greensabbath

n00b

- Joined

- Dec 5, 2005

- Messages

- 54

BackGround

You might remember me as the maker of Yuugou and Sangaku pictured below. Well, I'm back with a brand new case, however this time, it is for a customer.

Project Nakamura

I'd like to introduce to you, Project Nakamura. I was approached by a client after the release of Yuugou who was interested in an HTPC type case which turned out to be great since that was where I wanted to take this. He is half Japanese and wanted me to incorporate his family symbol (below) and I've turned it into the main influence of the case lines.

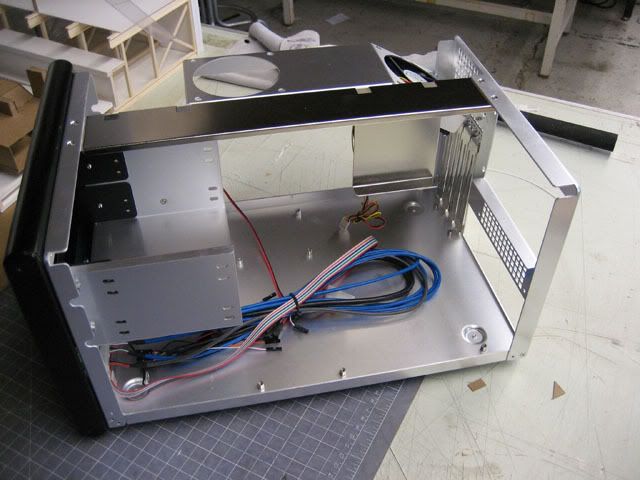

The case I will be using as a base will be the SilverStone SG01 which will serve as beautifully made chassis that will accept a Yuugou-esque frame.

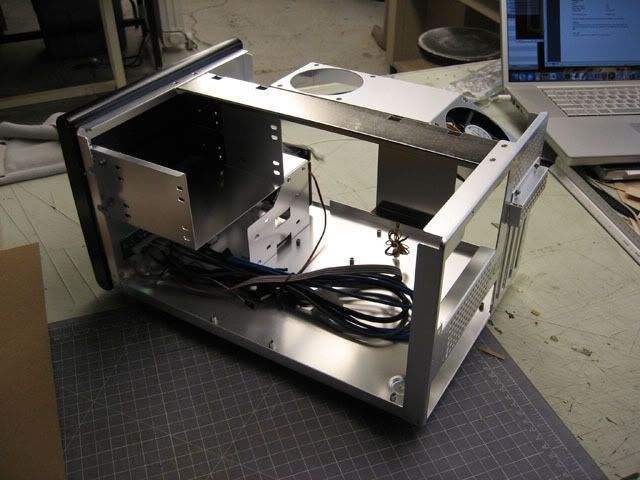

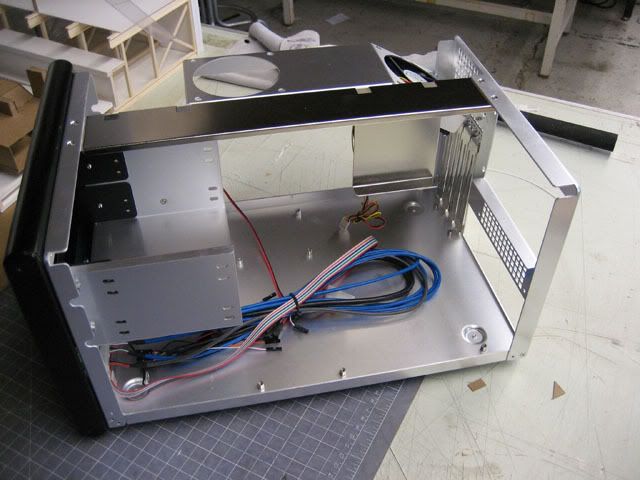

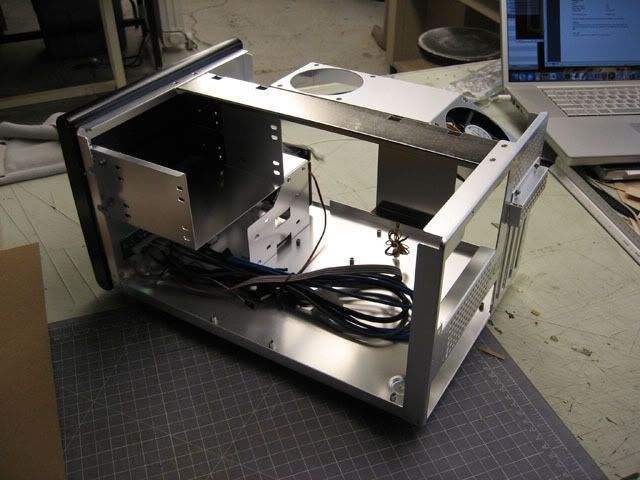

Here are some pictures of the chassis.

