notarat

2[H]4U

- Joined

- Mar 28, 2010

- Messages

- 2,501

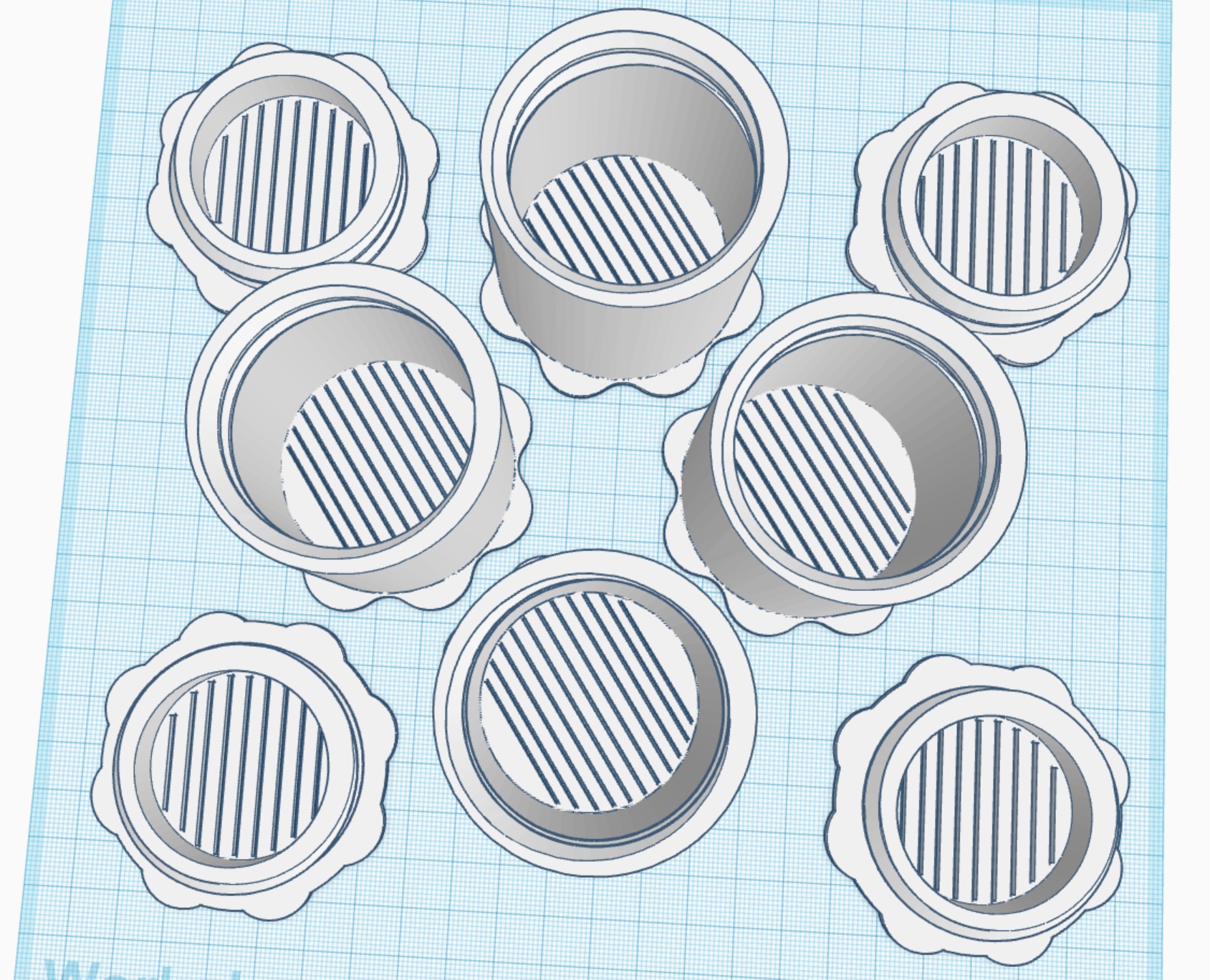

Bought a 3rd AMS for my original X1Carbon

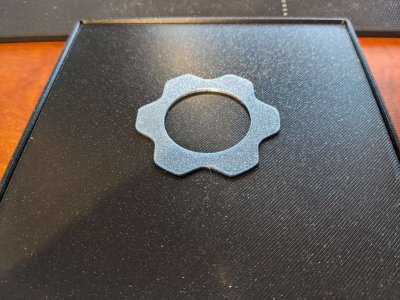

Gonna have to buy 3 more AMS units for the new printer because last night I swapped out the nozzle on the original X1Carbon to a .2mm so I can print some very detailed stuff that .4mm just can't do.

