For years now Aqua Computer and other imports have taken some real bitch slapping here in this forum for having the audacity to put aluminum and copper in the same loop. Also for years all these users of these products haven't reported corrosion problems when used according to the manufacturers direction.

So now that Swiftech is using aluminum bolted right next to copper in their blocks I have a couple of questions:

Are you guys sorry for bagging on us all this time?

Are you going to start bagging on Swiftech now?

Comment:

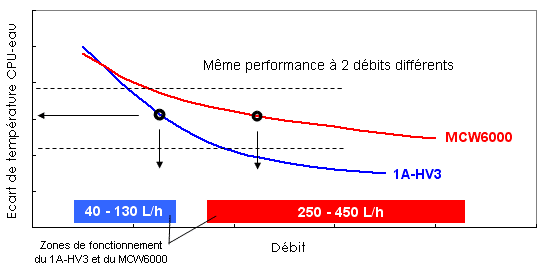

Since the imports were correct about this issue do you think that other cooling philosophies (low and medium flow) that the same importers express in their products are now viable water cooling solutions? Or do we have to wait another 3-4 years before the domestic companies follow suit to be be believed?

Edit: Please keep this conversation to a low roar and no FLAMES!

So now that Swiftech is using aluminum bolted right next to copper in their blocks I have a couple of questions:

Are you guys sorry for bagging on us all this time?

Are you going to start bagging on Swiftech now?

Comment:

Since the imports were correct about this issue do you think that other cooling philosophies (low and medium flow) that the same importers express in their products are now viable water cooling solutions? Or do we have to wait another 3-4 years before the domestic companies follow suit to be be believed?

Edit: Please keep this conversation to a low roar and no FLAMES!

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)