Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HP Blackbird 002

- Thread starter MrBean_Oz

- Start date

Hello everyone,

Ah, good news. My Wife has just informed me my PMP-400 heatsinks have arrived - yeay - now I can finalise my water-loop, and get those 2x DDC3.25's into action.

Post pics soon!!

Then, been to and fro wrt my PSU, and sleeving et al -> well, here's the idea:

Ordered the following from HobbyKing, for a total of $198-, and then $48 for shipping - high quality very flexible/soft/noodle-like silicone wire - on the 16AWG wire, there's something like 660 very fine strands making up the core......

Nice.

9680 Turnigy Pure-Silicone Wire 16AWG (1mtr) BLACK 100M

9654 Turnigy Pure-Silicone Wire 20AWG (1mtr) Black 50M

10936 Turnigy Pure-Silicone Wire 24AWG (1mtr) Black 50M

So, what a I going to do with this -> well, I considered all sorts of modular PSU's out there, but, just could not get it over my heart to dump my 5 year old PC Power&Cooling 1KW, 3x 12V rail TurboCool unit. We all know they are not modular, and the cables they come with are of a good quality, but really stiff....and difficult to work with in the confines of a PC, especially the BlackBird setup.

So, I will completely rewire this old stalwart with even better quality, but super-fexible, high-temp (yeah-yeah, I know) silicone wire. Color=black, black,back.

Let's see if I will still need sleeving afterwards, I doubt it, as this cable will look very good, and server-like - it has a real thick silicone jacket, and will fill the ATX- and other Molex connectors very nicely.

Order will arrive within next 2 weeks or so......

Exciting times ahead for my dear PSU, so all old cables will be desoldered, and new ones fitted, and tailored to exact length for this setup. Told you the wiring was going to be special

I will post a few pics of the pumps and new heatsinks tonight.

Ah, good news. My Wife has just informed me my PMP-400 heatsinks have arrived - yeay - now I can finalise my water-loop, and get those 2x DDC3.25's into action.

Post pics soon!!

Then, been to and fro wrt my PSU, and sleeving et al -> well, here's the idea:

Ordered the following from HobbyKing, for a total of $198-, and then $48 for shipping - high quality very flexible/soft/noodle-like silicone wire - on the 16AWG wire, there's something like 660 very fine strands making up the core......

Nice.

9680 Turnigy Pure-Silicone Wire 16AWG (1mtr) BLACK 100M

9654 Turnigy Pure-Silicone Wire 20AWG (1mtr) Black 50M

10936 Turnigy Pure-Silicone Wire 24AWG (1mtr) Black 50M

So, what a I going to do with this -> well, I considered all sorts of modular PSU's out there, but, just could not get it over my heart to dump my 5 year old PC Power&Cooling 1KW, 3x 12V rail TurboCool unit. We all know they are not modular, and the cables they come with are of a good quality, but really stiff....and difficult to work with in the confines of a PC, especially the BlackBird setup.

So, I will completely rewire this old stalwart with even better quality, but super-fexible, high-temp (yeah-yeah, I know) silicone wire. Color=black, black,back.

Let's see if I will still need sleeving afterwards, I doubt it, as this cable will look very good, and server-like - it has a real thick silicone jacket, and will fill the ATX- and other Molex connectors very nicely.

Order will arrive within next 2 weeks or so......

Exciting times ahead for my dear PSU, so all old cables will be desoldered, and new ones fitted, and tailored to exact length for this setup. Told you the wiring was going to be special

I will post a few pics of the pumps and new heatsinks tonight.

Hello everyone,

Ah, good news. My Wife has just informed me my PMP-400 heatsinks have arrived - yeay - now I can finalise my water-loop, and get those 2x DDC3.25's into action.

Post pics soon!!

Then, been to and fro wrt my PSU, and sleeving et al -> well, here's the idea:

Ordered the following from HobbyKing, for a total of $198-, and then $48 for shipping - high quality very flexible/soft/noodle-like silicone wire - on the 16AWG wire, there's something like 660 very fine strands making up the core......

Nice.

9680 Turnigy Pure-Silicone Wire 16AWG (1mtr) BLACK 100M

9654 Turnigy Pure-Silicone Wire 20AWG (1mtr) Black 50M

10936 Turnigy Pure-Silicone Wire 24AWG (1mtr) Black 50M

So, what a I going to do with this -> well, I considered all sorts of modular PSU's out there, but, just could not get it over my heart to dump my 5 year old PC Power&Cooling 1KW, 3x 12V rail TurboCool unit. We all know they are not modular, and the cables they come with are of a good quality, but really stiff....and difficult to work with in the confines of a PC, especially the BlackBird setup.

So, I will completely rewire this old stalwart with even better quality, but super-fexible, high-temp (yeah-yeah, I know) silicone wire. Color=black, black,back.

Let's see if I will still need sleeving afterwards, I doubt it, as this cable will look very good, and server-like - it has a real thick silicone jacket, and will fill the ATX- and other Molex connectors very nicely.

Order will arrive within next 2 weeks or so......

Exciting times ahead for my dear PSU, so all old cables will be desoldered, and new ones fitted, and tailored to exact length for this setup. Told you the wiring was going to be special

I will post a few pics of the pumps and new heatsinks tonight.

Sounds great, You can't top a PC power & cooling.

I fully agree, that's why I refuse to replace it with something 'supposedly more modern', even 5 years after initial purchase.

I might grab a new 1200W TurbCool and keep it in storage for when it's needed. I a not one for bling/modular supplies, so, I will be pretty happy to keep one in cold storage for the day it's needed

I might grab a new 1200W TurbCool and keep it in storage for when it's needed. I a not one for bling/modular supplies, so, I will be pretty happy to keep one in cold storage for the day it's needed

Hello Everyone,

A few pics of my recently arrived hardware - first up, the 2 Aquagrafix in-line temp sensors - one will be installed on the rad inlet, the other on the rad outlet. Would give a good indicator of hot-side and cold-side water temps.

