Hello

I am new to the forum and very new to the computer modding game. I wanted to take an opportunity to share my first ever mod and get some feedback (good or bad) from the community.

Bear in mind, when I started this mod, I had an idea of what I wanted to do, but knew nothing about where to start tor how to do it . . . Google and YouTube are a wonderful thing.

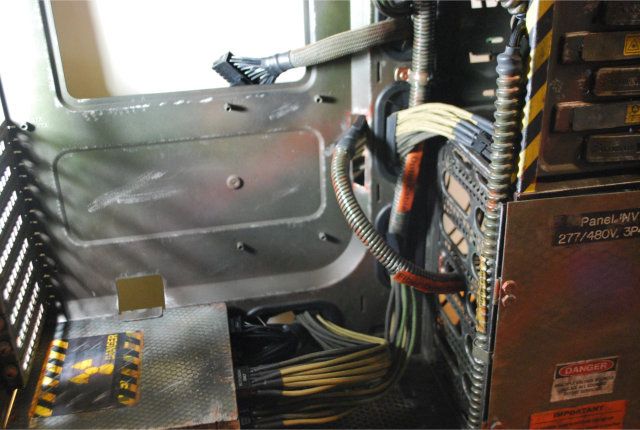

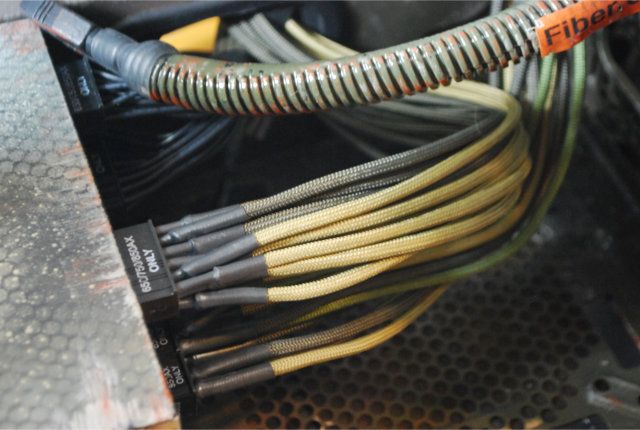

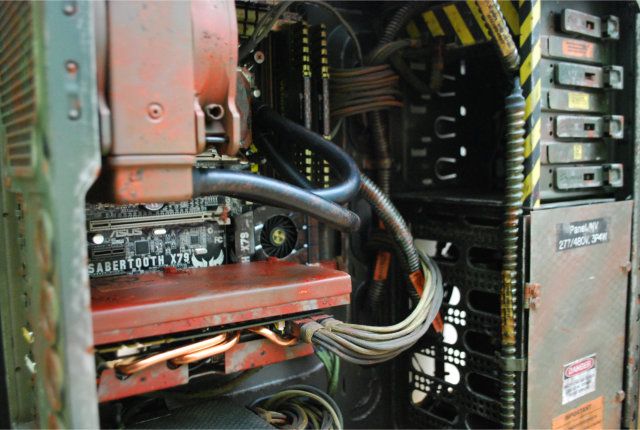

My mod was completed with basic (very basic) tools jig saw, drill, exacto knife and spray paint. So please do dont expect a truly professional polish as this in an amateur attempt. To date, I have completed the case only (exterior and interior). Now that I have my build components, I have begun working on the interior cable sleeving, component mods etc. (will update as I go along). Components going into the computer will be:

MOBO: ASUS Sabertooth X79

CPU: Intel i7 3820

GPU: Zotac 660Ti

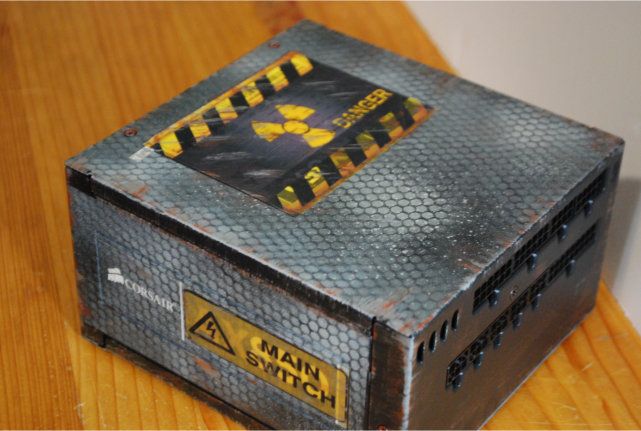

PSU: Corsair AX850

RAM: Corsair Vengeance (Olive Green) 16GB

Cooling: Corsair H80i

SSD: Adata 512GB

HD: WD 1TB

DVD: ASUS

Fans: BitFenix Spectre LED (red) x 4 (in addition to the 2 existing Corsair white LED)

Fan Controller: BitFenix Hydra Pro

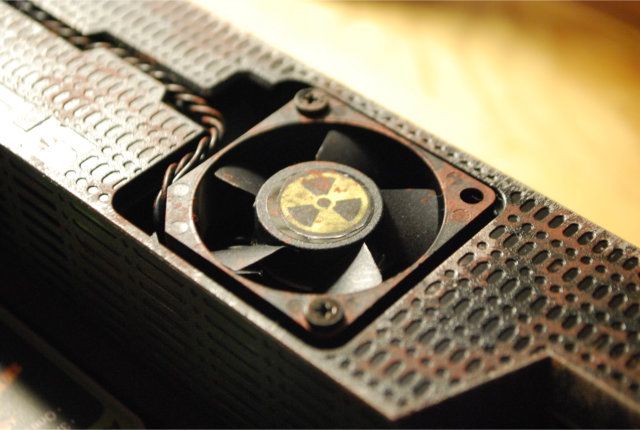

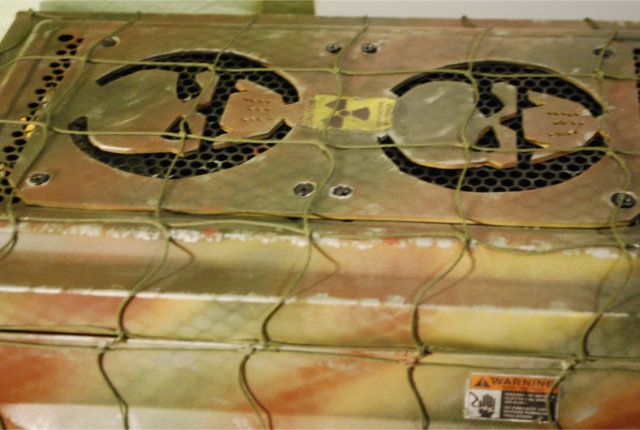

While new and shiny mods are very spectacular to the eye, I wanted something a bit more worn and used looking. Being a fan of all things zombie and a gamer of apocalyptic and military themed games, I wanted a computer that matched my interest. So I went about designing a mod that looked like a military radio which had seen service in a global war, survived and had been repurposed in a post-apocalyptic world.

