Now that my dual-cpu cube computer is built, I'm free to move on to a new project. Introducing TM-β:

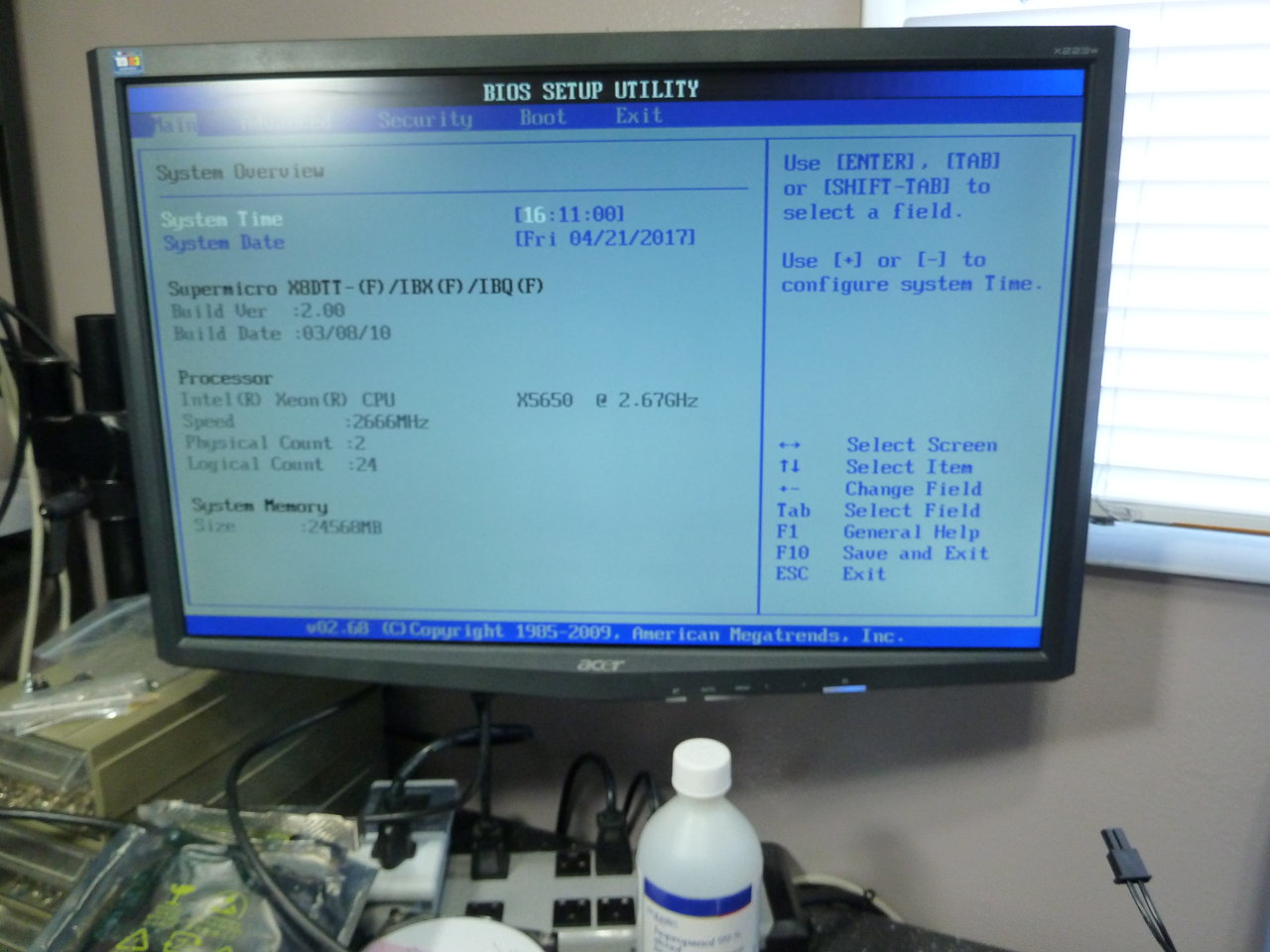

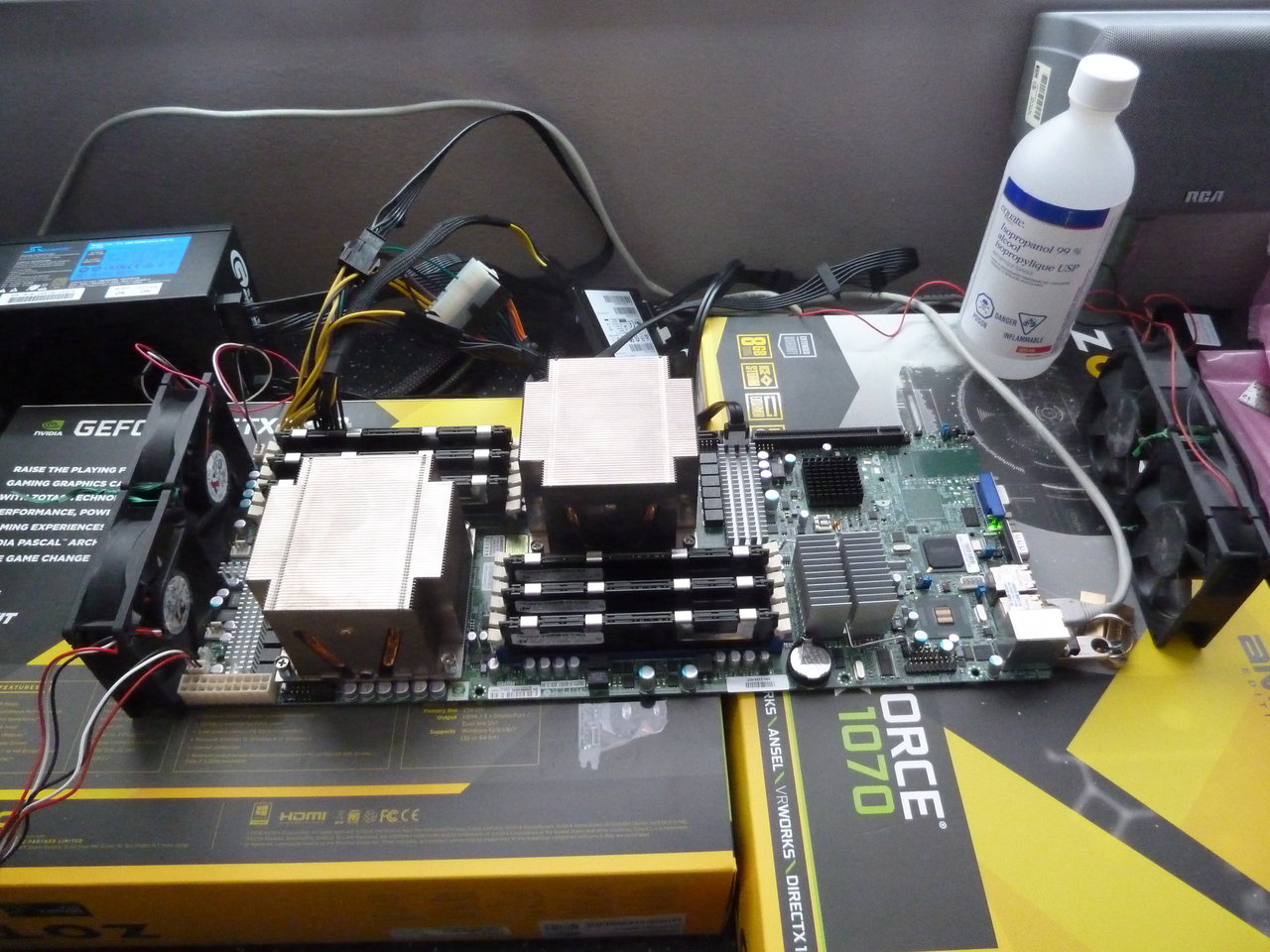

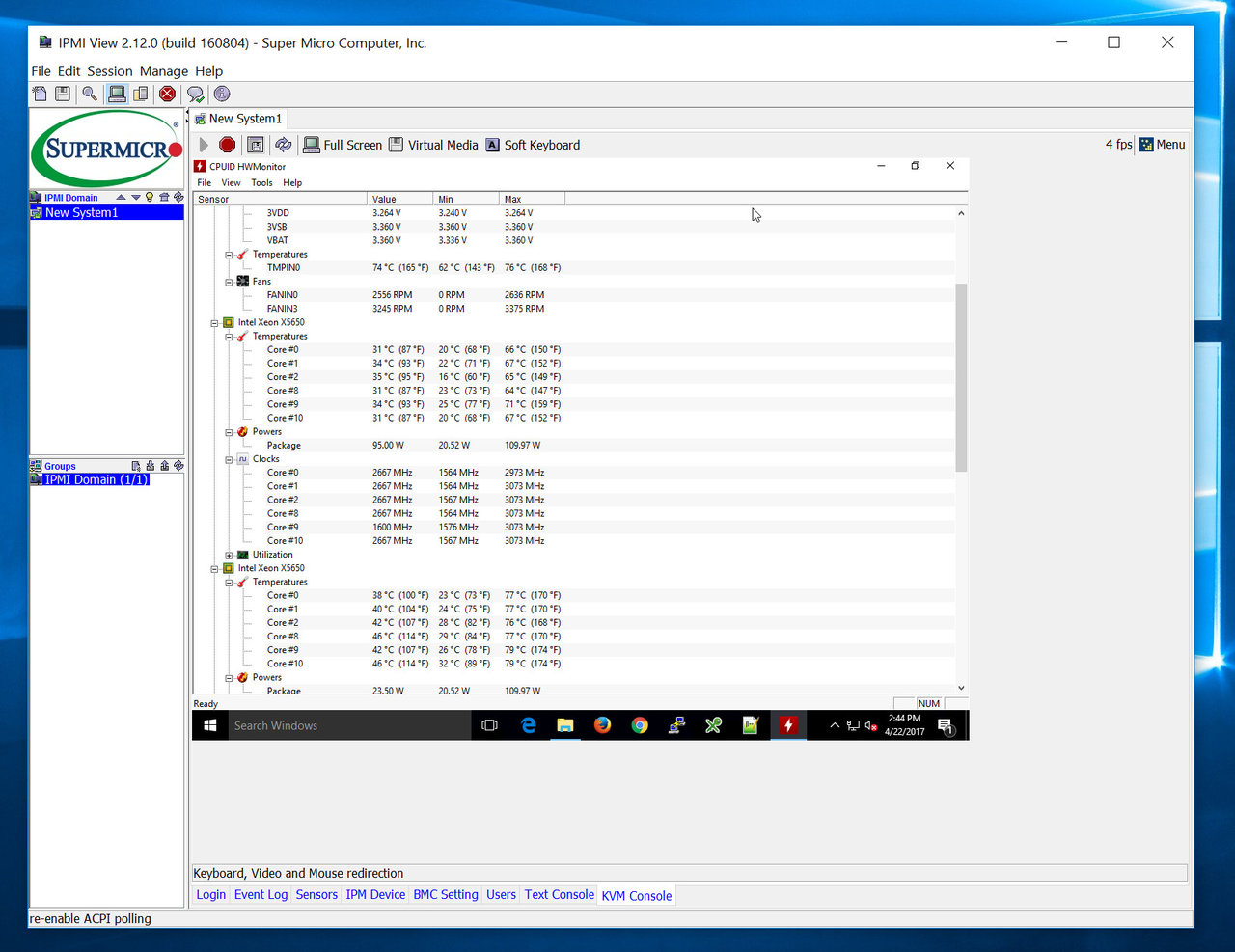