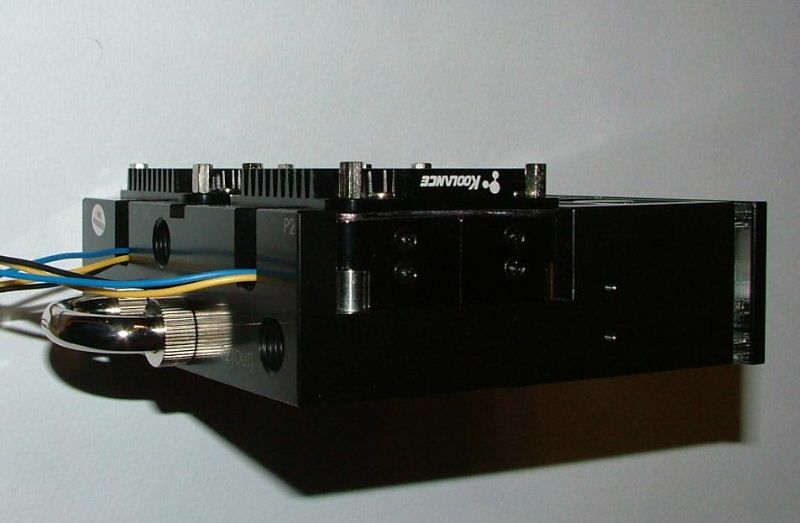

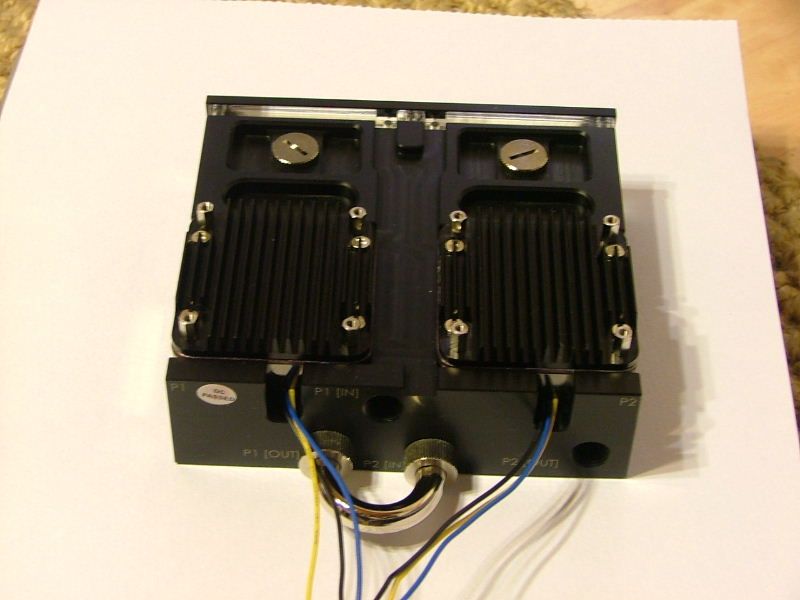

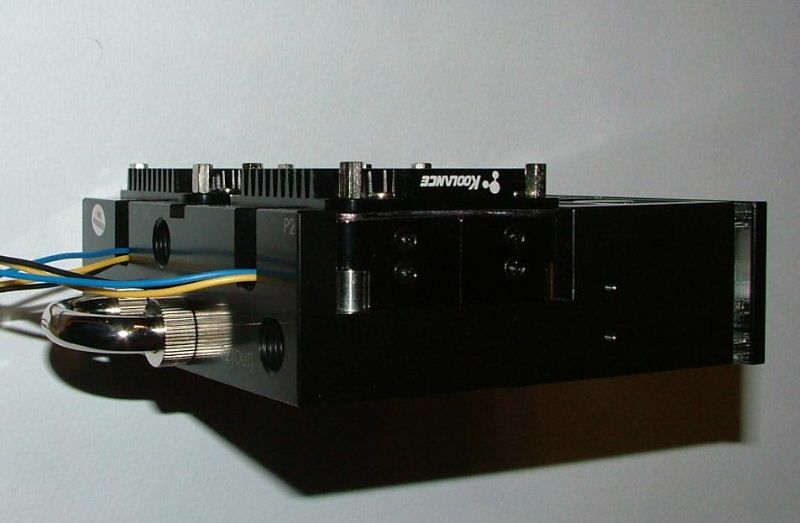

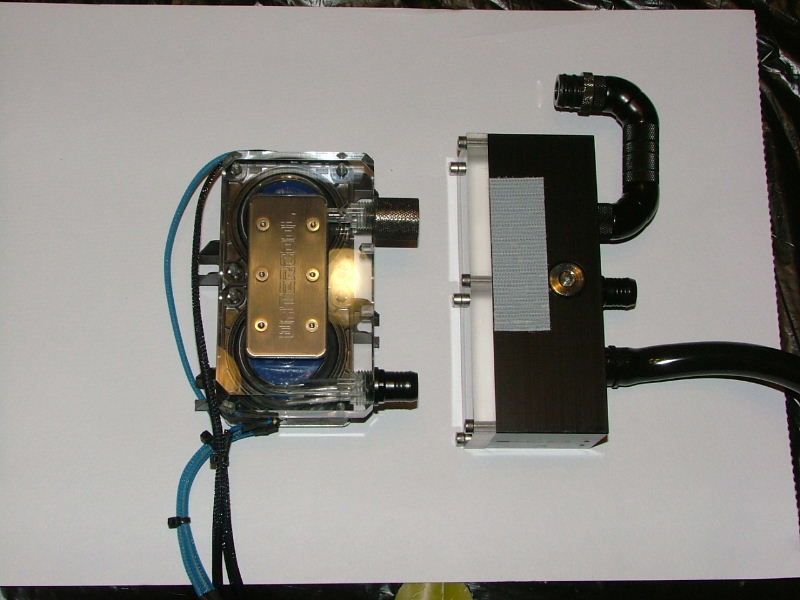

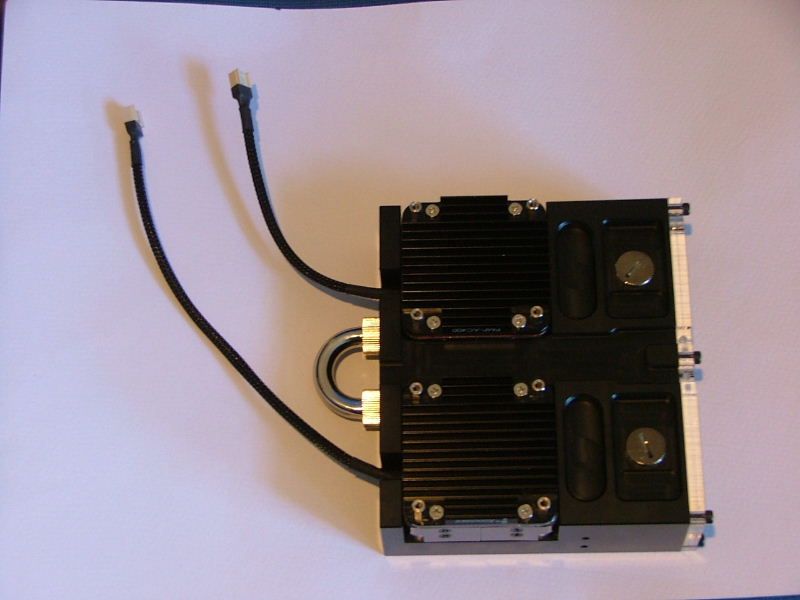

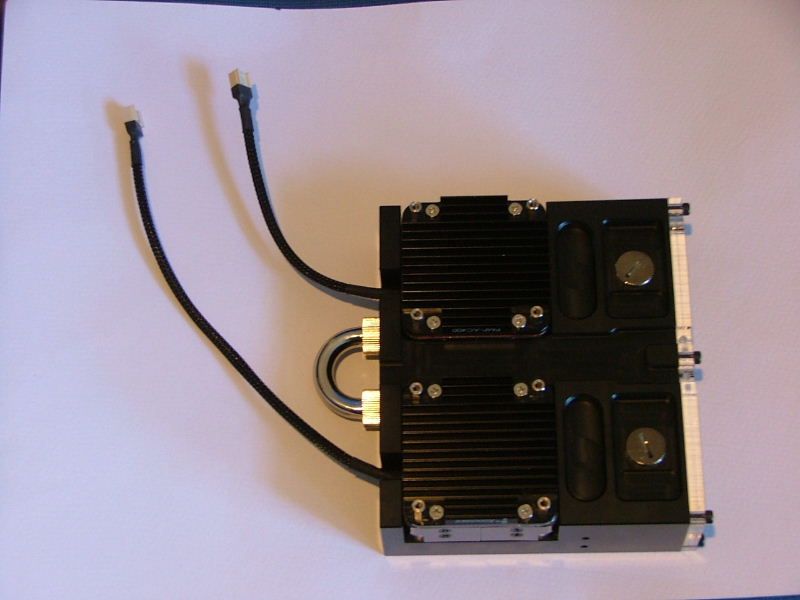

Then, the new PMP-400 heatsinks, one for each pump:

and

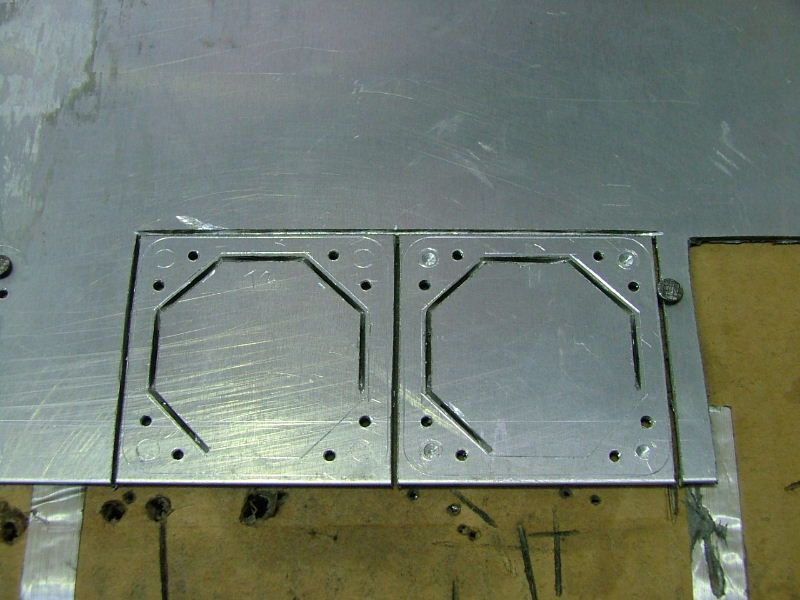

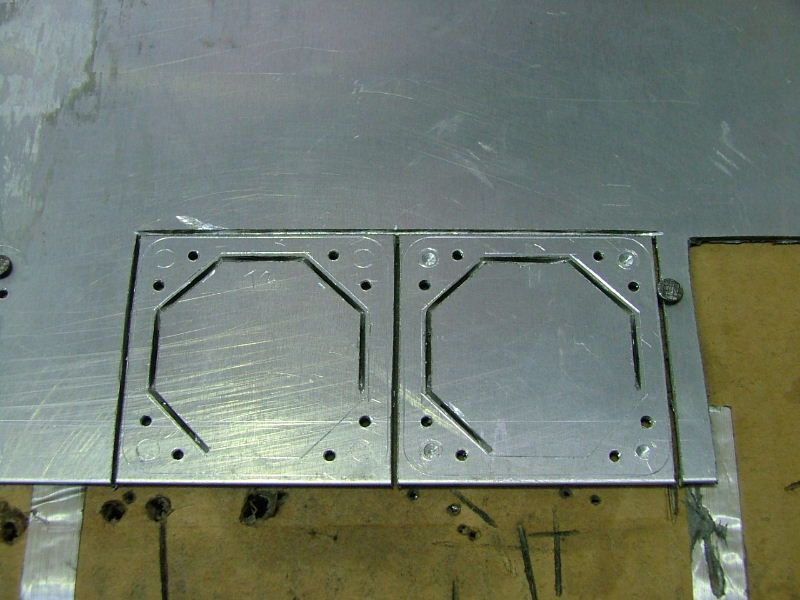

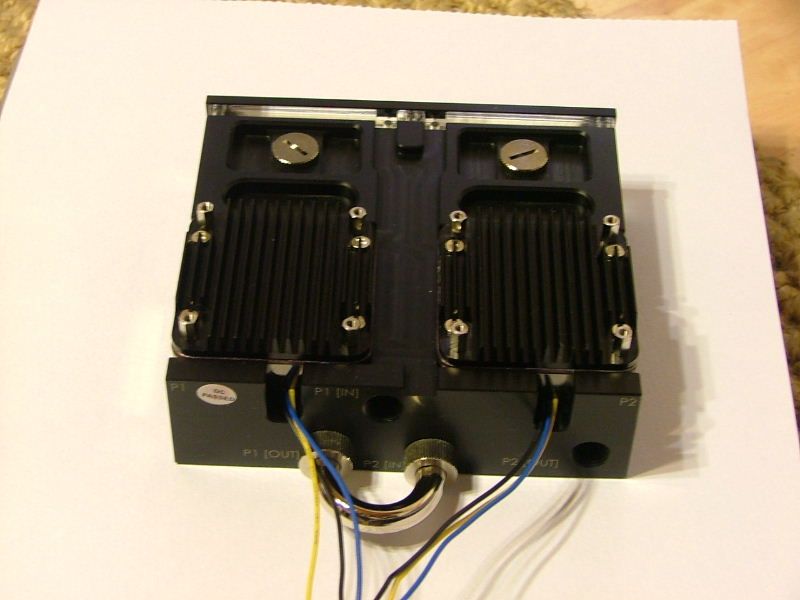

and then, to allow me to fit these to the pumps, and installing them on the RP-401X2 reservoir, I need to fab 2x new mid-plates, one for each pump - these are the culprits, and short of totally butchering them, they won't fit - I knew this, so got some nice 2mm thick aluminium which will become new midplates.

And all together, before modding - I will finish the plates, and water-loop setup on Saturday. Will post more updates then....

and then, something different - my Supermicro X7DWA-N motherboard has only a single dual-internal USB header, and seeing I need at least 2x, one for the Koolance TMS-200 controller, and the other for the Blackbird multi-card reader, I decided to get this - will work really well, be out of the way, and still give me a good few extra internal headers and ports:

Talk soon again

A few pics of my recently arrived hardware - first up, the 2 Aquagrafix in-line temp sensors - one will be installed on the rad inlet, the other on the rad outlet. Would give a good indicator of hot-side and cold-side water temps.

Then, the new PMP-400 heatsinks, one for each pump:

and

and then, to allow me to fit these to the pumps, and installing them on the RP-401X2 reservoir, I need to fab 2x new mid-plates, one for each pump - these are the culprits, and short of totally butchering them, they won't fit - I knew this, so got some nice 2mm thick aluminium which will become new midplates.

And all together, before modding - I will finish the plates, and water-loop setup on Saturday. Will post more updates then....

and then, something different - my Supermicro X7DWA-N motherboard has only a single dual-internal USB header, and seeing I need at least 2x, one for the Koolance TMS-200 controller, and the other for the Blackbird multi-card reader, I decided to get this - will work really well, be out of the way, and still give me a good few extra internal headers and ports:

Talk soon again

Tomorrow is the big day, with lots and lots to do - a short summary:

1) Remove existing pumps

2) Remove tubing

3) Remove motherboard

4) Remove Radiator.

