I need the advice of some modders on here far more accomplished than I am.

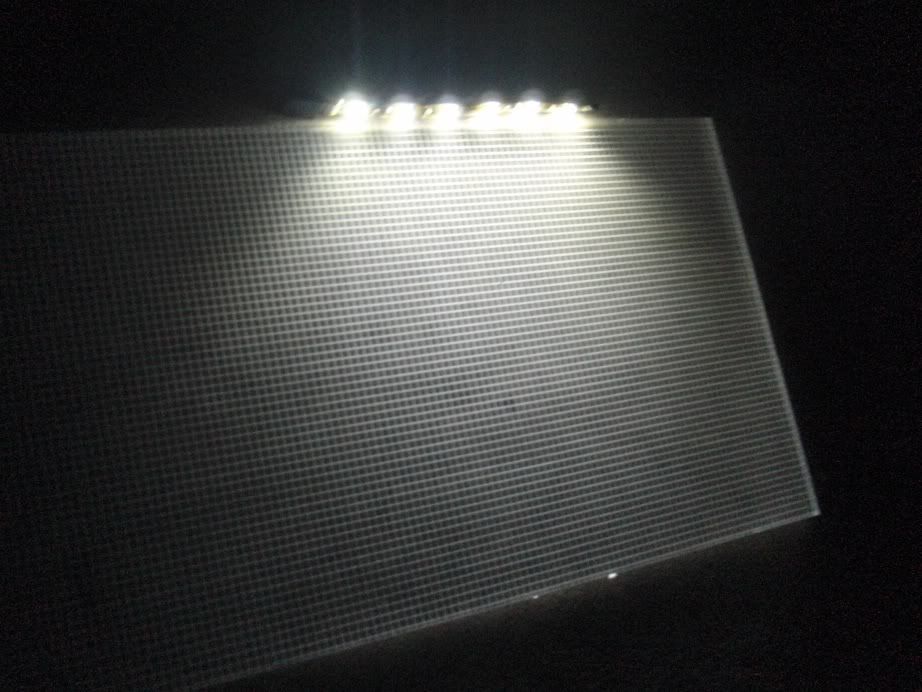

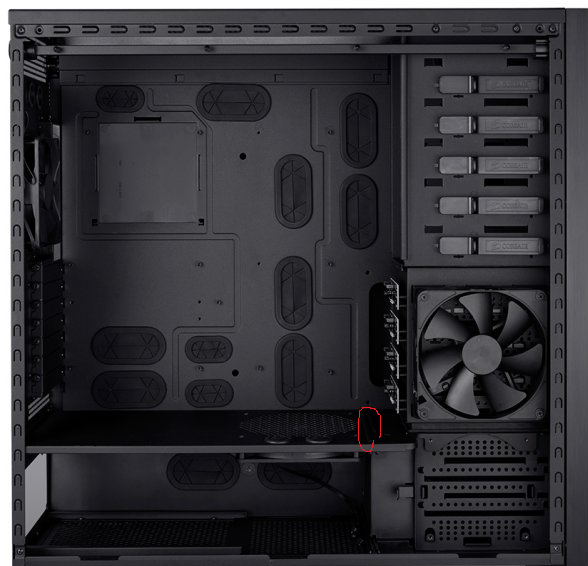

I wanted to recreate something similar in my 800d midpanel. What I was thinking was translucent top piece of white acrylic to diffuse the light, a bottom piece of reflective acrylic and white LEDs sandwiched between.

Unfortunately murdermod is pretty tight lipped when it comes to their methodologies and even the ones they fabricated for the TJ07 are no longer offered for sale.

I wanted to recreate something similar in my 800d midpanel. What I was thinking was translucent top piece of white acrylic to diffuse the light, a bottom piece of reflective acrylic and white LEDs sandwiched between.

Unfortunately murdermod is pretty tight lipped when it comes to their methodologies and even the ones they fabricated for the TJ07 are no longer offered for sale.

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)