Oh how hell must have frozen over,

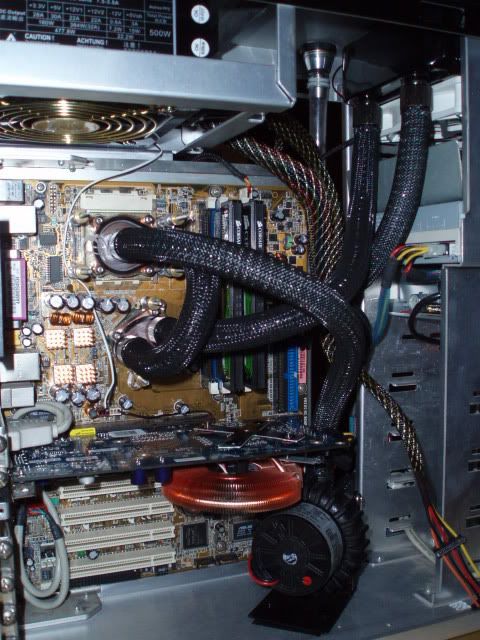

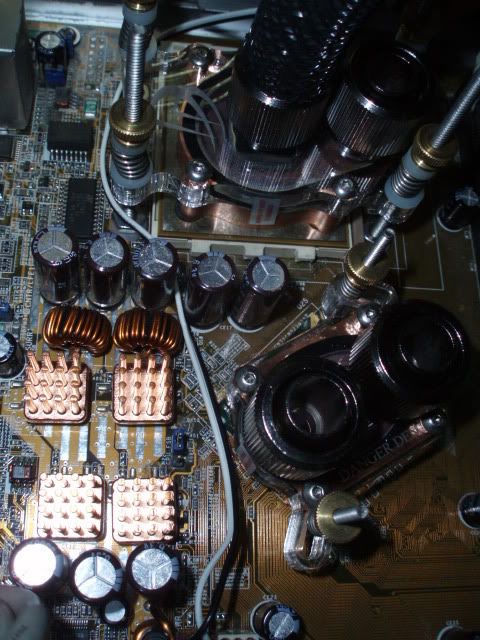

Anyhow, I'm considering going with the full compression fittings for one of my builds. Before I lay down the $200 to replace everything in that machine with Koolance nozzles (I still think their radiators/blocks are absolute shit ), I'd like to ask a few questions.

), I'd like to ask a few questions.

I'm mainly experienced with barb fittings and Swiftech's old push-fit style fittings. This will be my first use with Koolance's compression fittings. Now, is there anything I should know in advance about these fittings in either use, tightening or mounting onto blocks? What are the advantages and what are the draw backs (besides the ridiculous price tag).

Anyhow, I'm considering going with the full compression fittings for one of my builds. Before I lay down the $200 to replace everything in that machine with Koolance nozzles (I still think their radiators/blocks are absolute shit

I'm mainly experienced with barb fittings and Swiftech's old push-fit style fittings. This will be my first use with Koolance's compression fittings. Now, is there anything I should know in advance about these fittings in either use, tightening or mounting onto blocks? What are the advantages and what are the draw backs (besides the ridiculous price tag).

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)