5) Remove old pumps

6) Remove SAS cage

7) Make new base-plate for the Koolance TMS-200 controller and mount it where where existing pumps are located, in empty space above the SAS drive-cage -> important, as I need to route all sleeved cables to here. Reason TMS-200 won't be mounted in empty PCI-slot, well, I have a very nice SCSI controller, driving my external DLT VS160 Tape backup device, which needs to be mounted in the one PCI-X 64 slot.

8) Fit TMS-200 to allocated position.

9) Sleeve and fit new NoiseBlocker Fans to the radiator, as well as the drive-bay fans.

10) Make new mid-plates for PMP-400 heatsinks, and fit to pumps.

11) Mount pumps, and locate a temp-sensor to each pump

12) Sleeve pumps, temp-sensors and route cables to TMS-200

13)Fit radiator, and route fan-cables to TMS-200

14)Fit motherboard, drive-controllers, as well as SAS drive-cage.

15) Refit tubing, and redo to accommodate new pumps/reservoir.

16) Leaktest/dry-runs.

17) 20h00 tomorrow-evening - fire up the system.

Awaiting new SuperFlex silicone wire, so rewiring of the PSU will commence once that arrives. Also, a MAte of mine is in South-Africa, and I've asked him to bringback 500 cable-tie mounts, black, 20x14mm low-profile - will work out about $50 AUD, as opposed to big-bucks buying those from mod-shops. They will be just in time to finish of the wiring/cabling.

Above just for my own benefit to keep track of what needs to be done, please ignore this rantings of a madman

1) Remove existing pumps

2) Remove tubing

3) Remove motherboard

4) Remove Radiator.

5) Remove old pumps

6) Remove SAS cage

7) Make new base-plate for the Koolance TMS-200 controller and mount it where where existing pumps are located, in empty space above the SAS drive-cage -> important, as I need to route all sleeved cables to here. Reason TMS-200 won't be mounted in empty PCI-slot, well, I have a very nice SCSI controller, driving my external DLT VS160 Tape backup device, which needs to be mounted in the one PCI-X 64 slot.

8) Fit TMS-200 to allocated position.

9) Sleeve and fit new NoiseBlocker Fans to the radiator, as well as the drive-bay fans.

10) Make new mid-plates for PMP-400 heatsinks, and fit to pumps.

11) Mount pumps, and locate a temp-sensor to each pump

12) Sleeve pumps, temp-sensors and route cables to TMS-200

13)Fit radiator, and route fan-cables to TMS-200

14)Fit motherboard, drive-controllers, as well as SAS drive-cage.

15) Refit tubing, and redo to accommodate new pumps/reservoir.

16) Leaktest/dry-runs.

17) 20h00 tomorrow-evening - fire up the system.

Awaiting new SuperFlex silicone wire, so rewiring of the PSU will commence once that arrives. Also, a MAte of mine is in South-Africa, and I've asked him to bringback 500 cable-tie mounts, black, 20x14mm low-profile - will work out about $50 AUD, as opposed to big-bucks buying those from mod-shops. They will be just in time to finish of the wiring/cabling.

Above just for my own benefit to keep track of what needs to be done, please ignore this rantings of a madman

Hello Guys,

Jeesh, been a long day yesterday, these mid-plates are not that easy to make, a fair bit of precision-measurement, and filing, to get everything just right.

I ended up making 2 sets, the first ones had one of the mounting-holes off-center by a 1mm, and, because the usecountersunk screws, well, just say after me speaking in languages, I decided to redo them - 4 hours wasted, down the drain

But, as they say, where there is a will, there is a way.....all holes drilled, 8 small ones tapped to 3mmx0.5, and the larger ones countersunk. Fits 100% on the pumps...and came rather sassy mounted to the res.

A single photo of my first attempt, with the heatsink sitting on the new mid-plate, which was still in early stages...

Next follows the second attempt, following a different methodlogy.

Here I am cutting them out of 2mm aluminium plate....pre-drilled, tapped et al...

Post-cut, and ready for my various fine-tooth files....

Showing how far heatsinks protrude above the pumps, pretty slimline...

And a few other angles, I think it looks pretty decent...

and

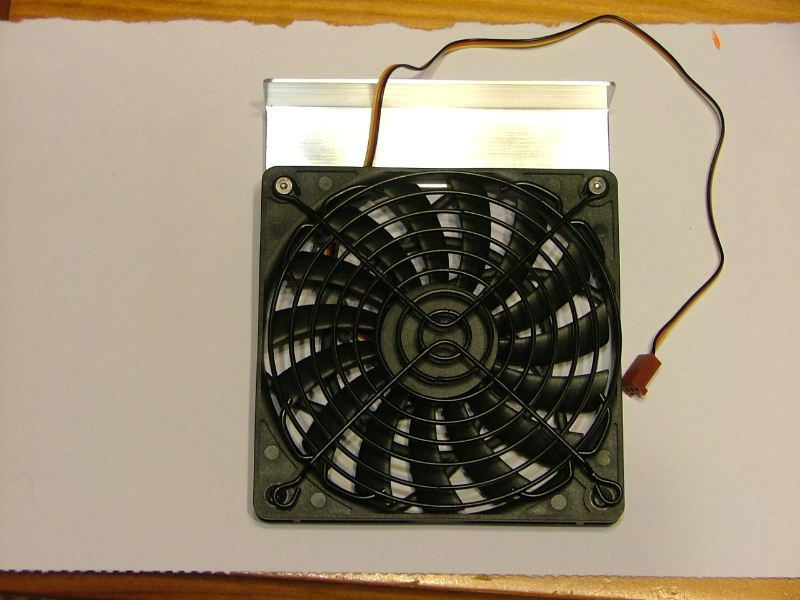

and a last one, showing how a stock 60mmx25mm fan sits on the heatsink - just for those who are considering something similar, the fan fits perfectly, even the mounting-holes are aligning 100% -> I will need to get slimline 60mmx10mm fans - they will also be controlled by the TMS-200, but probably overkill.....

More pics later, I need to sleeve pump-cables now....

Jeesh, been a long day yesterday, these mid-plates are not that easy to make, a fair bit of precision-measurement, and filing, to get everything just right.

I ended up making 2 sets, the first ones had one of the mounting-holes off-center by a 1mm, and, because the usecountersunk screws, well, just say after me speaking in languages, I decided to redo them - 4 hours wasted, down the drain

But, as they say, where there is a will, there is a way.....all holes drilled, 8 small ones tapped to 3mmx0.5, and the larger ones countersunk. Fits 100% on the pumps...and came rather sassy mounted to the res.

A single photo of my first attempt, with the heatsink sitting on the new mid-plate, which was still in early stages...

Next follows the second attempt, following a different methodlogy.

Here I am cutting them out of 2mm aluminium plate....pre-drilled, tapped et al...

Post-cut, and ready for my various fine-tooth files....

Showing how far heatsinks protrude above the pumps, pretty slimline...

And a few other angles, I think it looks pretty decent...

and

and a last one, showing how a stock 60mmx25mm fan sits on the heatsink - just for those who are considering something similar, the fan fits perfectly, even the mounting-holes are aligning 100% -> I will need to get slimline 60mmx10mm fans - they will also be controlled by the TMS-200, but probably overkill.....

More pics later, I need to sleeve pump-cables now....

I think you should go with this fan. http://www.newegg.com/Product/Product.aspx?Item=N82E16835119139 It is rated for 16 or less DB.

Hello Again,

A final Sunday-evening update.

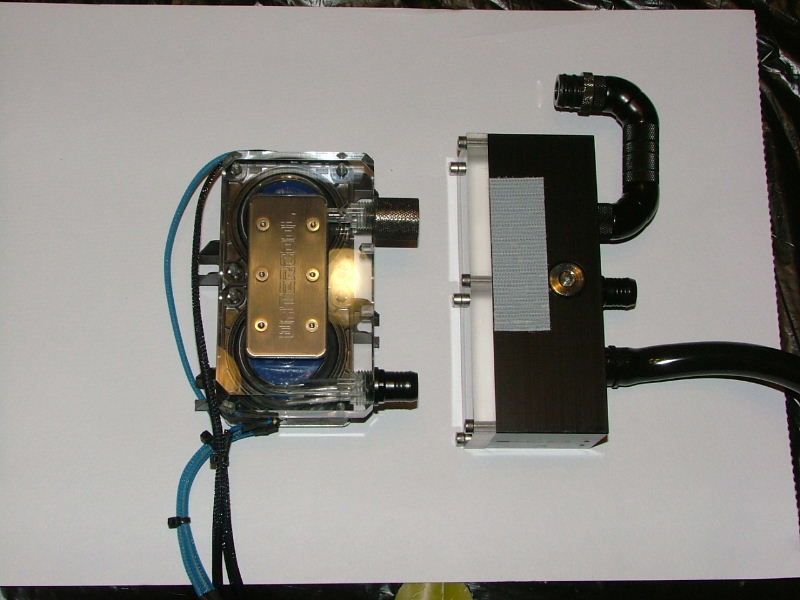

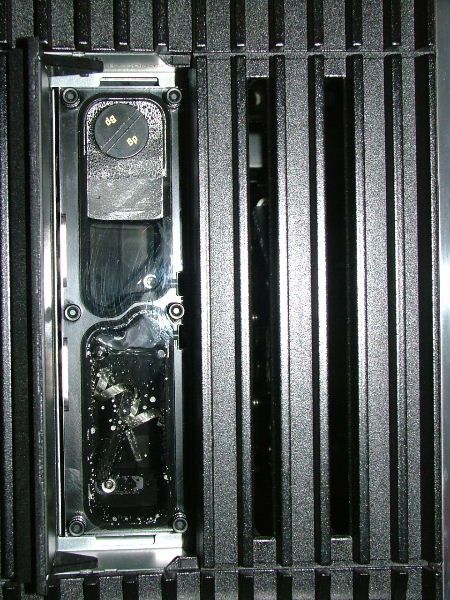

Removed the old pumps, a very decent combo in itself, connected to a Watercool dual-DDC top, and then being fed from a BP 5.25" reservoir - not to bad a setup, but, the new Koolance reservoir with 'integrated pumps' will give me a cleaner solution overall, and simplify routing of tubing.

