Worklog started Friday, April 06, 2007

----+----+----+----+----+----+----+----+----+----+----+----+----+----+----+

2010 REBUILD

This project is being rebuilt starting at post #164

----+----+----+----+----+----+----+----+----+----+----+----+----+----+----+

Well, here goes... post #1 at [H] is the start of a new worklog for my new workstation Typhoon. My current workstation Tornado was another project I did in mid 2005, but didn't document. This time, I'll be taking pictures along the way and will post them here. I hope you find it interesting!

Project Criteria:

More to come...

Updates:

10-11-2007: Update parts list

04-26-2010: Update image link

04-30-2010: Start rebuild posts

----+----+----+----+----+----+----+----+----+----+----+----+----+----+----+

2010 REBUILD

This project is being rebuilt starting at post #164

----+----+----+----+----+----+----+----+----+----+----+----+----+----+----+

Well, here goes... post #1 at [H] is the start of a new worklog for my new workstation Typhoon. My current workstation Tornado was another project I did in mid 2005, but didn't document. This time, I'll be taking pictures along the way and will post them here. I hope you find it interesting!

Project Criteria:

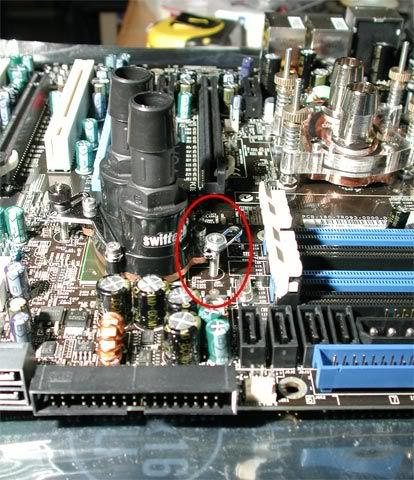

- Make it as quiet as possible, with maximum cooling.

- Squeeze in as many hard drives as possible to make one RAID 0 array and one large RAID 5 (or 6) array.

- Maximum hard drive cooling.

- Allow for decent overclock.

- 4GB RAM (probably need to run x64)

