Hi guys,

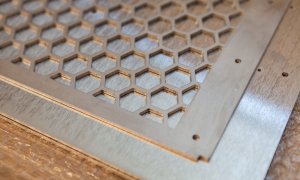

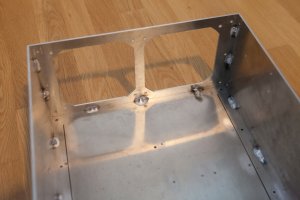

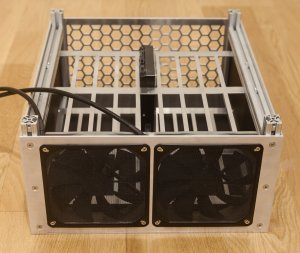

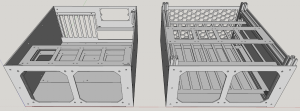

I'm back with another scratch build project. This time it is to replace my first scratch build, the IKEA Expedit compatible server wood case. Working with laser cut aluminium sheets on my Hexplo desktop case, I gained enough new knowledge and ideas to try to improve the original server case concept. The requirements I set went further than the previous case project:

As of right now, the drawings have been sent to the laser cutting shop, and I'm in the process of ordering all the other stuff I need.

I'm back with another scratch build project. This time it is to replace my first scratch build, the IKEA Expedit compatible server wood case. Working with laser cut aluminium sheets on my Hexplo desktop case, I gained enough new knowledge and ideas to try to improve the original server case concept. The requirements I set went further than the previous case project:

- Must fit into an IKEA Expedit/Kallax shelf, which means a box of no more than 33.5 x 33.5 x 39cm.

- Must hold an ATX size board, more than thirteen 3.5" and more than four 2.5" disks.

- Decent ventilation

- Even more living room compatible, i.e. cleaner visuals and lower noise

As of right now, the drawings have been sent to the laser cutting shop, and I'm in the process of ordering all the other stuff I need.

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)