charlesshoults

Weaksauce

- Joined

- Mar 18, 2008

- Messages

- 125

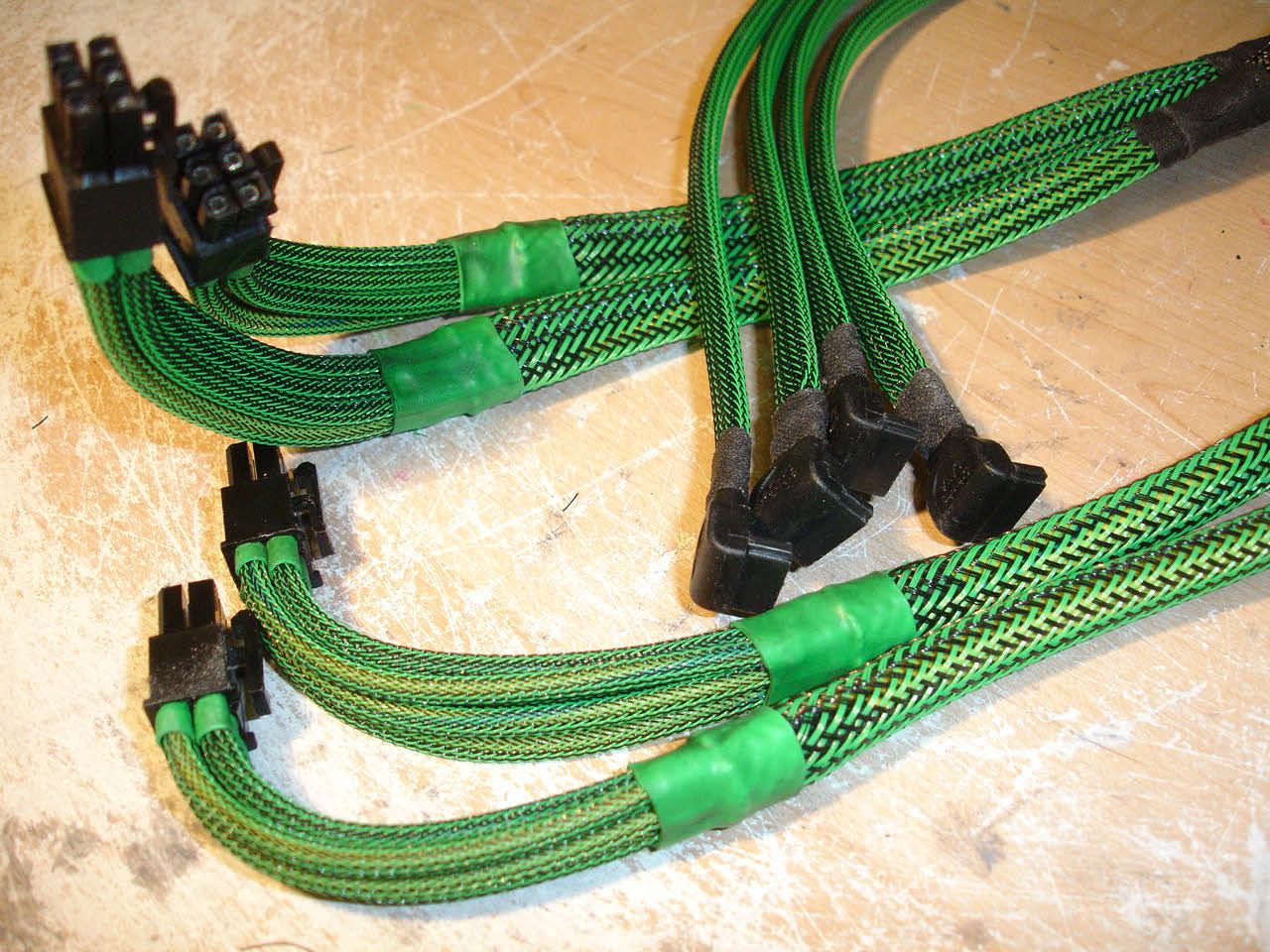

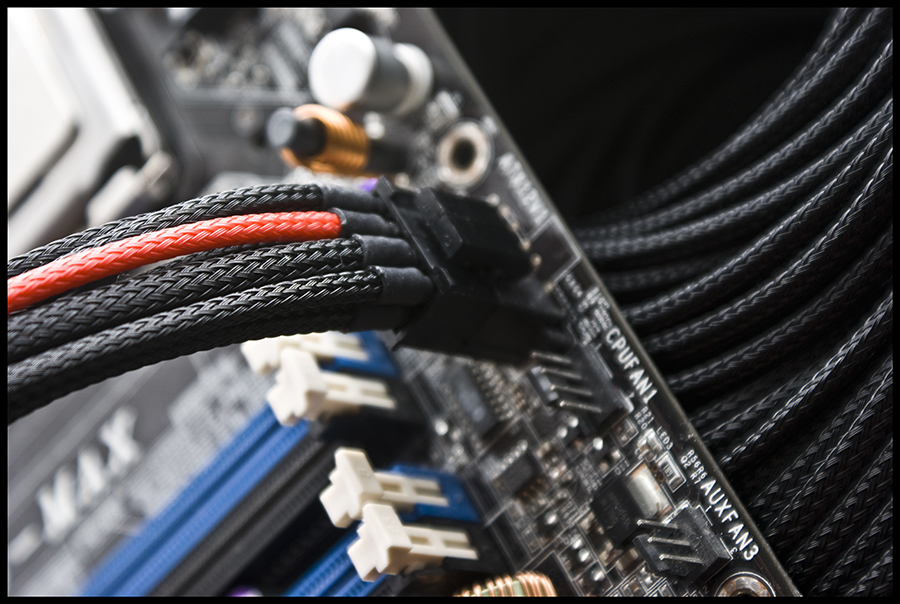

Lots of companies and individuals are doing cable sleeving, retailers, aftermarket and enthusiasts alike. Some do it well and some don't. For example, the following picture. While it was a good attempt, I consider this a fail. The cabling doesn't get close enough to the connector, leaving a lot of original wire exposed. The second picture is much, much better. The braided sleeve goes right up to the connector itself and the shrink tubing goes into the connector. MDCP makes some very nice colors. I particular like the grand bleu, providing a very subtle offset to the black. I would like to color-code my cables, while still keeping things predominantly black. Anyone know of companies that make sleeving that is not in solid colors? Something like what you see in the last two pictures.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)