officermartinez

[H]ard|Gawd

- Joined

- Jan 21, 2006

- Messages

- 2,012

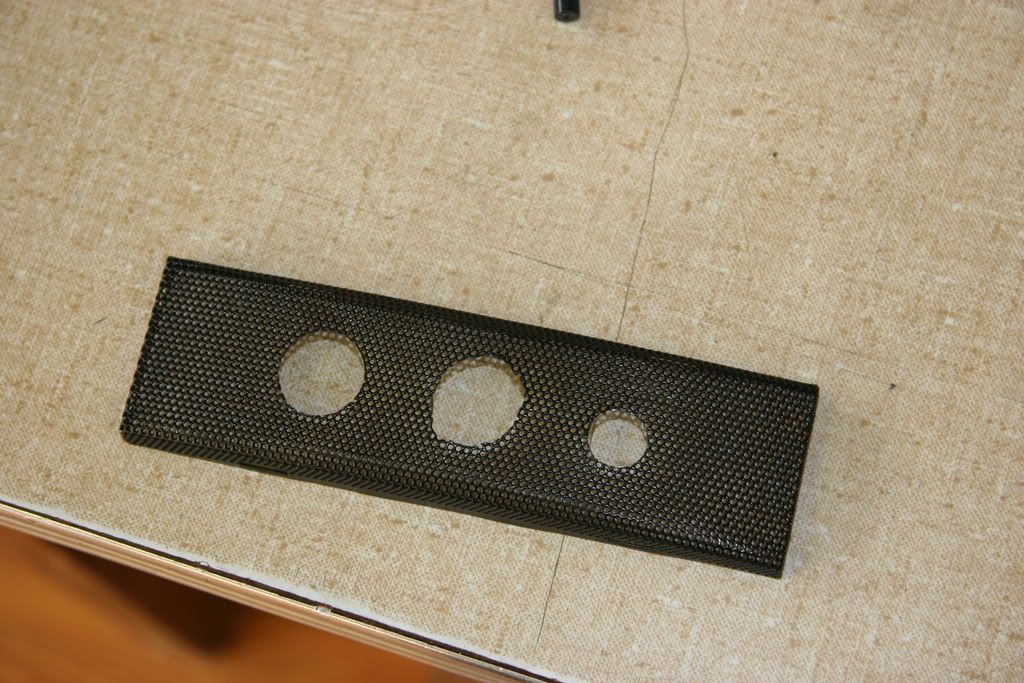

Wassup Bro!!! I just woke up so I'll call you in a little bit.. I stayed up all night and into the early morning modding my Lian Li PC-7A. I see you are coming along nicely. The wrinkle finish is AWESOME.. I tell you what makes it look weird is the FLASH on your camera. I too wrinkle finished some speaker boxes, panel, kick plates, etc.. That stuff is the shizniz.. You can really see how it looks when you took that picture of your side panels. The flash makes the finish look glossy, but in real life, its more of a dull finish. Thats exactly what I am doing to my Lian Li.. I am having the insides powder coated flat / dull black.

I have taken a few pics of my stuff and although I have a LONG way to go, I will send you some links before I post em in a worklog here on [H].. My case internals will be Black powder coated Diamond Plate Aluminum.. its different, thats for sure.

I have taken a few pics of my stuff and although I have a LONG way to go, I will send you some links before I post em in a worklog here on [H].. My case internals will be Black powder coated Diamond Plate Aluminum.. its different, thats for sure.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)