I've tried many things (exacto knife, jigsaw, regular saw, scissors, dremel) but haven't found anything that makes decent cuts in plastic. Recently I was trying to cut out a space for a 3 1/2" drive in a 5 1/4" bay and went through three drive covers before finally getting something that was passable (Later ended up buying five "converters" for future use). Using heavy duty scissors made the best cuts since the plastic isn't very thick, but it was hard to get them angled right after drilling holes in the plastic for a starter point. Using the jogsaw worked great... when it didn't get so hot that the plastic melted and bubbled together. Anyone have any tips out there for cutting somewhat thin plastic (Under 1/2") without destroying it in the process?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Best tool for cutting plastic?

- Thread starter veekay

- Start date

You doing interior cuts or exterior cuts?

If you have to cut a square out of some larger item, use a scroll saw.

If you are just cutting a square or rectangle shaped piece and it's relatively thin, use a paper cutter. Heavy duty ones are best.

If you have to cut a square out of some larger item, use a scroll saw.

If you are just cutting a square or rectangle shaped piece and it's relatively thin, use a paper cutter. Heavy duty ones are best.

kill4killin

Gawd

- Joined

- Jul 3, 2006

- Messages

- 842

For normal thickness plastic found in most of the cases I have worked with. I use a dremel with a carbon cutting wheel. They are usually used for metal and they seem to work rather well for plastic as well. The only difference between the normal ones and the carbon ones is that the carbon ones are carbon re-enforced for cutting through metal without shattering as easily so I would imagine the regular ones would work perfectly fine. Just be sure not to turn the RPMs up to high or you can and will melt the plastic with too much friction.

After cutting I usually finish off the edgest if there are any rough spots with either a file or sand paper or a sanding bit for my dremel depending on the situation.

After cutting I usually finish off the edgest if there are any rough spots with either a file or sand paper or a sanding bit for my dremel depending on the situation.

Most of it is interior. Normally been using a drill to cut a hole on the center, then trying to things mentioned. When using a cutting wheel on the dremel, that melted the plastic as well. Ended up with an outline cut out that rejoined back together when it cooled. Maybe the carbon ones will do better as I just used to ones that came with the kit (brown and rough)

skunkmunkey

Limp Gawd

- Joined

- Aug 8, 2005

- Messages

- 152

you just have to get the right speed and not press hard at all, I always use my dremel for cutting plastics, just select a lower speed and apply just enough pressure to cut. If you find it starts to melt, drop a small amount of water on your cutting wheel and on the plastic.

Arcygenical

Fully [H]

- Joined

- Jun 10, 2005

- Messages

- 25,066

veekay said:Most of it is interior. Normally been using a drill to cut a hole on the center, then trying to things mentioned. When using a cutting wheel on the dremel, that melted the plastic as well. Ended up with an outline cut out that rejoined back together when it cooled. Maybe the carbon ones will do better as I just used to ones that came with the kit (brown and rough)

yeah, waaay too High of an RPM level there!

To cut through plexi 1/3" thick, I use the regular cutoffs (the brown ones) with my Dremel at the third RPM setting. Make light grazes into the plastic. Dont go RIGHT THROUGH in one pass. Cut about 1/3 of it each time.

I also like to get the piece wet before I cut it. Really chunks up the plastic rather than melting it.

MonsterEnergy

Limp Gawd

- Joined

- Nov 3, 2006

- Messages

- 356

Just thought i'd toss my opinion in. I cut everything with a dremel. Depending on the exact cuts you'd be making you can always use the sanding bits to smooth out rough or coarse edges.

just something to note, every different cut off wheel and rpm setting i've used with my dremel has resulted in burnt/curled plastic. I just finish up my cuts with the sanding wheel I mentioned.

just something to note, every different cut off wheel and rpm setting i've used with my dremel has resulted in burnt/curled plastic. I just finish up my cuts with the sanding wheel I mentioned.