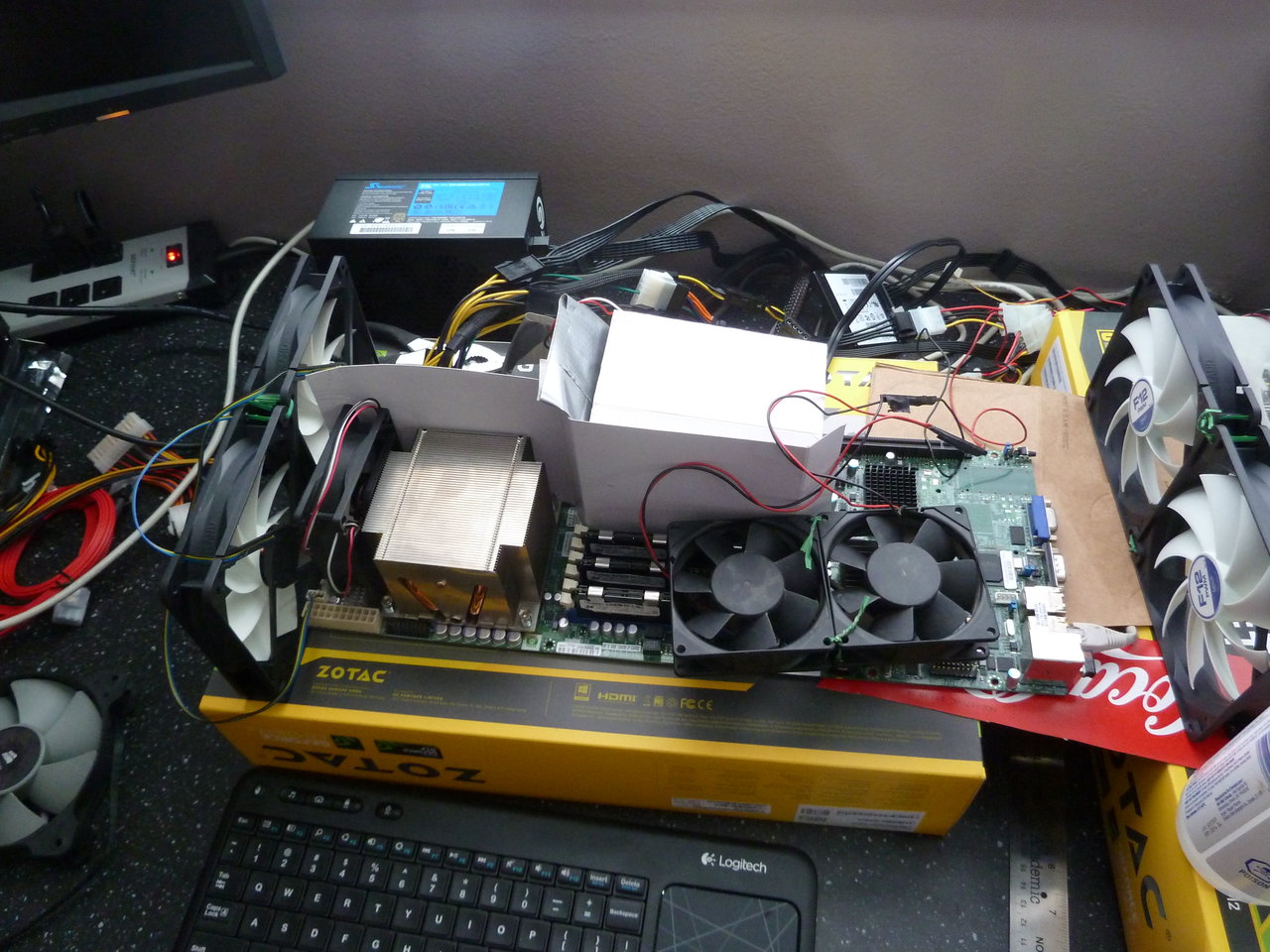

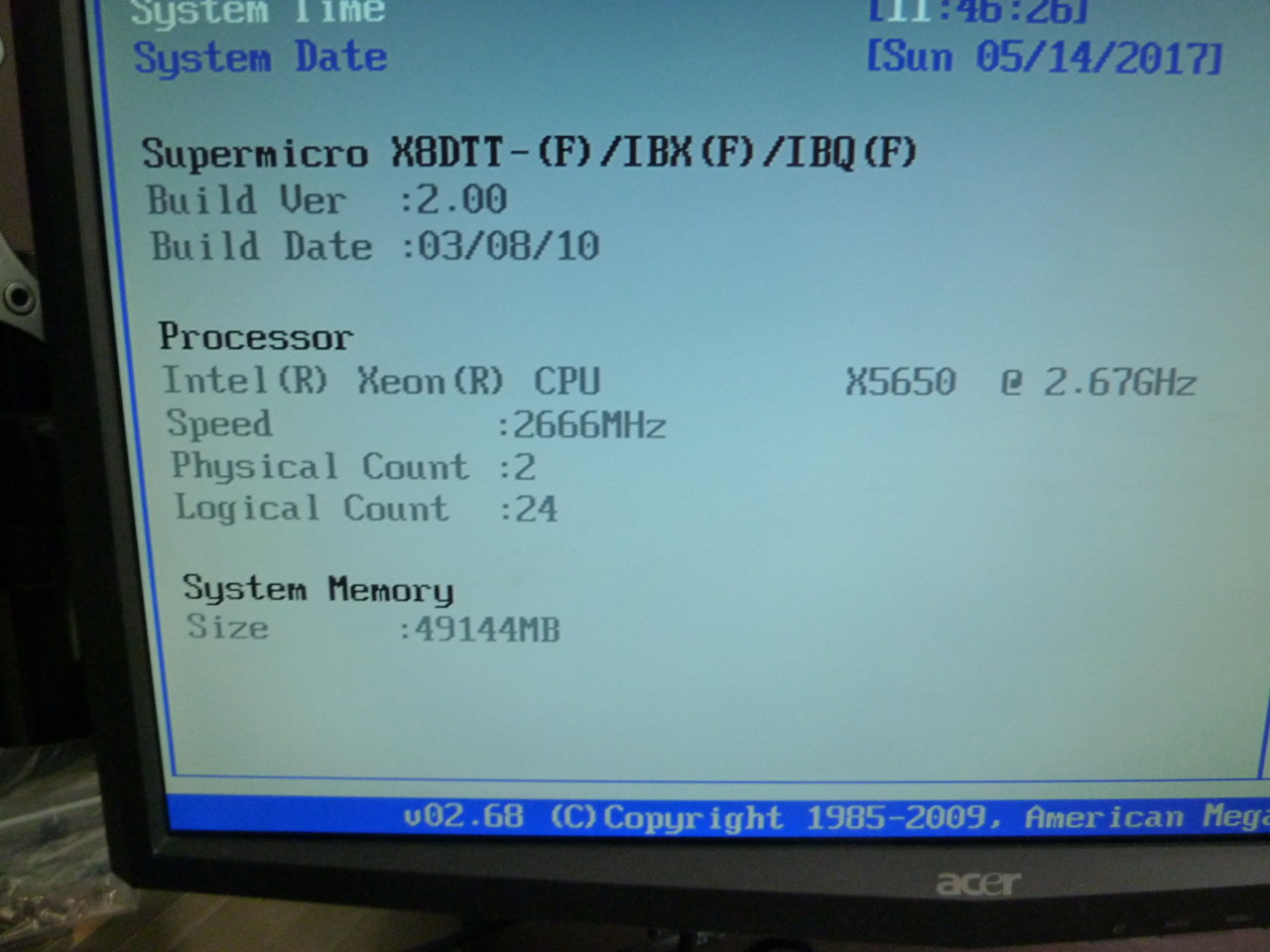

Those are Xeon X5650s - 2.66ghz, 6 core/12 thread, Socket 1366

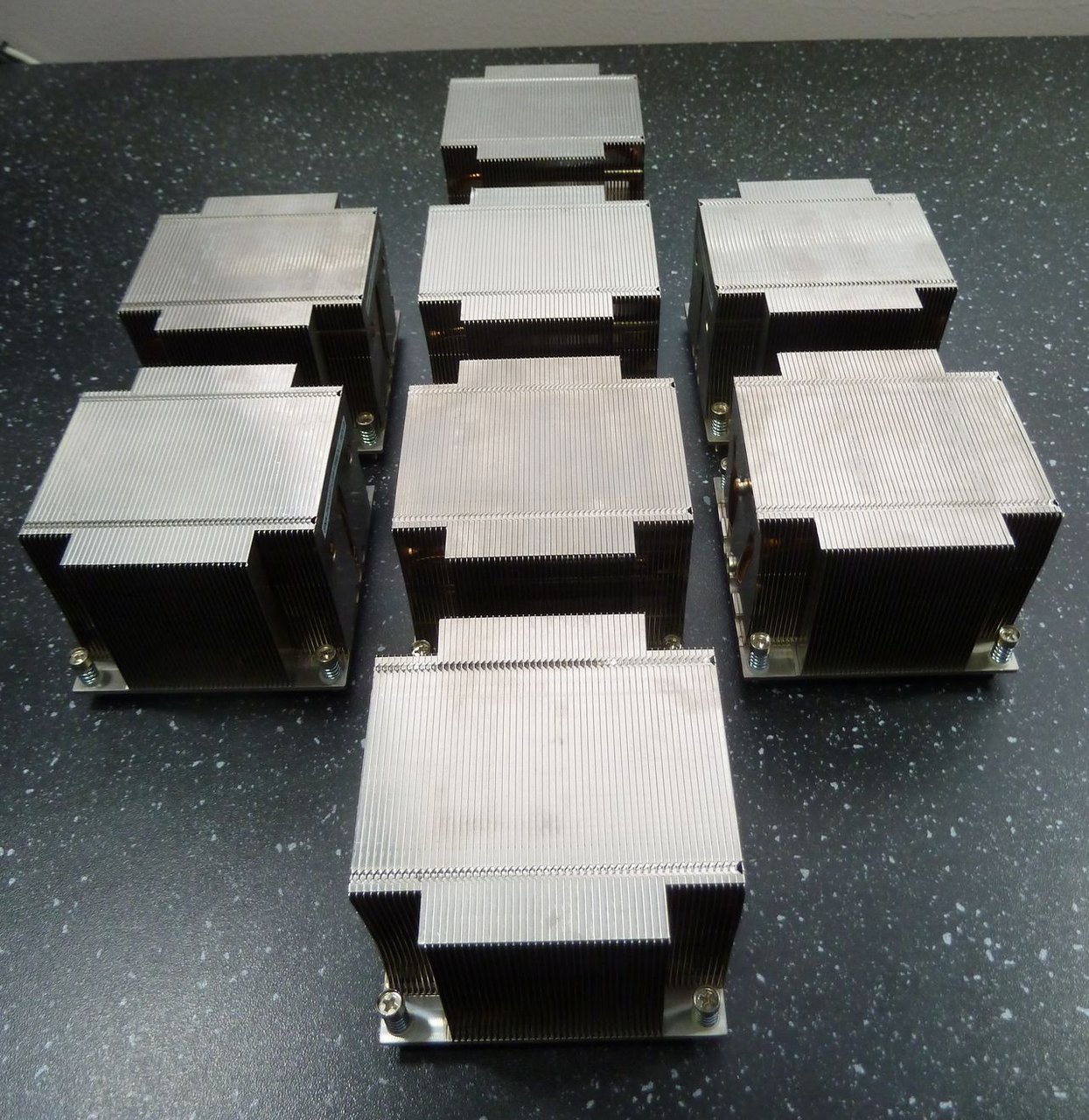

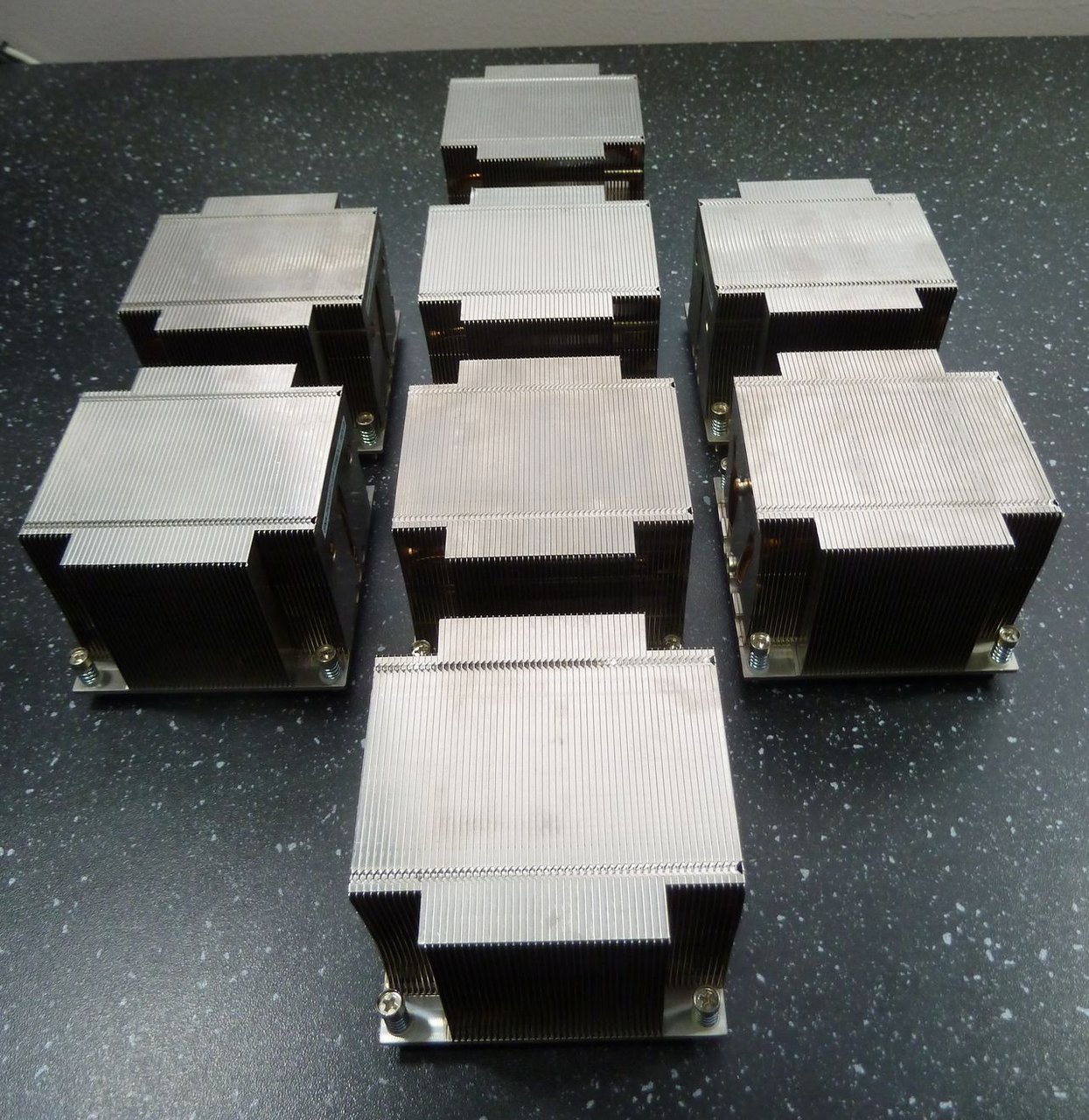

The heatsinks. Supermicro 2U passive, with heatpipes. I was going to go with something bigger, but the boards are... a little special, so I decided not to risk compatibility issues.

The Ram. 96gb of registered ECC.

And the boards. Supermicro X8DTT rev 2.

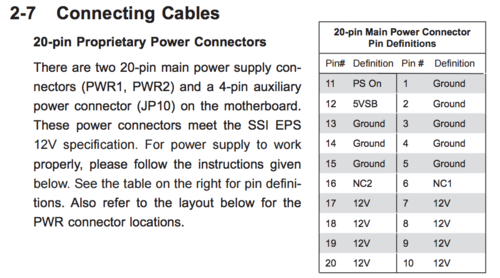

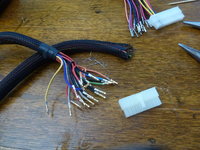

They take a non-standard 20pin power connection, with only 12v, ground, and 5vsb. I have adapters on order, but I'll hack something together for testing for now.