So I figured that since everyone tends to name their computer mods . . as this is my first one, I decided to give it a name.

After much deliberation I struck on "Canticle of the Apocalypse". Canticle comes from the latin "canticulum" meaning hymn or song of praise. As this was themed on a piece of communication equipment which had survived a world apocalypse I felt the word was reflective. In addition, this is a nod to the post-apocalyptic novel by Walter Miller "A Canticle for Lebowitz" which describes a world where technology is outlawed and that which survives (including those who use it) are eliminated. Surviving technology is collected and protected by an order of monks until humans are again ready for such technology again.

I know, a lot of work for a name but I figured if I was going to invest so much effort in building the rig, I should invest equal effort in a name

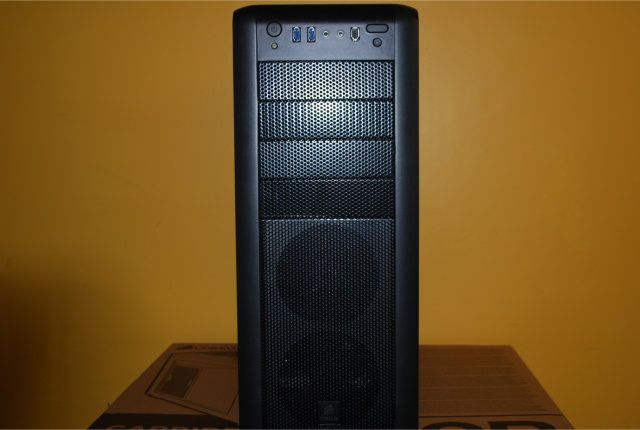

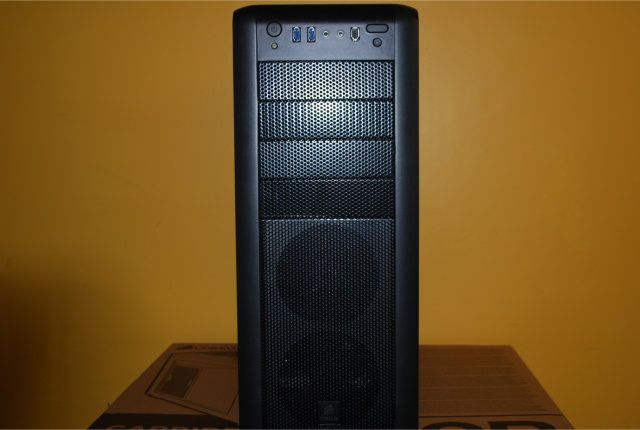

I decided to go with the Corsair Carbide 400R as the start point.

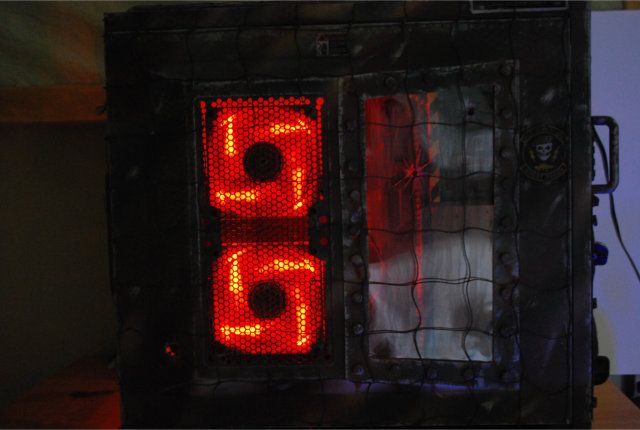

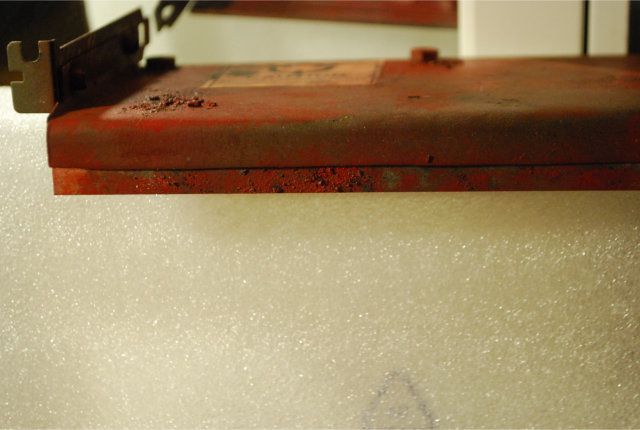

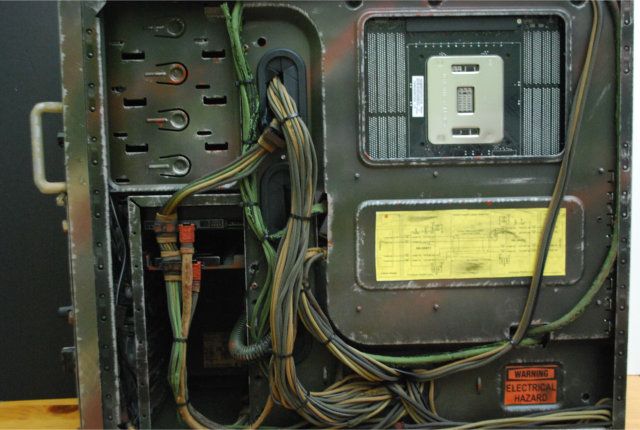

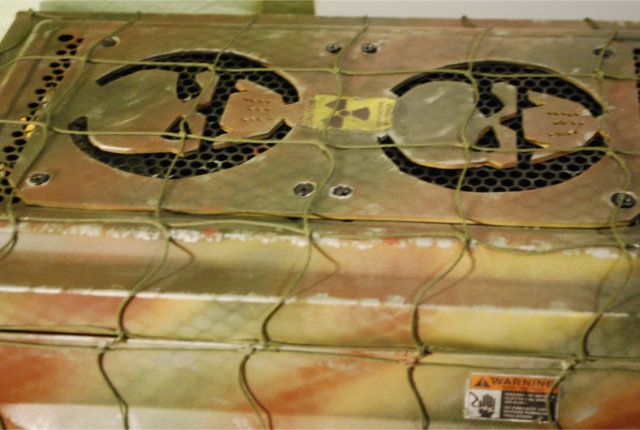

Using my limited knowledge, I added a window (gave it an armoured look heavy bolts), altered the bezel to look like communication equipment with speaker openings disguising the two existing fans. I added a top control box to give it an appearance of having been re-purposed later on in its life. I also added a cover plate for the top grill (plexi-glass skulls cut out using a jig saw going to mount two red led fans below). The whole thing was painted and aged (aluminum brushing for wear, rubbing with ash to darken and age everything sealed with a clear finish). The camouflage netting was individually glued to each side and top decals were applied to give it a used look.