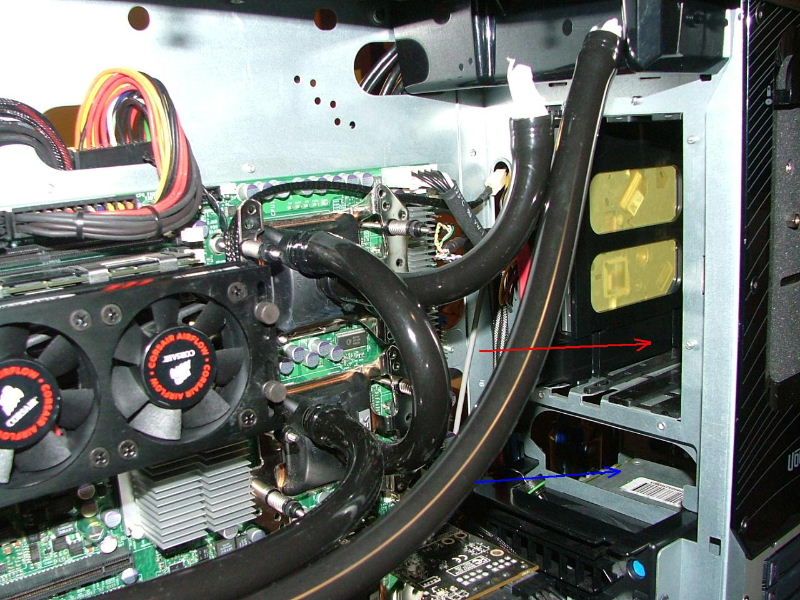

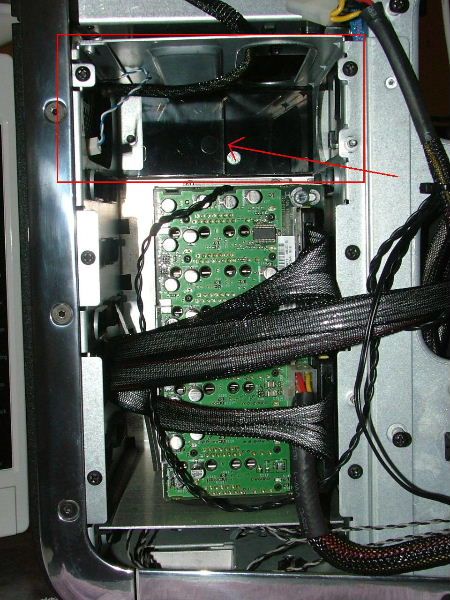

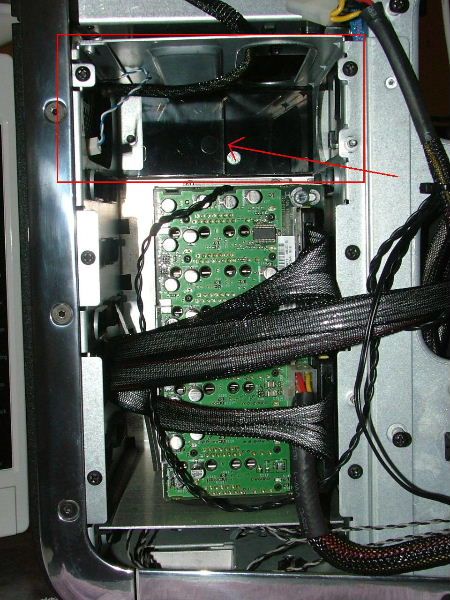

First shot:

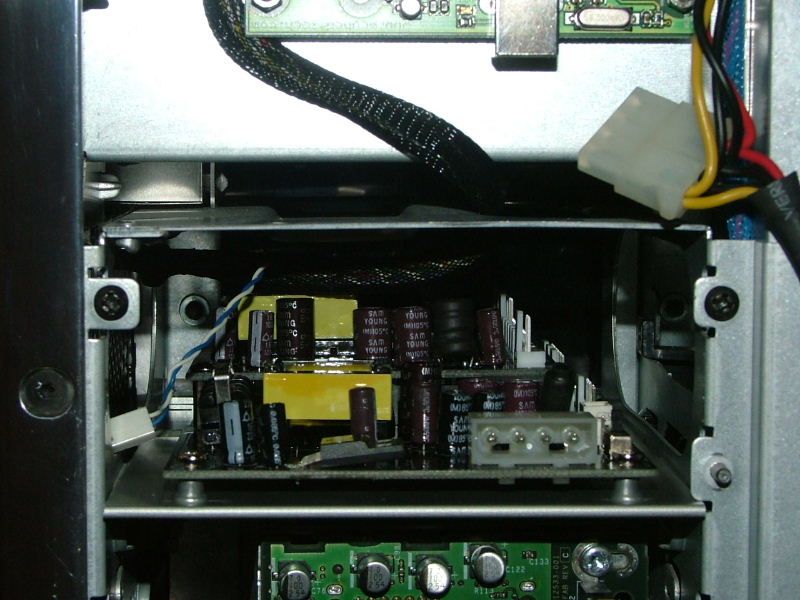

and here a shot of the bottom, showing the decent 'Bei Fei' heatsinks I fitted earlier.

The area indicated by the red arrow was where the old BP reservoir resided, and in blue, where the pumps used to live, immediately above the SAS drive-cage....

As mentioned earlier, the TMS-200 controller will be mounted in this now-vacant pump-space, as I would rather use the slot vacated by the TMS-200 to remount my SCSI VS160 Tape-drive controller....plus, mounting the TMS-200 in the old pump-location, will make for very easy, and tidy routing of fan/temp/flow/pump wiring....

This is where the controller will go:

and here....

well, I had to fab a mounting-base that would slide into the nominated area, fortunately, there are guides on which the old, original HP SATA harddrives used to slide in on - this will now assist locating the new TMS-200 mounting-base....

Here is the setup...

and controller mounted, I used the very handy RivNuts as standoffs, works like a dream....

and

and finally, into postion - I will fab a very small retainer clip to prevent it from sliding out, but, it is a tight-fit, and it cant go anywhere. It may seem like insignificant progress, but, now this controller is in place, I can start to measure all fans/pumps et al wire-lengths, and sleeve and route wiring.

Getting there

A final Sunday-evening update.

Removed the old pumps, a very decent combo in itself, connected to a Watercool dual-DDC top, and then being fed from a BP 5.25" reservoir - not to bad a setup, but, the new Koolance reservoir with 'integrated pumps' will give me a cleaner solution overall, and simplify routing of tubing.

First shot:

and here a shot of the bottom, showing the decent 'Bei Fei' heatsinks I fitted earlier.

The area indicated by the red arrow was where the old BP reservoir resided, and in blue, where the pumps used to live, immediately above the SAS drive-cage....

As mentioned earlier, the TMS-200 controller will be mounted in this now-vacant pump-space, as I would rather use the slot vacated by the TMS-200 to remount my SCSI VS160 Tape-drive controller....plus, mounting the TMS-200 in the old pump-location, will make for very easy, and tidy routing of fan/temp/flow/pump wiring....

This is where the controller will go:

and here....

well, I had to fab a mounting-base that would slide into the nominated area, fortunately, there are guides on which the old, original HP SATA harddrives used to slide in on - this will now assist locating the new TMS-200 mounting-base....

Here is the setup...

and controller mounted, I used the very handy RivNuts as standoffs, works like a dream....

and

and finally, into postion - I will fab a very small retainer clip to prevent it from sliding out, but, it is a tight-fit, and it cant go anywhere. It may seem like insignificant progress, but, now this controller is in place, I can start to measure all fans/pumps et al wire-lengths, and sleeve and route wiring.

Getting there

Last edited:

Thanx Mate, yep, I can hardly wait too

Next tricky bit is to get the new reservoir/pumps into the vertical 5.25" BB's drive-bay - I will need to fab a new face-plate for the reservoir, as the one fitted by Koolance is approximately 1.5mm to tall.....

No biggie, and the reason why I did not mount the pumps on Sunday.

Next tricky bit is to get the new reservoir/pumps into the vertical 5.25" BB's drive-bay - I will need to fab a new face-plate for the reservoir, as the one fitted by Koolance is approximately 1.5mm to tall.....

No biggie, and the reason why I did not mount the pumps on Sunday.

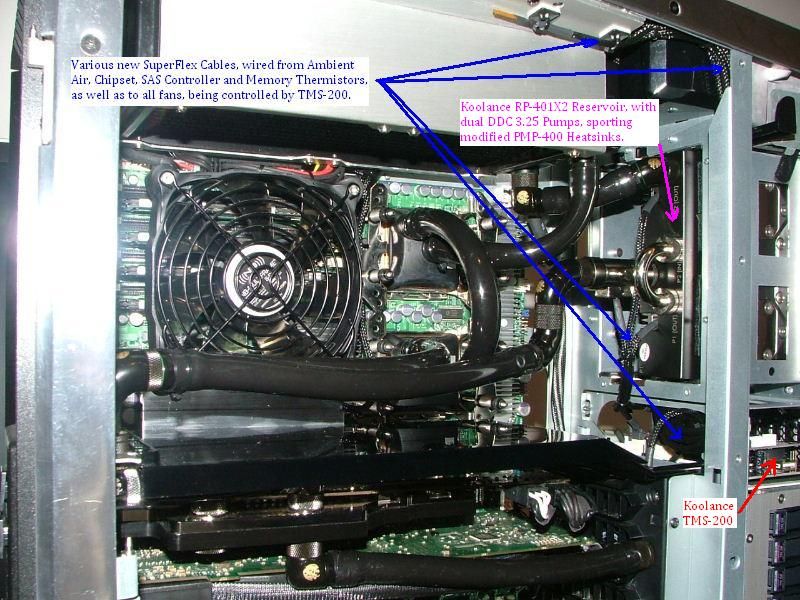

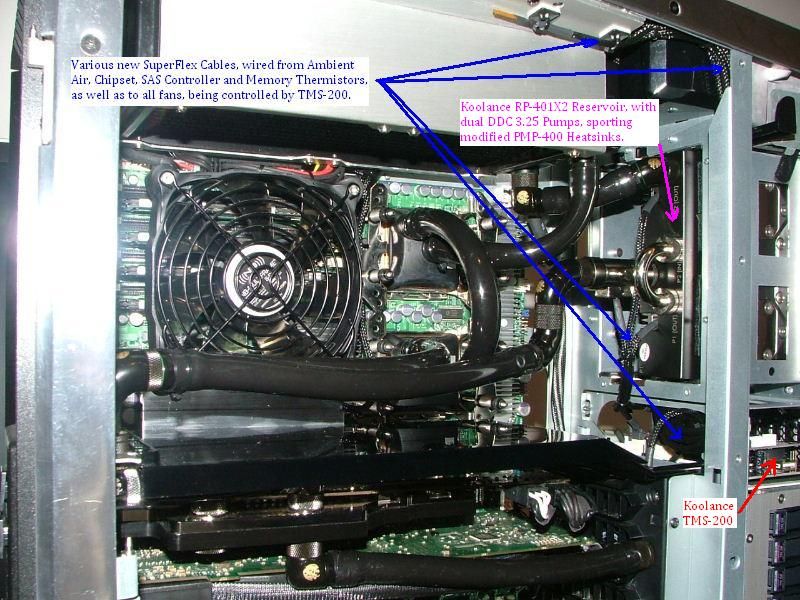

1) Some of my superflex wiring has arrived - the 24AWG for fans etc. Well, I rewired and sleeved the 2x NoiseBlockers on the rad, as well as the drive-bay Noiseblocker. Fitted the fans, and re-mounted the rad, and adjusted cable-lengths and routed wiring to the TMS controller.