MonsterEnergy

Limp Gawd

- Joined

- Nov 3, 2006

- Messages

- 356

I know I could give you some more specific details on the process if you explain what exactly you are doing in a little more detail. I know your gutting some 5 1/4 case, and trying to put a 3 1/2 in it but what kinda case is the 5 1/4 ?

MonsterEnergy

Limp Gawd

- Joined

- Nov 3, 2006

- Messages

- 356

yeah i cut large pieces of mdf all the time, unfourtantely my table saw can't cut things quite that big.

Susquehannock

Supreme [H]ardness

- Joined

- Jul 26, 2005

- Messages

- 4,616

Susquehannock

Supreme [H]ardness

- Joined

- Jul 26, 2005

- Messages

- 4,616

Sure ... what exactly do you need to know? Here is a closeup of my favorite case modding tools ~

An air compressor is required. I realize many don't have one available, but some do. Might work in a drill but would take longer obviously.

Here is where I buy the carbide burs ~ http://www.discount-tools.com/40double.cfm

The bur/bit in the tool above is #FUL-40137 = $9.32. Awesome tools - many uses.

An air compressor is required. I realize many don't have one available, but some do. Might work in a drill but would take longer obviously.

Here is where I buy the carbide burs ~ http://www.discount-tools.com/40double.cfm

The bur/bit in the tool above is #FUL-40137 = $9.32. Awesome tools - many uses.

MonsterEnergy

Limp Gawd

- Joined

- Nov 3, 2006

- Messages

- 356

hmm those look alot like dremel bits

OkumaCaptain

n00b

- Joined

- Aug 13, 2006

- Messages

- 42

Arcygenical said:yeah, waaay too High of an RPM level there!

To cut through plexi 1/3" thick, I use the regular cutoffs (the brown ones) with my Dremel at the third RPM setting. Make light grazes into the plastic. Dont go RIGHT THROUGH in one pass. Cut about 1/3 of it each time.

I also like to get the piece wet before I cut it. Really chunks up the plastic rather than melting it.

what is this 1/3 of an inch buisiness?! Table Saw FTW!

MrWizard6600

Supreme [H]ardness

- Joined

- Jan 15, 2006

- Messages

- 5,791

if you do any kind of other construction, bandsaws just rips thru plastic like butter. it dubs as a wood and metal cutter too. best power tool any shop has to offer imho.

but if you dont have the money to drop on a brand spankin new bandsaw, I would stick with a (blaggh having a brain fart here.... spinny thing that cuts stuff...) and/or jig saw.

but if you dont have the money to drop on a brand spankin new bandsaw, I would stick with a (blaggh having a brain fart here.... spinny thing that cuts stuff...) and/or jig saw.

MonsterEnergy

Limp Gawd

- Joined

- Nov 3, 2006

- Messages

- 356

Haha I think that would probally cause just as much burning and melting as the other tools suggested, if not morebandsaws just rips thru plastic like butter

SarverSystems

Supreme [H]ardness

- Joined

- Feb 9, 2002

- Messages

- 7,408

I use rotary cutting bits, not cut-off wheels. If you don't know what they are, let me know, and I'll post pics.

I do have a compressor, though it isn't very big and only does about 90psi continuous. Do you have any specifics on the models you are using? I know the pneumatic die grinder was mentioned.

I believe my dremel came with a rotary bit, but have yet to try that on plastic since the paperwork always mentioned how it was made for drywall and figured it would just be another plastic melter.

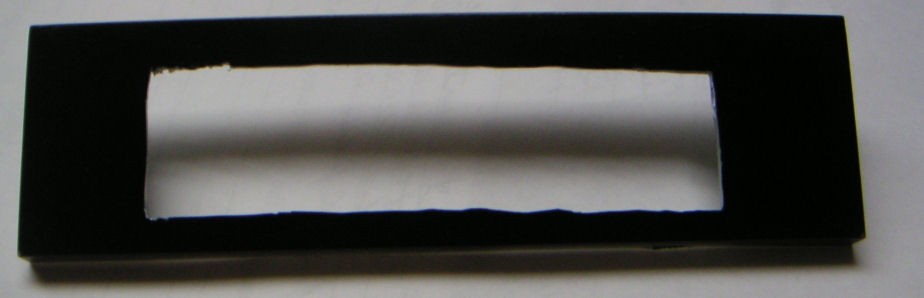

Finally got around to taking a picture of what I was trying to do. This was attempt three and still I could never get things straight or non-jagged, even though everything was drawn out on the back perfectly. Each time I tried to even things out, something was cut too much or wrong.

