I have a very basic question.

A lot of after market air coolers have heat pipes which go up to a radiator like structure with a fan. The Hyper 212 is a great example.

I was reading about the thermal solution in the Shuttle bare-bone PC and there ICE-2 cooling. They say that the heat pipe is filled with distilled water. Is this true of all these type of air-coolers?

I have been reluctant to try out liquid cooling so far because I am worried about leaks but if the heat-pipe coolers are also filled with water this changes the game...

http://global.shuttle.com/unique/page?pageName=cooling

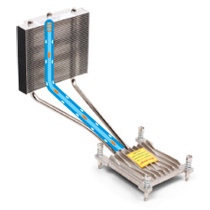

Integrated Cooling Engine 2 (ICE 2)

Like its predecessor Integrated Cooling Engine 2 (ICE 2) uses convection cooling to dissipate heat away from and around the CPU. With all the same basic concepts and designs, the new improved version ICE 2 includes, copper tubes coated in nickel enhances tube hardness and rust-proof protection are filled with distilled water, effectively channels heat away, providing high efficiency processor and chassis cooling. Allows XPC to remain under a stable, cool, concise and silent condition.

A lot of after market air coolers have heat pipes which go up to a radiator like structure with a fan. The Hyper 212 is a great example.

I was reading about the thermal solution in the Shuttle bare-bone PC and there ICE-2 cooling. They say that the heat pipe is filled with distilled water. Is this true of all these type of air-coolers?

I have been reluctant to try out liquid cooling so far because I am worried about leaks but if the heat-pipe coolers are also filled with water this changes the game...

http://global.shuttle.com/unique/page?pageName=cooling

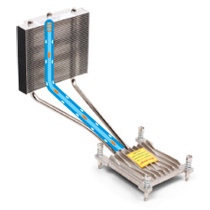

Integrated Cooling Engine 2 (ICE 2)

Like its predecessor Integrated Cooling Engine 2 (ICE 2) uses convection cooling to dissipate heat away from and around the CPU. With all the same basic concepts and designs, the new improved version ICE 2 includes, copper tubes coated in nickel enhances tube hardness and rust-proof protection are filled with distilled water, effectively channels heat away, providing high efficiency processor and chassis cooling. Allows XPC to remain under a stable, cool, concise and silent condition.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)