I thought I would provide some background to the first pictures I posted to show how the case got to its new state before I move forward with the interior build log.

Firstly the paint and tools used:

The work done to transform the case:

Dial Plate

I wanted to have a place to mount some communication dials while some might say why give up two bays, my thoughts were I only need two (DVD and Fan Controller). The dials were salvage from an electric guitar, the dial pad an old phone and the handles I had lying around.

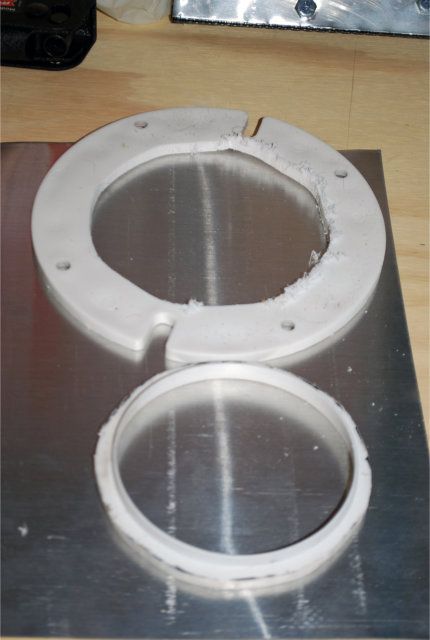

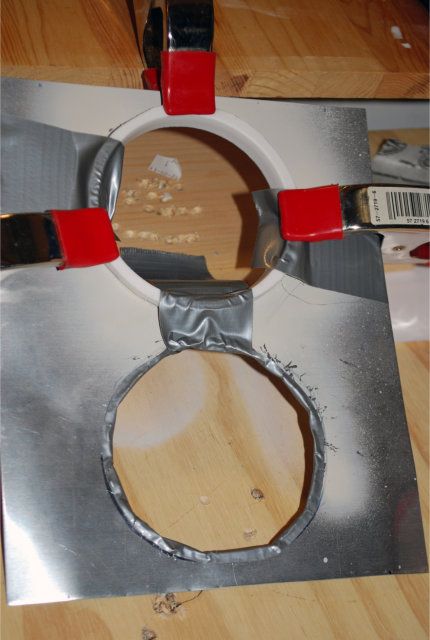

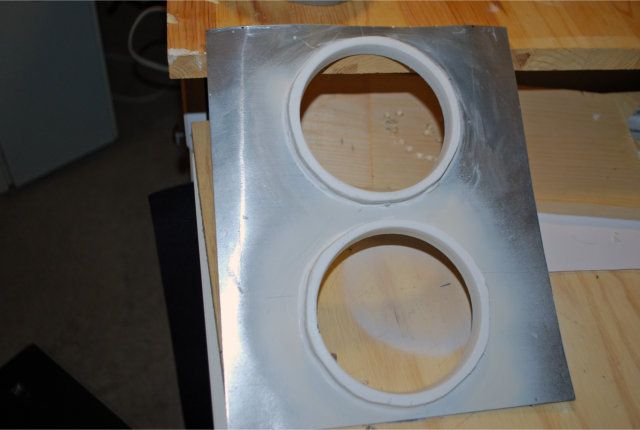

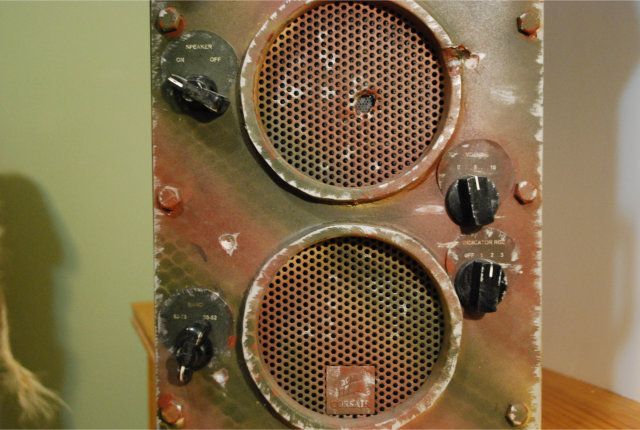

Speakers

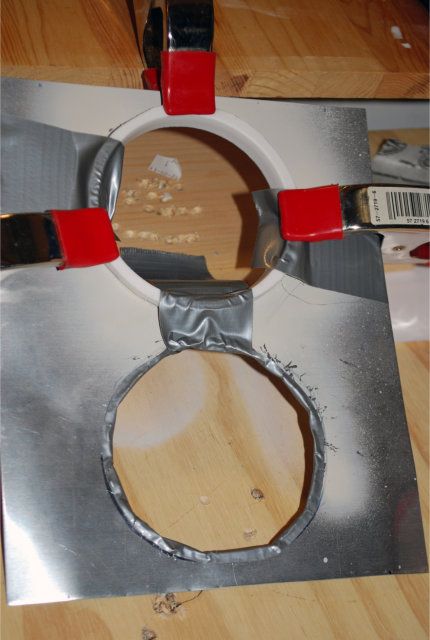

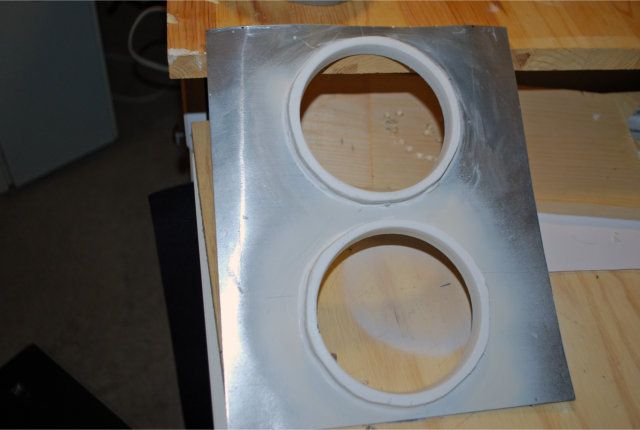

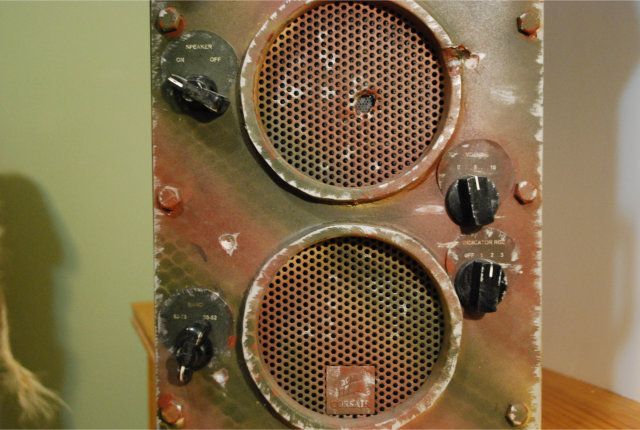

Every radio needs speakers so I thought the two existing fan openings on the case would do for this purpose. In making the openings, I wanted them to stand out so I cut down two toilet installation brackets (yes toilet installation brackets - anything can be repurposed ), to form the framing of the speaker ports. They were glued in place and then I used caulking to seal and smooth them to the front sheeting. The bolts were used to give the front a rugged armoured look and dials were added for effect.

), to form the framing of the speaker ports. They were glued in place and then I used caulking to seal and smooth them to the front sheeting. The bolts were used to give the front a rugged armoured look and dials were added for effect.

