- Joined

- May 18, 1997

- Messages

- 55,602

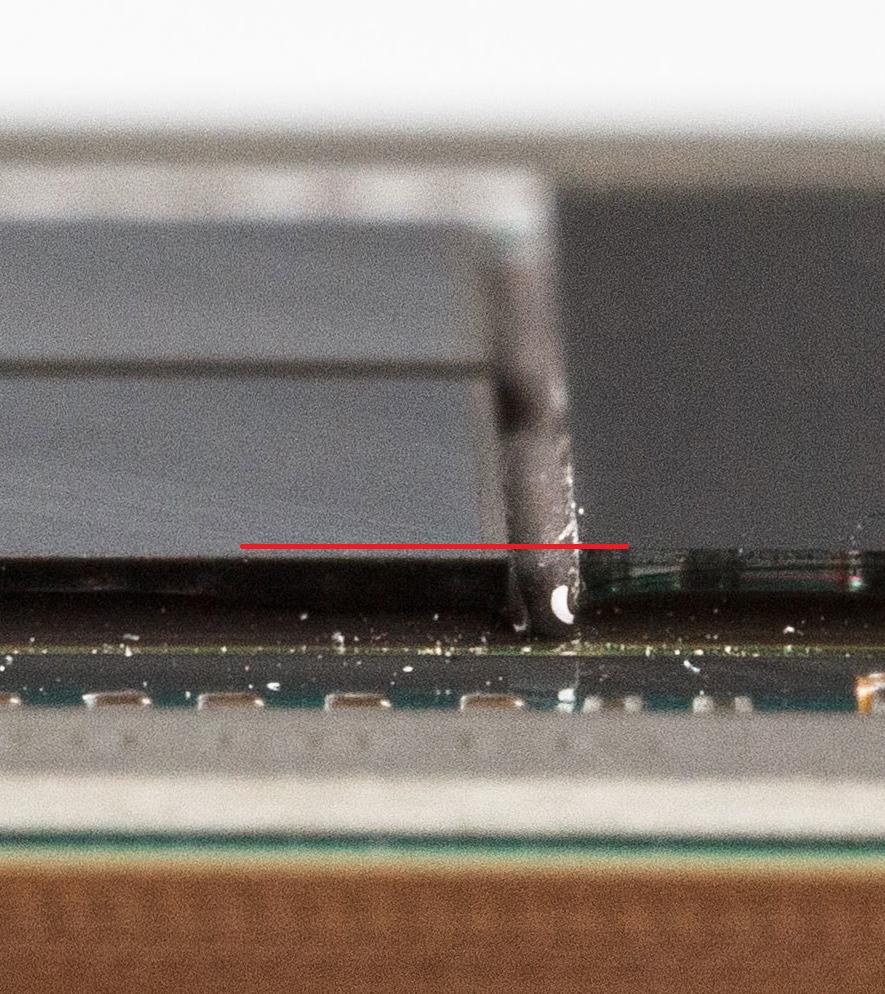

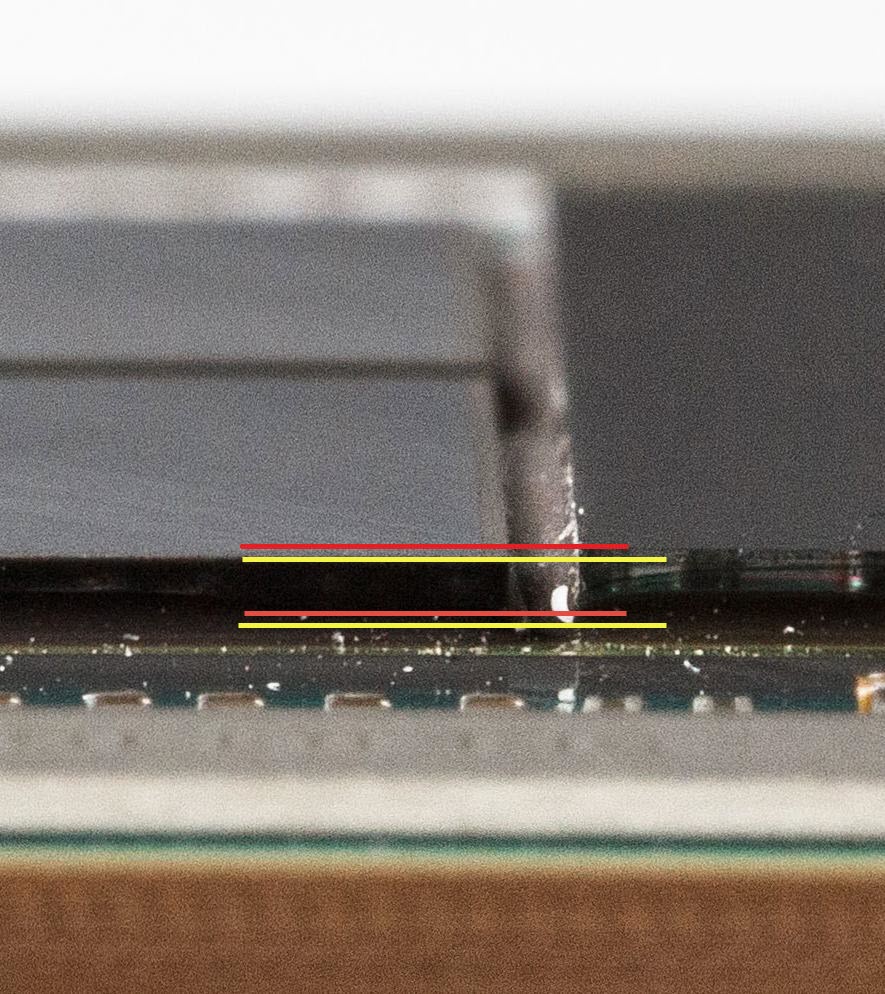

OMG! There are packaging differences in AMD Vega 64 GPUs! What the hell is AMD trying to pull? The short answer is, "nothing." Some have epoxy around the silicon, others don't. Here is the official answer from AMD. - "We have multiple manufacturing partners for Vega, one of them uses an epoxy fill to level the SOC surface, otherwise they’re functionally identical."

Check out the pic.

Crisis averted. No AMD conspiracy today. Trombone sound...

Check out the pic.

Crisis averted. No AMD conspiracy today. Trombone sound...

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)