- Fit everything inside the case, if possible

- 1x - COOLER MASTER Stacker 810 RC-810-SKN1, black

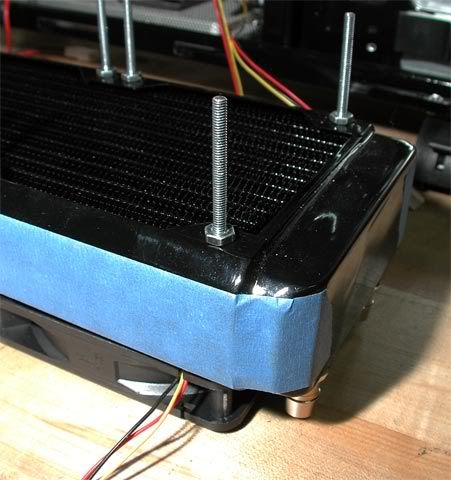

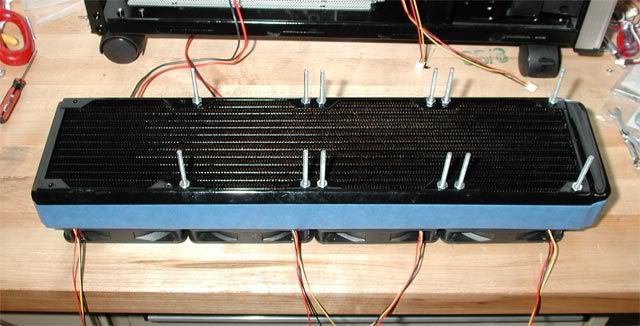

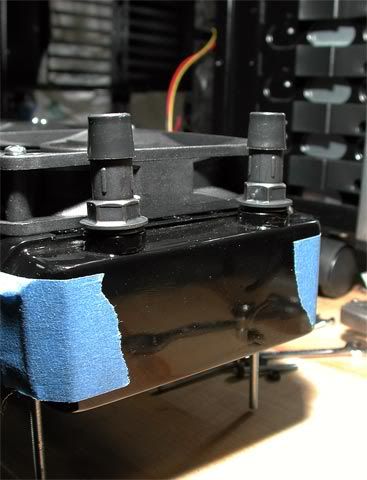

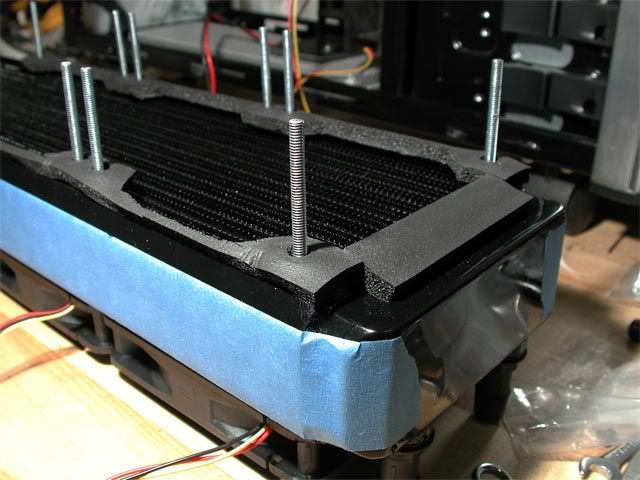

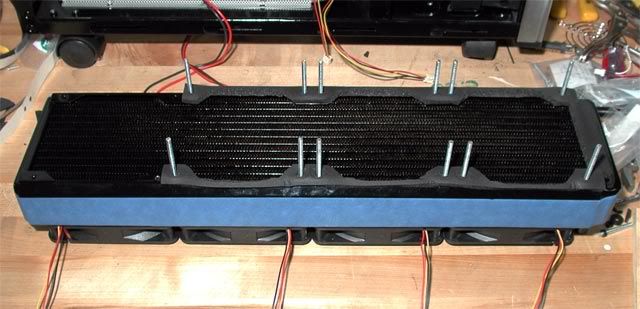

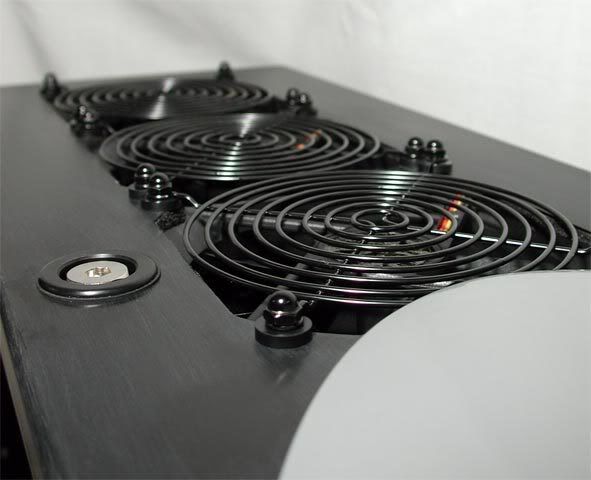

- 1x - Black Ice GTX480

- 7x - Yate Loon 120mm Case Fan - D12SL-12 for GTX480 radiator

- 2x - SUPERMICRO CSE-M35T-1B SATA hard drive enclosure with backplane, black

- 2x - Panaflo FBA12G12U 120mm ultra high speed fan for hard drive enclosures

- 1x - Sunbeam 5-1/4" Rheobus, black (got one from Petra's!)