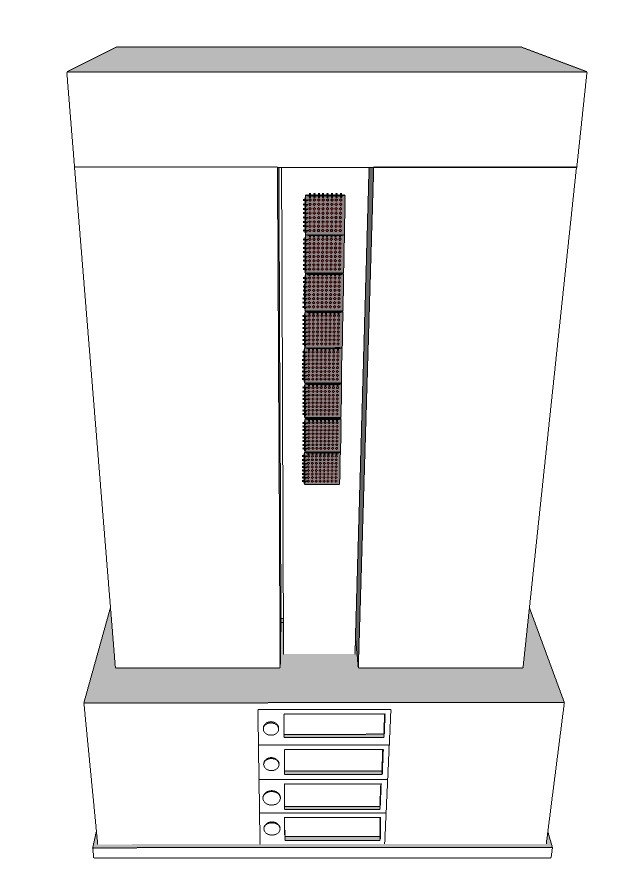

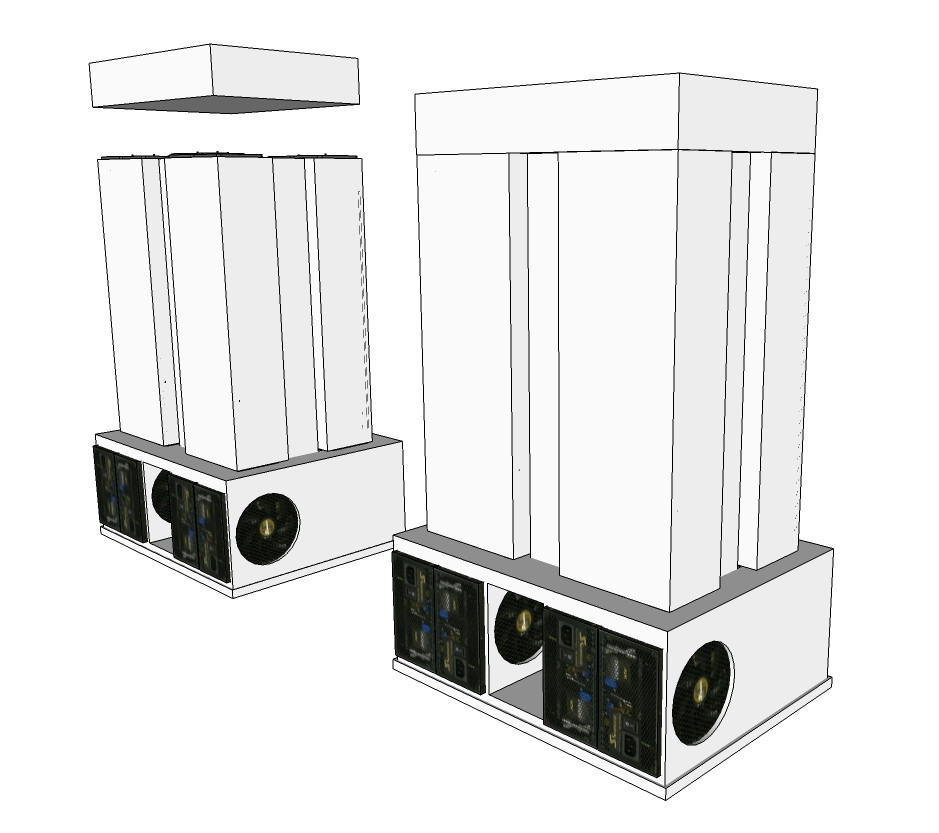

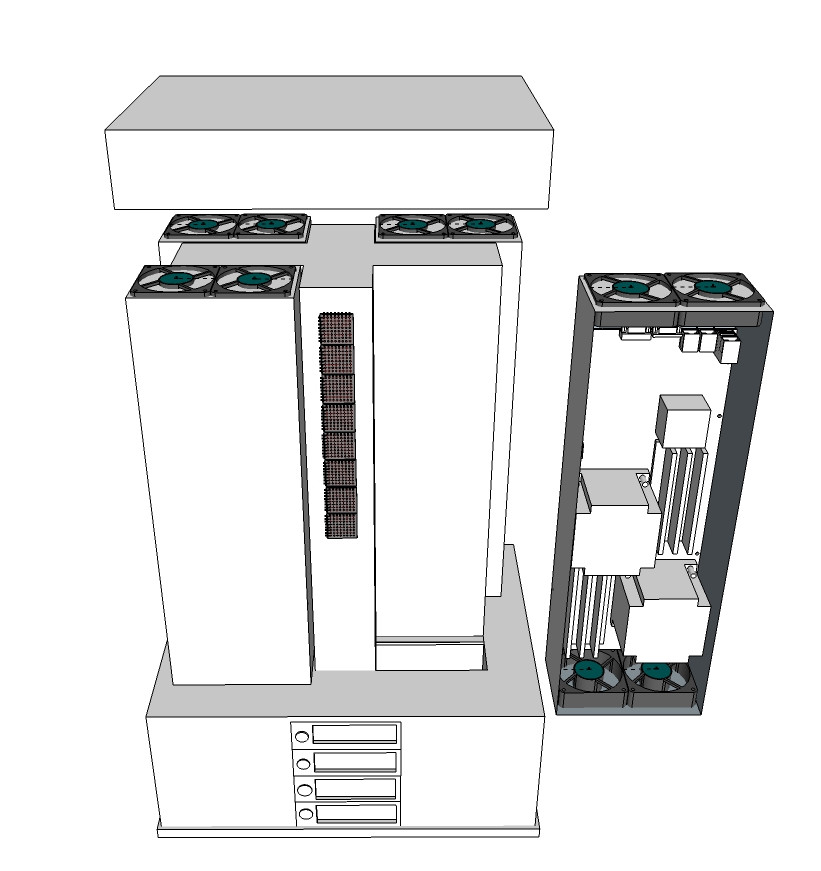

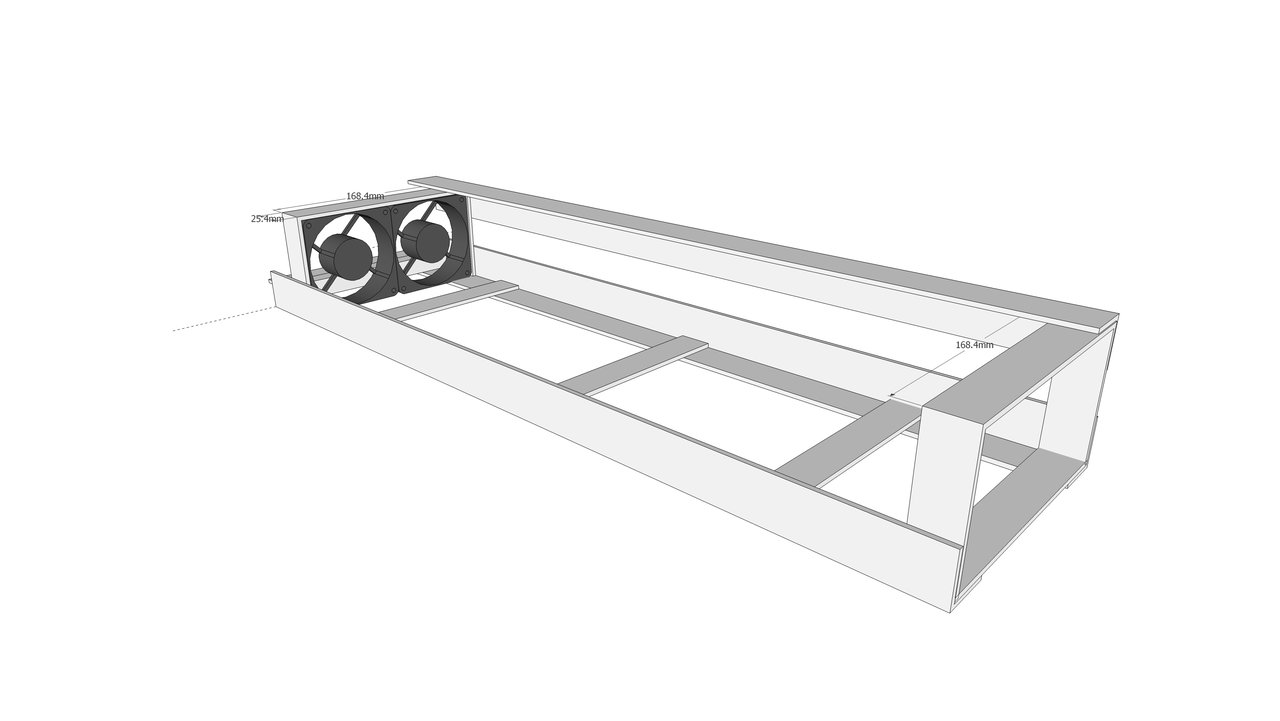

