It's been a while since I've fooled around with my watercooled rig.

Hardware:

•Motherboard - MSI 890GXM-G65

• CPU - AMD Phenom II X6 1055T @ 3800mhz @ 1.375v

• RAM - 8GB DDR3-1600 (2x2GB Kingston HyperX, 2x2GB Geil)

• GPU - eVGA GTX260

• PSU - Silverstone Olympia OP650

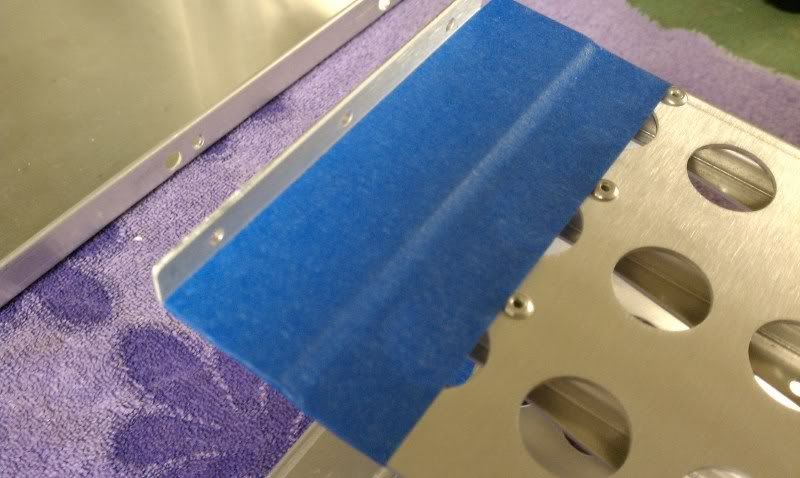

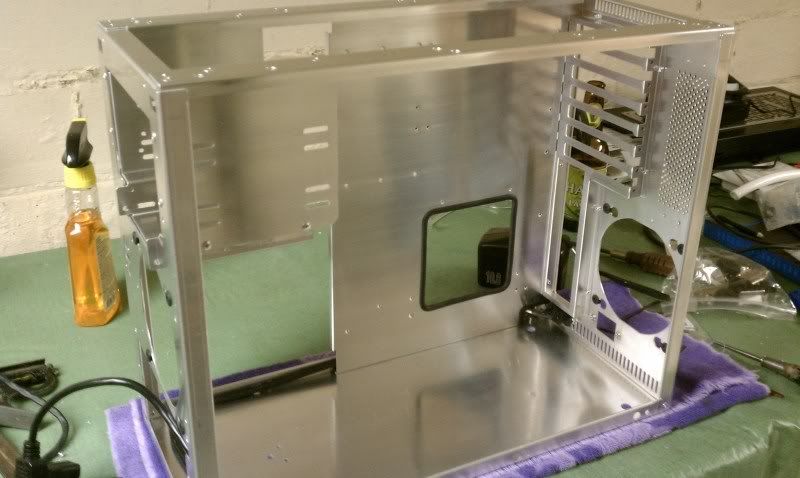

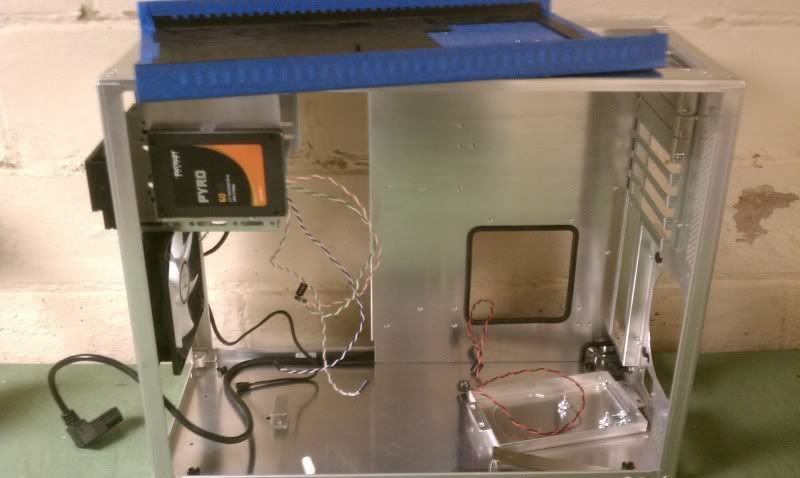

• Case - Lian Li v351B

Currently that's watercooled with:

•CPU - EK Supreme HF v1 (the one that screws together from the top side)

• GPU - EK FC280

• Radiator - HW Labs Black Ice GTX 240

• Pump - Laing DDC3.2 + XSPC top

• Tubing - Primochill Primoflex Pro LRT white 3/8-5/8

• Fittings - Bitspower Black Chrome compressions

• Fans - Panaflo FBG12M12 (something like that)

• Reservoir - Swiftech MC Res micro v1

I get some pretty nice temperatures given the small radiator for the heat load. In my 19-21°C room, the CPU loads at about 31°C and the GPU at 43°C when loaded separately. Loading them 100% together doesn't make sense (no real world use seeing as I don't Fold/WCG at the time), and after playing BF3 for 1-3 hours, they're at about 28 and 42.

I've grown tired of the fan noise, and having watercooled an mATX case (just to see if I could), I've decided to bump up to a mid tower. I've always loved the smaller size of the Lian Li A05B, the inverted ATX layout, and the fact that it can still house a full ATX board.

In the quest for more cooling power with vastly quieter operation, I perused Martin's and Skinnee's sites, crunched some numbers, and arrived at something that I think will be equally as challenging as watercooling the v351, while giving me better performance at a quieter profile.

I've bought recently:•Case - Lian Li A05B

•Radiators - EK CoolStream XT 360 and XT 120

•Fittings - 2x Bitspower compressions

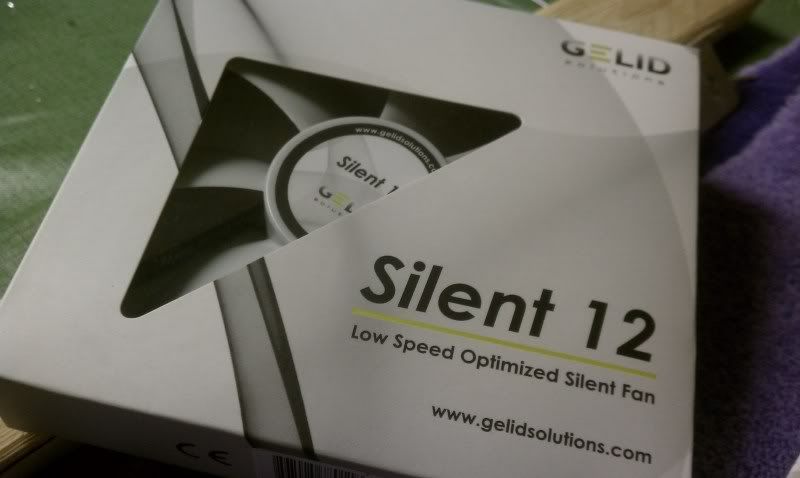

•Fans - 5x Gelid Silent 12 (per Martin's review)