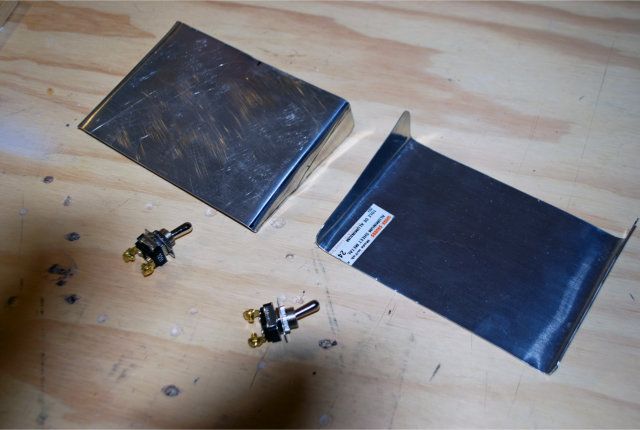

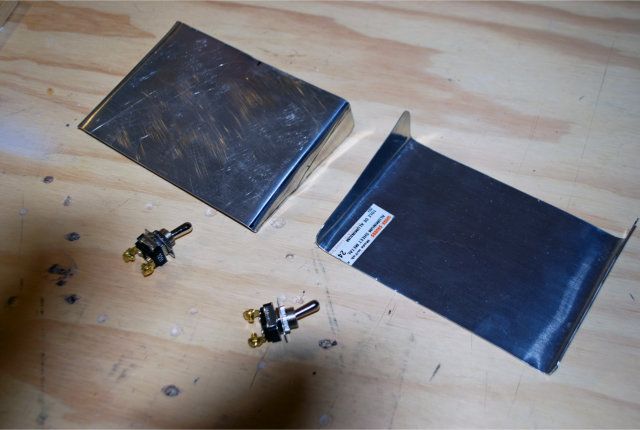

Control Box

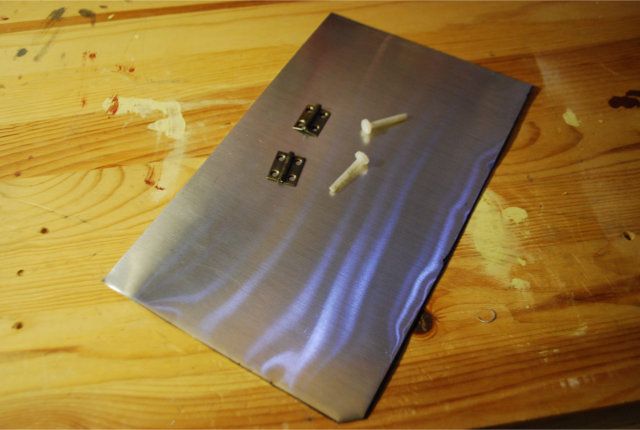

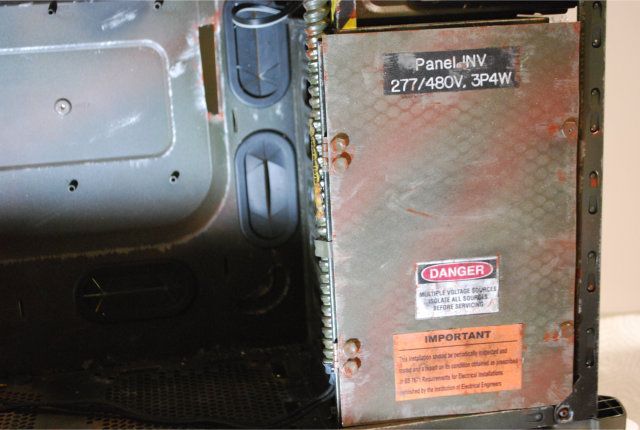

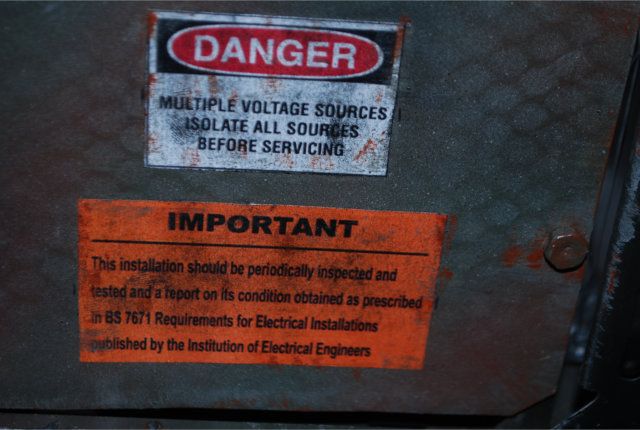

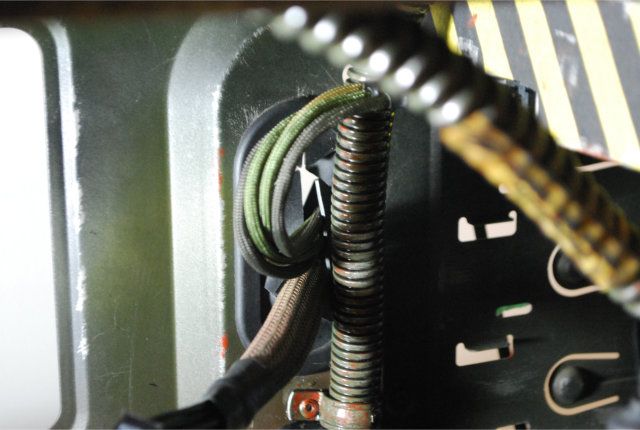

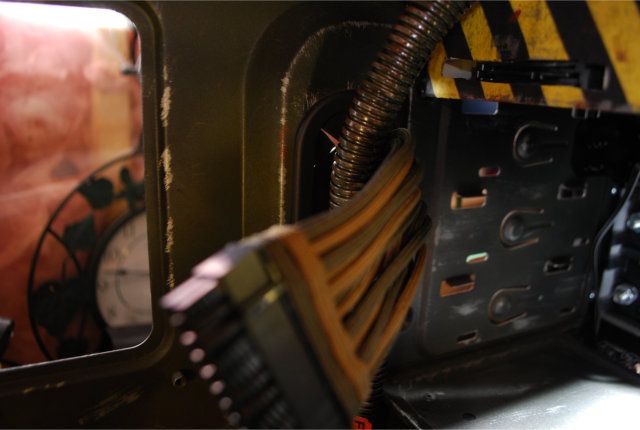

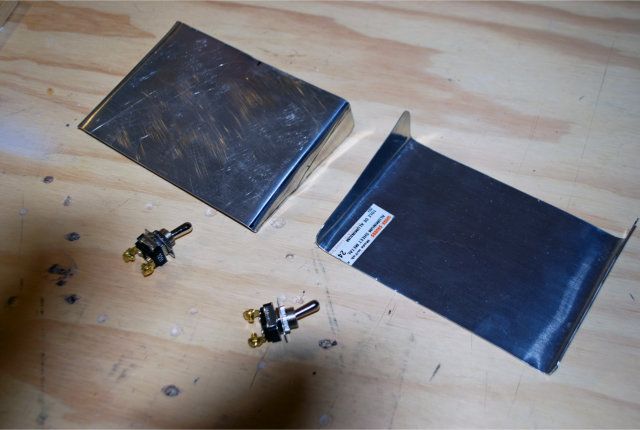

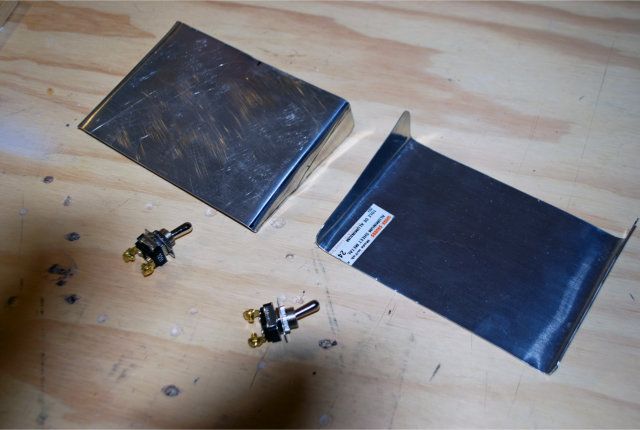

I wanted to add a control box which would look like a retro-fit. This was done using aluminum sheeting, toggle switches, LEDs and cannibalizing an old dial I had lying around. I also wanted to give it a damaged an repaired look, so added some exposed wiring for effect:

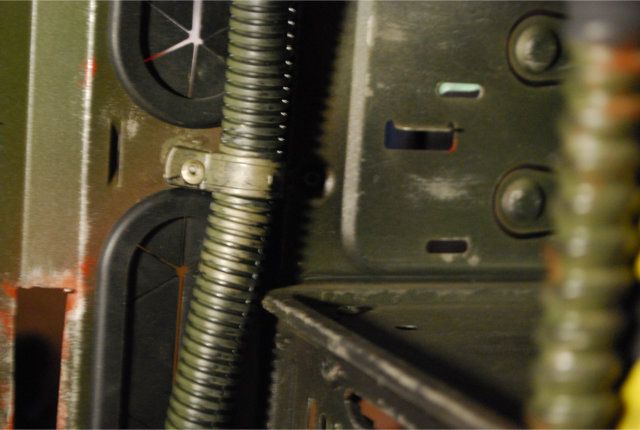

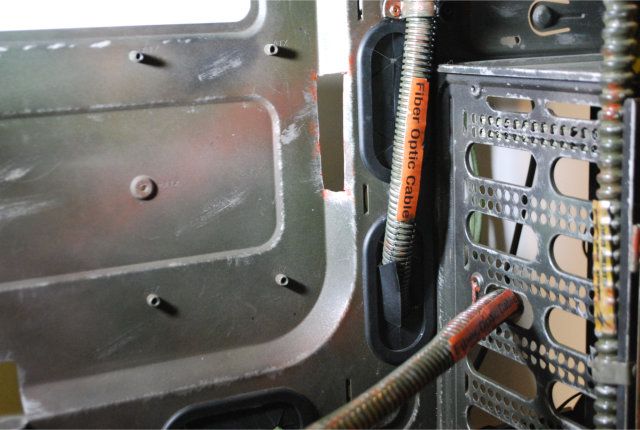

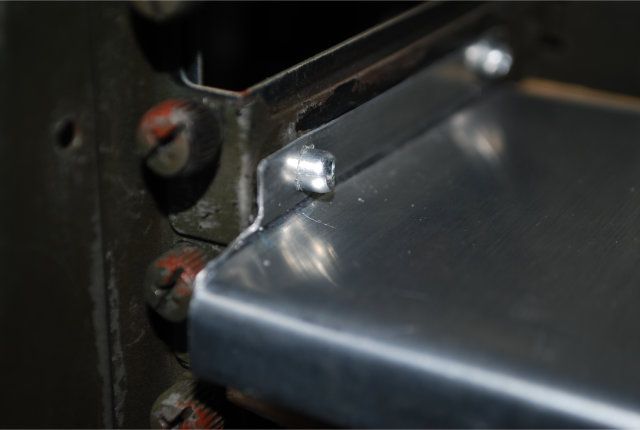

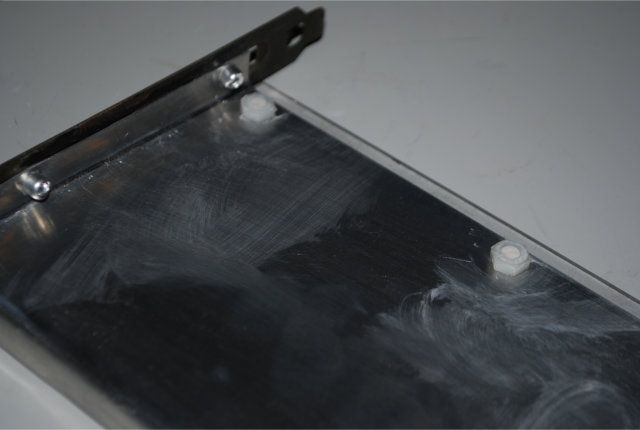

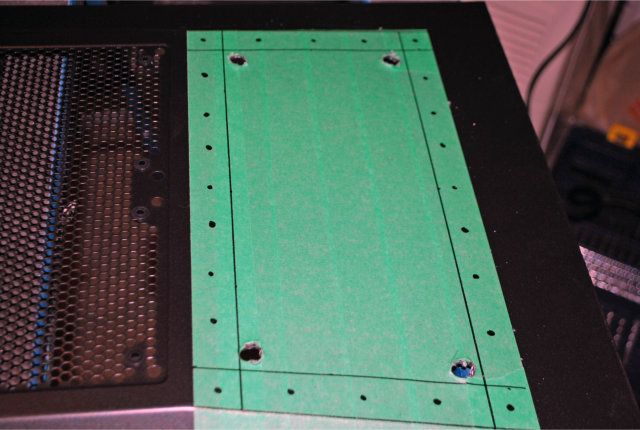

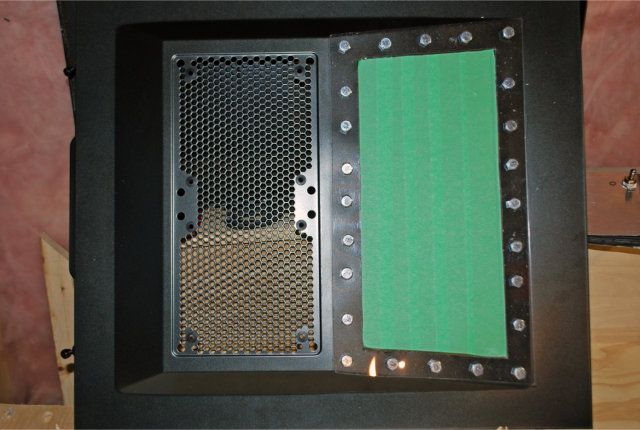

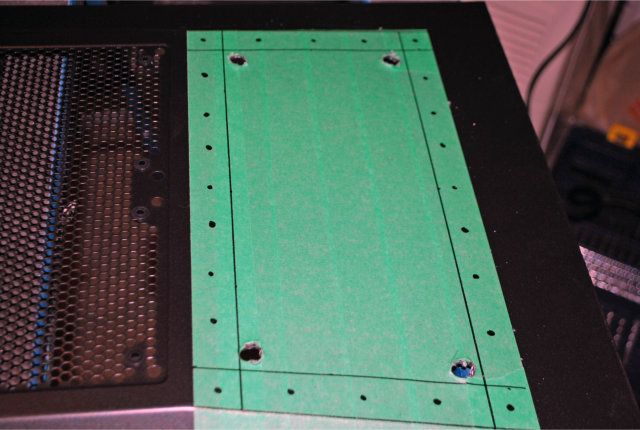

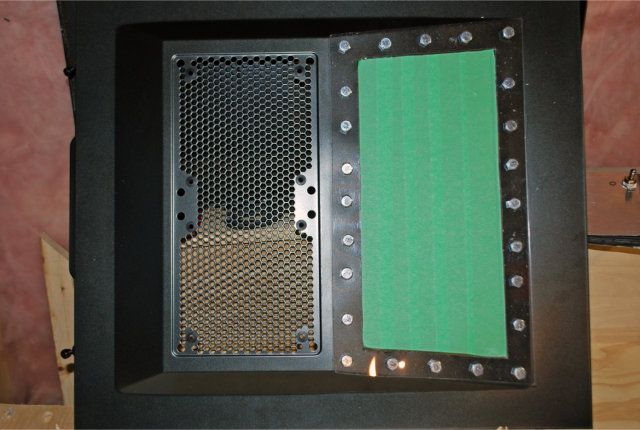

Window Mod

The 400R does not have an existing window and I wanted to be able to see my interior. I cut out a window opening and used plexi to create a frame. Bolts were added to give it a rugged armoured look - I know not exactly something a radio would have but I needed something to go with the theme:

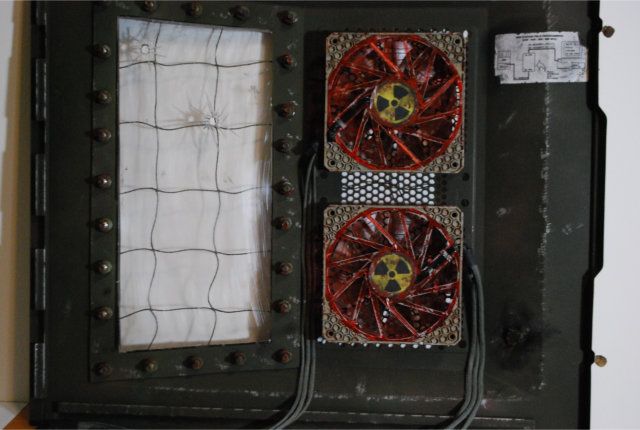

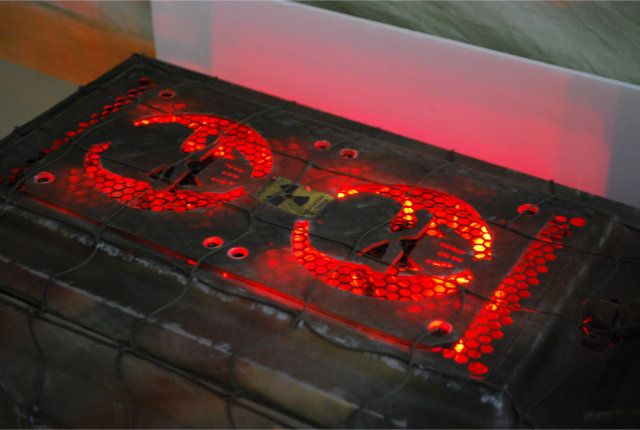

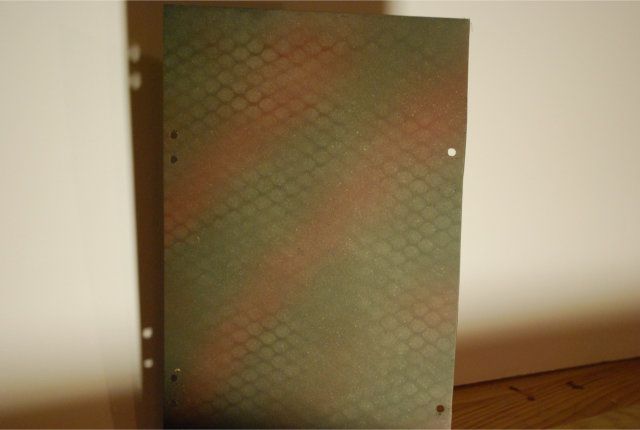

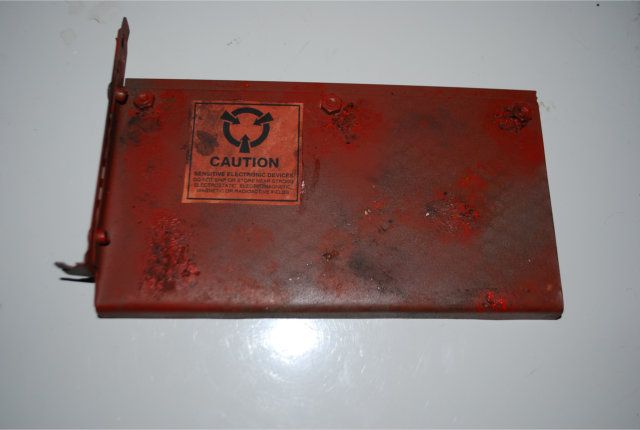

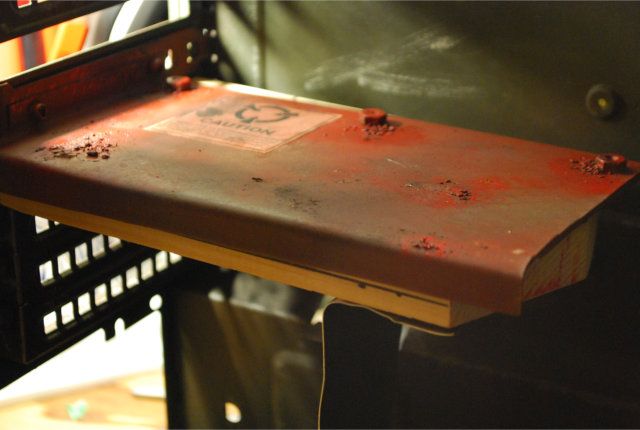

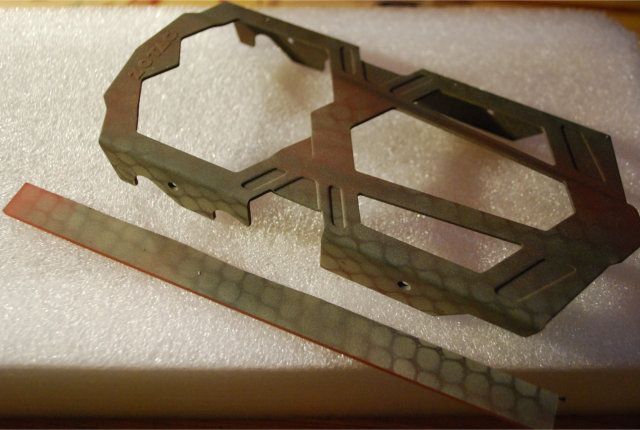

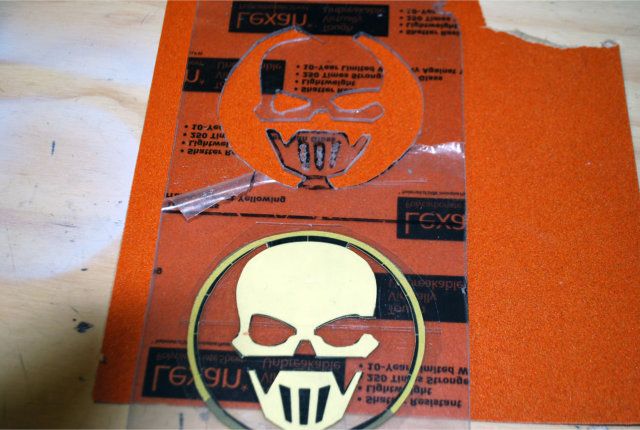

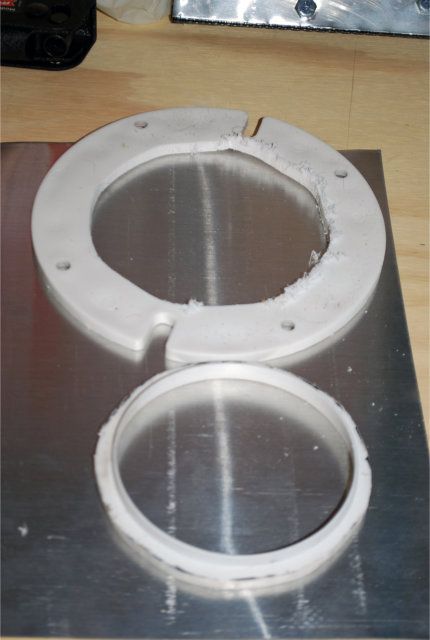

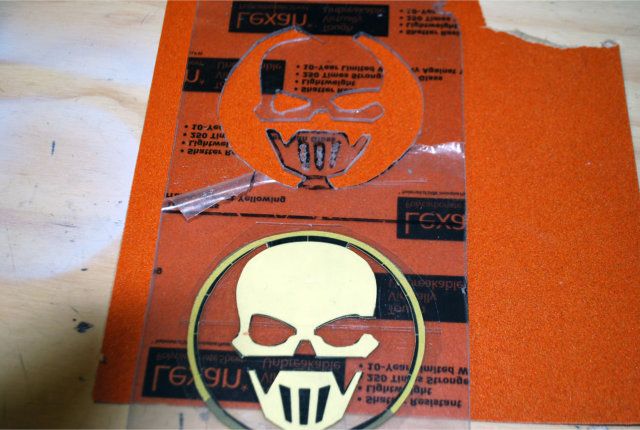

Top Fan Grill Plate

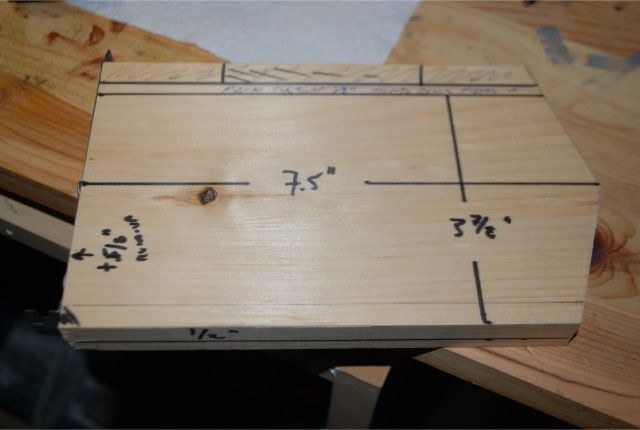

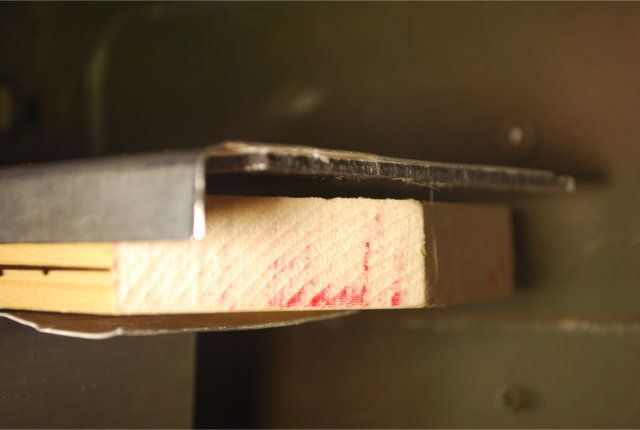

Originally I wasn't going to do this. I had seen lots of top grill plates on other mods and thought that would be cool However, I did not have the equipment to mill a metal plate or even a good saw to cut one out of metal sheeting. Then it dawned on me, why not plexi? So I drew the templates for cutting and gave it try with a jig saw. Worse case it would look horrible and I would scrap the idea. I didn't think it turned out too badly - so I kept it. I will be mounting two red LED Spectre Pros below the plate.

That's about it leading up to the outside of the case. I will update soon.

Cheers

Fen

I am new to the forum and very new to the computer modding game. I wanted to take an opportunity to share my first ever mod and get some feedback (good or bad) from the community.

Bear in mind, when I started this mod, I had an idea of what I wanted to do, but knew nothing about where to start tor how to do it . . . Google and YouTube are a wonderful thing.

My mod was completed with basic (very basic) tools jig saw, drill, exacto knife and spray paint. So please do dont expect a truly professional polish as this in an amateur attempt. To date, I have completed the case only (exterior and interior). Now that I have my build components, I have begun working on the interior cable sleeving, component mods etc. (will update as I go along). Components going into the computer will be:

MOBO: ASUS Sabertooth X79

CPU: Intel i7 3820

GPU: Zotac 660Ti

PSU: Corsair AX850

RAM: Corsair Vengeance (Olive Green) 16GB

Cooling: Corsair H80i

SSD: Adata 512GB

HD: WD 1TB

DVD: ASUS

Fans: BitFenix Spectre LED (red) x 4 (in addition to the 2 existing Corsair white LED)