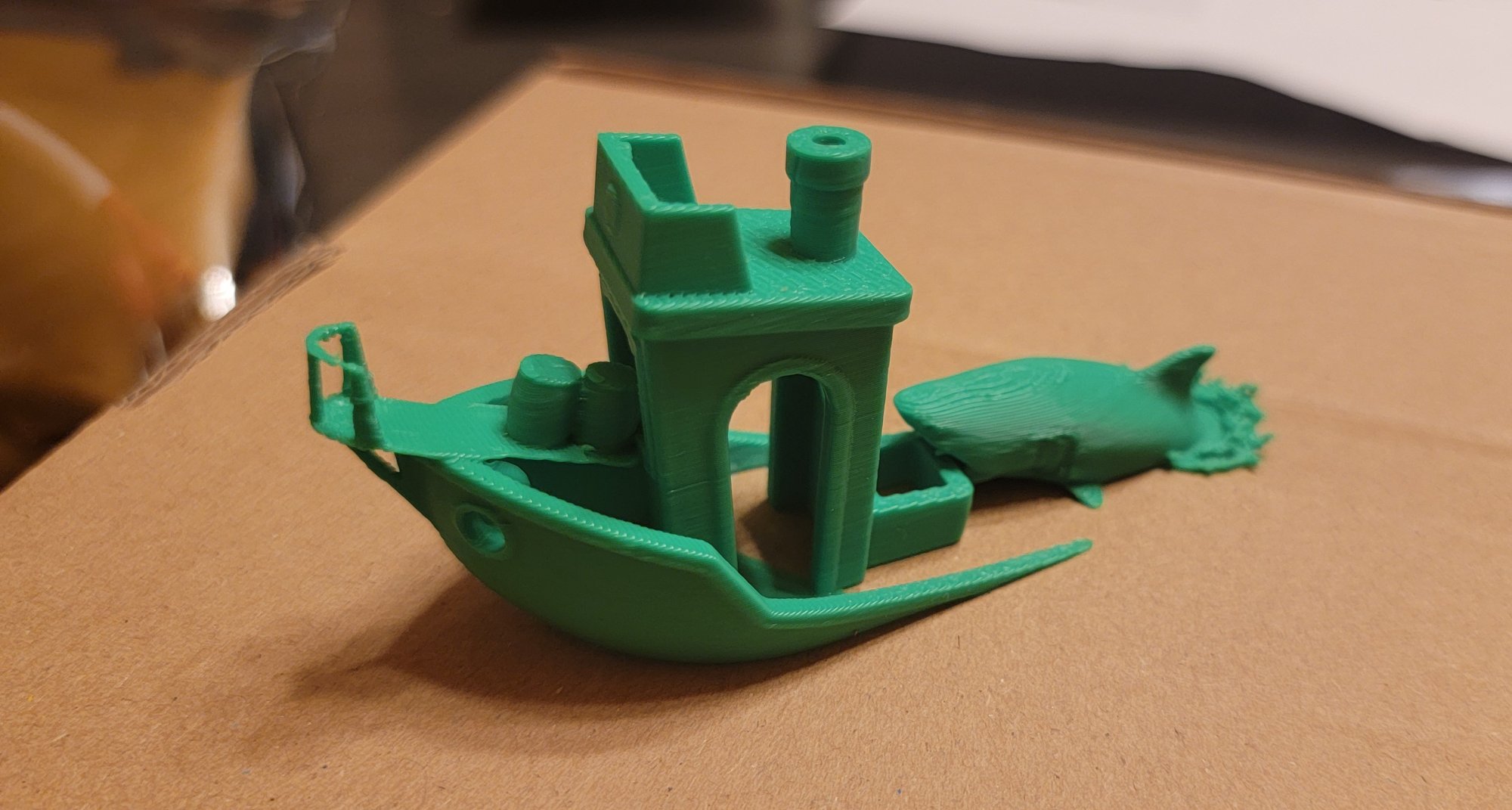

Tested the new nozzle out with this "benchy". It's sitting on a dime. It is far from perfect but perfect from afar.

Gonna have to buy 3 more AMS units for the new printer because last night I swapped out the nozzle on the original X1Carbon to a .2mm so I can print some very detailed stuff that .4mm just can't do.

Tested the new nozzle out with this "benchy". It's sitting on a dime. It is far from perfect but perfect from afar.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)