Mr_Armageddon

Limp Gawd

- Joined

- Jun 3, 2009

- Messages

- 252

Introduction

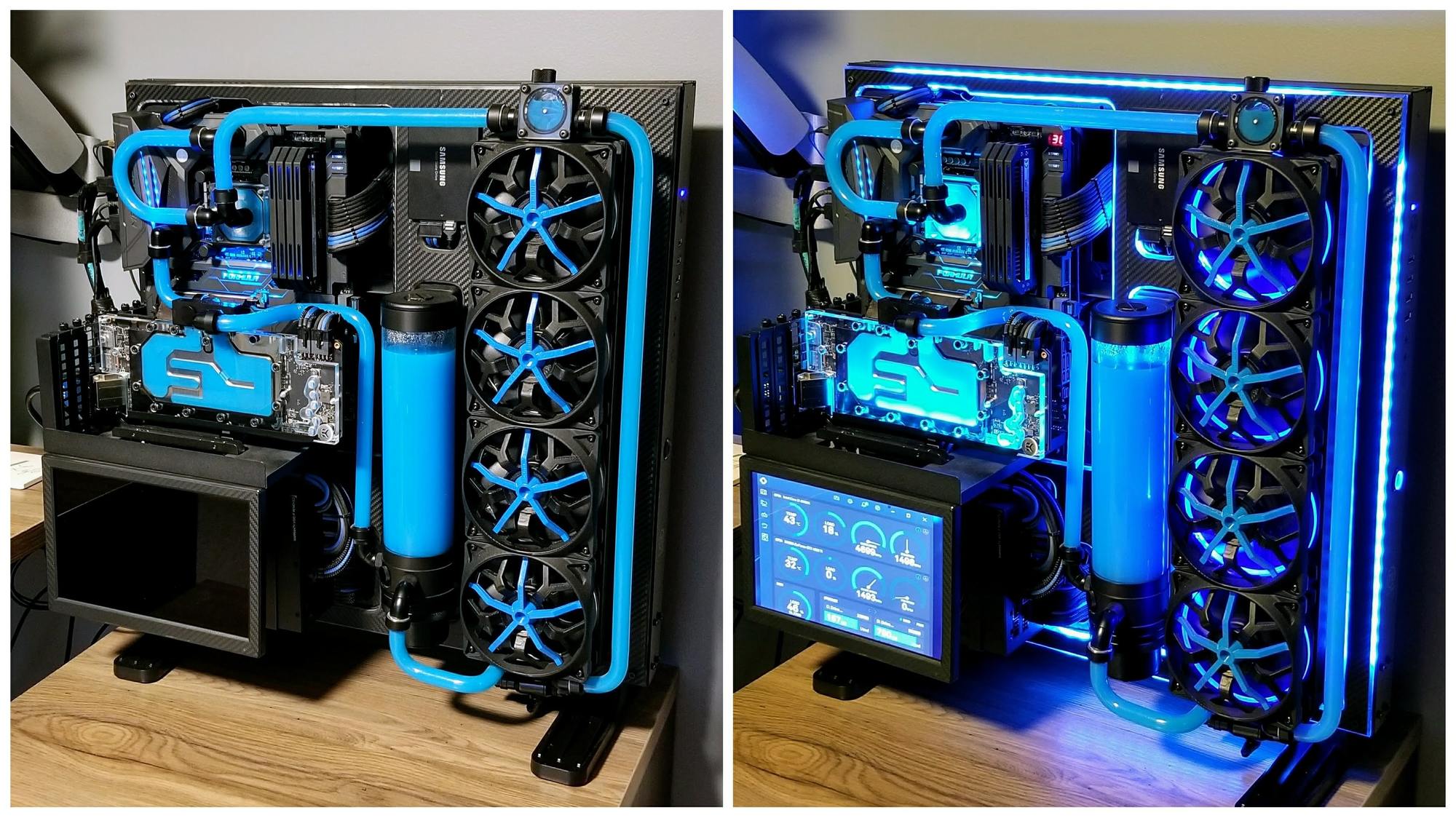

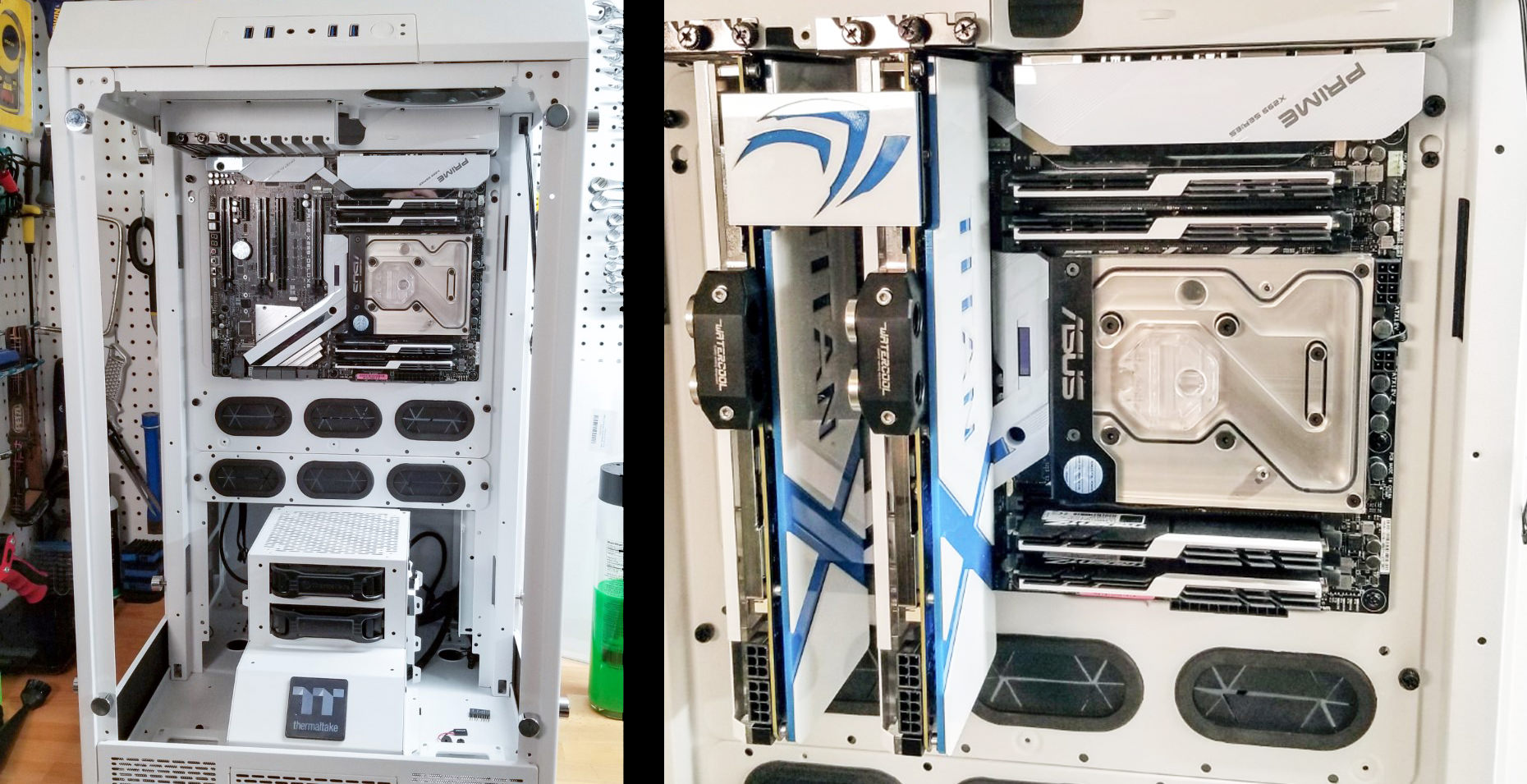

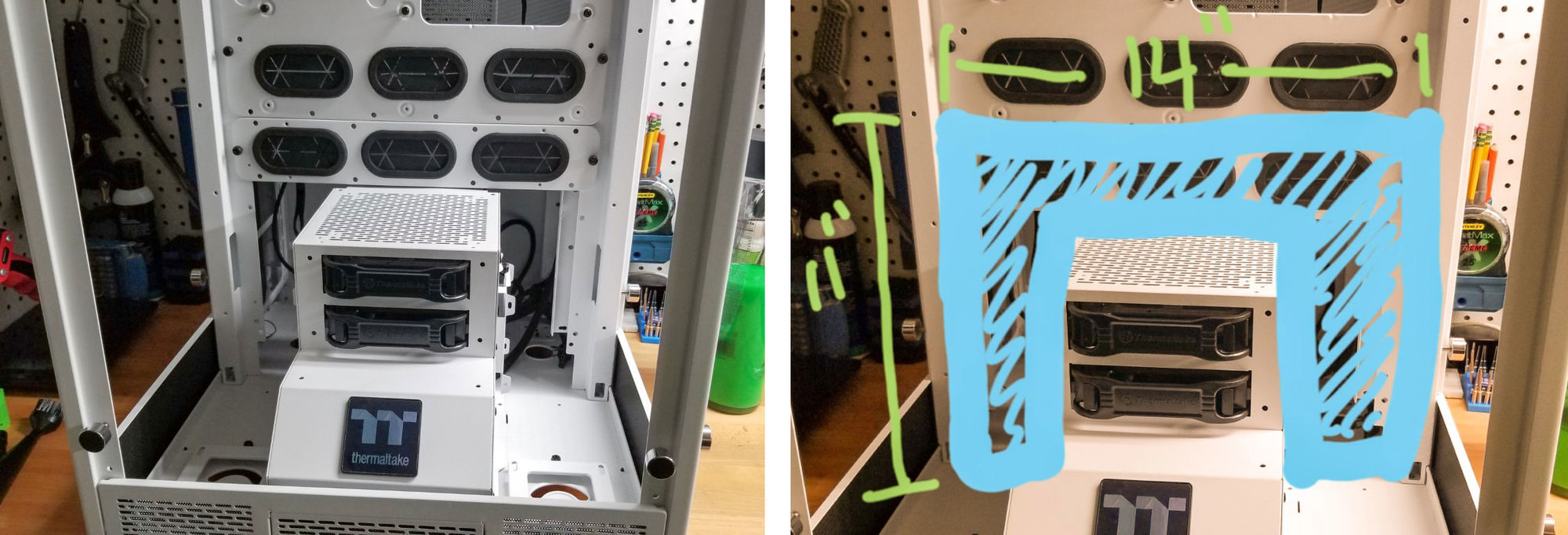

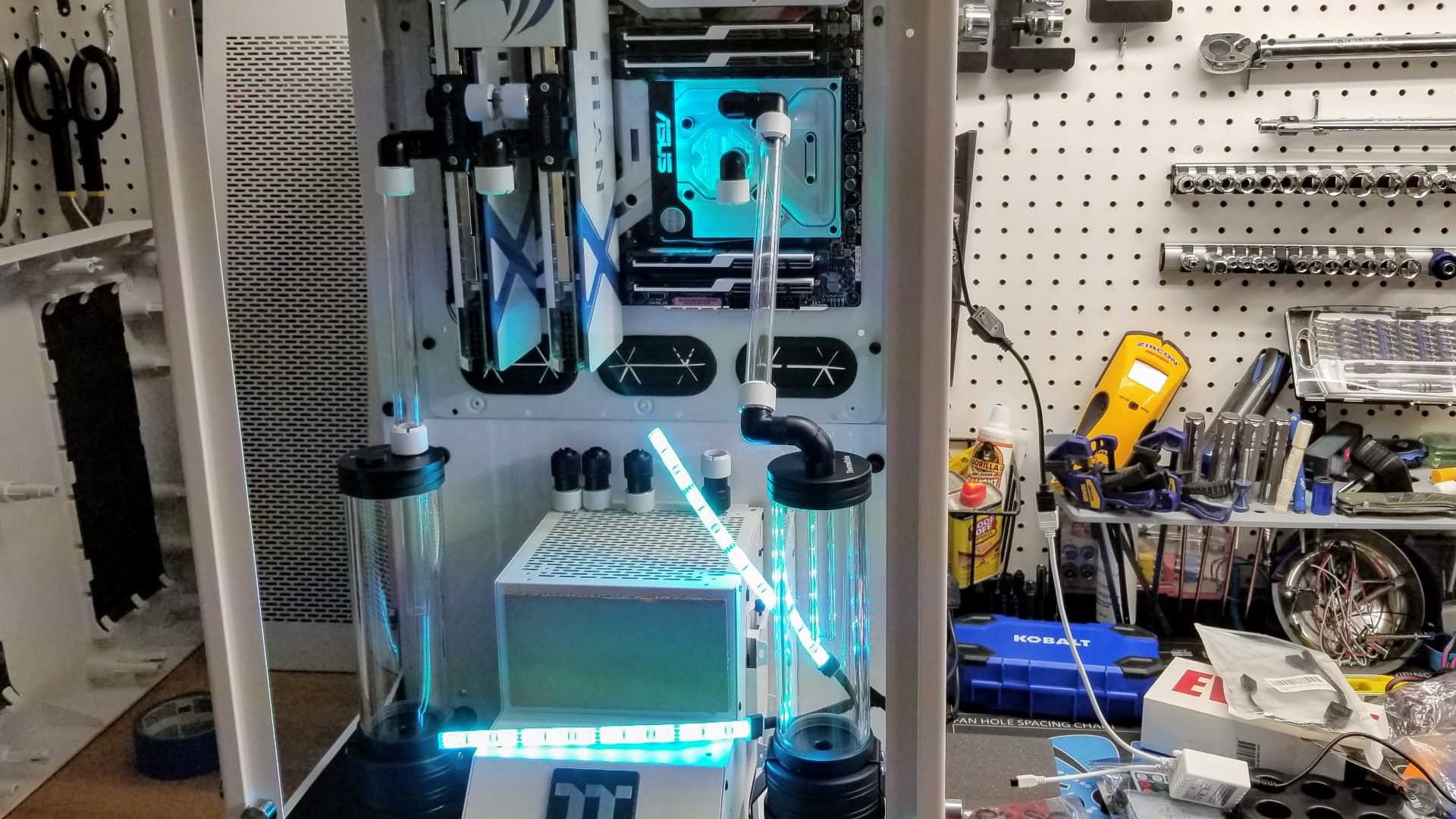

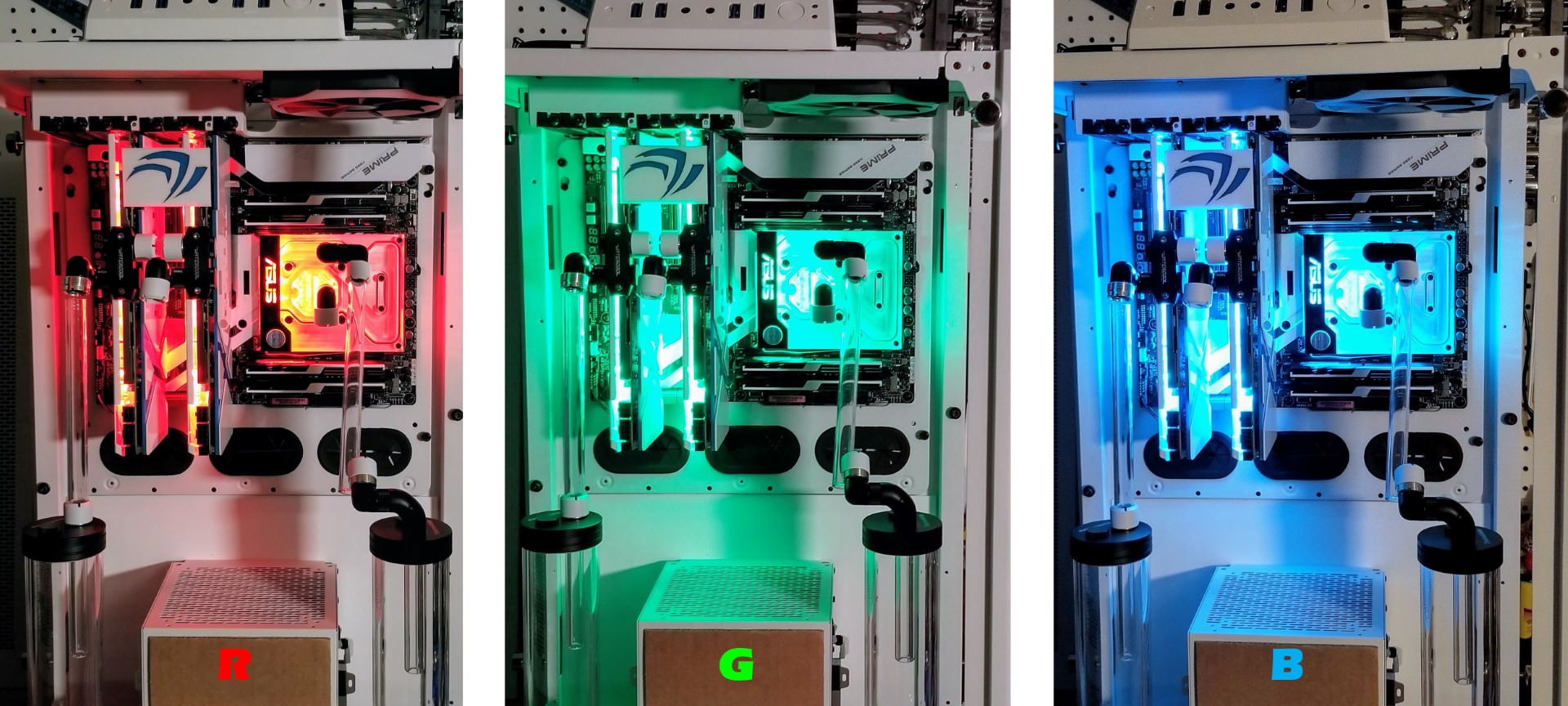

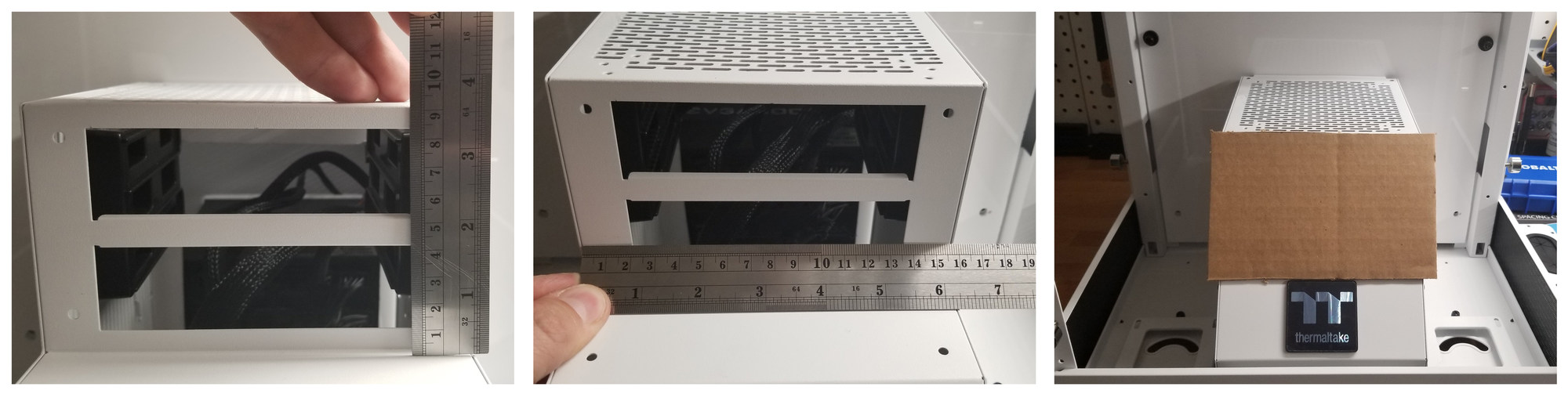