Fan Controller: BitFenix Hydra Pro

While new and shiny mods are very spectacular to the eye, I wanted something a bit more worn and used looking. Being a fan of all things zombie and a gamer of apocalyptic and military themed games, I wanted a computer that matched my interest. So I went about designing a mod that looked like a military radio which had seen service in a global war, survived and had been repurposed in a post-apocalyptic world.

So I figured that since everyone tends to name their computer mods . . as this is my first one, I decided to give it a name.

After much deliberation I struck on "Canticle of the Apocalypse". Canticle comes from the latin "canticulum" meaning hymn or song of praise. As this was themed on a piece of communication equipment which had survived a world apocalypse I felt the word was reflective. In addition, this is a nod to the post-apocalyptic novel by Walter Miller "A Canticle for Lebowitz" which describes a world where technology is outlawed and that which survives (including those who use it) are eliminated. Surviving technology is collected and protected by an order of monks until humans are again ready for such technology again.

I know, a lot of work for a name but I figured if I was going to invest so much effort in building the rig, I should invest equal effort in a name

I decided to go with the Corsair Carbide 400R as the start point.

Using my limited knowledge, I added a window (gave it an armoured look heavy bolts), altered the bezel to look like communication equipment with speaker openings disguising the two existing fans. I added a top control box to give it an appearance of having been re-purposed later on in its life. I also added a cover plate for the top grill (plexi-glass skulls cut out using a jig saw going to mount two red led fans below). The whole thing was painted and aged (aluminum brushing for wear, rubbing with ash to darken and age everything sealed with a clear finish). The camouflage netting was individually glued to each side and top decals were applied to give it a used look.