- 2x - 1/4" NPSM, 1/2" OD nylon hose barb, black

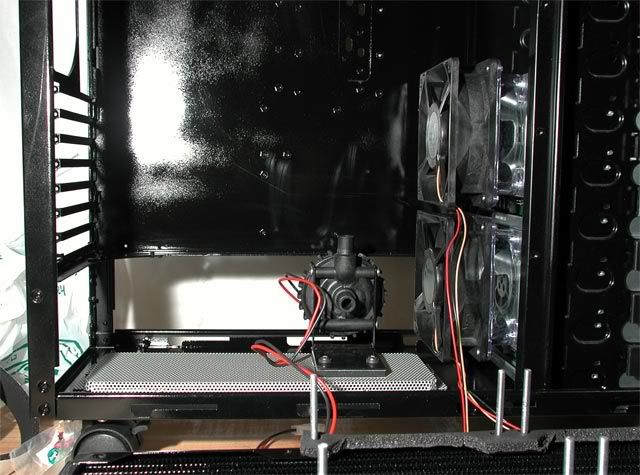

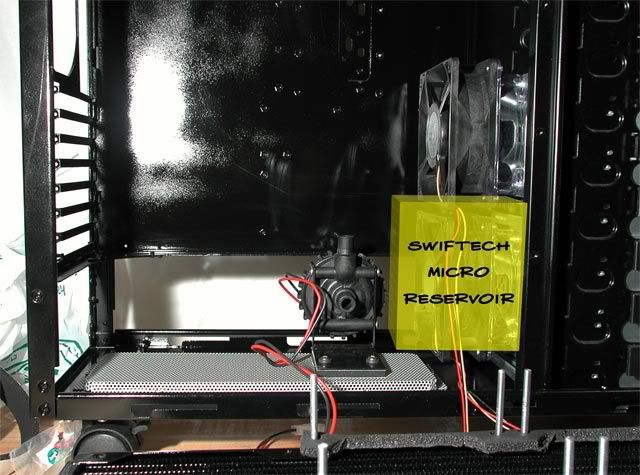

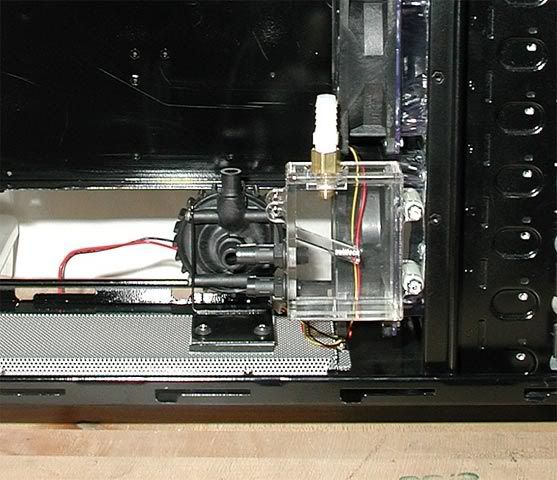

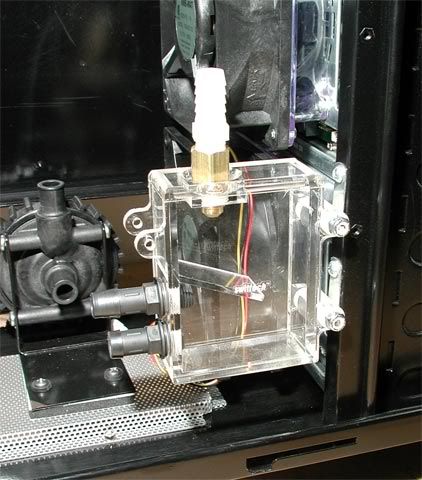

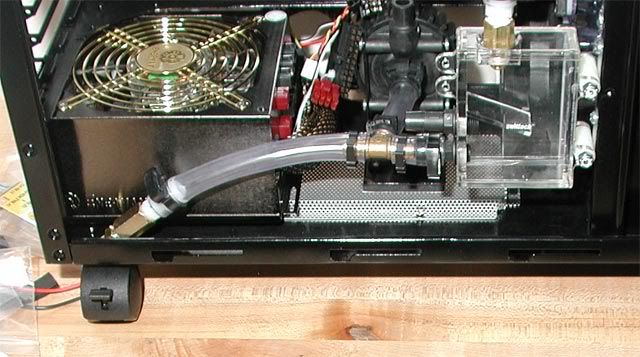

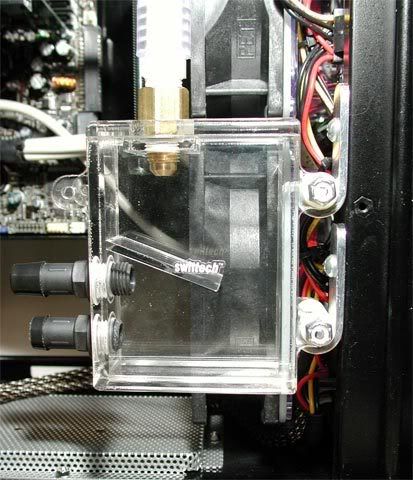

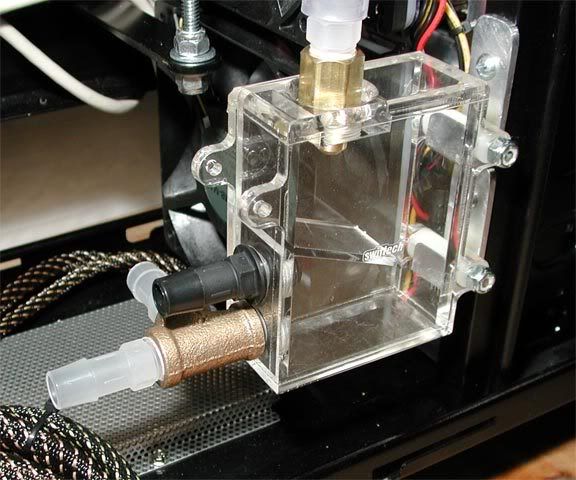

- 1x - Swiftech MCP655 pump

- 1x - Enermax Infiniti 720W PSU

- 10' - Tygon tubing

- 8x - Seagate 320GB (ST3320620NS)

- 2x - 150GB Raptor

- 1x - Areca 1231ML PCI-E RAID card

- ...

More to come...

Updates:

10-11-2007: Update parts list

04-26-2010: Update image link

04-30-2010: Start rebuild posts

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)