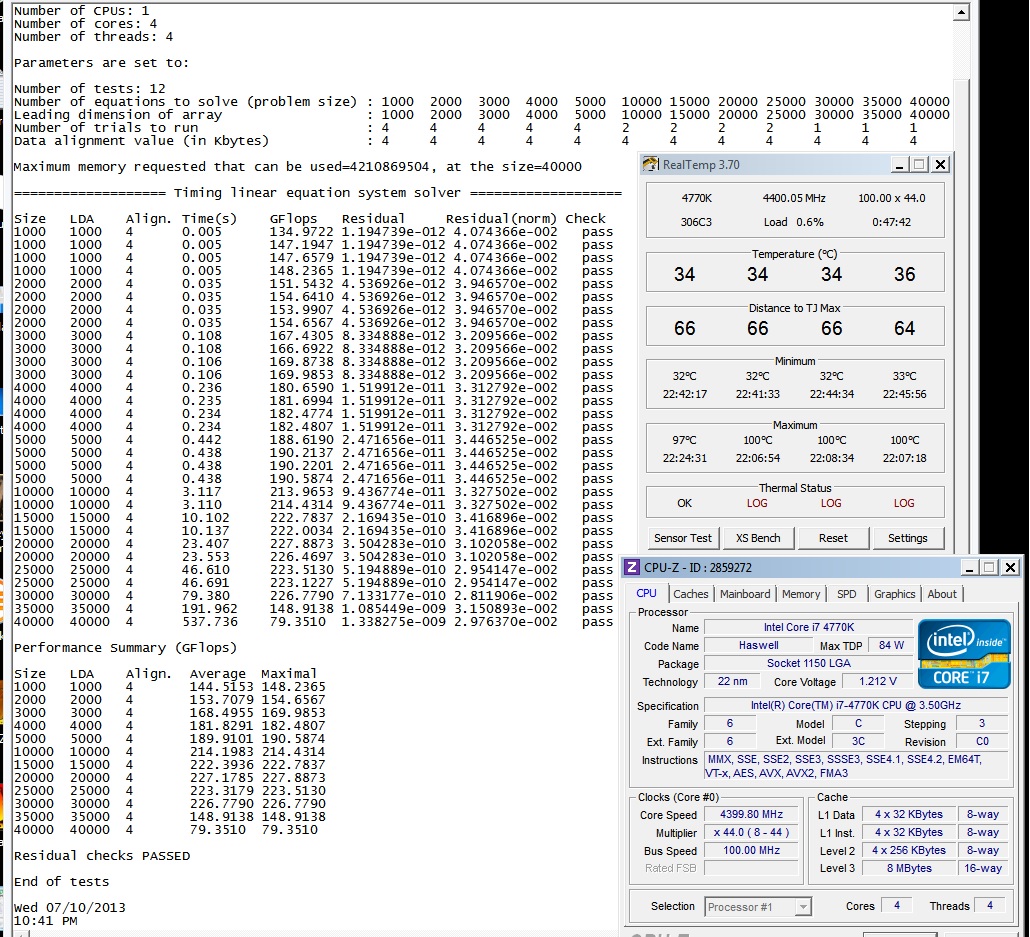

Here are my results for my maximum performance over clock on my 4770k before I delid it.

Powered by Intel's latest AVX2 linpack code.

Look at the Gflop performance and the heat.

4770k with HT off at 4.4GHZ.

Custom water loop, not delidded yet

Ambient temps 24C

http://valid.canardpc.com/2859272

This chip is worthy and ready for delidding.

Delidded no IHS direct core mount.

Same water cooling as before.

Same BIOS settings as before.

Coolaboratory Liquid Pro TIM between DIE and Block.

http://valid.canardpc.com/2865214

Process Gflop performance is up!

With ambient temps taken into consideration temps dropped at least 29C per core!

Also important to note that during the before delid test a 100C TDP heat was topping out and the CPU slows down a little by itself to keep from heating up. So max operation temps were never seen for the before delid test.

Conclusion:

Delidding was a big win for my hot 4770k.

Currently gaming at 4.7GHZ and temps max out at 50C range on each core.

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)