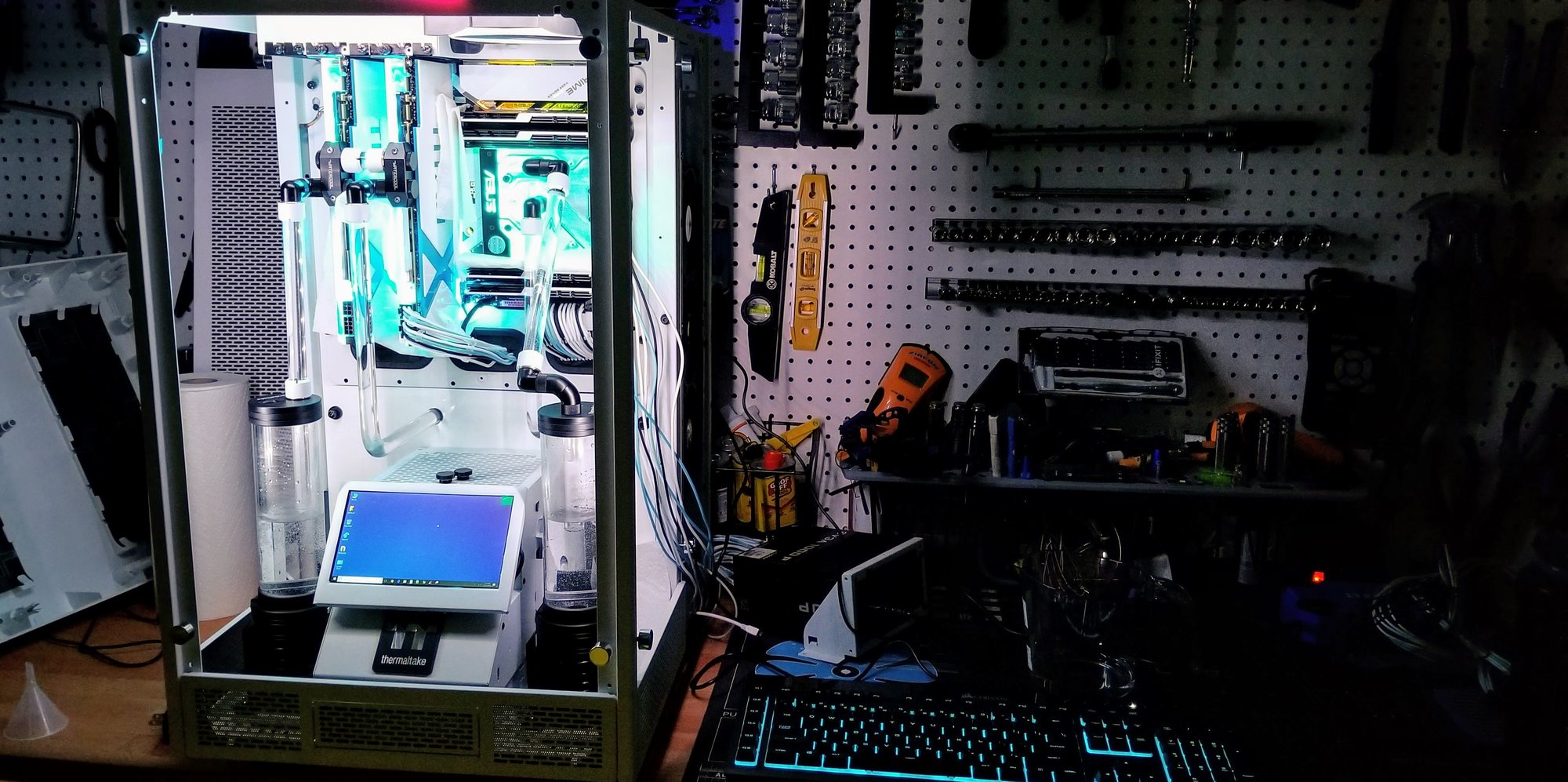

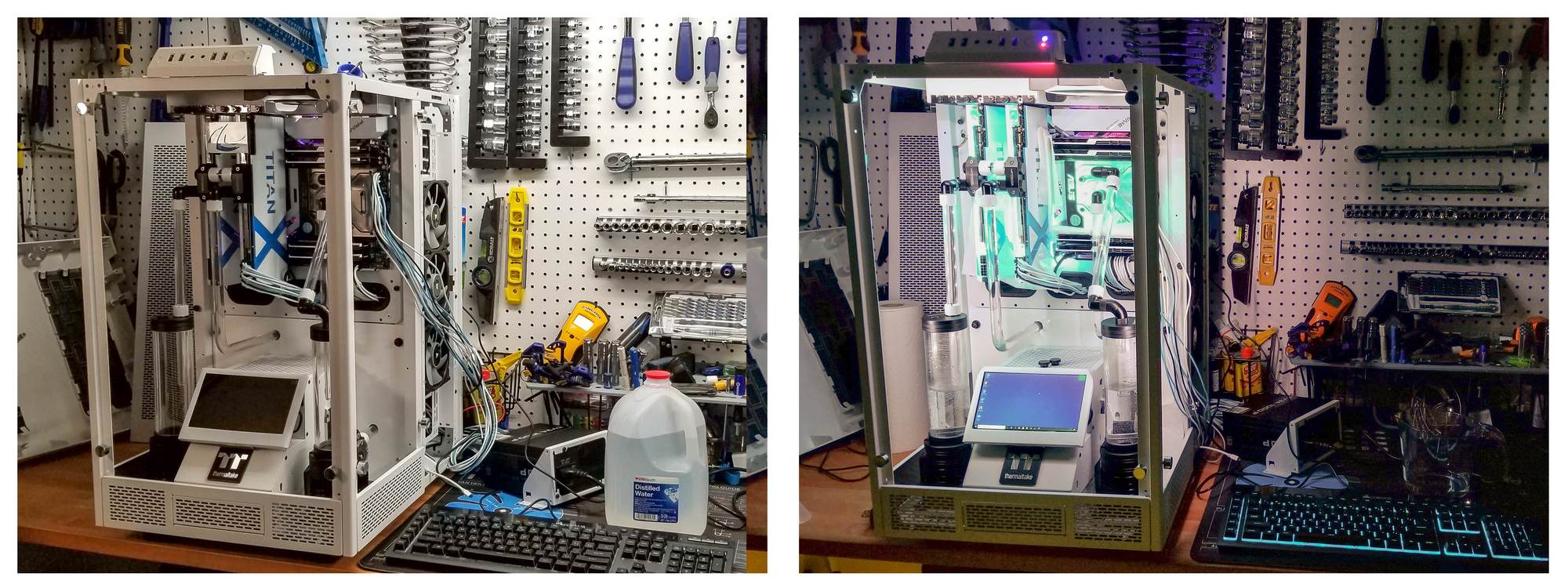

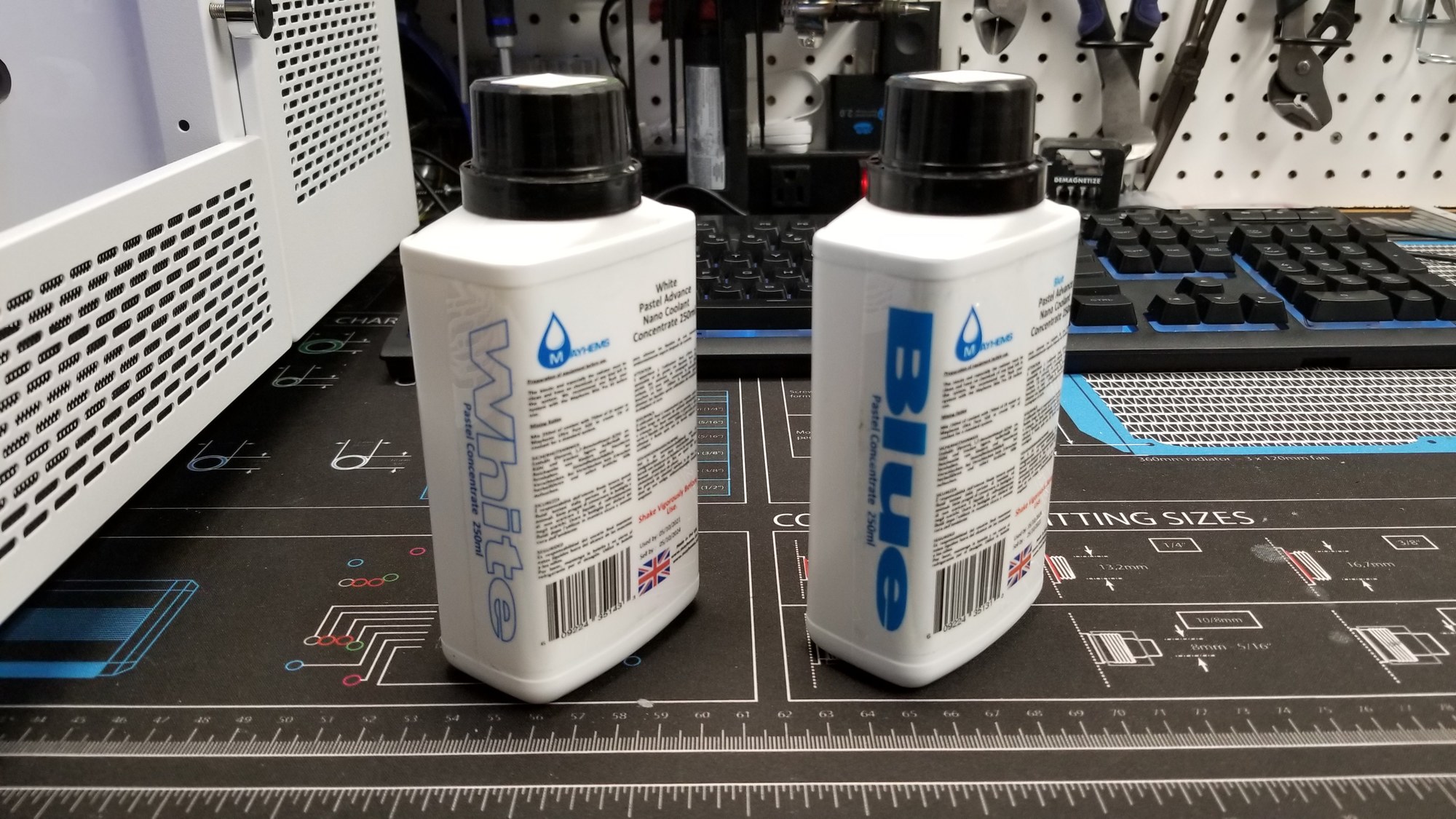

It's time for another custom Liquid Cooled build, and this time we are utilizing the MASSIVE Thermaltake Tower 900 case! This is a commissioned build, using some extreme hardware, and I am really excited to get started.