2) Sleeved the pumps.

3) Made up 5x new temp sensors for the TMS-200, and routed them to the TMS controller - 1x Chipset, 1x FB-Dimm, 1x SAS Controller, 1x Ambient Air and 1x Water senors.

4) Finally fitted the new res/pump combo, and finalised new tubing runs.

Did water-runs, and yes, the RP-401X2 is not the easiest to prime, but at least in the vertical configuration I have mounted it, a lot easier than the boys with default setups.

All good, and system working again - one big annoyance, the TMS-200 software doesn't start in Server 2008. I hope Tim at Koolance will have the software-boys address this issue, as it's a serious flaw.

Yep, tried the latest V2.30 release from their site....

So, with the inability to configure the sensors, had a very annoying alarm, triggered by the SAS controller temp - saw this once I connected the Controller to my Laptop via USB, and setup the software there, which allowed me to reconfigure all settings for the controller.

IMHO, I think the mCubed bigNG is a much better device, as at first glance, the Koolance doesn't allow you to predefine control-curves, which the bigNG does.

Ah well, will see how this goes, might revert back to the bigNG - just a damn pity the sensors will have to be rewired, as the Koolance uses 100kOhm thermistors, vs the 10kOhm's of the mCubed.

Will post pics later.

2) Sleeved the pumps.

3) Made up 5x new temp sensors for the TMS-200, and routed them to the TMS controller - 1x Chipset, 1x FB-Dimm, 1x SAS Controller, 1x Ambient Air and 1x Water senors.

4) Finally fitted the new res/pump combo, and finalised new tubing runs.

Did water-runs, and yes, the RP-401X2 is not the easiest to prime, but at least in the vertical configuration I have mounted it, a lot easier than the boys with default setups.

All good, and system working again - one big annoyance, the TMS-200 software doesn't start in Server 2008. I hope Tim at Koolance will have the software-boys address this issue, as it's a serious flaw.

Yep, tried the latest V2.30 release from their site....

So, with the inability to configure the sensors, had a very annoying alarm, triggered by the SAS controller temp - saw this once I connected the Controller to my Laptop via USB, and setup the software there, which allowed me to reconfigure all settings for the controller.

IMHO, I think the mCubed bigNG is a much better device, as at first glance, the Koolance doesn't allow you to predefine control-curves, which the bigNG does.

Ah well, will see how this goes, might revert back to the bigNG - just a damn pity the sensors will have to be rewired, as the Koolance uses 100kOhm thermistors, vs the 10kOhm's of the mCubed.

Will post pics later.

Ok, a few pictures of yesterdays work.

I will not bore you with countless photos of sleeving, wiring et al, just a few quick ones.

Some of my 'spaghetti Noodle' wires have arrived, and, the most important one just in time for the weekend -> the 24AWG Superflexible Silicone, which will do the fans, sensors et al. Let me start of by saying that this 'Turnigy' brand is an absolute pleasure to work with, easy to strip, easy to crimp onto the correct Molex lugs, and pretty easy to sleeve. The end-result was fantabulous, soft, easy to route, et al.

Of course, I had to measure exact lengths, and re-wire all my fans, all the TMS-200 100kOhm temp sensors, et al. Here are a few shots of the temp-sensors, with original 'hard' wiring next to the prepped noodles......

and here are 3x temp-sensors ready to go, these ones will be for the FB-Dimm-, Chipset- and SAS Controller temperatures.

I don't have any photos of work done on the fans, I had to totally strip them, remove pcb, resolder et al - I have one more to do, and I will take plenty pics to show those uncertain how to rewire a NoiseBlocker Fan Next few days I will get to that....

Next few days I will get to that....

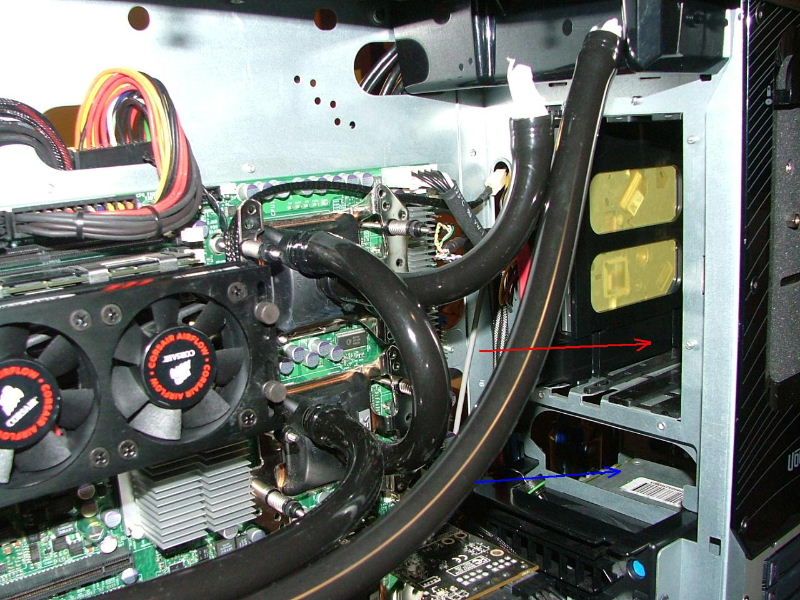

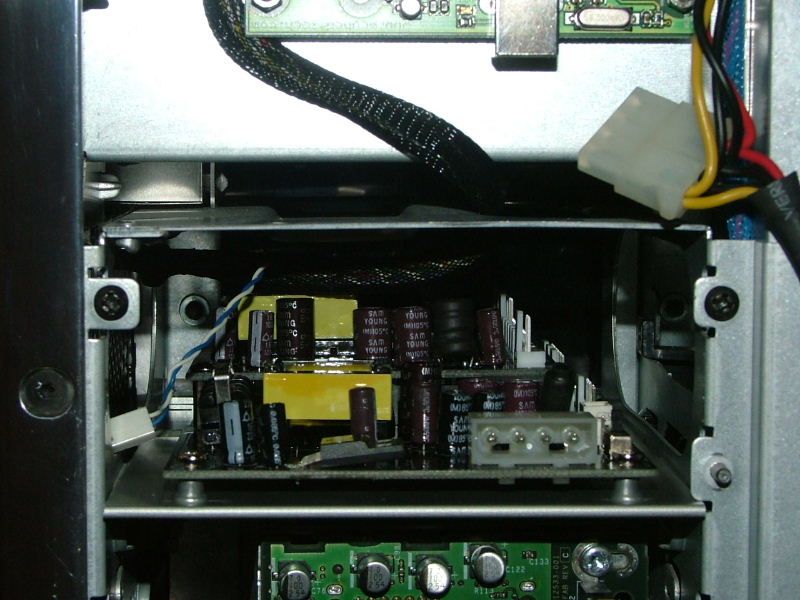

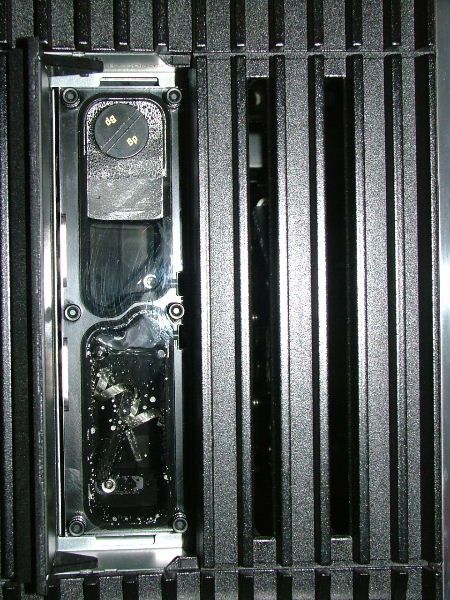

Here is one shot of the shortened wires, sleeved and ready to go, on the 2x DDC3.25's on the Koolance RP-401X2 reservoir - remember, the pumps/reservoir will be mounted vertically, directly above the TMS-200 controller, which is located where the previous dual-pump setup use to live, in the space just above the SAS drive-cage.

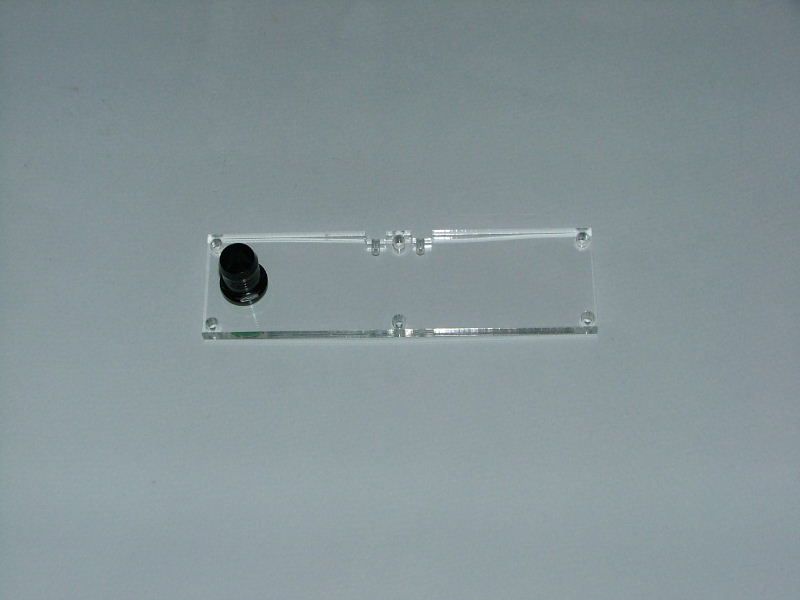

Then, as mentioned a few days ago, the RP-401X2 comes with an aluminium bezel, which is slightly wider than the plexi-window on the front of the reservoir - similar to how the bezel of say, a ROM drive is wider than the metal body of the drive. What this means is, that, you cannot fit the reservoir from inside the case, pushing from the back of the 5.25" drive-bay, to the front.....

You have to push it through from the front -> this I could not do, as I have already fitted the Koolance heatsinks to the pumps, and there is no way you can mount these after installing the reservoir in the case, it has to be done prior - like I did.