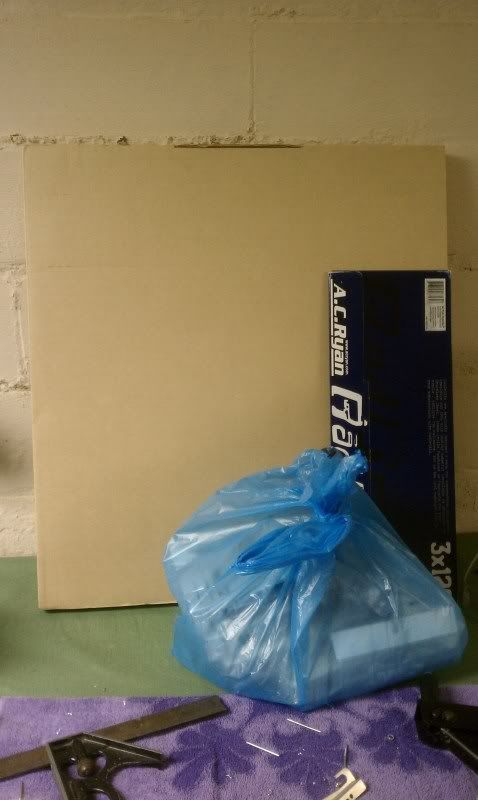

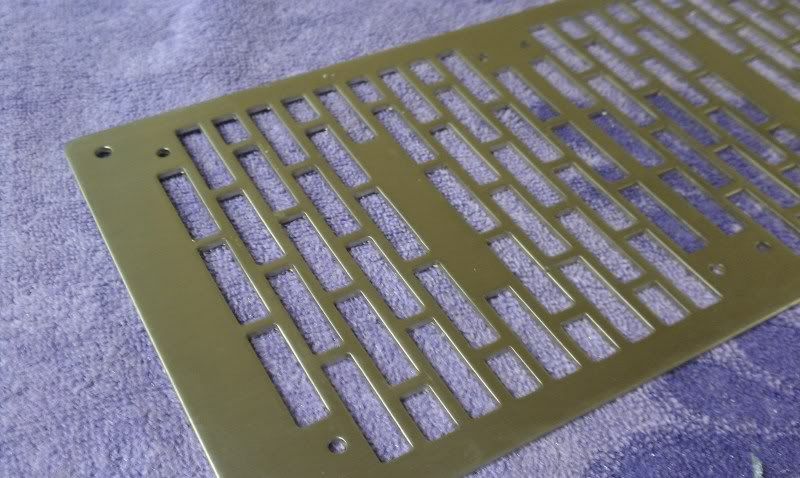

•Grill - AC Ryan Bricky 3x120 in stainless

I'll keep this post updated here at the bottom with links to updates every time I post a new update.

