DogsofJune

Supreme [H]ardness

- Joined

- Nov 7, 2008

- Messages

- 4,643

Nice work, thanks for posting sir.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

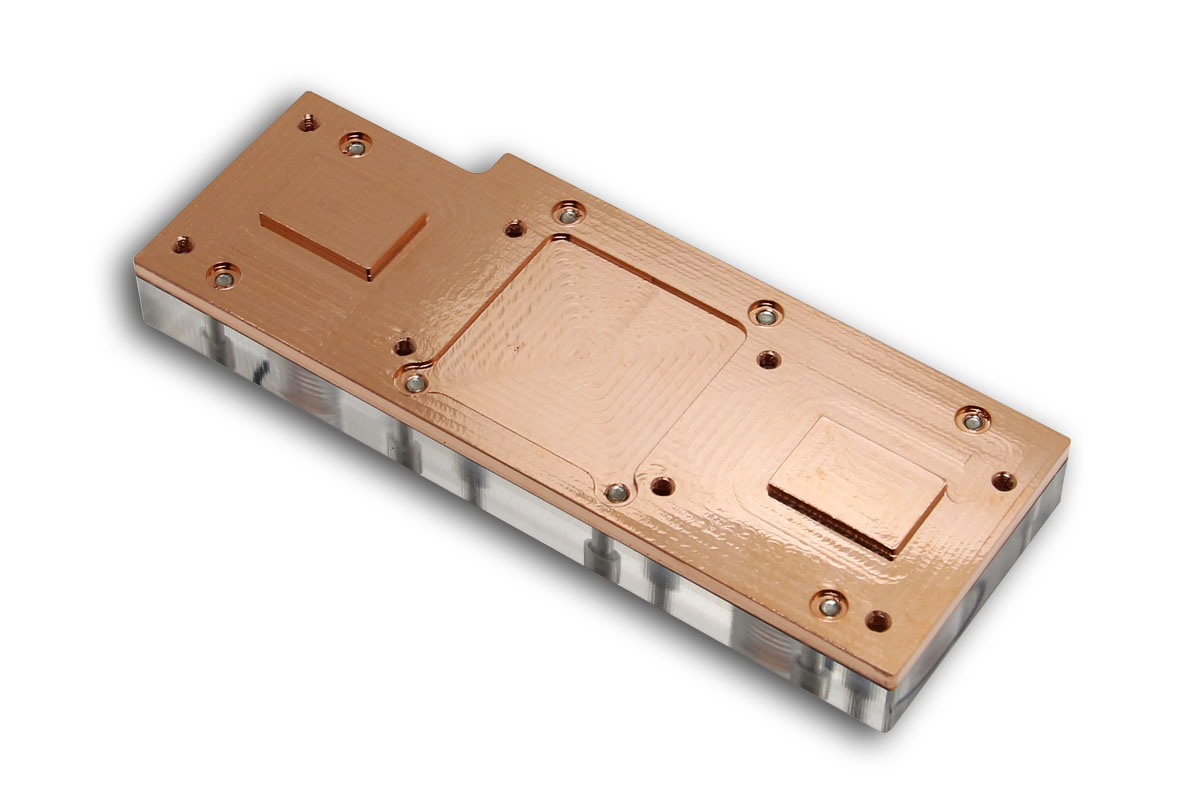

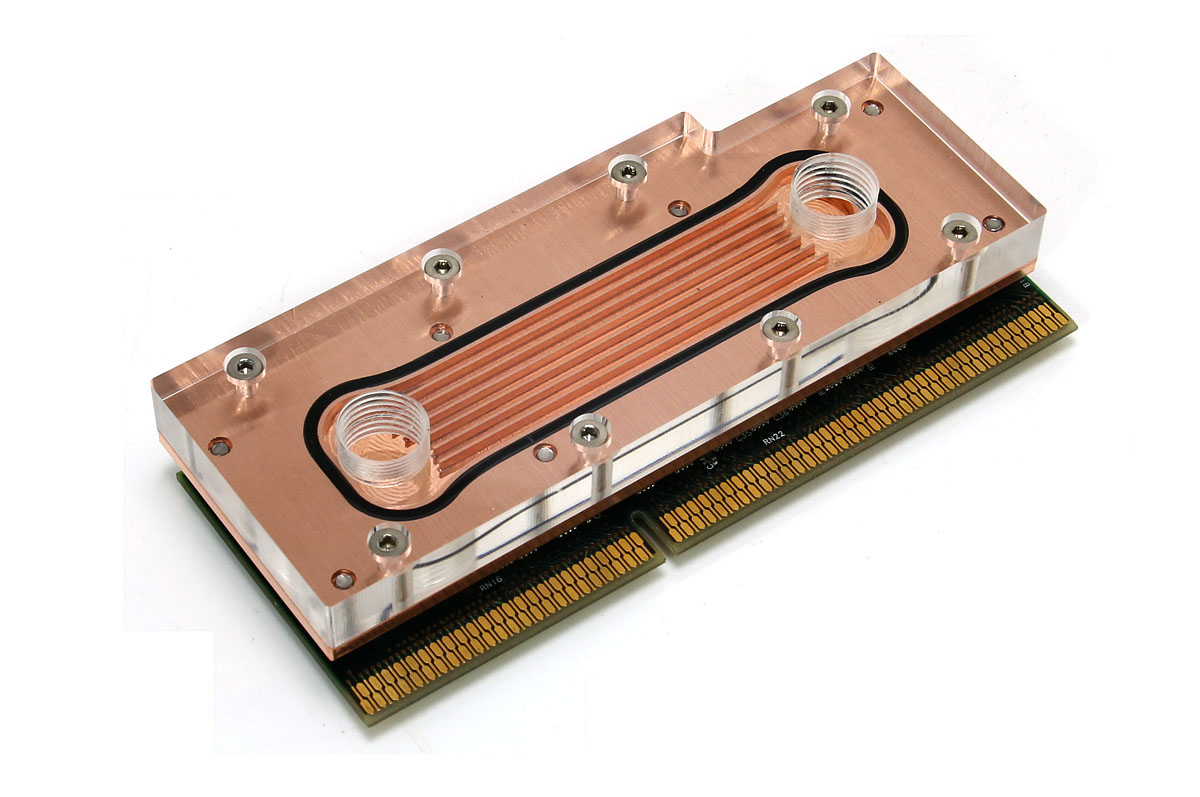

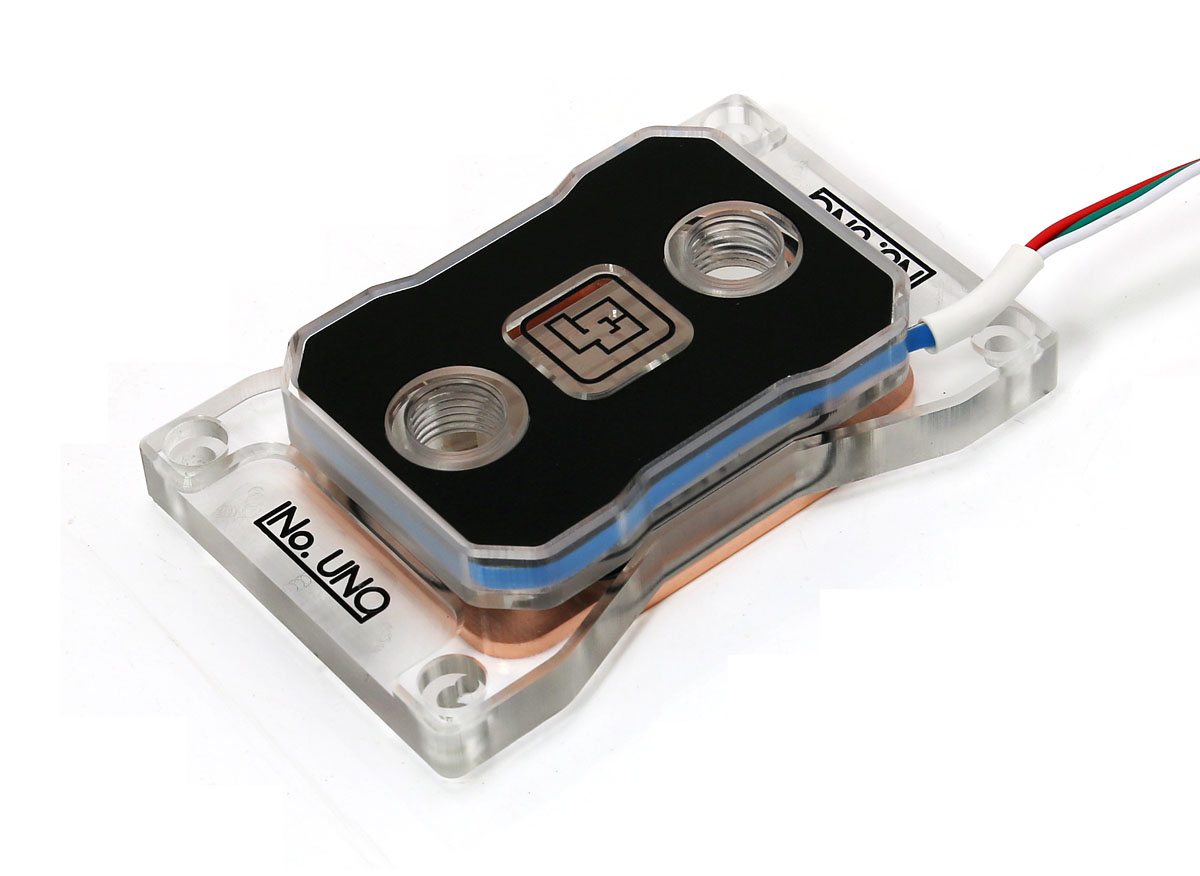