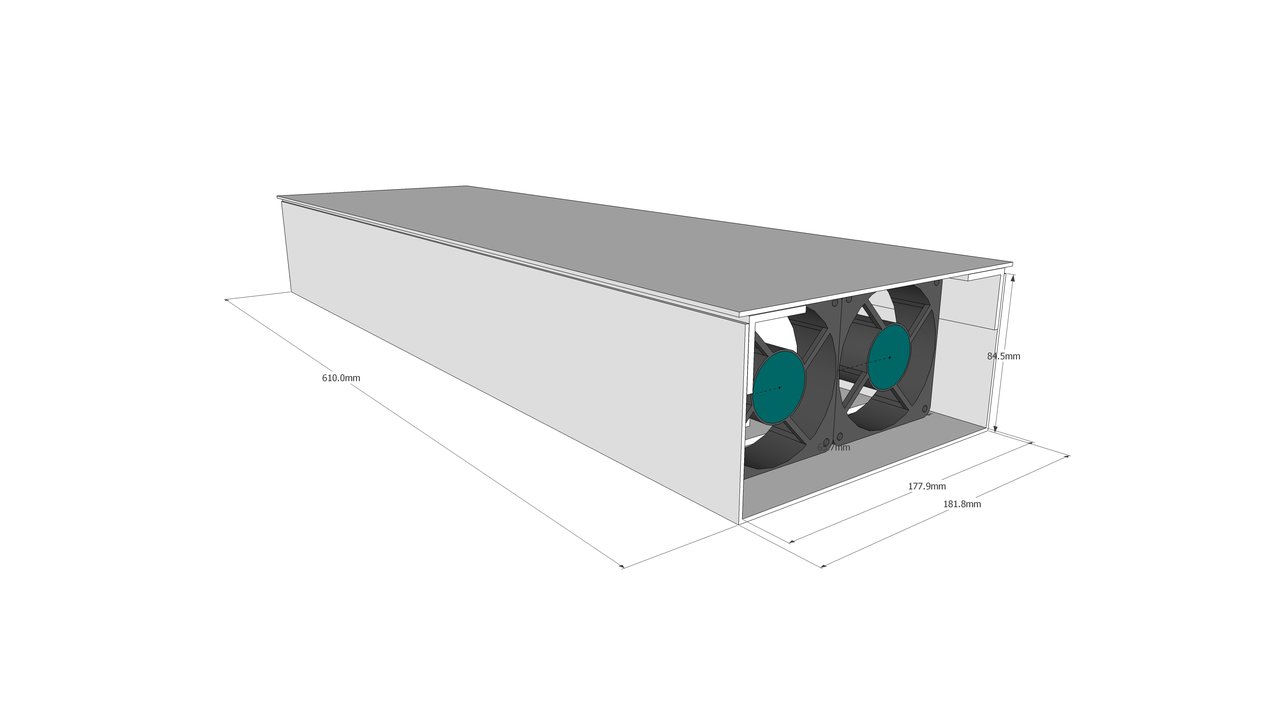

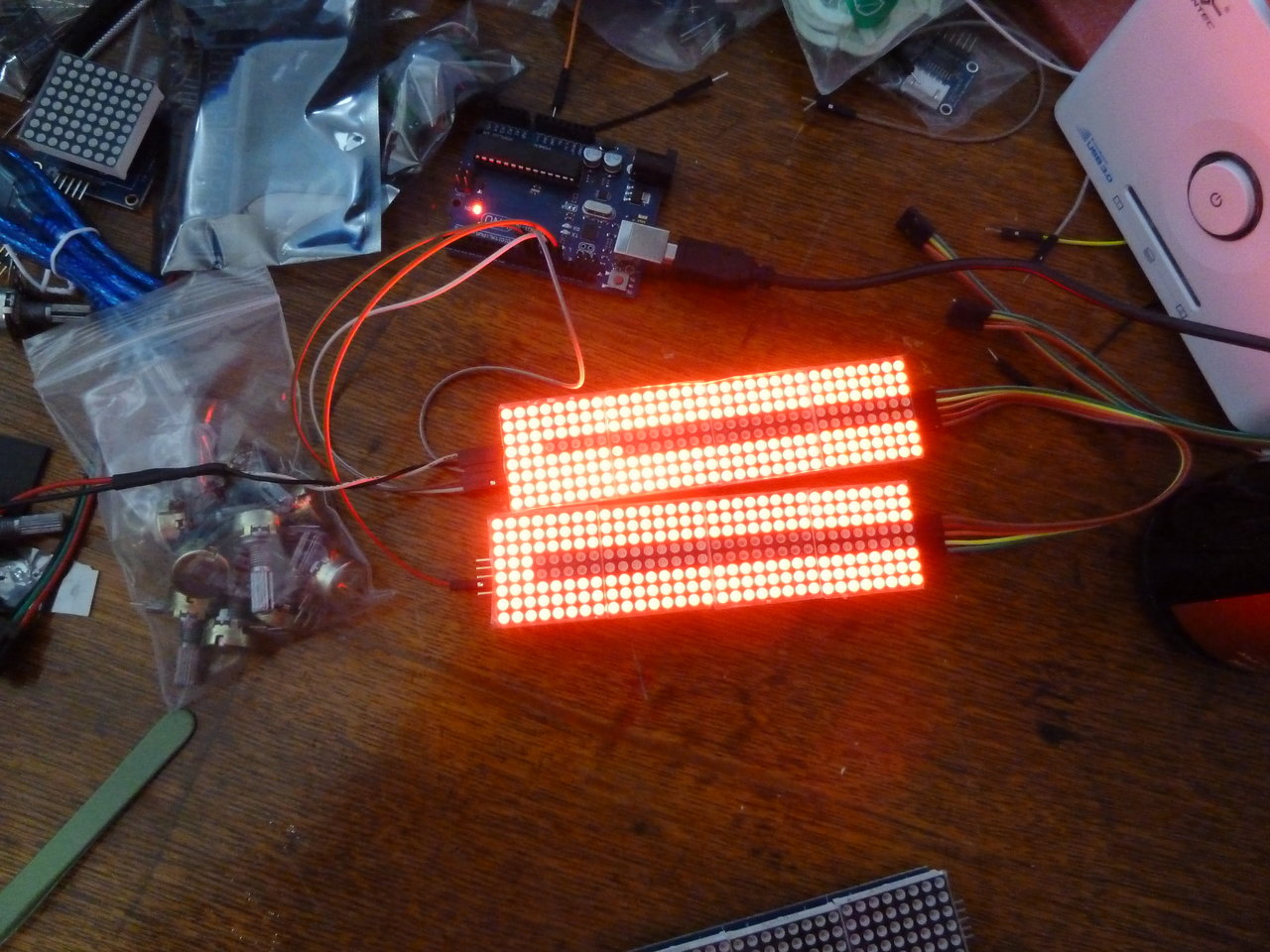

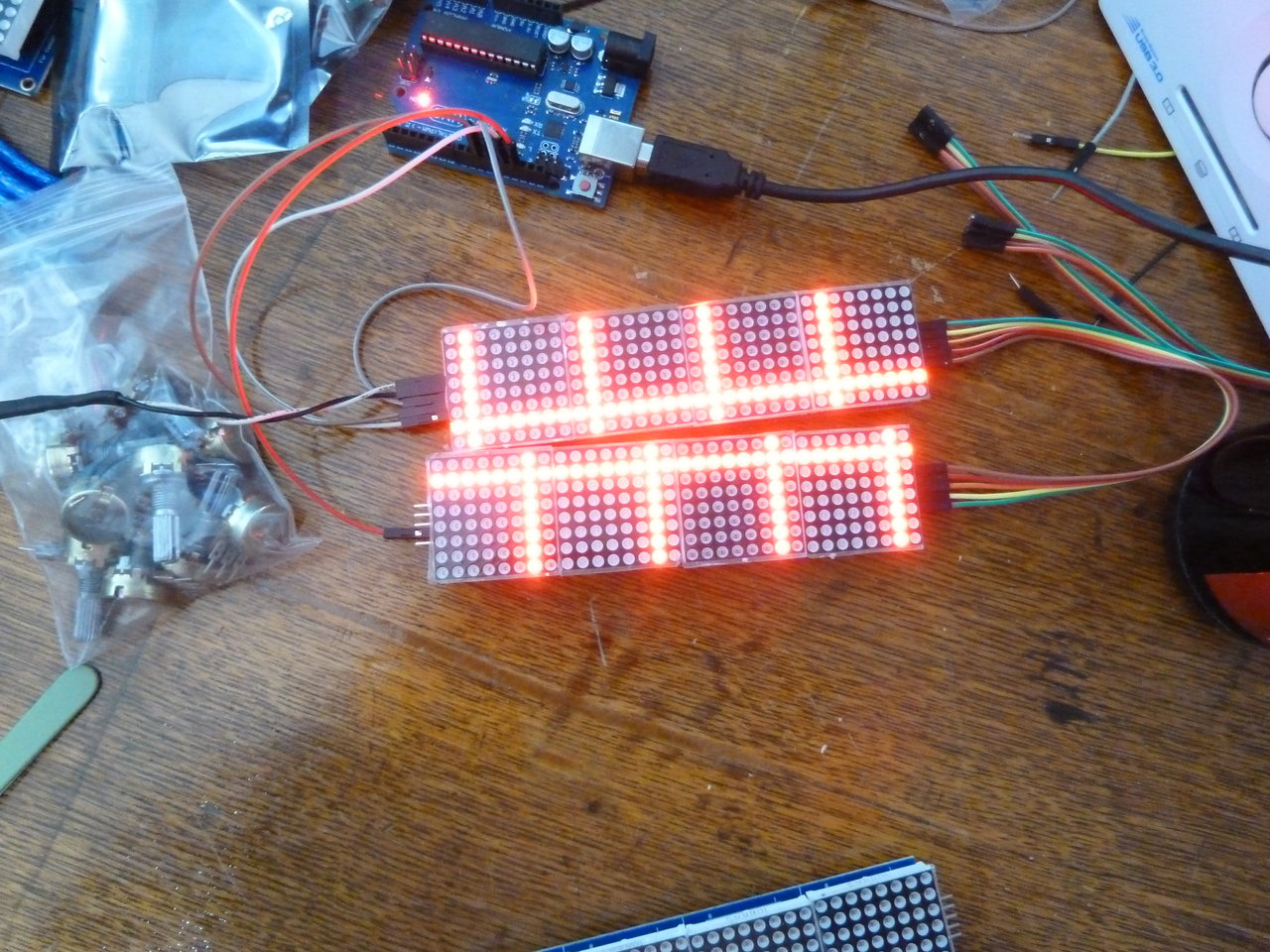

TM-β is for Thinking Machine - Beta, or Beowulf. I wanted to build a small cluster to mess around with - a little rendering here, some distributed computing there. I'm going to be custom building a case for these, inspired by various supercomputers:

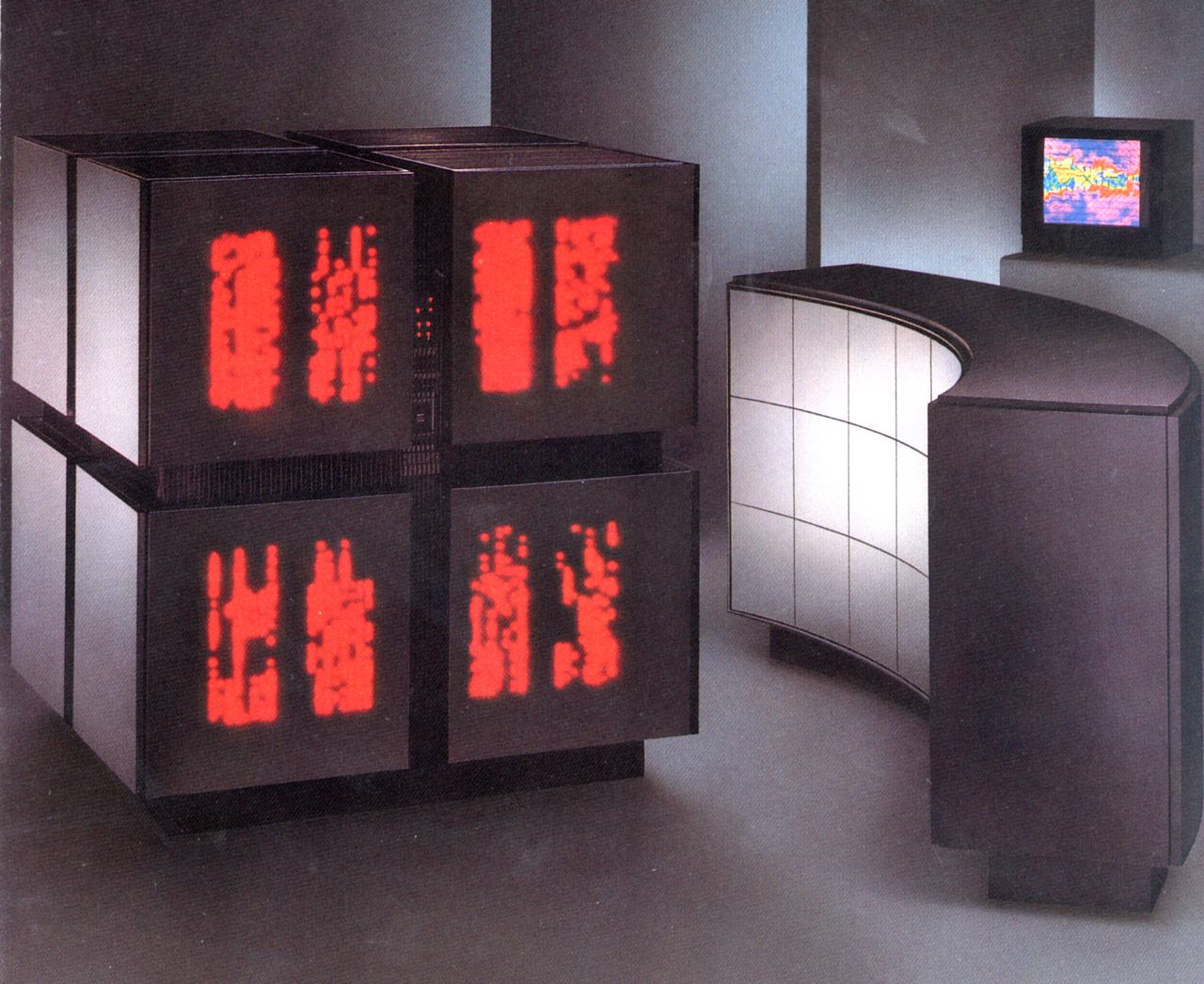

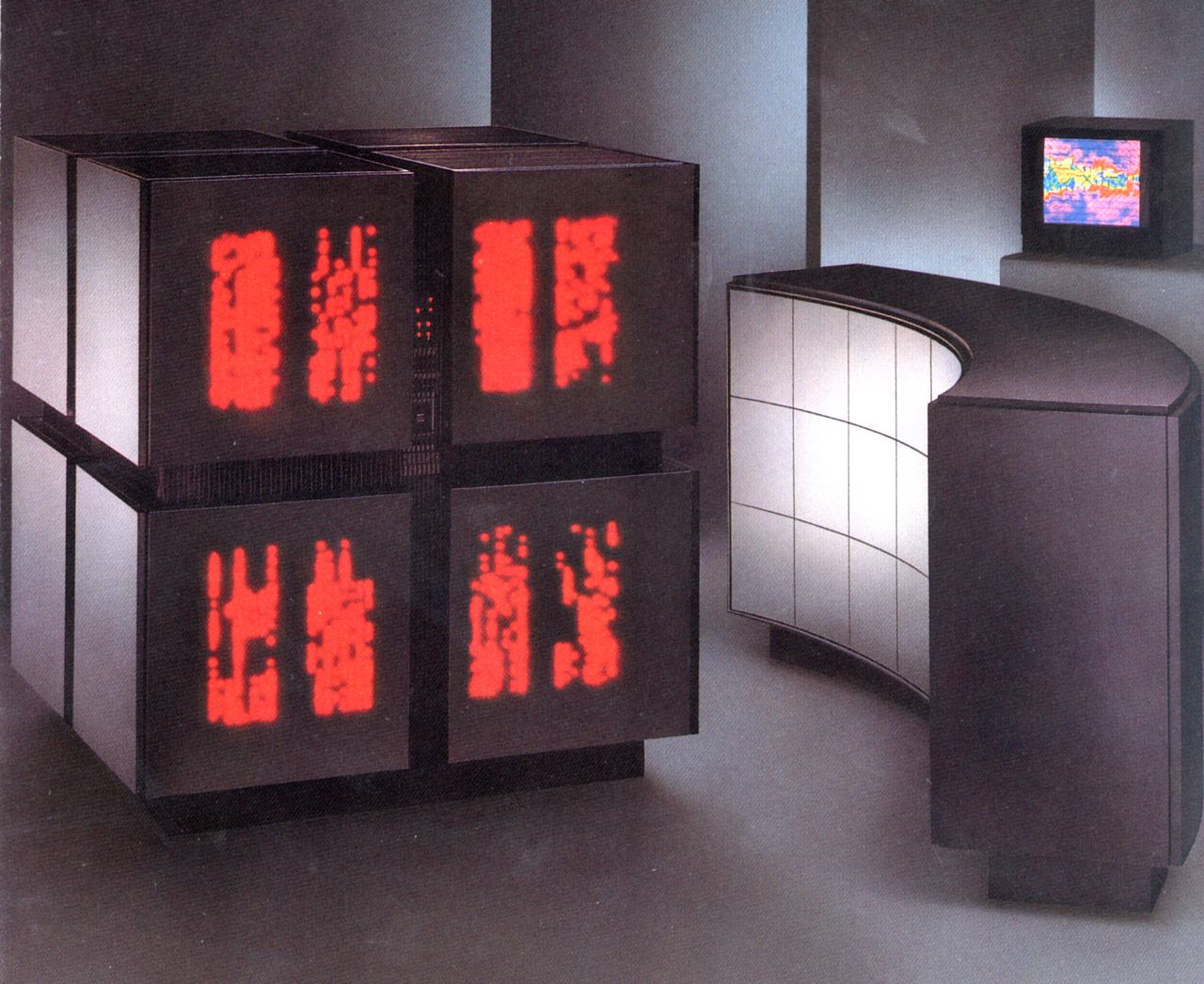

A little bit of Thinking Machine's CM-2:

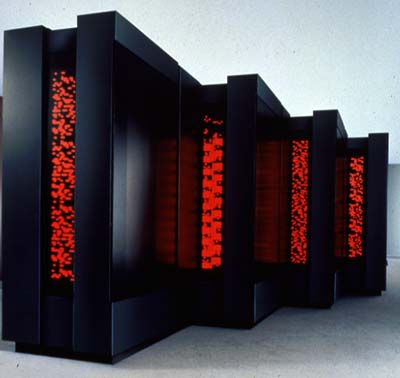

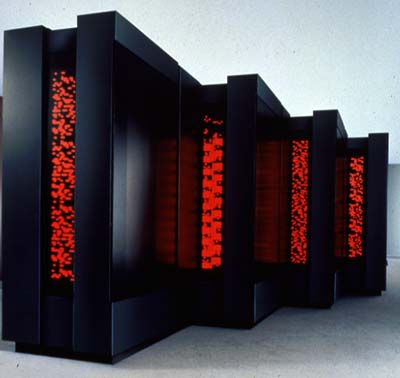

A little bit of Thinking Machine's CM-5 (Yes, the Jurassic Park one):

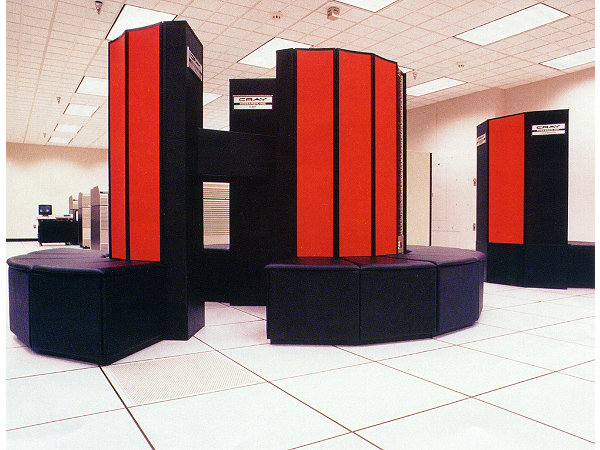

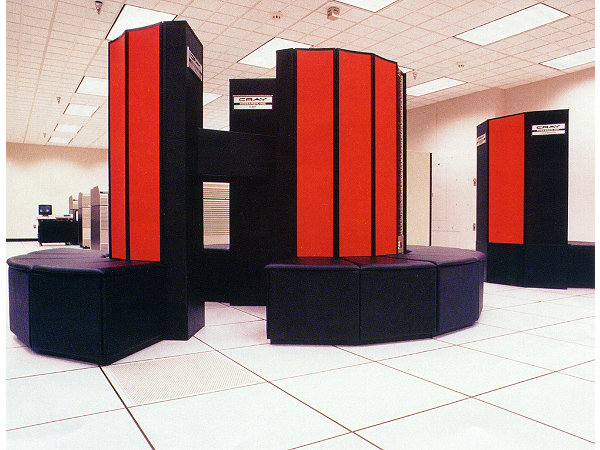

With just a dash of Cray:

I've got a lot of other stuff going on, so I won't be updating often, but I hope someone finds this at least a little entertaining.

Those are Xeon X5650s - 2.66ghz, 6 core/12 thread, Socket 1366

The heatsinks. Supermicro 2U passive, with heatpipes. I was going to go with something bigger, but the boards are... a little special, so I decided not to risk compatibility issues.

The Ram. 96gb of registered ECC.

And the boards. Supermicro X8DTT rev 2.

They take a non-standard 20pin power connection, with only 12v, ground, and 5vsb. I have adapters on order, but I'll hack something together for testing for now.

TM-β is for Thinking Machine - Beta, or Beowulf. I wanted to build a small cluster to mess around with - a little rendering here, some distributed computing there. I'm going to be custom building a case for these, inspired by various supercomputers:

A little bit of Thinking Machine's CM-2:

A little bit of Thinking Machine's CM-5 (Yes, the Jurassic Park one):

With just a dash of Cray:

I've got a lot of other stuff going on, so I won't be updating often, but I hope someone finds this at least a little entertaining.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)