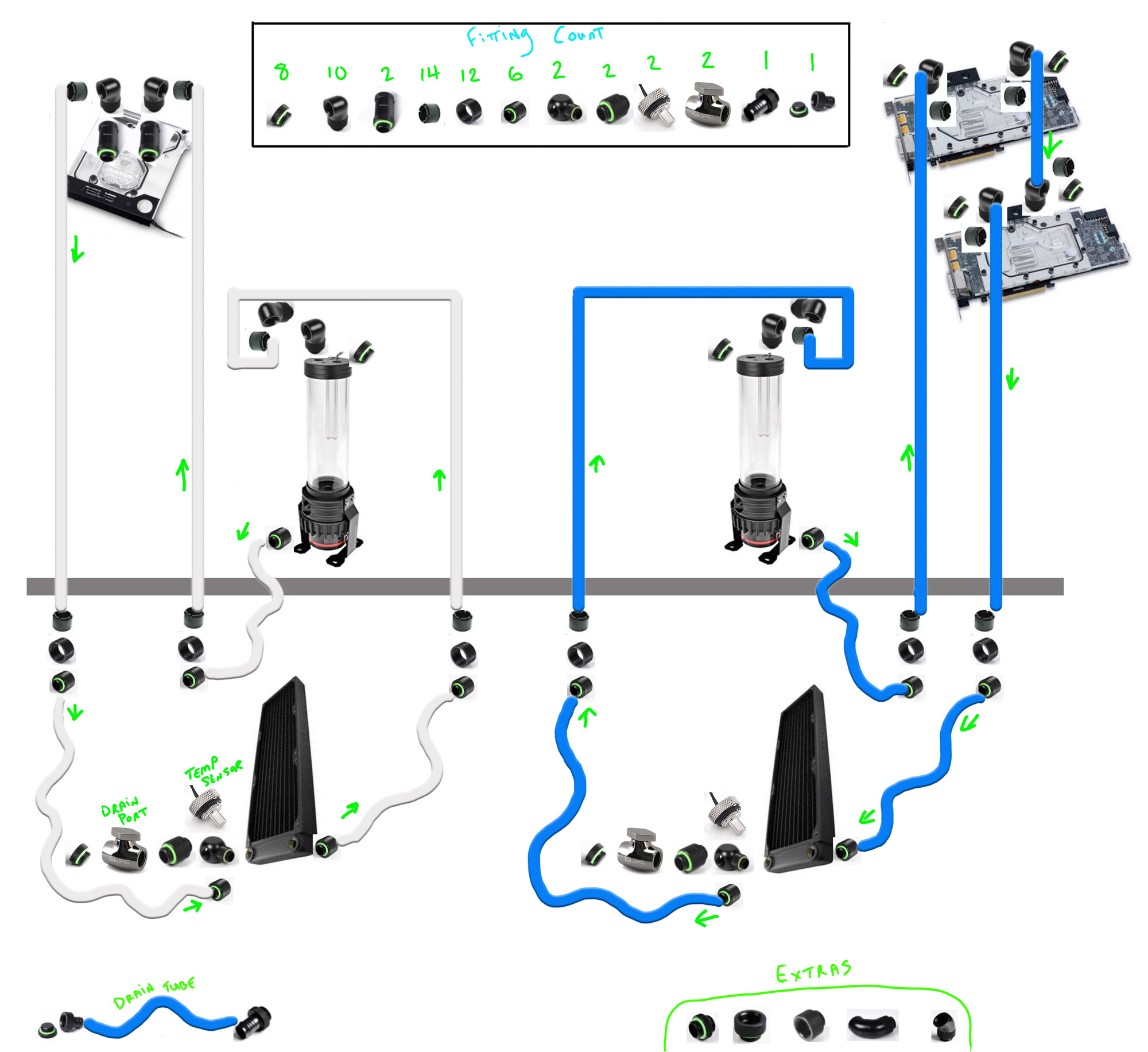

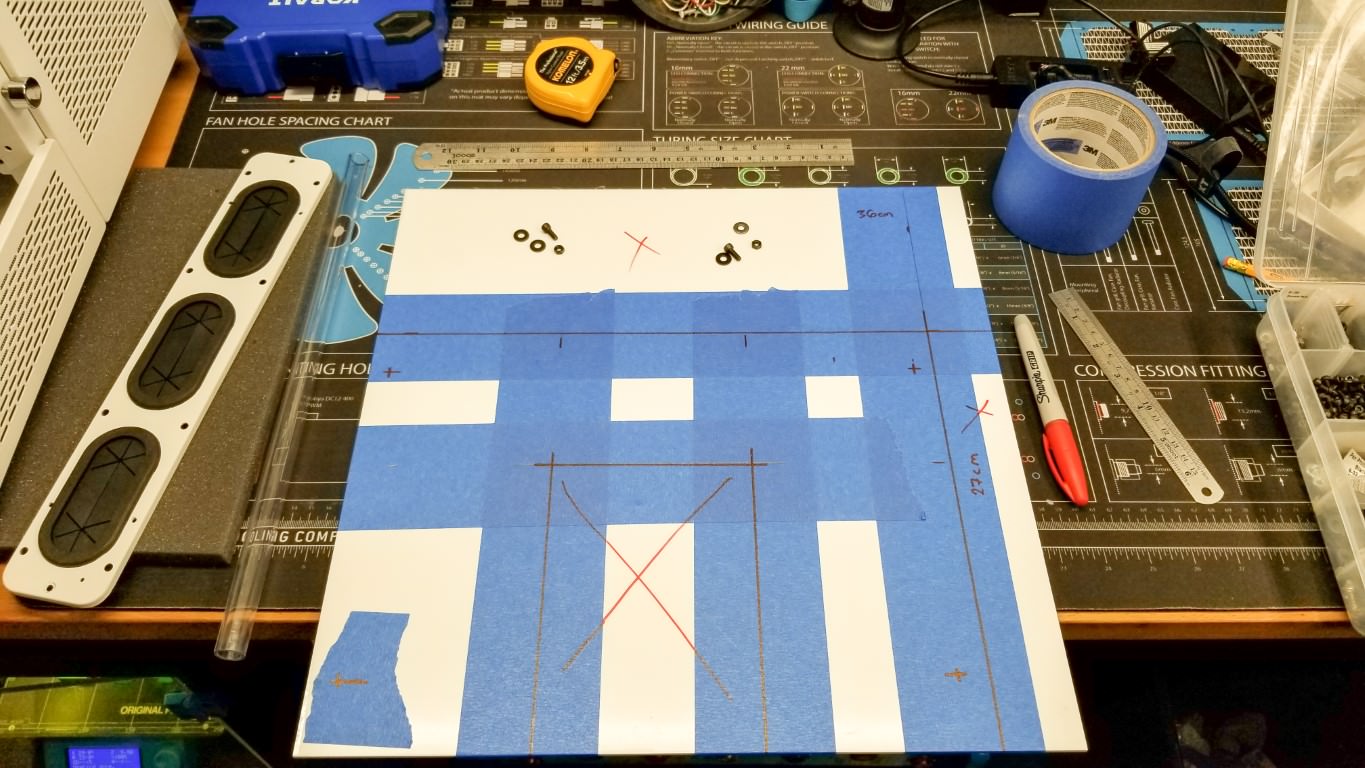

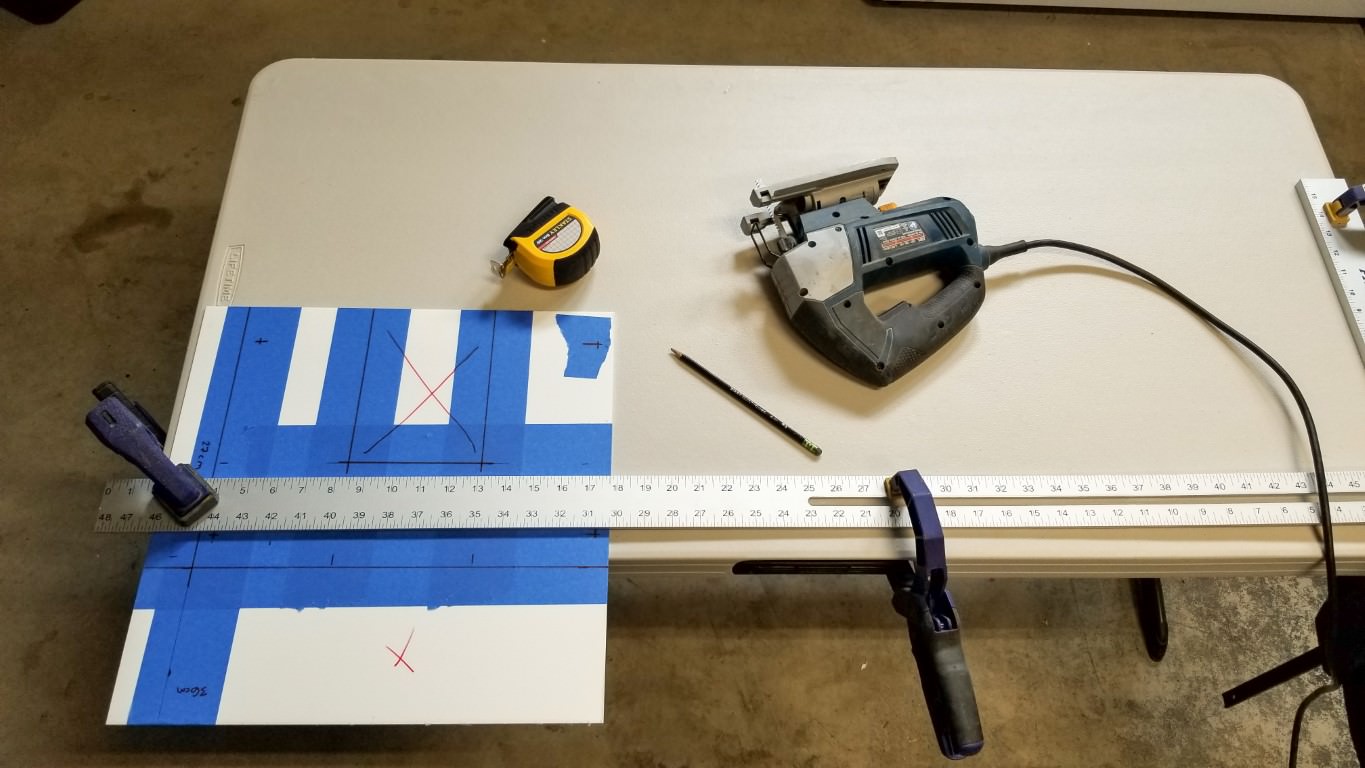

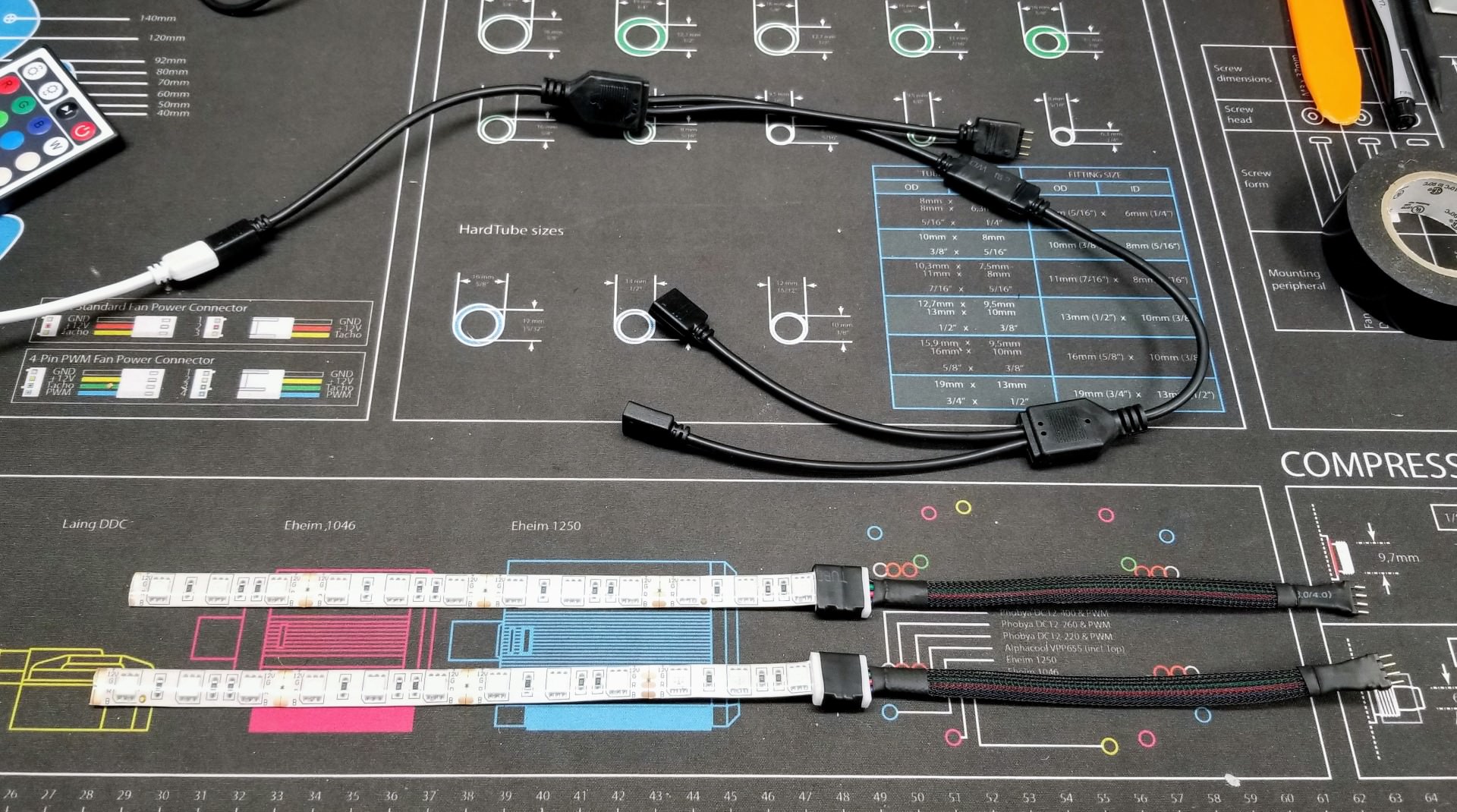

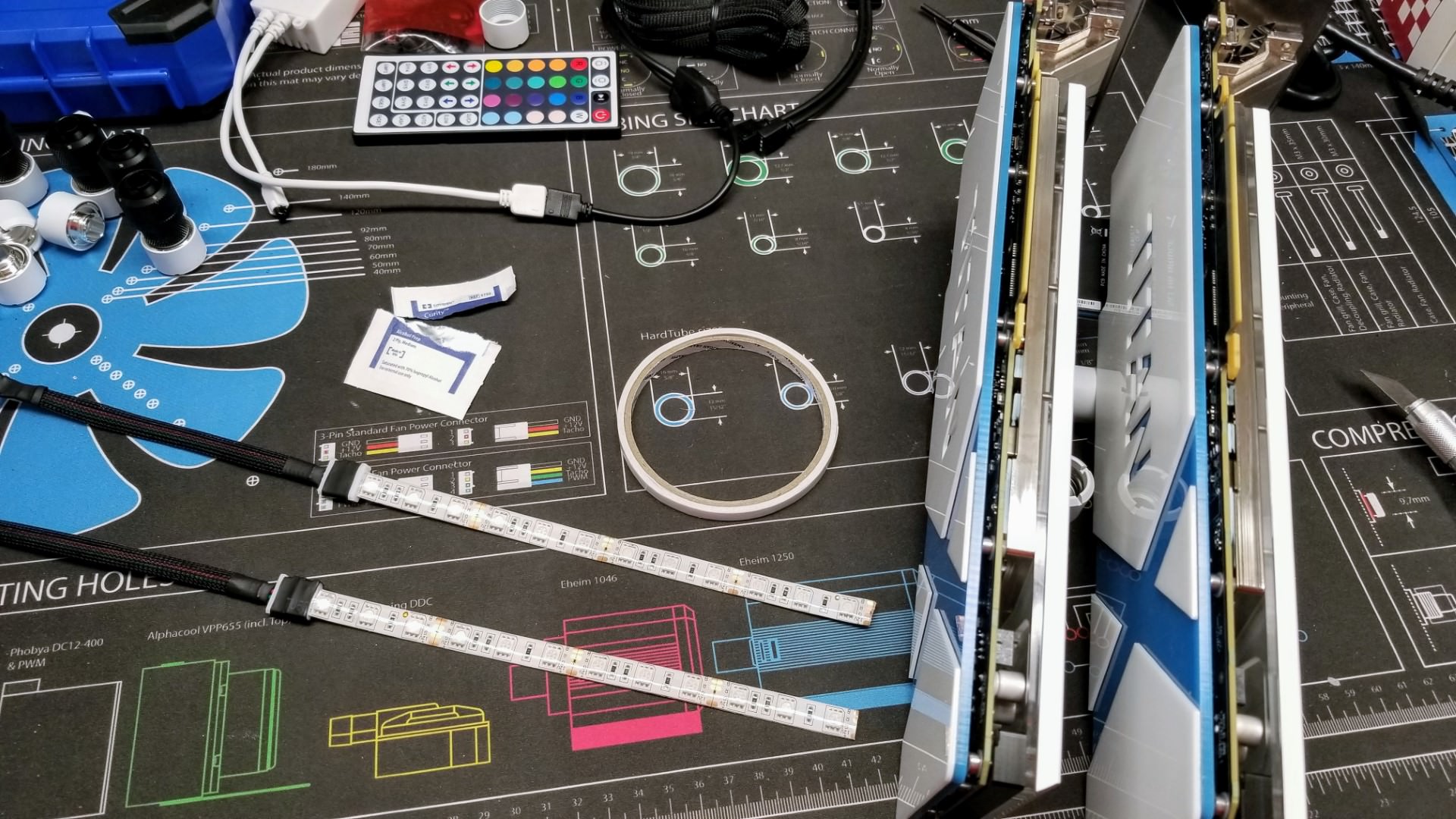

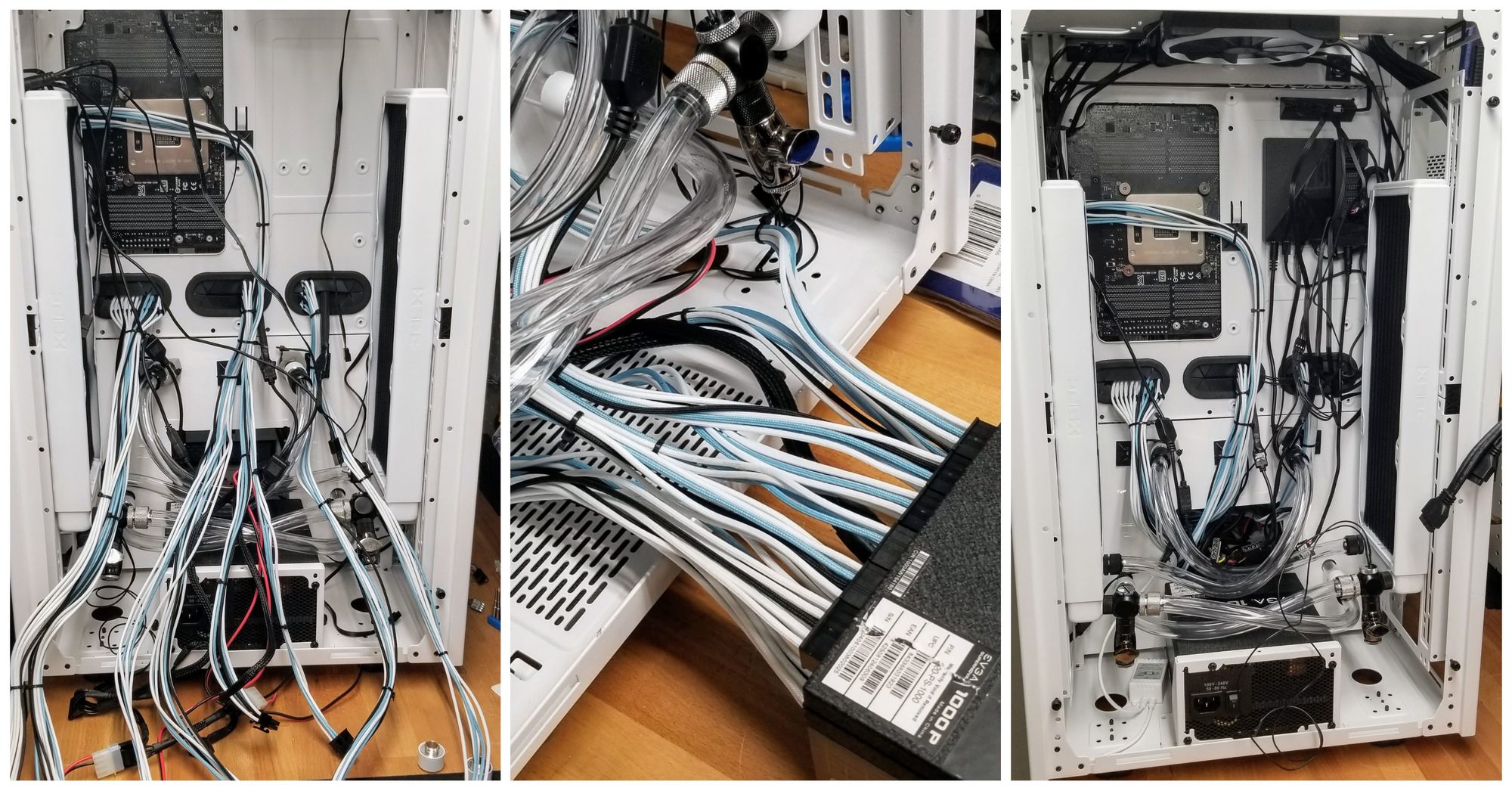

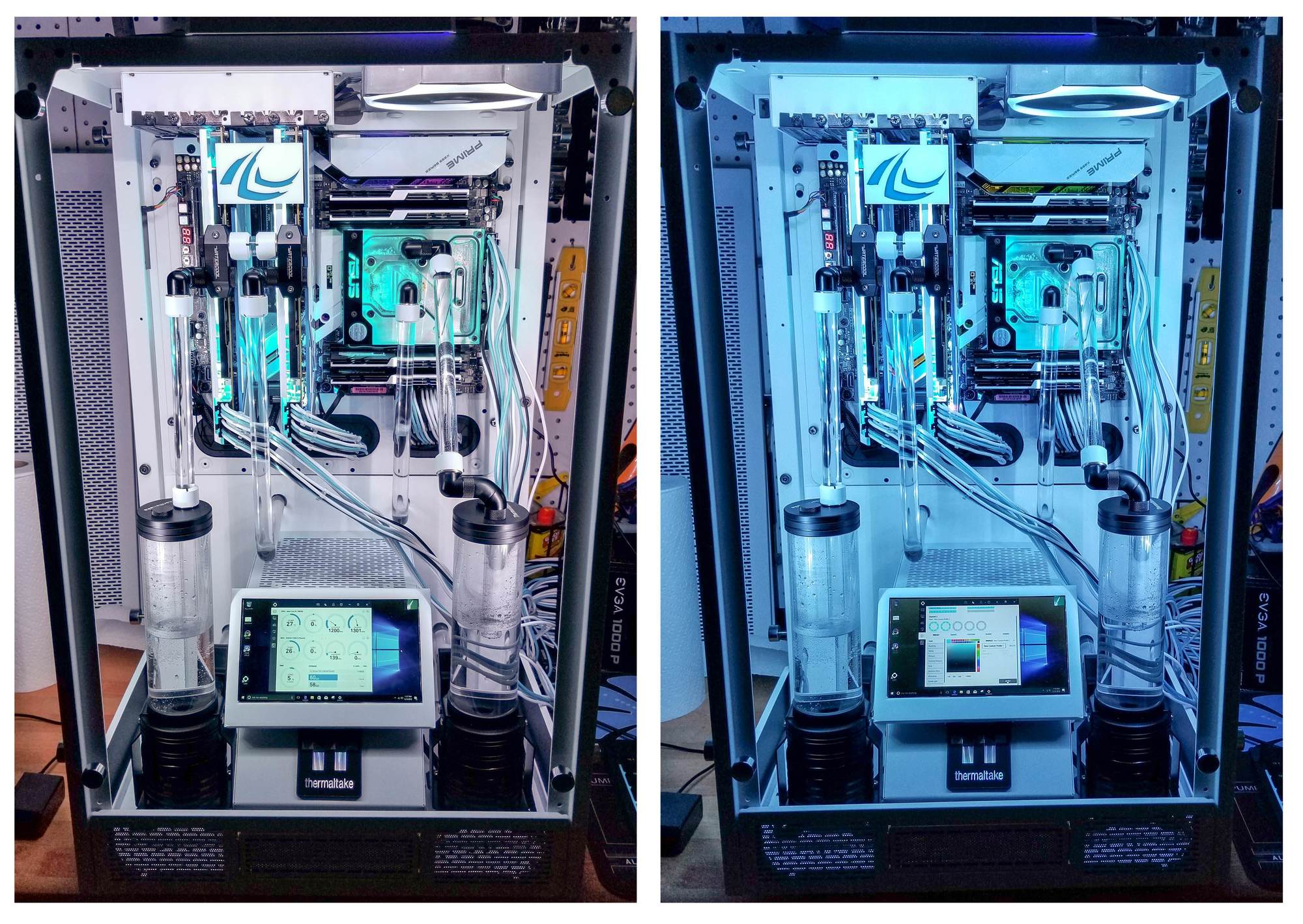

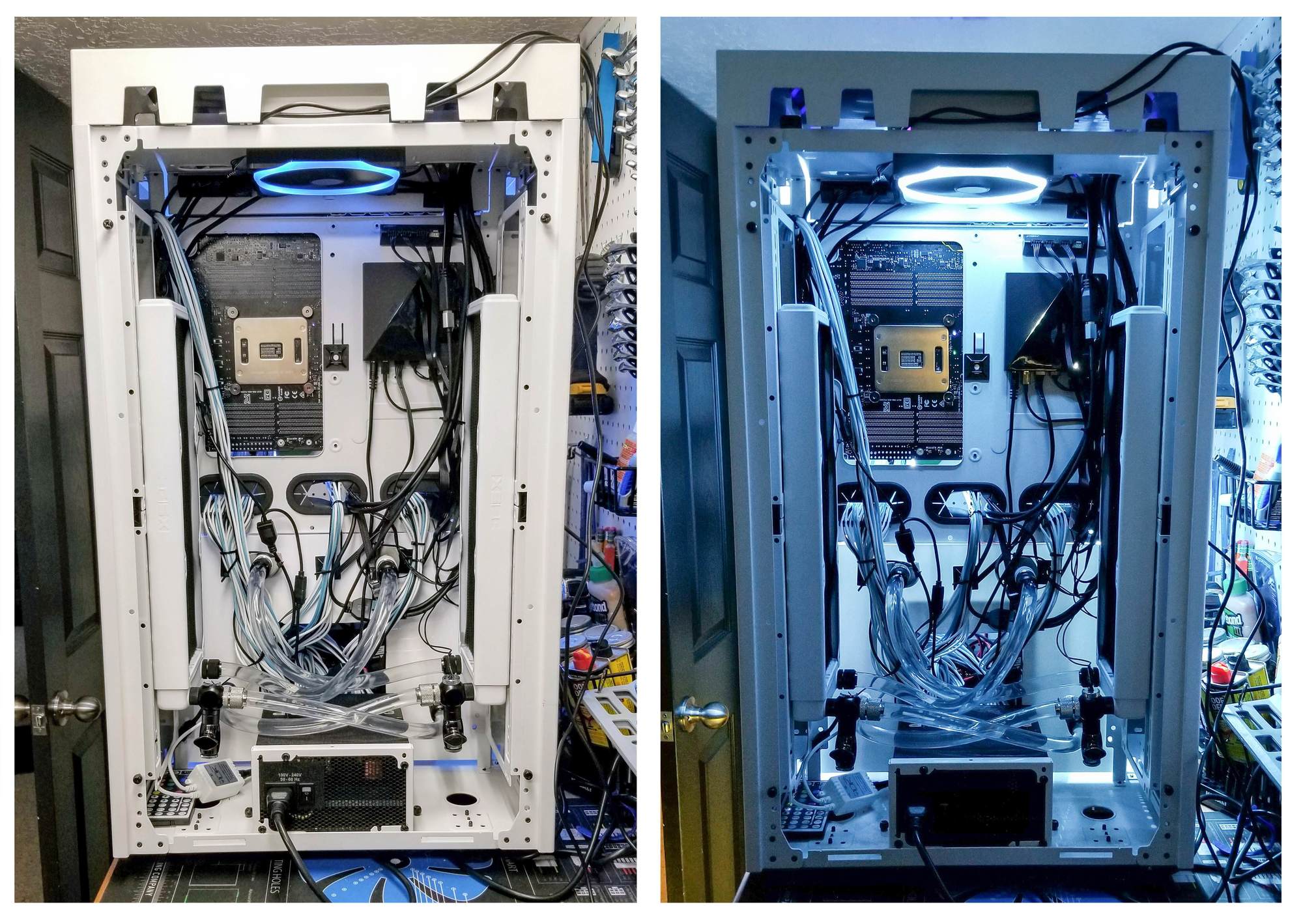

Will feature dual liquid loops, one for the i9-7980 Extreme CPU, and the other cooling 2x Nvidia Titan X Pascals in SLI. We will incorporate a little bit of acrylic work to clean things up, along with some painting, and RGB lighting. Take a look at all the components below to see just how impressive (and powerful) this build will be when completed. I present Project Ecthelion!