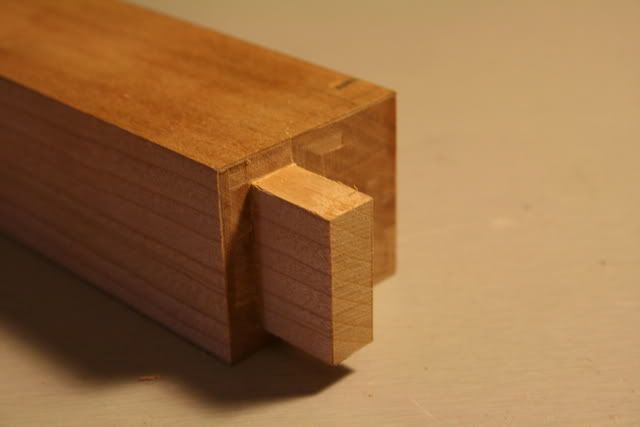

The main woods will be Cherry for the frame and shoji, and Sitka Spruce for the panels.

This old growth spruce has an amazing grain. This piece has over 250 rings alone.

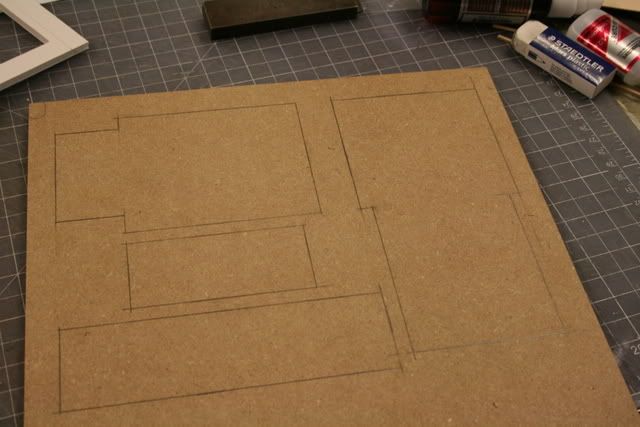

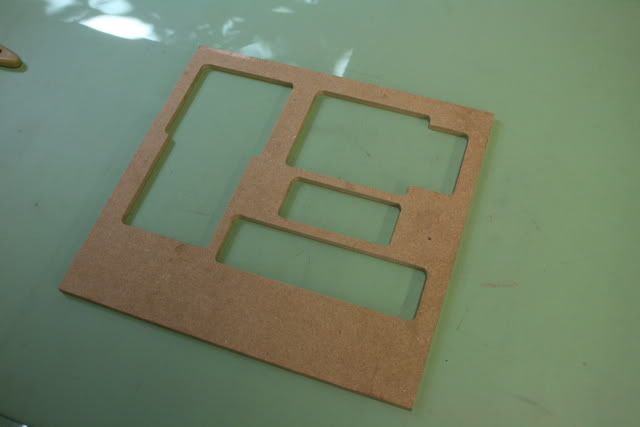

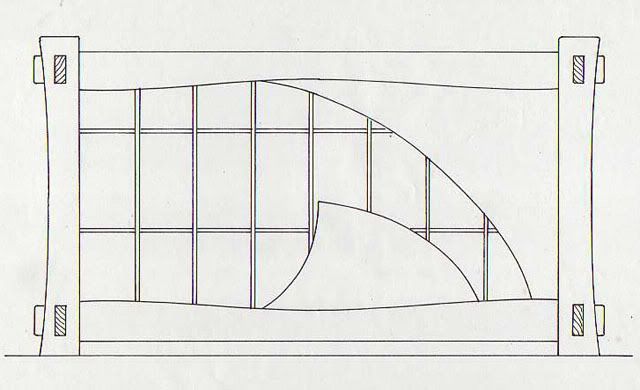

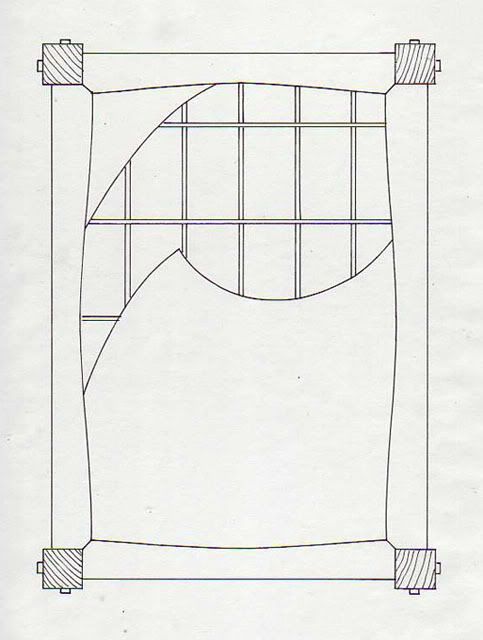

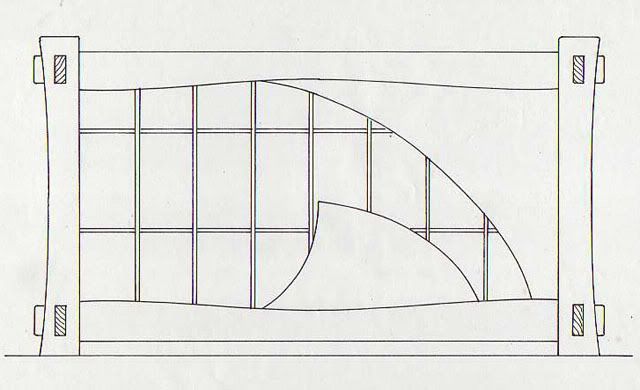

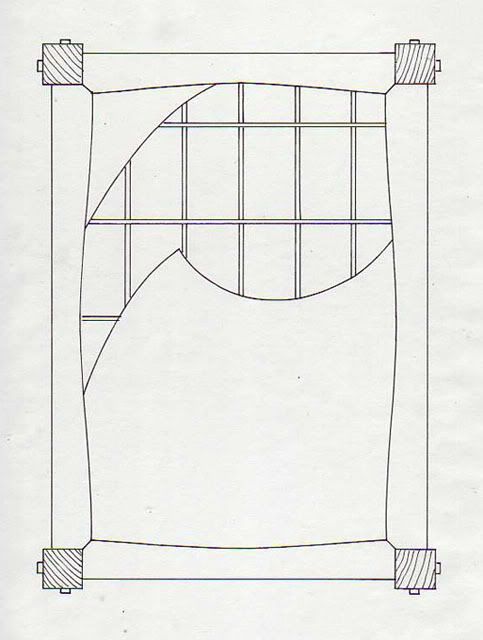

As for the design, the influence of the client's family symbol is evident.

Side View:

Top View:

As always, I'm very much looking forward to sharing this project with you all and your comments and suggestions are much appreiciated. If all goes well, I'll get a good start on the wood this weekend. Stay tuned, this will be a relatively quick project.

Nick (GreenSabbath)

You might remember me as the maker of Yuugou and Sangaku pictured below. Well, I'm back with a brand new case, however this time, it is for a customer.

Project Nakamura

I'd like to introduce to you, Project Nakamura. I was approached by a client after the release of Yuugou who was interested in an HTPC type case which turned out to be great since that was where I wanted to take this. He is half Japanese and wanted me to incorporate his family symbol (below) and I've turned it into the main influence of the case lines.

The case I will be using as a base will be the SilverStone SG01 which will serve as beautifully made chassis that will accept a Yuugou-esque frame.

Here are some pictures of the chassis.

The main woods will be Cherry for the frame and shoji, and Sitka Spruce for the panels.

This old growth spruce has an amazing grain. This piece has over 250 rings alone.

As for the design, the influence of the client's family symbol is evident.

Side View:

Top View:

As always, I'm very much looking forward to sharing this project with you all and your comments and suggestions are much appreiciated. If all goes well, I'll get a good start on the wood this weekend. Stay tuned, this will be a relatively quick project.

Nick (GreenSabbath)

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)