I believe my dremel came with a rotary bit, but have yet to try that on plastic since the paperwork always mentioned how it was made for drywall and figured it would just be another plastic melter.

Finally got around to taking a picture of what I was trying to do. This was attempt three and still I could never get things straight or non-jagged, even though everything was drawn out on the back perfectly. Each time I tried to even things out, something was cut too much or wrong.

No matter how good of a cutter you are things are always going to be a bit "jagged." Go to your local hardware store and buy a deburring kit, or file kit. These will help with smoothing out the plastic once you get straight lines cut. I cannot tell you how many people do not practice first before cutting, make sure you get a little practice in and by all means TAKE YOUR TIME. I would rather take an extra 20 mins to cut something CORRECTLY then get done 20mins early only to have to do it over again.

For what you have already I would recommend getting a cut-off wheel and slowly taking sections out until your area is straight. Give yourself a little room for filing and sanding and then go at it.

For what you have already I would recommend getting a cut-off wheel and slowly taking sections out until your area is straight. Give yourself a little room for filing and sanding and then go at it.

Susquehannock

Supreme [H]ardness

- Joined

- Jul 26, 2005

- Messages

- 4,616

Only if you can fit 1/4" shank in your Dremel. Actually the reinforced cutting disks are Dremel items. I prefer them over the usual die grinder cut off wheels because they are thin - less material to remove. As you can see I have hogged out the small center hole on two disks of them to use on my die grinder.MonsterEnergy said:hmm those look alot like dremel bits

90psi continuous is not bad. However the volume at 90psi is what you need to look at. Most die grinders require a fair amount of volume. The better your compressor, the less time you will have to wait for the tank to recharge. Here is the compressor that I have, and it being used for my side spindow project :veekay said:I do have a compressor, though it isn't very big and only does about 90psi continuous. Do you have any specifics on the models you are using? I know the pneumatic die grinder was mentioned.

Smaller tank but large twin cylinder pump which provides roughly 9cfm at 90psi. Which is great because I can run my die grinder while the pump is running instead of having to wait for the tank to repressurize. A compressor with smaller pump will work fine but will take longer as mentioned.

MonsterEnergy

Limp Gawd

- Joined

- Nov 3, 2006

- Messages

- 356

Wow. Seeing exactly what you are cutting makes me suggest a dremel all the more.

Do you have a sanding bit like this one?

It is perfect for cutting into the plastic without burning it, or cause any other warping

Do you have a sanding bit like this one?

It is perfect for cutting into the plastic without burning it, or cause any other warping

Yes, I used the dremel to start grinding the edges, but after just ordering the part never did anything more to it. I still have all three pieces that I am going to practice on a little. I need to try and find some plastic that is the same thickness that I can use for testing, but don't know if they sell anything like that at lowes/home depot aside from the plexiglass stuff.

Do yourself a favor and goto Homedepot and pick up a Coping Saw.

Drill a small hole in your plastic and slid the saw through and cut. With a nice steady hand you can make nice straight cuts. And with a coping saw you and even shapes. It was made to cope out moldings but I have used it for 1000x other jobs.

Drill a small hole in your plastic and slid the saw through and cut. With a nice steady hand you can make nice straight cuts. And with a coping saw you and even shapes. It was made to cope out moldings but I have used it for 1000x other jobs.

MonsterEnergy said:Haha I think that would probally cause just as much burning and melting as the other tools suggested, if not more

that's what you get the right blade for a bandsaw. Understand there is a multitude of blades for them. Higher the teeth count, the better for plastic. They don't melt plastic unless you're using the wrong stuff.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)