Component List

Component Type (PC Hardware)

Build Log Project Index

It's time for another custom Liquid Cooled build, and this time we are utilizing the MASSIVE Thermaltake Tower 900 case! This is a commissioned build, using some extreme hardware, and I am really excited to get started.

Will feature dual liquid loops, one for the i9-7980 Extreme CPU, and the other cooling 2x Nvidia Titan X Pascals in SLI. We will incorporate a little bit of acrylic work to clean things up, along with some painting, and RGB lighting. Take a look at all the components below to see just how impressive (and powerful) this build will be when completed. I present Project Ecthelion!

Component List

Component Type (PC Hardware)

- Case Thermaltake Tower 900 White x1

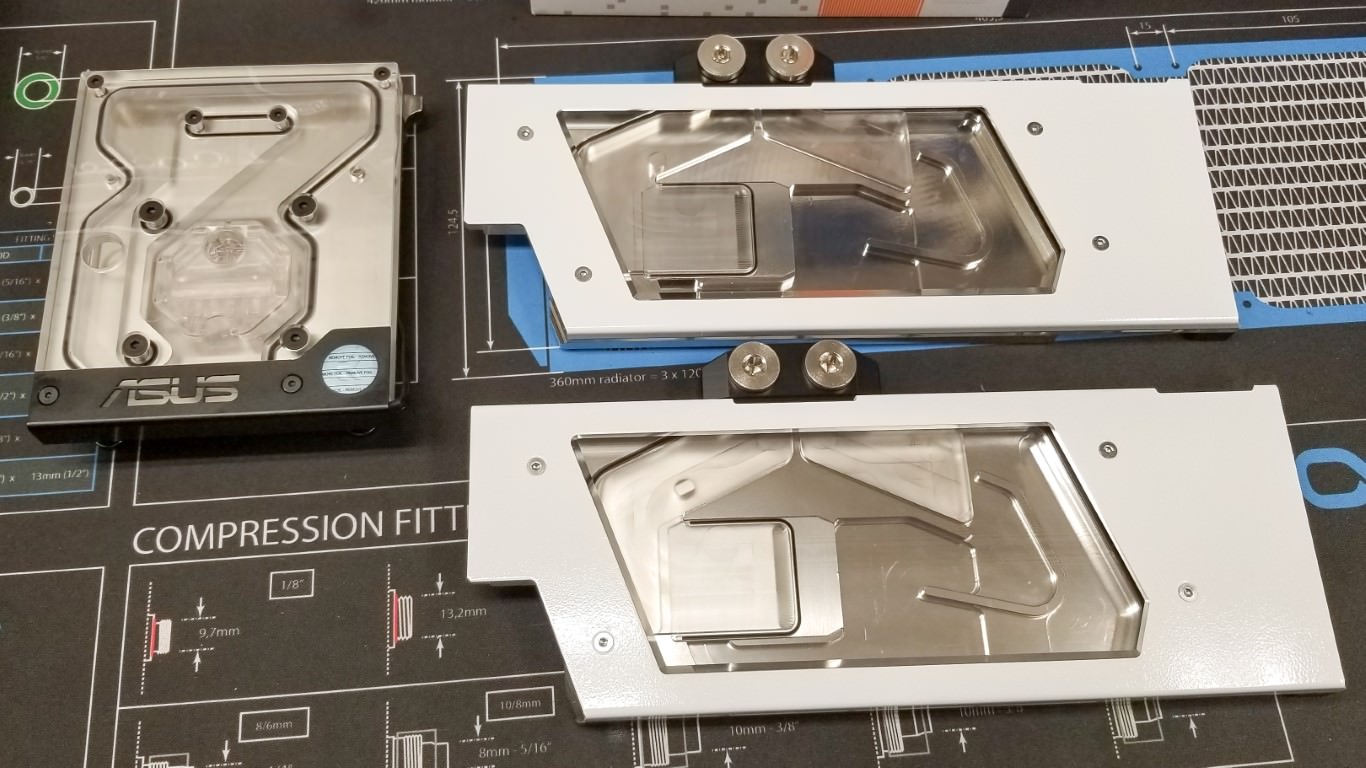

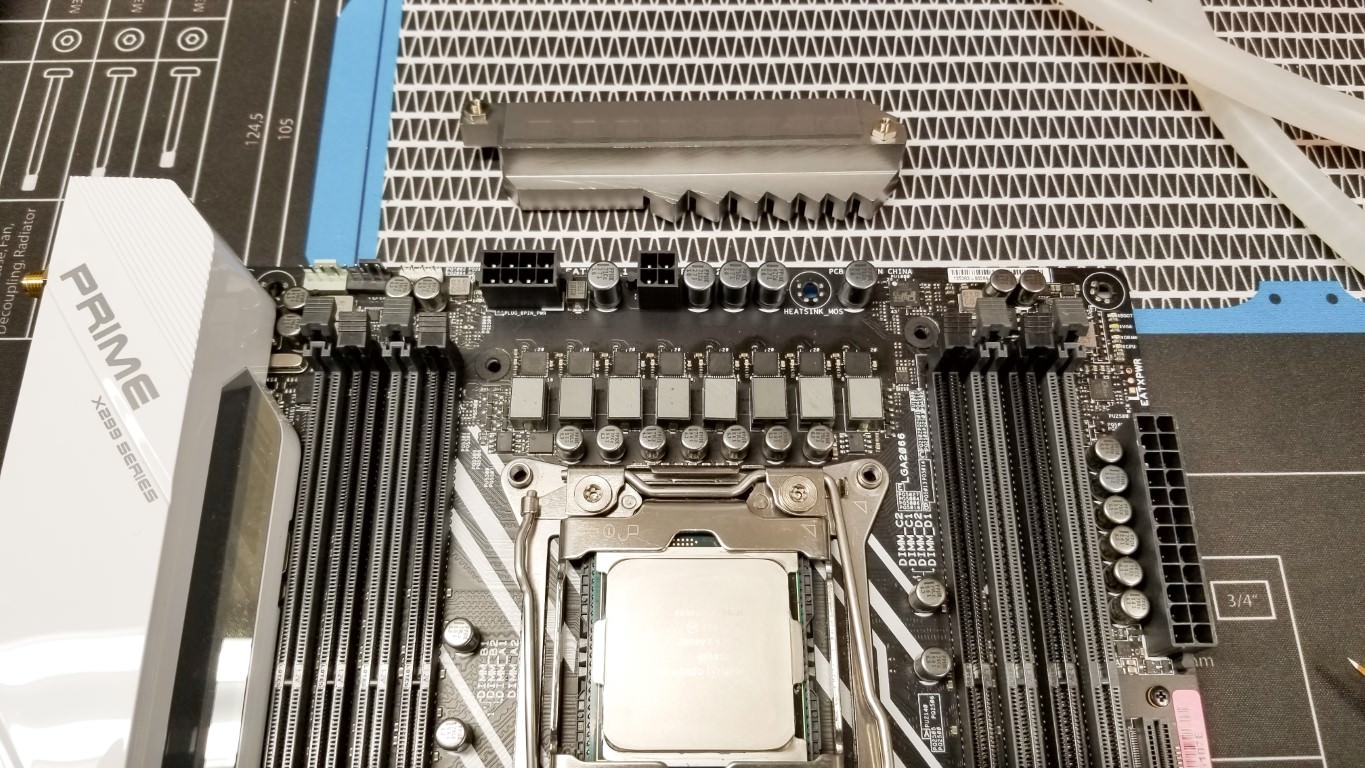

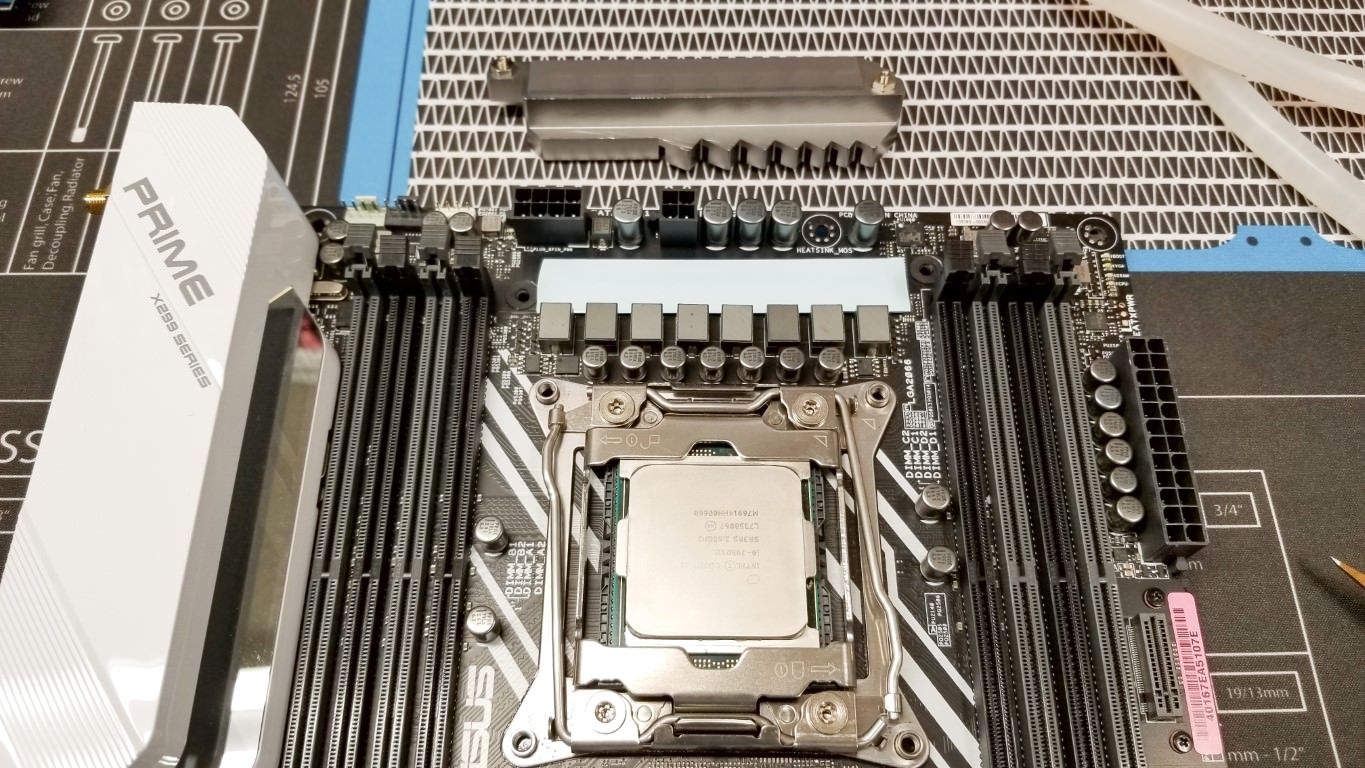

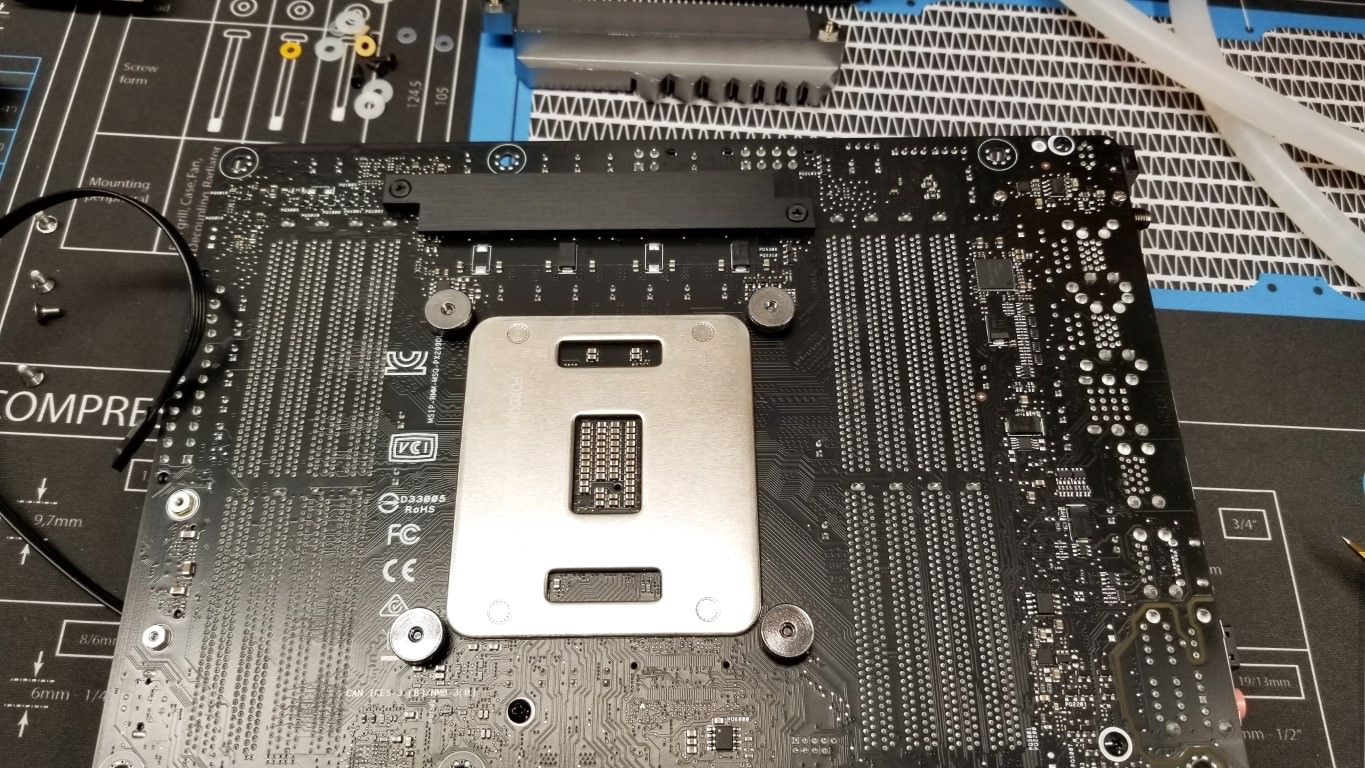

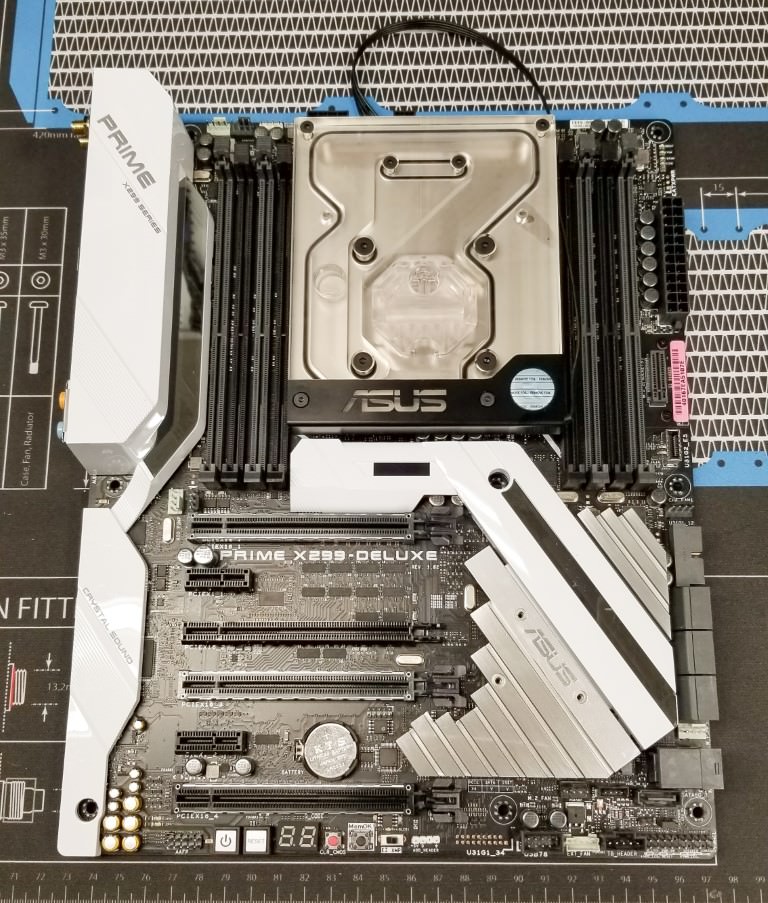