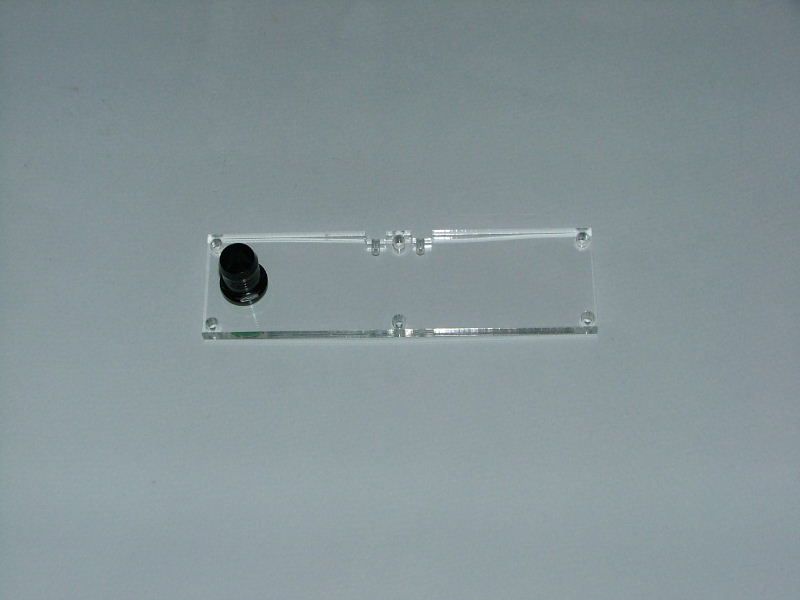

So, a catch 22, as I could not get my reservoir in place. Oh well, that's why we are modders -> so, I removed the aluminium bezel from the front, and no, I did not do the unthinkable, by filing away, as I may want to resuse this later, who knows. So, I left it off, and while I was at that, I modded the plexi front window to become a fill-port -> this will be hidden behind the ROM cover in the front of the BB case, it has a little access door there....

Because my reservoir is mounted vertical, and no easy way to access the original fill-ports machined by Koolance, I did my own. Much easier, and actually, a lot better than the original, at least for my application -- plus, the pumps prime a lot easier than if the reservoir was installed in the intended orientation. Of course, I had the correct 1/4" BSP TAP too, so it made life easy. Enough talk, this is what I did:

and here

and here

giving us the end result, after installation, and in the running system, with BP stop-plug fitted after filling the system, and bleeding

Came pretty nice, I reckon, and a very practical, and neat solution to a major obstacle in getting this reservoir/pump combo to work. Yes, the plexi is thick enough, doesn't need the aluminium support, I firmly believe it was added for aesthetics only. Not needed in my case, pun intended.

Anyway, all the fans and temp-sensors wiring are now running immediately above in front of the radiator, close to the roof of the case. It cleaned out the back of the motherboard tray a lot, and this is where I will run the PSU cables soon.

Please do not look at the temporary fan, cooling the ram/chipset, and the unsleeved Koolance FMS-18 flowmeter cables, this will be fixed/routed soon. Also visible here is the Ambient Air Temp sensor, I will affix it with a proper holder. But, it is working anyhow

And a quick shot showing the new tubing-routing to the reservoir/rad, as well as the new Flowmeter. Again, ignore cables hanging loose, those unsleeved ones, et al - all in good time - this is merely to show new tubing-routing exercise....

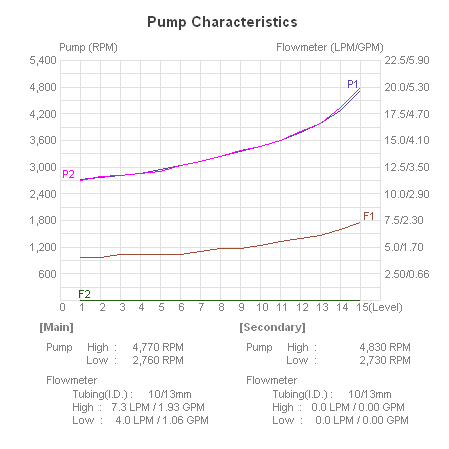

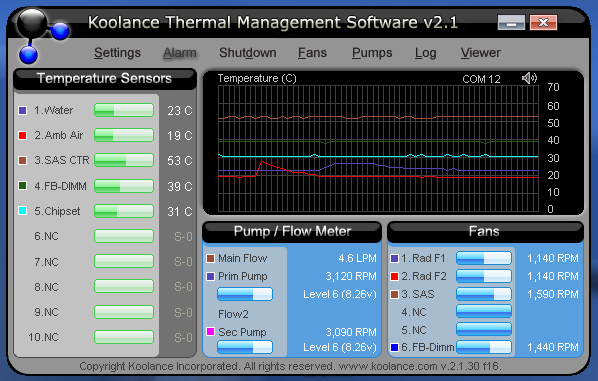

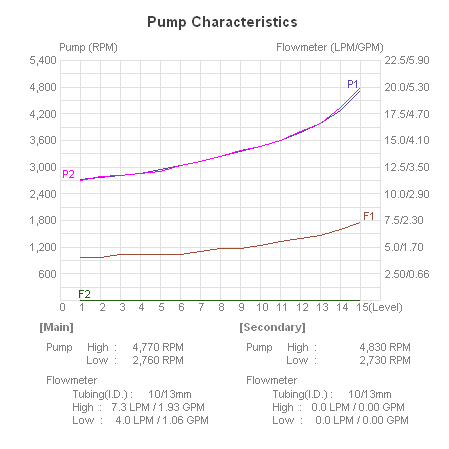

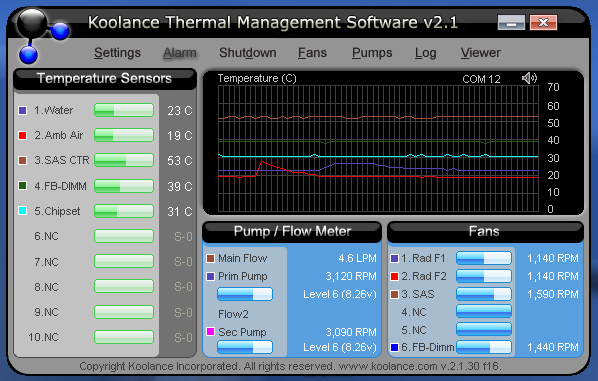

And here, proof that the setup is working -> ok, a little trick here, as the TMS-200m software is not running on myBlackbird OS, Server 2008 - so I have the controller connected to my laptop, via USB, to do the setup, as it is running WinXP. I hope Koolance will fix this issue soon. Nevertheless, I managed to run a pump-flow test, which adjust from highest to lowest RPM, and measures flow via TMS-18 flowmeter.

Pretty nice, I can run pump at a quiet level, and still have about 4.5Lpm flow. Lovely.

and a final shot, showing what I have currently connected, and in auto-control......

I will not bore you with countless photos of sleeving, wiring et al, just a few quick ones.

Some of my 'spaghetti Noodle' wires have arrived, and, the most important one just in time for the weekend -> the 24AWG Superflexible Silicone, which will do the fans, sensors et al. Let me start of by saying that this 'Turnigy' brand is an absolute pleasure to work with, easy to strip, easy to crimp onto the correct Molex lugs, and pretty easy to sleeve. The end-result was fantabulous, soft, easy to route, et al.

Of course, I had to measure exact lengths, and re-wire all my fans, all the TMS-200 100kOhm temp sensors, et al. Here are a few shots of the temp-sensors, with original 'hard' wiring next to the prepped noodles......

and here are 3x temp-sensors ready to go, these ones will be for the FB-Dimm-, Chipset- and SAS Controller temperatures.

I don't have any photos of work done on the fans, I had to totally strip them, remove pcb, resolder et al - I have one more to do, and I will take plenty pics to show those uncertain how to rewire a NoiseBlocker Fan

Here is one shot of the shortened wires, sleeved and ready to go, on the 2x DDC3.25's on the Koolance RP-401X2 reservoir - remember, the pumps/reservoir will be mounted vertically, directly above the TMS-200 controller, which is located where the previous dual-pump setup use to live, in the space just above the SAS drive-cage.

Then, as mentioned a few days ago, the RP-401X2 comes with an aluminium bezel, which is slightly wider than the plexi-window on the front of the reservoir - similar to how the bezel of say, a ROM drive is wider than the metal body of the drive. What this means is, that, you cannot fit the reservoir from inside the case, pushing from the back of the 5.25" drive-bay, to the front.....

You have to push it through from the front -> this I could not do, as I have already fitted the Koolance heatsinks to the pumps, and there is no way you can mount these after installing the reservoir in the case, it has to be done prior - like I did.

So, a catch 22, as I could not get my reservoir in place. Oh well, that's why we are modders -> so, I removed the aluminium bezel from the front, and no, I did not do the unthinkable, by filing away, as I may want to resuse this later, who knows. So, I left it off, and while I was at that, I modded the plexi front window to become a fill-port -> this will be hidden behind the ROM cover in the front of the BB case, it has a little access door there....

Because my reservoir is mounted vertical, and no easy way to access the original fill-ports machined by Koolance, I did my own. Much easier, and actually, a lot better than the original, at least for my application -- plus, the pumps prime a lot easier than if the reservoir was installed in the intended orientation. Of course, I had the correct 1/4" BSP TAP too, so it made life easy. Enough talk, this is what I did:

and here

and here

giving us the end result, after installation, and in the running system, with BP stop-plug fitted after filling the system, and bleeding

Came pretty nice, I reckon, and a very practical, and neat solution to a major obstacle in getting this reservoir/pump combo to work. Yes, the plexi is thick enough, doesn't need the aluminium support, I firmly believe it was added for aesthetics only. Not needed in my case, pun intended.

Anyway, all the fans and temp-sensors wiring are now running immediately above in front of the radiator, close to the roof of the case. It cleaned out the back of the motherboard tray a lot, and this is where I will run the PSU cables soon.

Please do not look at the temporary fan, cooling the ram/chipset, and the unsleeved Koolance FMS-18 flowmeter cables, this will be fixed/routed soon. Also visible here is the Ambient Air Temp sensor, I will affix it with a proper holder. But, it is working anyhow

And a quick shot showing the new tubing-routing to the reservoir/rad, as well as the new Flowmeter. Again, ignore cables hanging loose, those unsleeved ones, et al - all in good time - this is merely to show new tubing-routing exercise....

And here, proof that the setup is working -> ok, a little trick here, as the TMS-200m software is not running on myBlackbird OS, Server 2008 - so I have the controller connected to my laptop, via USB, to do the setup, as it is running WinXP. I hope Koolance will fix this issue soon. Nevertheless, I managed to run a pump-flow test, which adjust from highest to lowest RPM, and measures flow via TMS-18 flowmeter.

Pretty nice, I can run pump at a quiet level, and still have about 4.5Lpm flow. Lovely.

and a final shot, showing what I have currently connected, and in auto-control......

Hello Everyone,

Ok, some real progress this last few nights, not to much, but the end is in sight

On normal systems, running any DDR3 Ram, memory coolers are a waste, and not needed - waterblocks, like for example the MIPS, are added for aesthetics only.

Running FB-DIMMS though, is a totally different kettle of fish -> this memory uses an AMB chip - Advanced Memroy Buffer,controlling data-flow in/out the various ram-chips on any specific FB-DIMM. These boys get real toasty, and even on servers, with some good airflow, it is not uncommon to see them at 70-85 deg C.

With that in mind, I decided to use a nice big 120mm fan to cool my FB-DIMMs as well as 5400 Chipset. Two birds with one stone, so to speak.