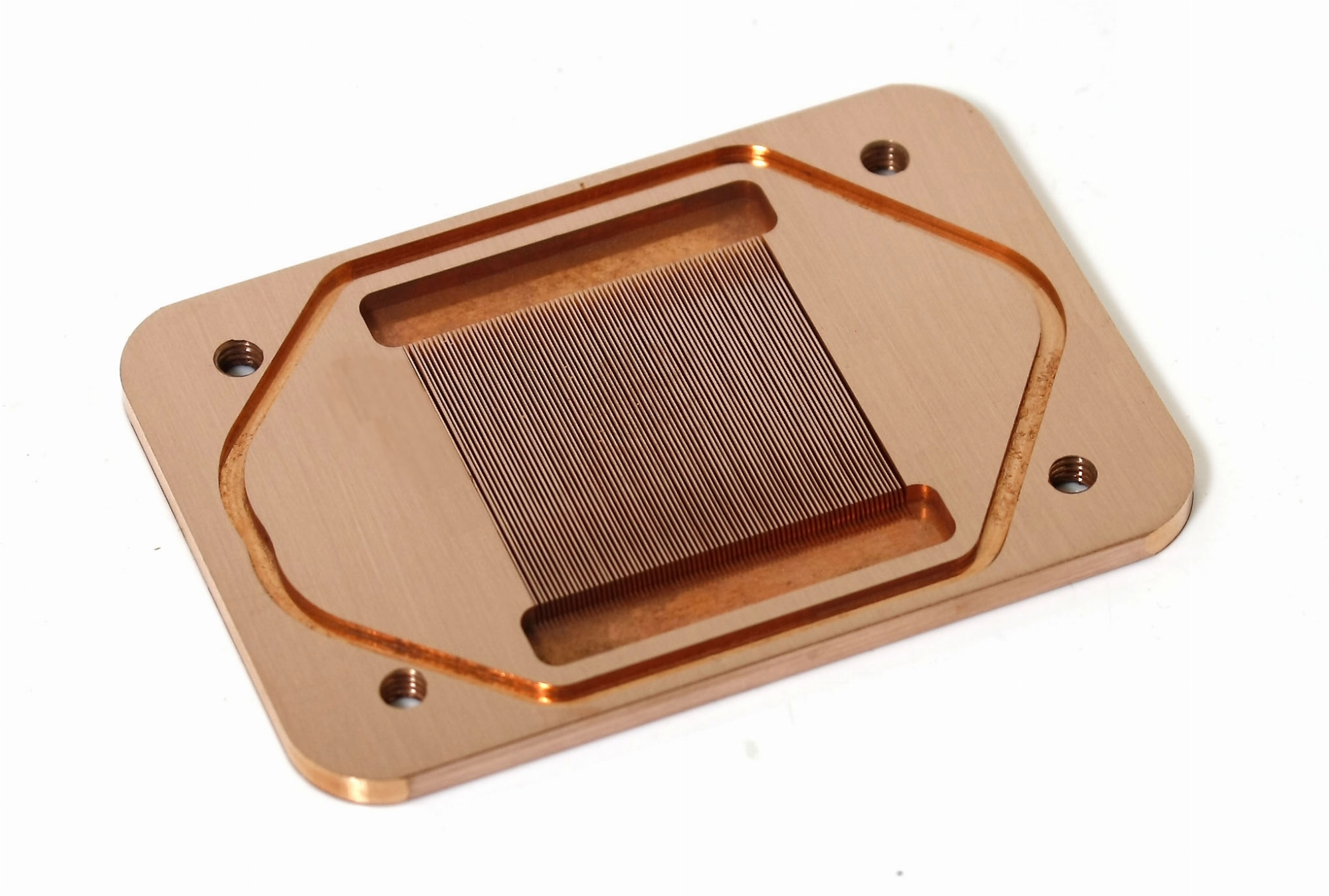

The waterblock will perform much better at a flat IHS. Coz his IHS is concave -> worst case scenario for the waterblock