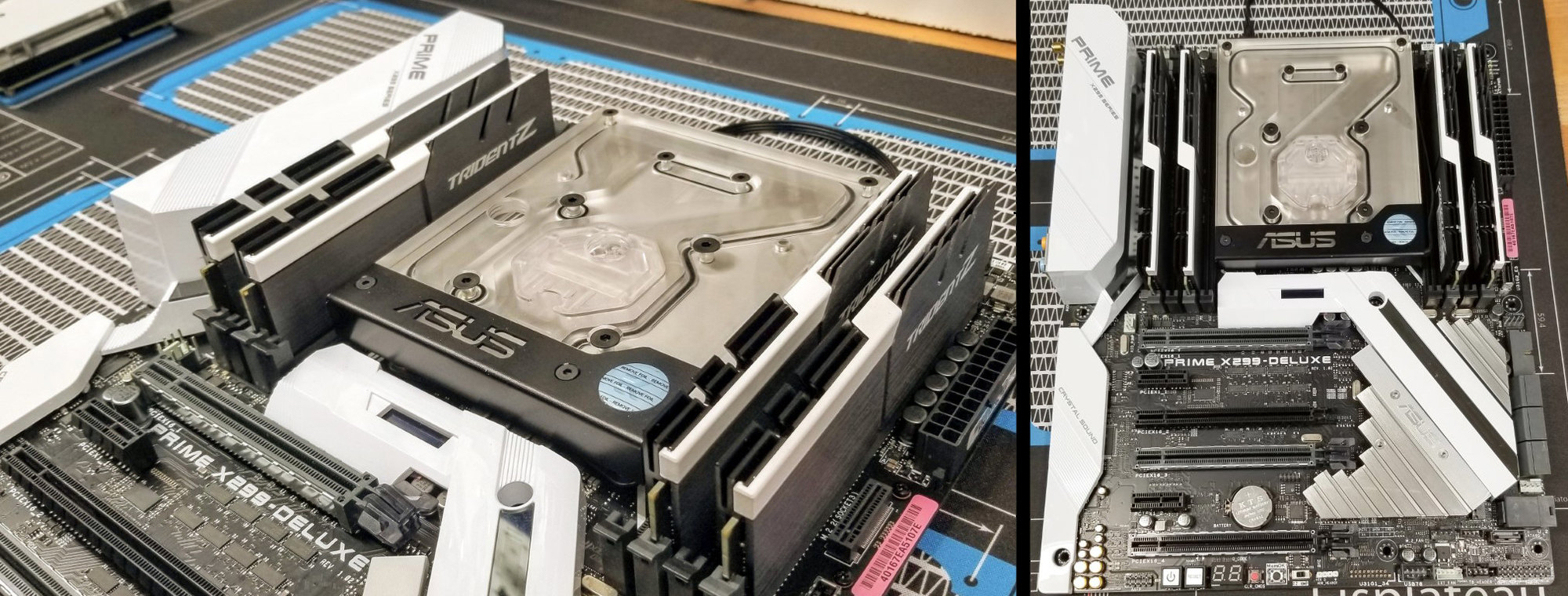

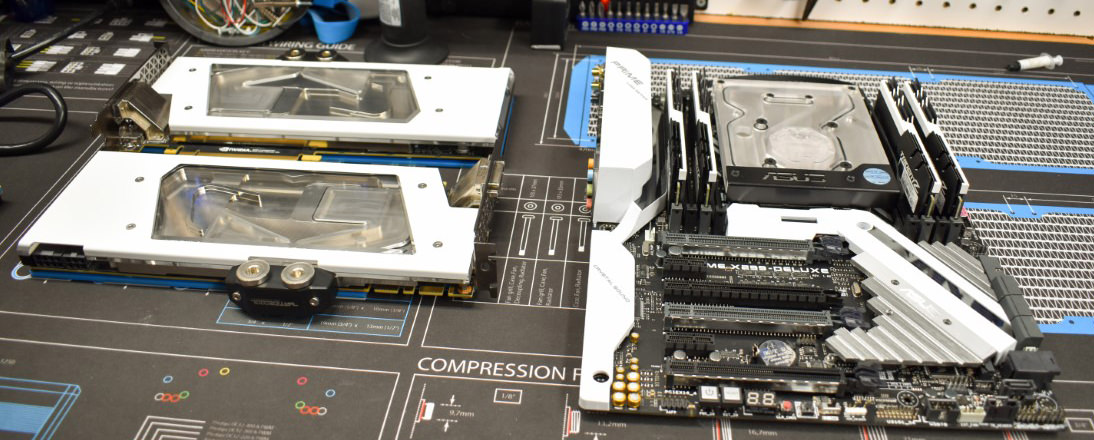

- Motherboard ASUS Prime x299 Deluxe x1

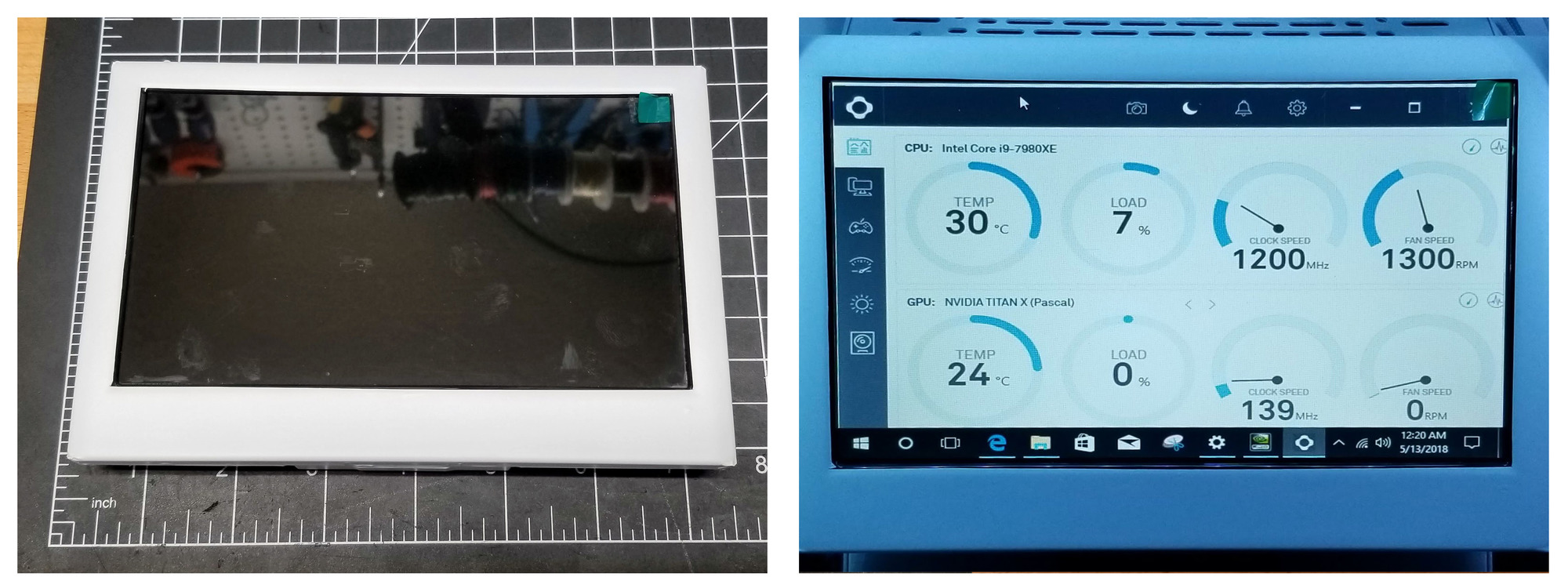

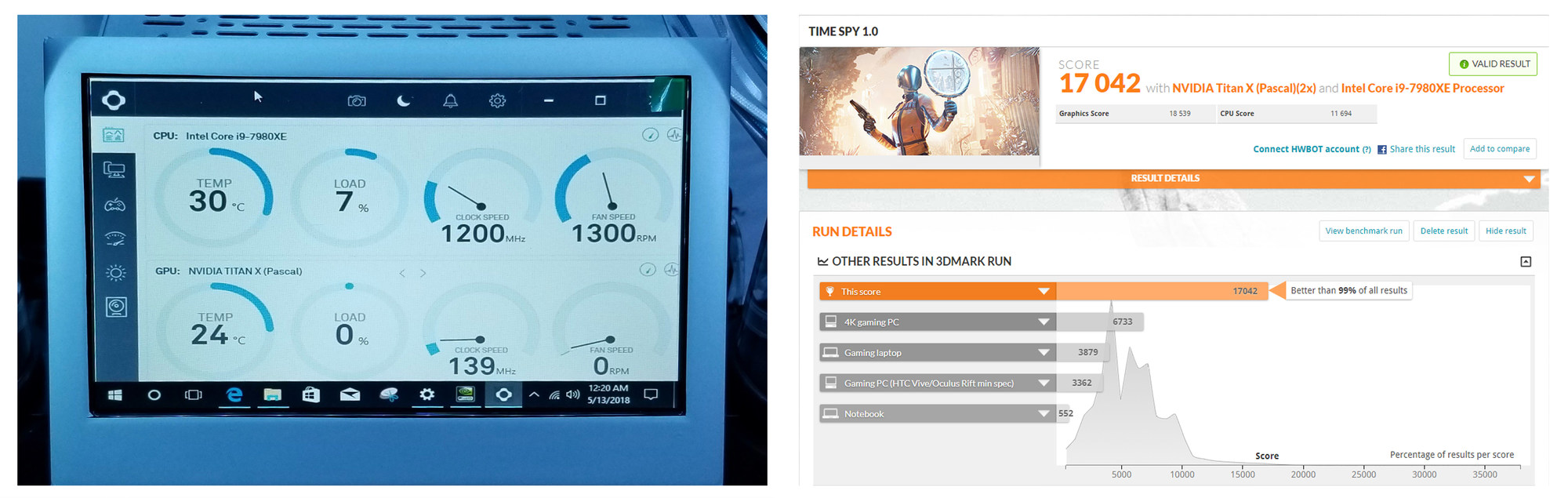

- CPU Intel i9-7980XE Extreme 18 Core Processor x1

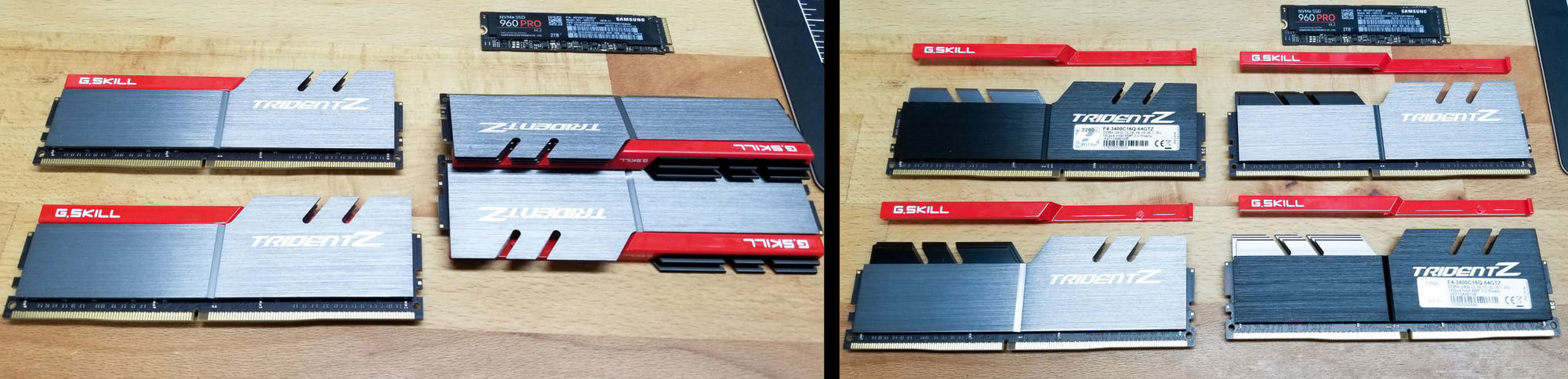

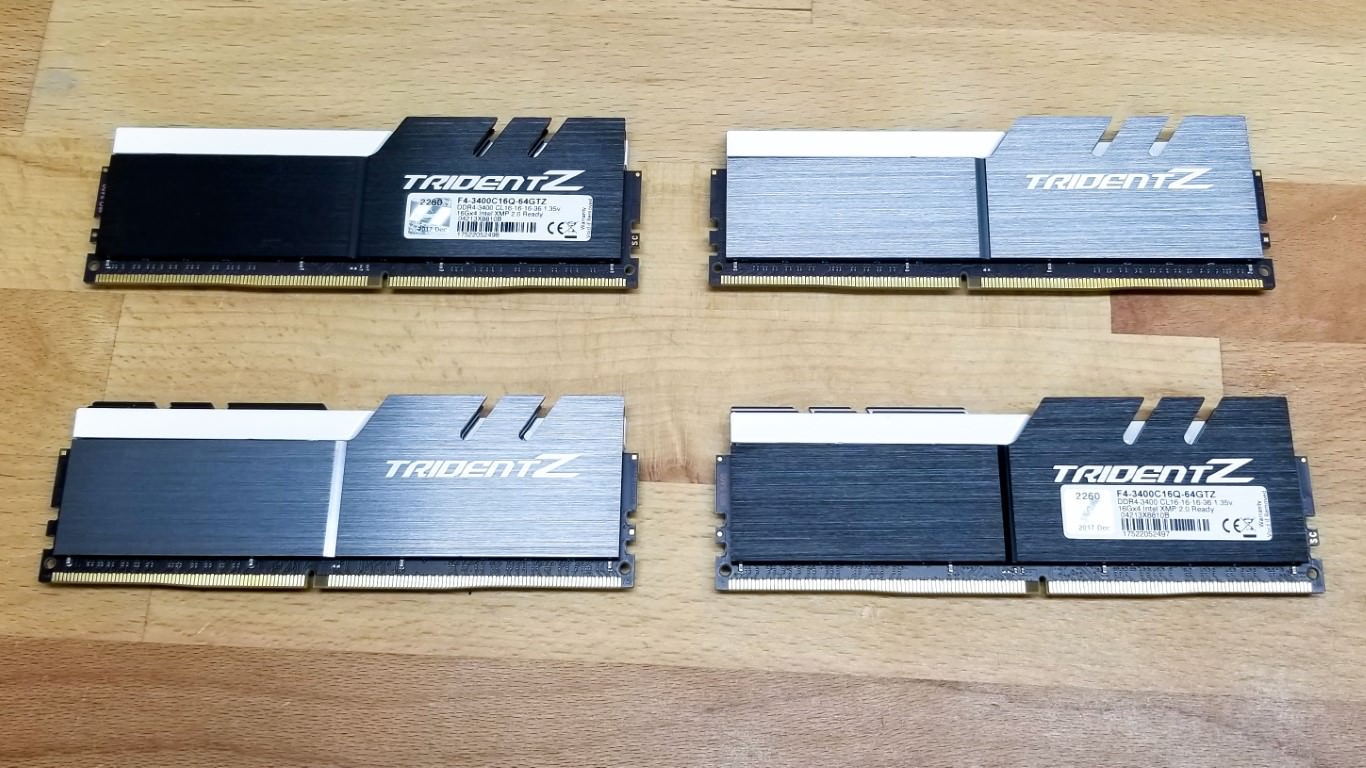

- RAM G.SKILL 64GB (4 x 16GB) TridentZ Series DDR4 PC4-27200 3400MHZ x1

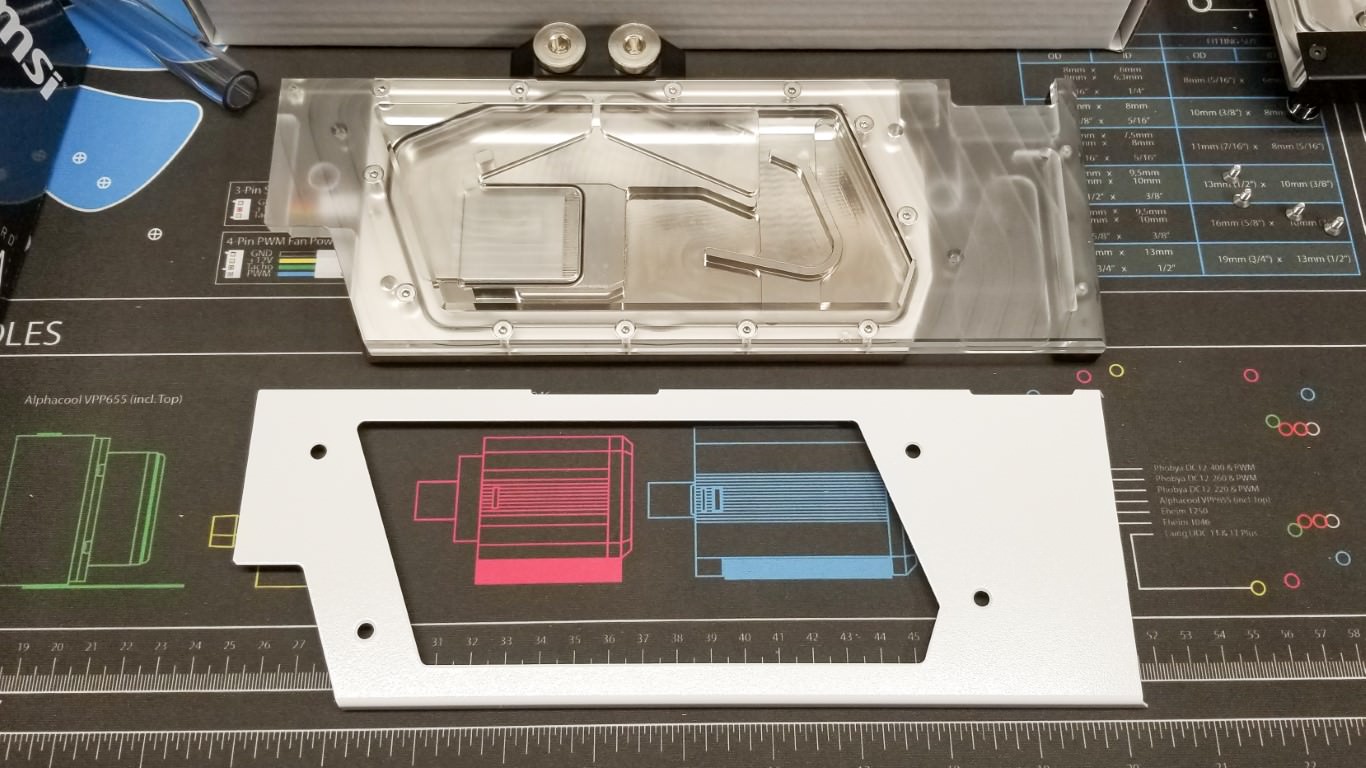

