quasimodem

Gawd

- Joined

- Jan 13, 2005

- Messages

- 516

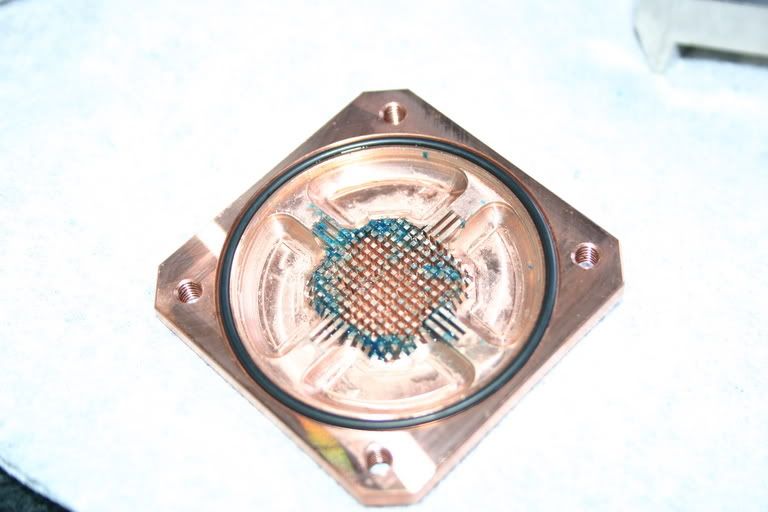

I read in another post that you shouldn't mix the two as it will cause problems, but where do you get copper radiators? I already have a nice copper waterblock, and I have an aluminum radiator but now I'm not sure I want to use them together....

Am I overly worried, or is it justified?

Thanx

QM

Am I overly worried, or is it justified?

Thanx

QM

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)