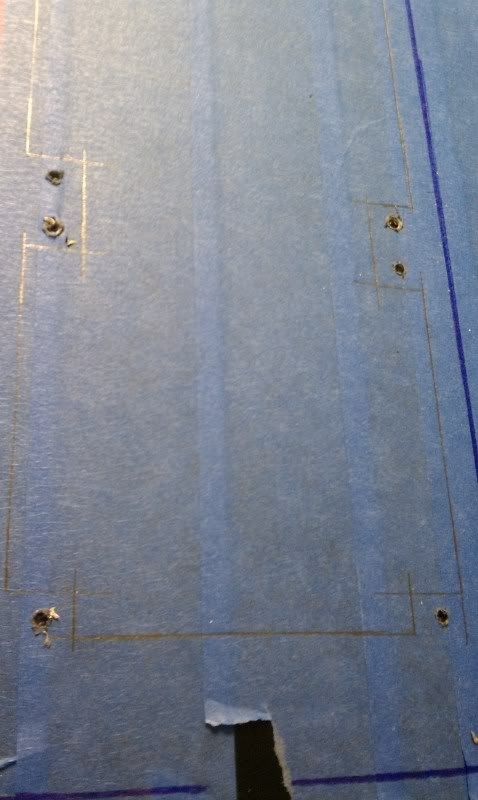

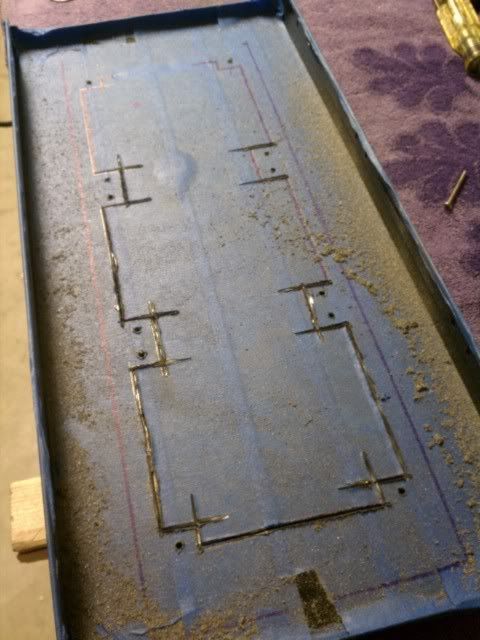

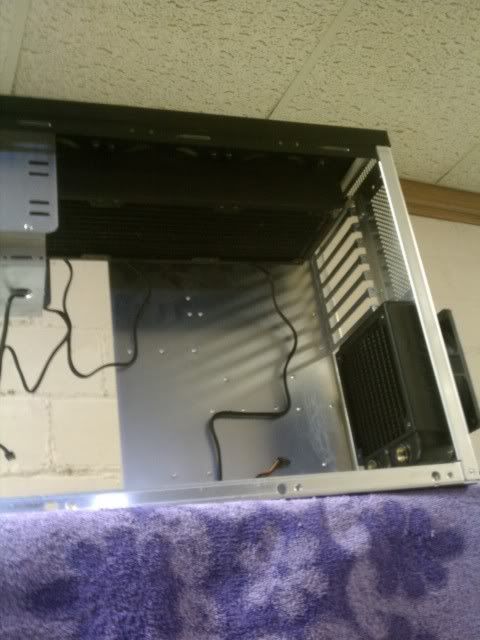

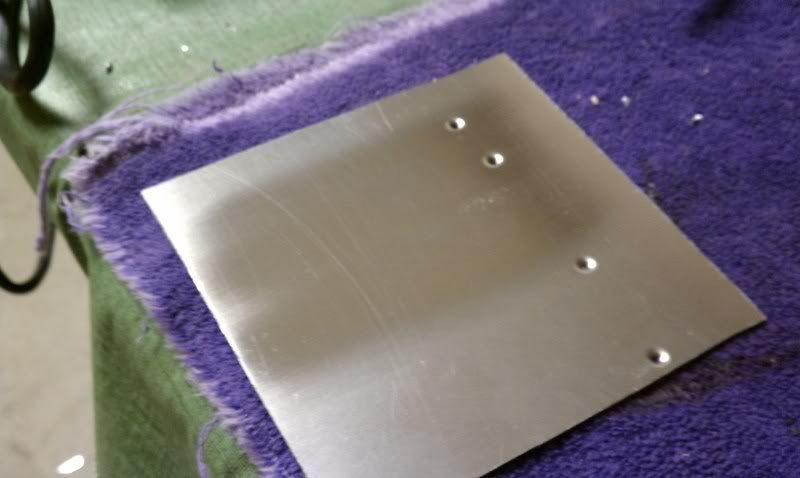

Bear with my pictures... my basement is lit well enough to work, but not well enough to take proper pictures. Ignore the fact that I'm also limited to using my cell phone...

Hardware:

•Motherboard - MSI 890GXM-G65

• CPU - AMD Phenom II X6 1055T @ 3800mhz @ 1.375v

• RAM - 8GB DDR3-1600 (2x2GB Kingston HyperX, 2x2GB Geil)

• GPU - eVGA GTX260

• PSU - Silverstone Olympia OP650

• Case - Lian Li v351B

Currently that's watercooled with:

•CPU - EK Supreme HF v1 (the one that screws together from the top side)

• GPU - EK FC280

• Radiator - HW Labs Black Ice GTX 240

• Pump - Laing DDC3.2 + XSPC top

• Tubing - Primochill Primoflex Pro LRT white 3/8-5/8

• Fittings - Bitspower Black Chrome compressions

• Fans - Panaflo FBG12M12 (something like that)

• Reservoir - Swiftech MC Res micro v1

I get some pretty nice temperatures given the small radiator for the heat load. In my 19-21°C room, the CPU loads at about 31°C and the GPU at 43°C when loaded separately. Loading them 100% together doesn't make sense (no real world use seeing as I don't Fold/WCG at the time), and after playing BF3 for 1-3 hours, they're at about 28 and 42.

I've grown tired of the fan noise, and having watercooled an mATX case (just to see if I could), I've decided to bump up to a mid tower. I've always loved the smaller size of the Lian Li A05B, the inverted ATX layout, and the fact that it can still house a full ATX board.

In the quest for more cooling power with vastly quieter operation, I perused Martin's and Skinnee's sites, crunched some numbers, and arrived at something that I think will be equally as challenging as watercooling the v351, while giving me better performance at a quieter profile.

I've bought recently:•Case - Lian Li A05B

•Radiators - EK CoolStream XT 360 and XT 120

•Fittings - 2x Bitspower compressions

•Fans - 5x Gelid Silent 12 (per Martin's review)

•Grill - AC Ryan Bricky 3x120 in stainless

I'll keep this post updated here at the bottom with links to updates every time I post a new update.

Bear with my pictures... my basement is lit well enough to work, but not well enough to take proper pictures. Ignore the fact that I'm also limited to using my cell phone...

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)