Zarathustra[H]

Extremely [H]

- Joined

- Oct 29, 2000

- Messages

- 38,819

So,

I've kinda wanted to build a custom loop for more than 15 years, since back in the day when people were using open loops with shower heads instead of radiators, but I never got around to it.

After exhaustive research, I ordered the parts list below.

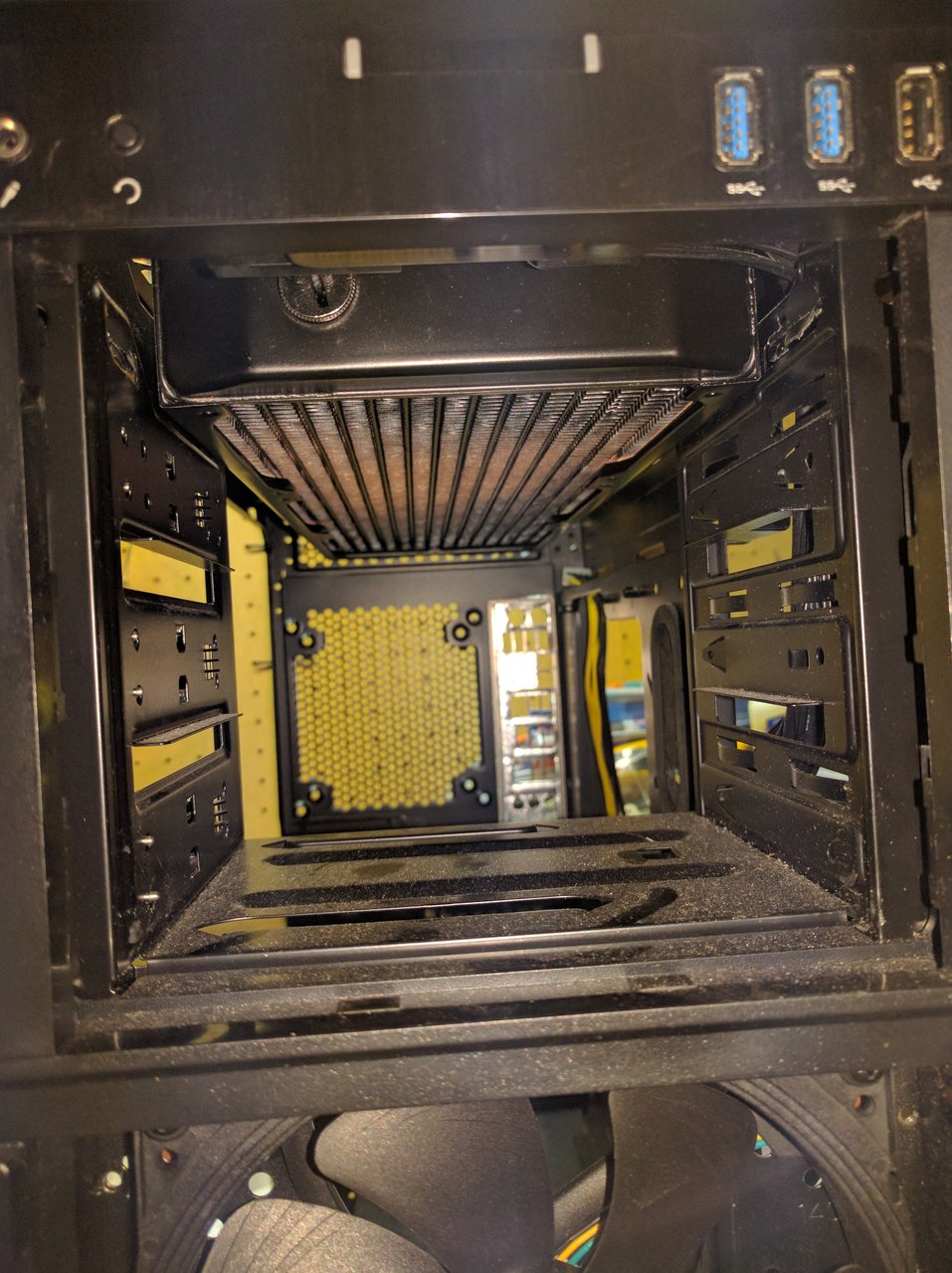

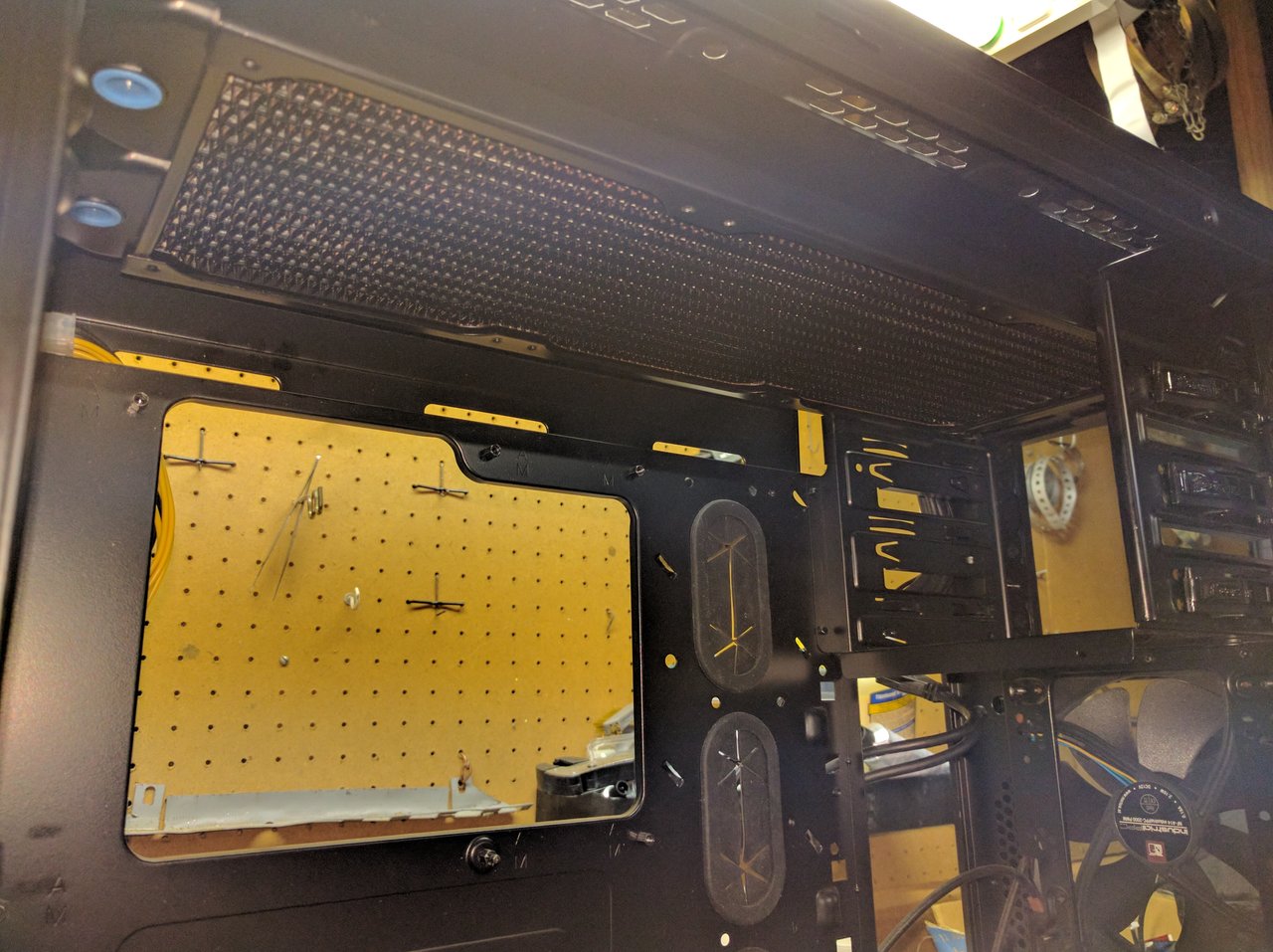

I'll be cooling a single i7-3930k and Pascal Titan X GPU with this loop. The intent is to go overkill on the radiators in order to be able to not have to rev up the fans too much. All of it will be going into a Corsair 750D

The plan is to hook up the temperature probes to a PWM fan controller in order to control fan speed based on loop temp.

I will be using Ekoolant, one bottle UV blue, two bottles clear. The original plan was to just use plain deionized/distilled water with no additives and a kill-coil, but I decided to play it safe with somethign that has corrosion inhibitors.

Hopefully I didn't screw up, but if you think I did, I'd like to know!

The overkill radiators will hopefully allow me to keep the fans slow and quiet, and also allow me to get the absolute most out of the GPU, as I'll only be using one of them for my 4k monitor. (I am SO done with SLI)

Thanks for reading.

edit: Updated parts list with final one

I've kinda wanted to build a custom loop for more than 15 years, since back in the day when people were using open loops with shower heads instead of radiators, but I never got around to it.

After exhaustive research, I ordered the parts list below.