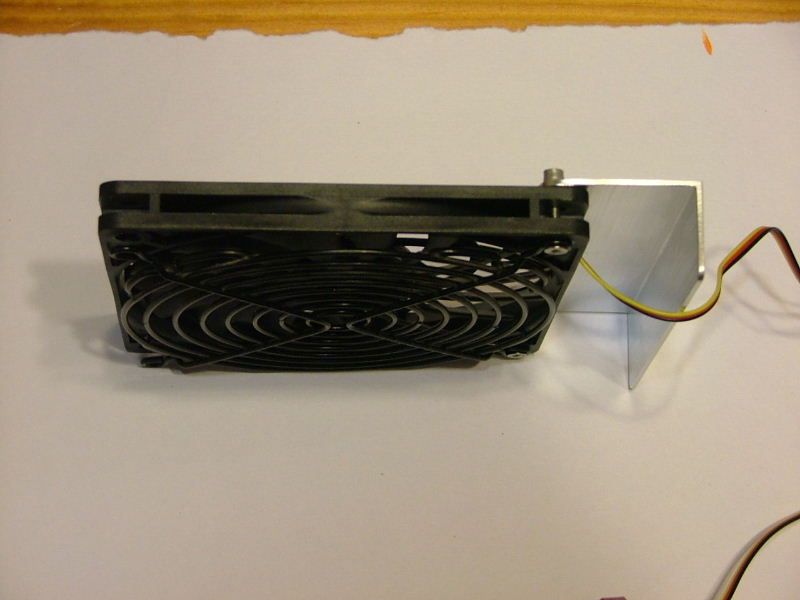

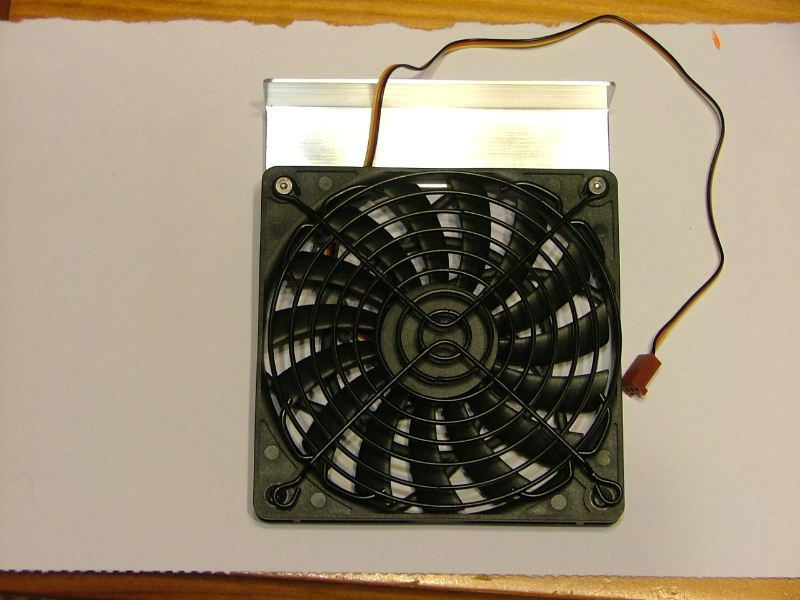

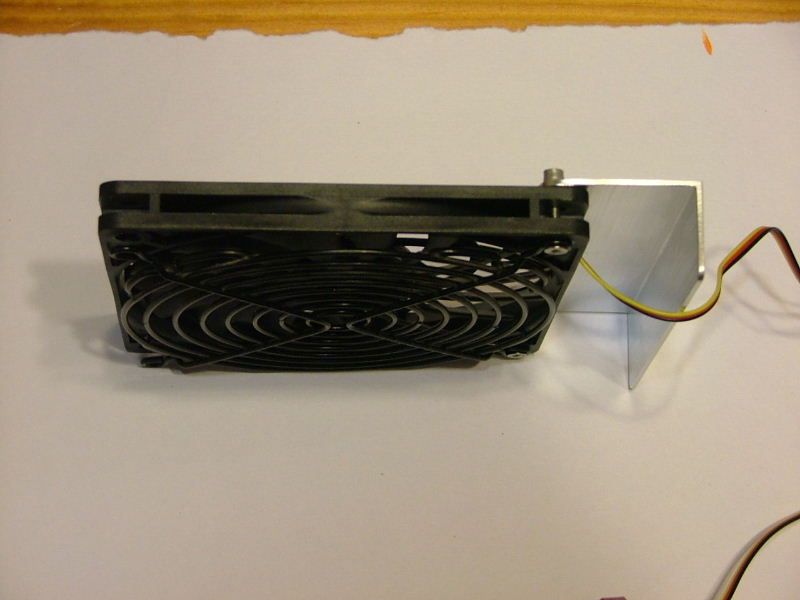

So I grabbed some angled aluminium, and hacked at it for a while, followed buy some filing, and a bit of TLC, and I came up with this:

A while back I decided the ideal fan for this would be the 120mmx10mm Scythe Slipstream.....

and

Well, fitted all together, mounted it in the PC, and set TMS-200 to 100% for that channel. All good, fan is working as expected. But, these specific fans don't at all like the TMS-200 PWM output, as soon as you switch to auto-control, and output drops to below 80%, the fan simply stops.

That won't work, damn.

Ah well, I still had 1x NoiseBlocker multi-frame, and this is anyway a better fan, much better flow/pressure than the Scythe Slimline.

Of course, I rewired all the new fans, thermistors et al with the Superflex Silicone 24AWG wire, and this fan was no exception. Just 2 photos to show what this entails, should you wish to try it....

and totally naked....

I desoldered the old wires, solderd in new ones, assembled, and sleeved, mounted to the system etc.....with this result....

and another one

and another

Starting to look real fresh and clean, this all for a dual Xeon, and 5970 ATI, all watercooled.....of course, don't forget the 8x SAS drives, TMDS-200 controller, 5 thermistors, 4x 120mm fans.....so, not to bad

Here's another shot with some text to highlight where I've routed the Superflex cables for the fans/thermistors, and also pointing which wiring you should ignore for now - I still need to rewire the PSU, so those cables will be cleaned up.

Comments welcome.

Ok, some real progress this last few nights, not to much, but the end is in sight

On normal systems, running any DDR3 Ram, memory coolers are a waste, and not needed - waterblocks, like for example the MIPS, are added for aesthetics only.

Running FB-DIMMS though, is a totally different kettle of fish -> this memory uses an AMB chip - Advanced Memroy Buffer,controlling data-flow in/out the various ram-chips on any specific FB-DIMM. These boys get real toasty, and even on servers, with some good airflow, it is not uncommon to see them at 70-85 deg C.

With that in mind, I decided to use a nice big 120mm fan to cool my FB-DIMMs as well as 5400 Chipset. Two birds with one stone, so to speak.

So I grabbed some angled aluminium, and hacked at it for a while, followed buy some filing, and a bit of TLC, and I came up with this:

A while back I decided the ideal fan for this would be the 120mmx10mm Scythe Slipstream.....

and

Well, fitted all together, mounted it in the PC, and set TMS-200 to 100% for that channel. All good, fan is working as expected. But, these specific fans don't at all like the TMS-200 PWM output, as soon as you switch to auto-control, and output drops to below 80%, the fan simply stops.

That won't work, damn.

Ah well, I still had 1x NoiseBlocker multi-frame, and this is anyway a better fan, much better flow/pressure than the Scythe Slimline.

Of course, I rewired all the new fans, thermistors et al with the Superflex Silicone 24AWG wire, and this fan was no exception. Just 2 photos to show what this entails, should you wish to try it....

and totally naked....

I desoldered the old wires, solderd in new ones, assembled, and sleeved, mounted to the system etc.....with this result....

and another one

and another

Starting to look real fresh and clean, this all for a dual Xeon, and 5970 ATI, all watercooled.....of course, don't forget the 8x SAS drives, TMDS-200 controller, 5 thermistors, 4x 120mm fans.....so, not to bad

Here's another shot with some text to highlight where I've routed the Superflex cables for the fans/thermistors, and also pointing which wiring you should ignore for now - I still need to rewire the PSU, so those cables will be cleaned up.

Comments welcome.

zer0gravity

[H]ard|Gawd

- Joined

- Dec 8, 2008

- Messages

- 1,131

Looks so good! Take some pics of the full setup / case and desk when all done!

Heya Mate,

Thanx for the feedback, appreciated

Yes, I am using the very good Feser 240mm rad, and currently running NoiseBlockers on it. Rad has been performing very well during the past 2 years on this particular setup, right through the infamously hot Melbourne summers too, where ambient can reach 47 deg C.

So, overall, doing an excellent job

Thanx for the feedback, appreciated

Yes, I am using the very good Feser 240mm rad, and currently running NoiseBlockers on it. Rad has been performing very well during the past 2 years on this particular setup, right through the infamously hot Melbourne summers too, where ambient can reach 47 deg C.

So, overall, doing an excellent job

As an eBay Associate, HardForum may earn from qualifying purchases.

zer0gravity

[H]ard|Gawd

- Joined

- Dec 8, 2008

- Messages

- 1,131

i would like some pics of it finished

Heya Mate,

We're packing up, getting ready to move into our own newly build house end of November, so it will be a while before I will post picks of the finished desk et al.

Would look pretty good, I would think, and finally I will have a decent place for my Nixim frame too

Will keep you posted, currently modding a Wade-8011 mini-itx server board into a PQ-08, complete with Xeon E3-1245, and, wait for it....a 8x HP 2.5" SAS cage, same as used in BB.

Will open a log within the next few days....looking forward having a low-power(ful) home-server...yeay!

We're packing up, getting ready to move into our own newly build house end of November, so it will be a while before I will post picks of the finished desk et al.

Would look pretty good, I would think, and finally I will have a decent place for my Nixim frame too

Will keep you posted, currently modding a Wade-8011 mini-itx server board into a PQ-08, complete with Xeon E3-1245, and, wait for it....a 8x HP 2.5" SAS cage, same as used in BB.

Will open a log within the next few days....looking forward having a low-power(ful) home-server...yeay!

Last edited:

Matthew Kane

Supreme [H]ardness

- Joined

- Dec 1, 2007

- Messages

- 4,233

Man this is nuts and great so see you modding this beast a year later. I would hate to think of the total cost spent if I was in your shoes.

Ah, ta Mate.

The hardware is getting a bit dated, but, to be honest, if you choose/pick well, it will serve you for years to come.

I so like this system, I just cannot get it over ny heart to get newer motherboard et al. If I do make that move in the next year or 2, it surely will be another SuperMicro board, and associated components.

But, the way this sytem is behaving, well, as I said, I just cannot justify it. Simply bulletproof, and so overkill, even for this process-simulator/gaming platform, and whatever else I can chuck at it

The hardware is getting a bit dated, but, to be honest, if you choose/pick well, it will serve you for years to come.