I thought I would provide some background to the first pictures I posted to show how the case got to its new state before I move forward with the interior build log.

Firstly the paint and tools used:

The work done to transform the case:

Dial Plate

I wanted to have a place to mount some communication dials while some might say why give up two bays, my thoughts were I only need two (DVD and Fan Controller). The dials were salvage from an electric guitar, the dial pad an old phone and the handles I had lying around.

Speakers

Every radio needs speakers so I thought the two existing fan openings on the case would do for this purpose. In making the openings, I wanted them to stand out so I cut down two toilet installation brackets (yes toilet installation brackets - anything can be repurposed

Control Box

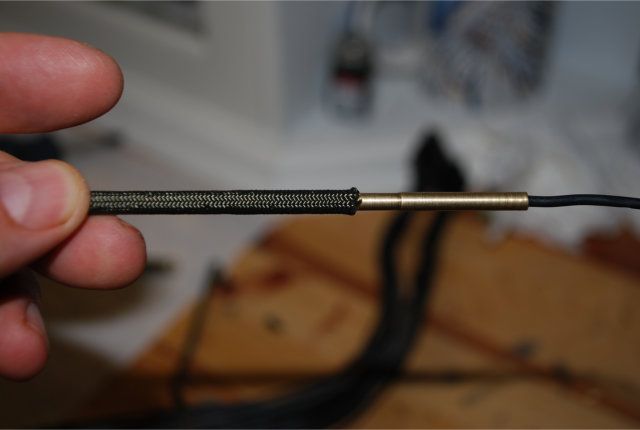

I wanted to add a control box which would look like a retro-fit. This was done using aluminum sheeting, toggle switches, LEDs and cannibalizing an old dial I had lying around. I also wanted to give it a damaged an repaired look, so added some exposed wiring for effect:

Window Mod

The 400R does not have an existing window and I wanted to be able to see my interior. I cut out a window opening and used plexi to create a frame. Bolts were added to give it a rugged armoured look - I know not exactly something a radio would have but I needed something to go with the theme:

Top Fan Grill Plate

Originally I wasn't going to do this. I had seen lots of top grill plates on other mods and thought that would be cool However, I did not have the equipment to mill a metal plate or even a good saw to cut one out of metal sheeting. Then it dawned on me, why not plexi? So I drew the templates for cutting and gave it try with a jig saw. Worse case it would look horrible and I would scrap the idea. I didn't think it turned out too badly - so I kept it. I will be mounting two red LED Spectre Pros below the plate.

That's about it leading up to the outside of the case. I will update soon.

Cheers

Fen

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)