I'll be cooling a single i7-3930k and Pascal Titan X GPU with this loop. The intent is to go overkill on the radiators in order to be able to not have to rev up the fans too much. All of it will be going into a Corsair 750D

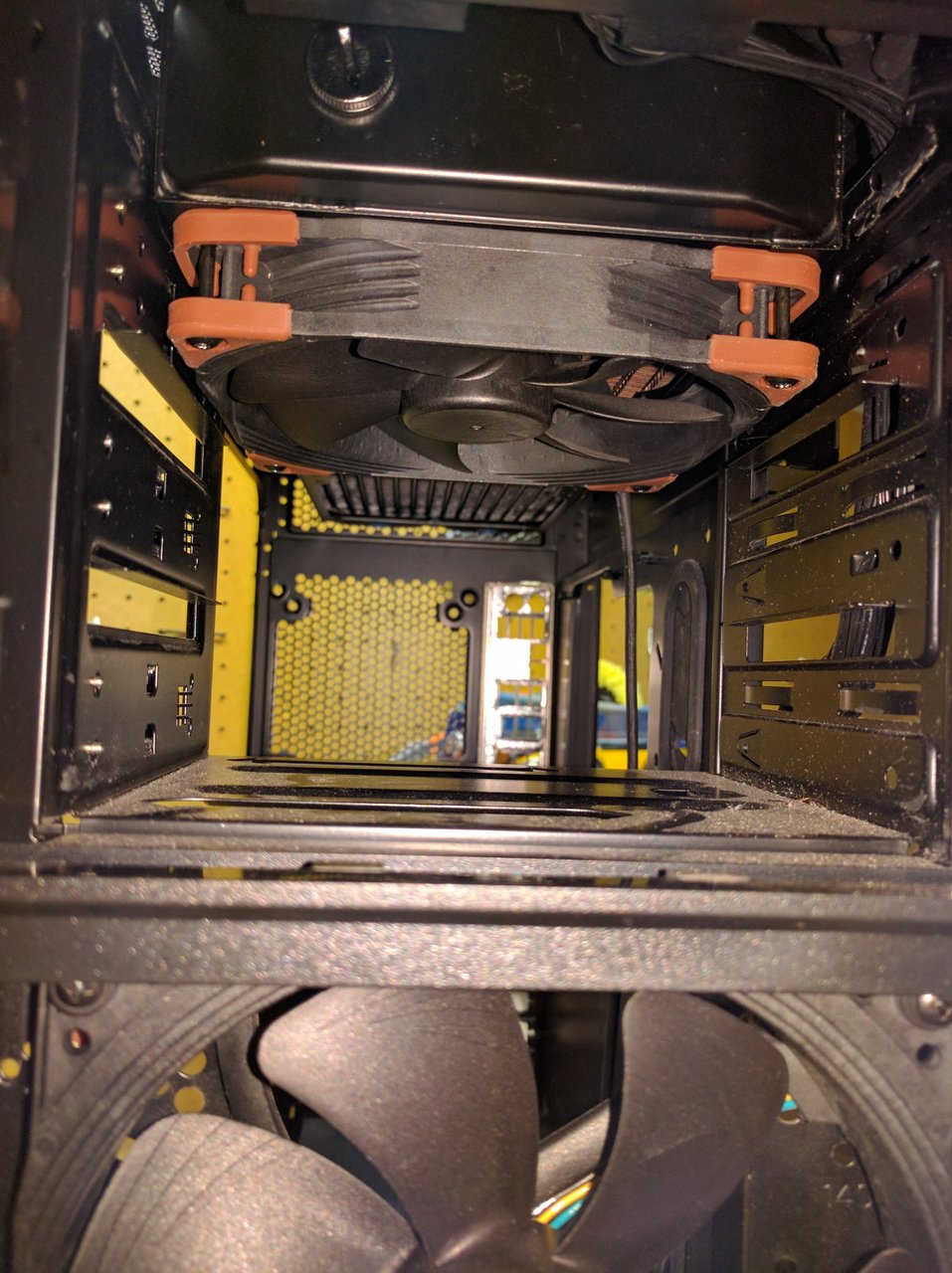

- Top Radiator: Alphacool XT45 420mm, with three 140mm Noctua 140mm iPPC-2000 PWM fans pushing out.

- Front Radiator: Alphacool Monsta 280, with four 140mm Noctua 140mm iPPC-2000 PWM fans in push-pull

- GPU Block: EK Pascal Titan full cover block (was originally Gigabyte G1 Gaming block)

- CPU Block: EK Supremacy EVO Elite LGA2011

- Reservoir/Pump Combo: XSPC D5 Photon 270 Reservoir / Pump Combo w. Fillcap g1/4 adapter

- Fittings:12x XSPC G1/4" to 3/8" ID, 1/2" OD Compression Fitting Black Chrome V2