I so like this system, I just cannot get it over ny heart to get newer motherboard et al. If I do make that move in the next year or 2, it surely will be another SuperMicro board, and associated components.

But, the way this sytem is behaving, well, as I said, I just cannot justify it. Simply bulletproof, and so overkill, even for this process-simulator/gaming platform, and whatever else I can chuck at it

Hello Guys,

Happy Festive Season to everyone, hope you're all enjoying it.

Not so much an update, as much as putting my thoughts together on where to go with this mod.

A while ago, I got the (pretty decent) TMS-200 from Koolance - for those that don't know, the TMS-200 is simlar to the Aquaero5/mCubed bigNG, where you can install a few temp sensors, and fans, and use curves/graphs/setpoints to automatically control said fans and/or pump(s) to specific measured variables or manual setpoints, or a combination of both.

The problem is, I am running Windows 2008 R2 on this setup, which is a must for the process simulator I have installed on here, and, the TMS-200 doesn't run under Server 2008 R2 I only realised this after I have installed it, made up cables, rewired temp-sensors, et al.

I only realised this after I have installed it, made up cables, rewired temp-sensors, et al.

It would have been pretty easy to dump this, and refit an Aquaero5, for example, the only problem is the TMS-200 doesn't use std thermistors - only the later TMS-205 use the same ones as the bigNG and Aquaero5. So it means I will have to replace all custom thermistors-, fans- and pumps cables with new ones....a pretty time-consuming exercise, considering these were all made up of Turnigy silicone wire.

So, to cut a long story short, I need to do something - the system is supposed to be on auto-control, but cannot make changes if the OS is not running the GUI/USB connection is not present.

This in my opinion is a very lame effort by Koolance (sorry boys, had to say it), as one would expect that once you update parameters to the TMS-200, and disconnect the USB cable from the host system, it would function autonomously. Coming from a process-control background, this is essential.

Second issue is your lack of support for Server 2008, and unwillingness to rectify the situation, and paying what we do for these devices, well, let's just say it falls way short from realistic expectations, and designers/manufacturers in this watercooling world gets away with murder.

So, anyway, realising Server 2008 R2 won't allow this software to run -> I have decided on a different tact.

I have left over from my carputer projects, a very nice and small 3.5" Commell LS-373 SBC, sporting 2GB Ram, and running a very powerful (Mac) E8435 @ 3.06Ghz Core2Duo processor.

This little board is the size of a 3.5" harddrive, and blazingly fast. With it, there is also an OCZ Agility 2 40GB SSD, and combined, this will form the basis of a 2nd small computer, hosting the GUI and USB interface to the TMS-200.

I also have left over a very nifty Xenarc 7" Touchscreen TFT LCD. So, you can see where I am going with this.....

I was hoping to get my hands on a Kontron pITX-SP Atom-based board, which will be better for this application, as this particular 3.5" SBC setup is waaayyy overkill, but, such is life.

So, in the next few weeks, I will be manufacturing a new internal hinged side-panel, to replace the existing plastic one in place just above the PSU cover - this panel will be made of a regular aluminium heatsink, and I will bolt the 3.5" SBC, with 7" LCD, directly to it from behind.

I have designed (and a friend CNC'ed) a lovely heatblock, covering both the NB and CPU, and will use some of my Coolermaster Heatpipes to connect this to the aluminium heatsink.

Will work really well, passively cooled, touchscreen LCD, and the only connections to the main rig will be a 12V DC line, as well as the USB connection back to the TMS-200.

Of course, the touchscreen will be the input device on this...

I will design the new side-cover in AutoCAD, and post a rendering here in the next couple of days.

Soz for the long post, without pics, but excited enough to at least share my ideas

Take care, and talk soon.

Happy Festive Season to everyone, hope you're all enjoying it.

Not so much an update, as much as putting my thoughts together on where to go with this mod.

A while ago, I got the (pretty decent) TMS-200 from Koolance - for those that don't know, the TMS-200 is simlar to the Aquaero5/mCubed bigNG, where you can install a few temp sensors, and fans, and use curves/graphs/setpoints to automatically control said fans and/or pump(s) to specific measured variables or manual setpoints, or a combination of both.

The problem is, I am running Windows 2008 R2 on this setup, which is a must for the process simulator I have installed on here, and, the TMS-200 doesn't run under Server 2008 R2

It would have been pretty easy to dump this, and refit an Aquaero5, for example, the only problem is the TMS-200 doesn't use std thermistors - only the later TMS-205 use the same ones as the bigNG and Aquaero5. So it means I will have to replace all custom thermistors-, fans- and pumps cables with new ones....a pretty time-consuming exercise, considering these were all made up of Turnigy silicone wire.

So, to cut a long story short, I need to do something - the system is supposed to be on auto-control, but cannot make changes if the OS is not running the GUI/USB connection is not present.

This in my opinion is a very lame effort by Koolance (sorry boys, had to say it), as one would expect that once you update parameters to the TMS-200, and disconnect the USB cable from the host system, it would function autonomously. Coming from a process-control background, this is essential.

Second issue is your lack of support for Server 2008, and unwillingness to rectify the situation, and paying what we do for these devices, well, let's just say it falls way short from realistic expectations, and designers/manufacturers in this watercooling world gets away with murder.

So, anyway, realising Server 2008 R2 won't allow this software to run -> I have decided on a different tact.

I have left over from my carputer projects, a very nice and small 3.5" Commell LS-373 SBC, sporting 2GB Ram, and running a very powerful (Mac) E8435 @ 3.06Ghz Core2Duo processor.

This little board is the size of a 3.5" harddrive, and blazingly fast. With it, there is also an OCZ Agility 2 40GB SSD, and combined, this will form the basis of a 2nd small computer, hosting the GUI and USB interface to the TMS-200.

I also have left over a very nifty Xenarc 7" Touchscreen TFT LCD. So, you can see where I am going with this.....

I was hoping to get my hands on a Kontron pITX-SP Atom-based board, which will be better for this application, as this particular 3.5" SBC setup is waaayyy overkill, but, such is life.

So, in the next few weeks, I will be manufacturing a new internal hinged side-panel, to replace the existing plastic one in place just above the PSU cover - this panel will be made of a regular aluminium heatsink, and I will bolt the 3.5" SBC, with 7" LCD, directly to it from behind.

I have designed (and a friend CNC'ed) a lovely heatblock, covering both the NB and CPU, and will use some of my Coolermaster Heatpipes to connect this to the aluminium heatsink.

Will work really well, passively cooled, touchscreen LCD, and the only connections to the main rig will be a 12V DC line, as well as the USB connection back to the TMS-200.

Of course, the touchscreen will be the input device on this...

I will design the new side-cover in AutoCAD, and post a rendering here in the next couple of days.

Soz for the long post, without pics, but excited enough to at least share my ideas

Take care, and talk soon.

zer0gravity

[H]ard|Gawd

- Joined

- Dec 8, 2008

- Messages

- 1,131

Hope to see some work soon

omegatotal

Gawd

- Joined

- Mar 15, 2002

- Messages

- 672

you could always use a VM running winxp and just pass the usb connection to the guest... or if the usb connection actually shows up as a usb to serial just pass the serial port to the guest..

however the secondary pc idea is kinda cool because that could run even when/if the main machine needs to get powered off because of an alarm condition :-P

however the secondary pc idea is kinda cool because that could run even when/if the main machine needs to get powered off because of an alarm condition :-P

Thanx for your feedback, and ideas, Guys, appreciated!

So, I am not getting any positive reply wrt Server 2008 R2 support for the Aquaero LT, neither was it confirmed that LT Master-slave-mode, which was touted more than a year ago, is supported - so, what to do?

I am really tired of forking out monies for devices that are dumped on the unsuspecting watercooling fraternity, so, until we get a product that is properly supported by it's software, I have to hang onto the Koolance TMS-200 for a while longer.

In all honesty, it is a pretty decent device, the only let-down is its lack of Server 2008 support.

So, as I have intimated a while back, I have a nifty little Xenarc 7" LCD lying about doing nothing, and I decided that I will retrofit this into the existing BB sidepanel.

I was going to use my old trusty 3.5" Commell LS-373 to interface to the TMS-200, and running standard windows 7 on the setup, which would enable proper control and functionality of the TMS-200.

Well, I am pretty impulsive sometimes when it comes to hardware, and last night on Ebay, I grabbed a nice Axiomtek pico820 board for a very decent price - this should arrive during the next week, as it was expedited from Spain.

It will come with a nice 16gb CF card, but I will probably replace that with a 32GB SLC version I have lying around, and trim Windows 7 down with nLite - this will make a nice little stand-alone PC that would control the TMS-200.

Check back for more in a few short weeks

A while ago, I got the (pretty decent) TMS-200 from Koolance - for those that don't know, the TMS-200 is simlar to the Aquaero5/mCubed bigNG, where you can install a few temp sensors, and fans, and use curves/graphs/setpoints to automatically control said fans and/or pump(s) to specific measured variables or manual setpoints, or a combination of both.

The problem is, I am running Windows 2008 R2 on this setup, which is a must for the process simulator I have installed on here, and, the TMS-200 doesn't run under Server 2008 R2 I only realised this after I have installed it, made up cables, rewired temp-sensors, et al.

It would have been pretty easy to dump this, and refit an Aquaero5, for example, the only problem is the TMS-200 doesn't use std thermistors - only the later TMS-205 use the same ones as the bigNG and Aquaero5. So it means I will have to replace all custom thermistors-, fans- and pumps cables with new ones....a pretty time-consuming exercise, considering these were all made up of Turnigy silicone wire.

So, I am not getting any positive reply wrt Server 2008 R2 support for the Aquaero LT, neither was it confirmed that LT Master-slave-mode, which was touted more than a year ago, is supported - so, what to do?

I am really tired of forking out monies for devices that are dumped on the unsuspecting watercooling fraternity, so, until we get a product that is properly supported by it's software, I have to hang onto the Koolance TMS-200 for a while longer.

In all honesty, it is a pretty decent device, the only let-down is its lack of Server 2008 support.

So, as I have intimated a while back, I have a nifty little Xenarc 7" LCD lying about doing nothing, and I decided that I will retrofit this into the existing BB sidepanel.

I was going to use my old trusty 3.5" Commell LS-373 to interface to the TMS-200, and running standard windows 7 on the setup, which would enable proper control and functionality of the TMS-200.

Well, I am pretty impulsive sometimes when it comes to hardware, and last night on Ebay, I grabbed a nice Axiomtek pico820 board for a very decent price - this should arrive during the next week, as it was expedited from Spain.

It will come with a nice 16gb CF card, but I will probably replace that with a 32GB SLC version I have lying around, and trim Windows 7 down with nLite - this will make a nice little stand-alone PC that would control the TMS-200.

Check back for more in a few short weeks

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)