- Tubing:PrimoFlex Advanced LRT 3/8in. x 1/2in. Tubing (10ft pack) - Onyx Black

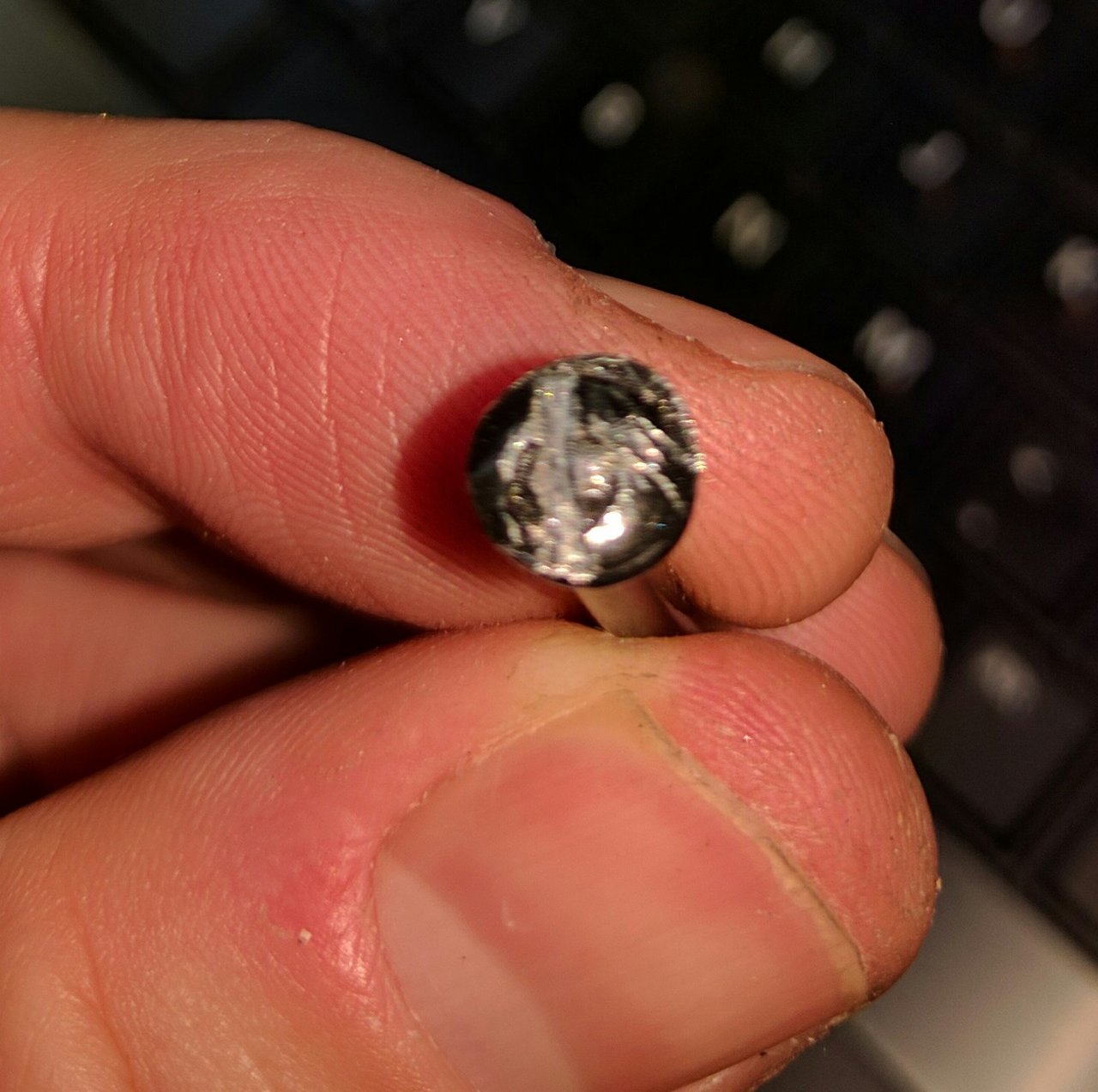

- Sealing Plugs: 2x Enzotech Sealing Plug for 3/8" ID Tubing, Black (for filling on top and draining on bottom)

- Temperature Probes: 2x Phobya G1/4" Inline Temperature Sensor, 50cm, Black Nickel

The plan is to hook up the temperature probes to a PWM fan controller in order to control fan speed based on loop temp.

I will be using Ekoolant, one bottle UV blue, two bottles clear. The original plan was to just use plain deionized/distilled water with no additives and a kill-coil, but I decided to play it safe with somethign that has corrosion inhibitors.

Hopefully I didn't screw up, but if you think I did, I'd like to know!

The overkill radiators will hopefully allow me to keep the fans slow and quiet, and also allow me to get the absolute most out of the GPU, as I'll only be using one of them for my 4k monitor. (I am SO done with SLI)

Thanks for reading.

edit: Updated parts list with final one

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)