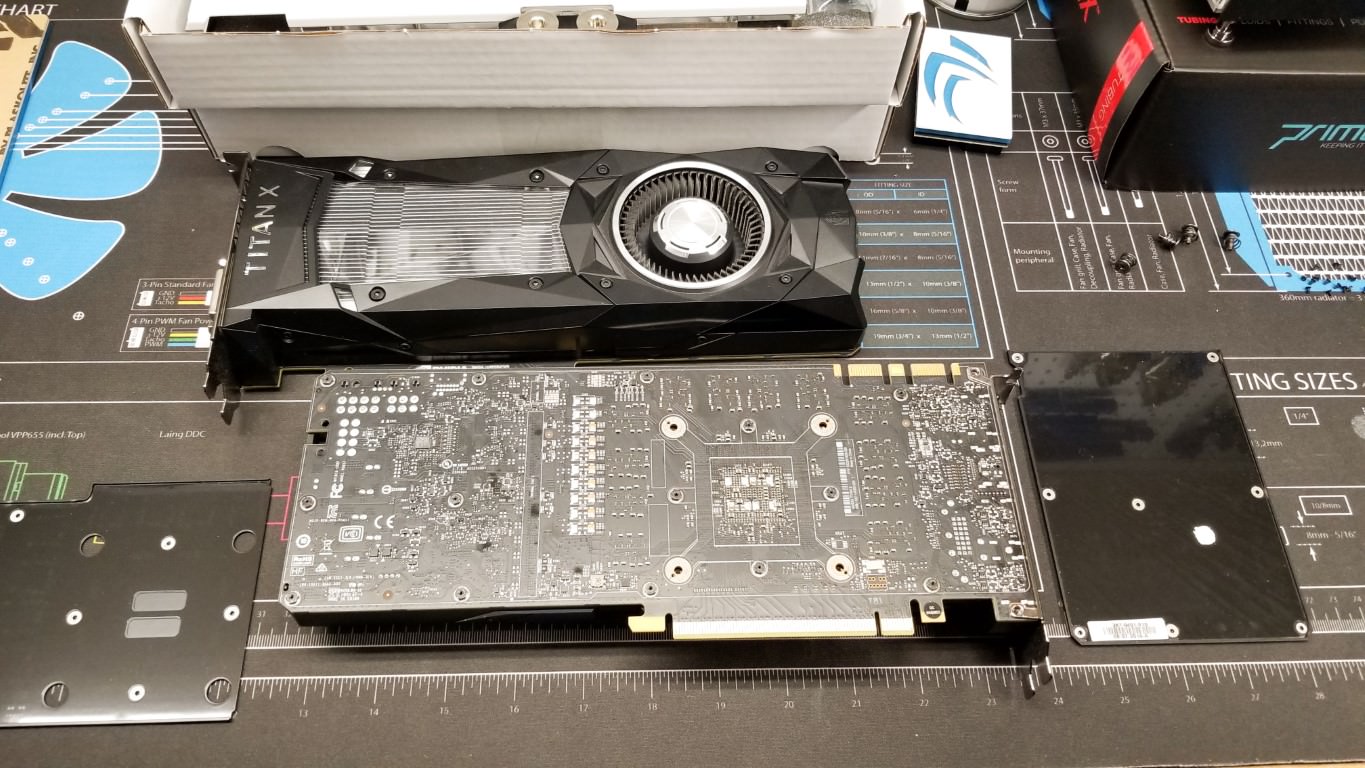

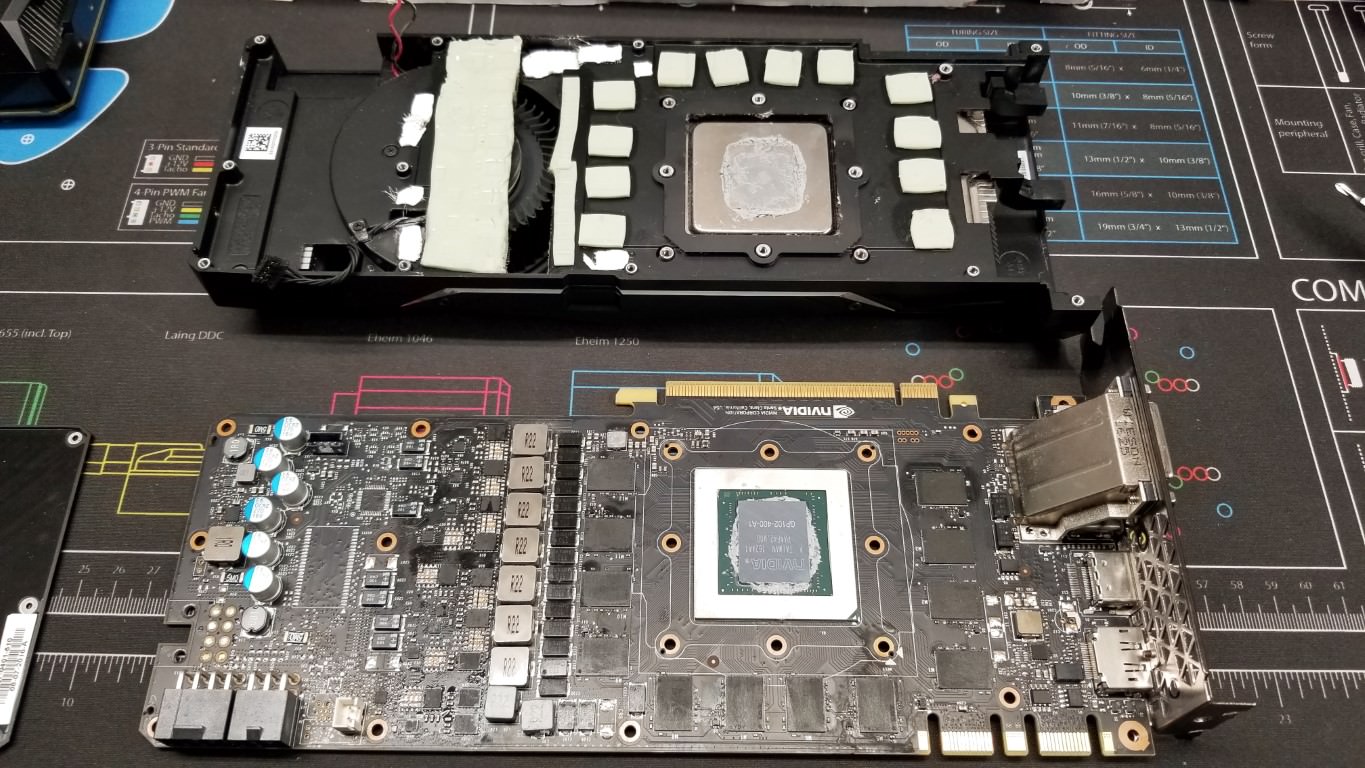

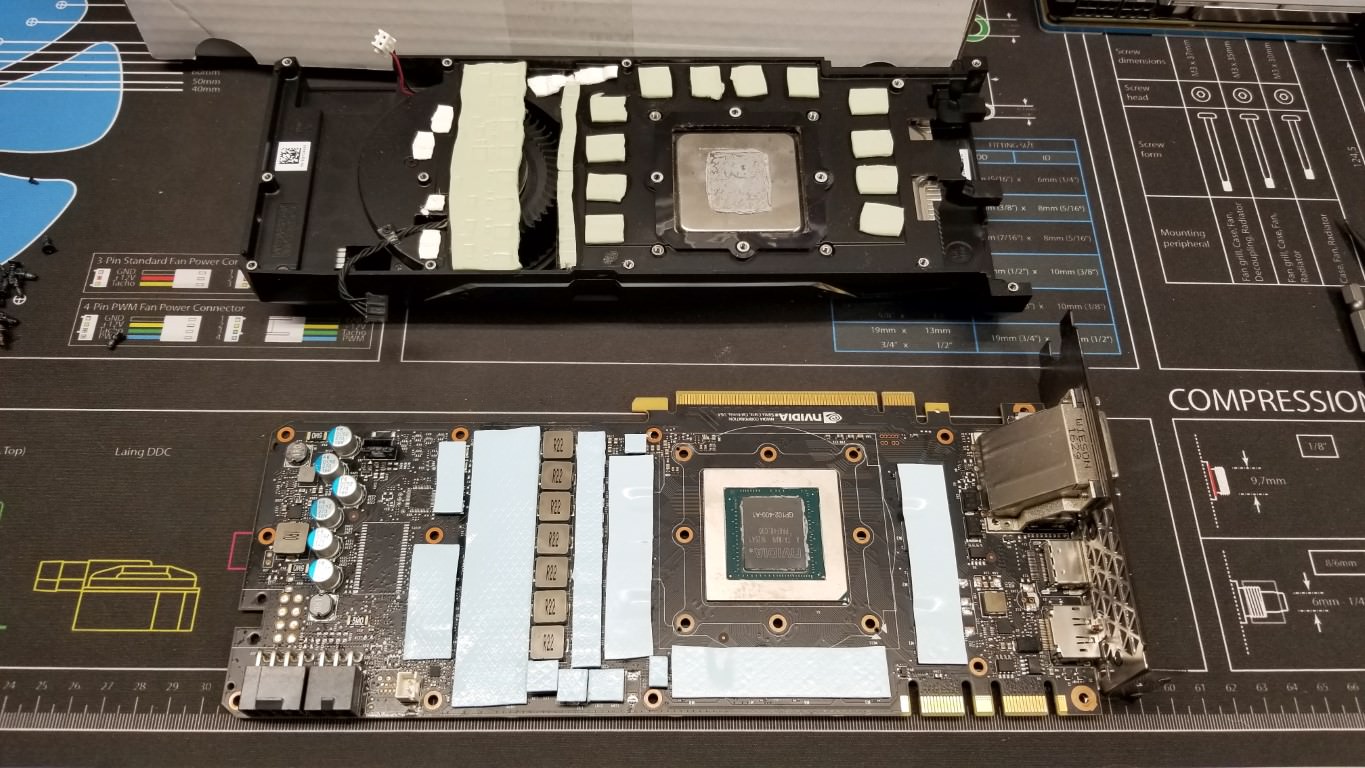

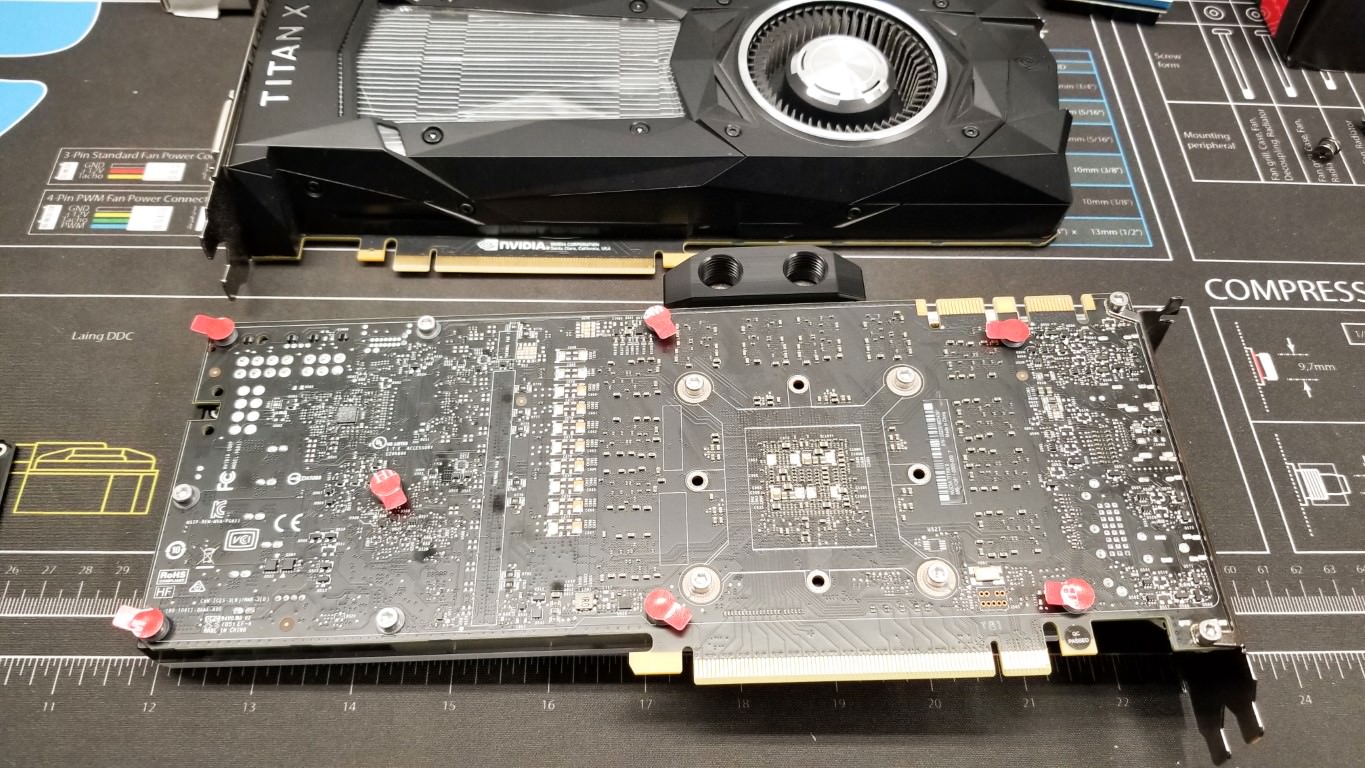

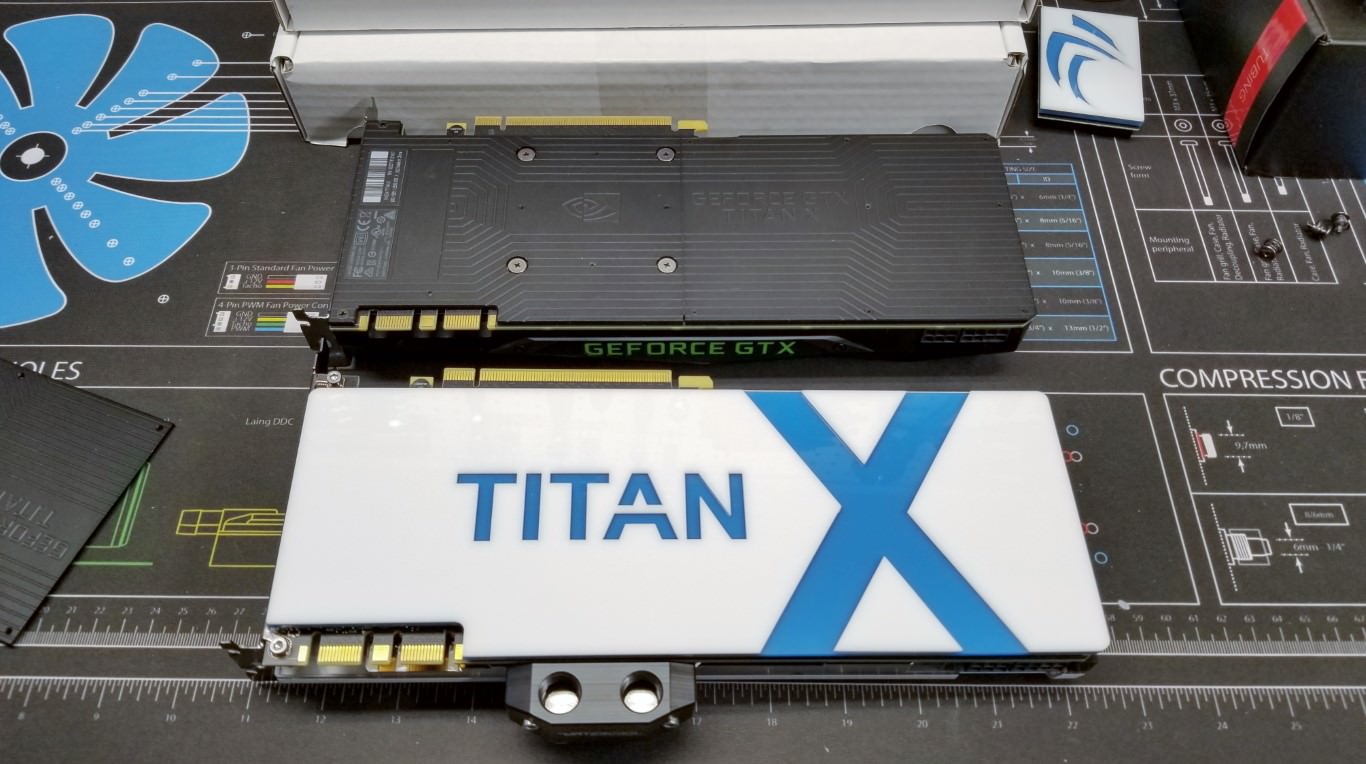

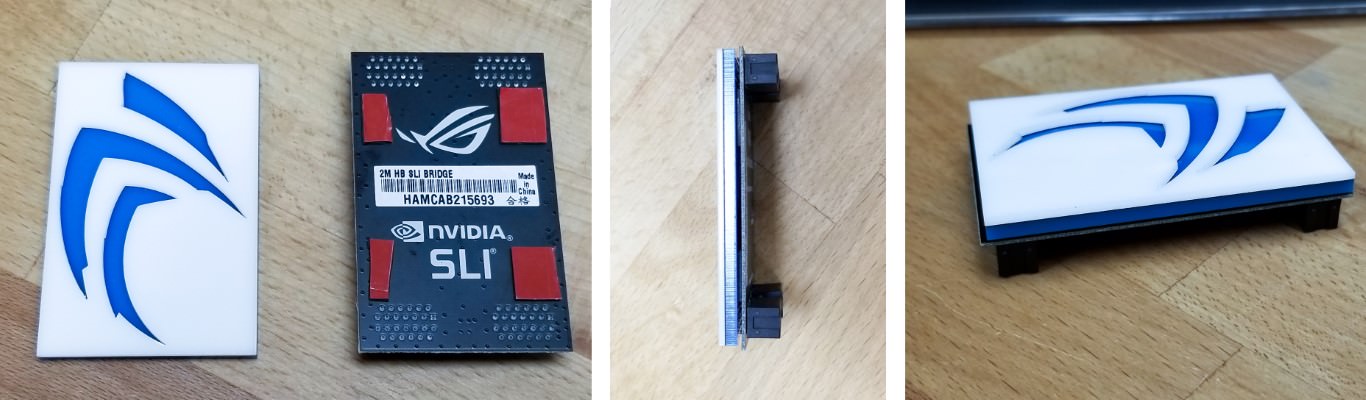

- Video Cards Nvidia Titan X Pascal x2 SLI x2

- GPU Backplate Titan X Design x2 Color Backplates x2

- SSD NVMe Samsung 960 Pro M.2 2TB x2 (RAID) x2

- SSD 2.5in Samsung 860 EVO 1TB x1

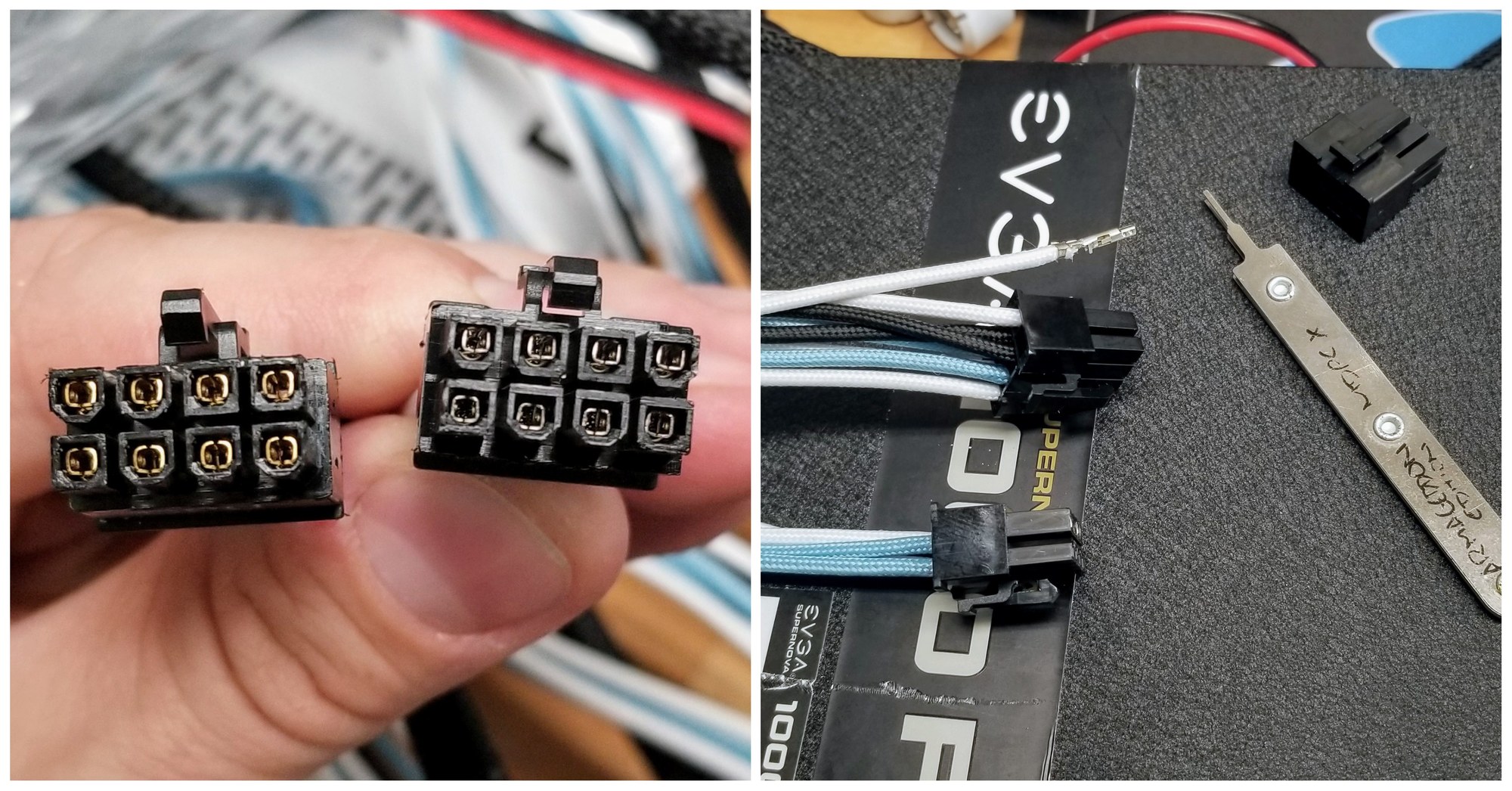

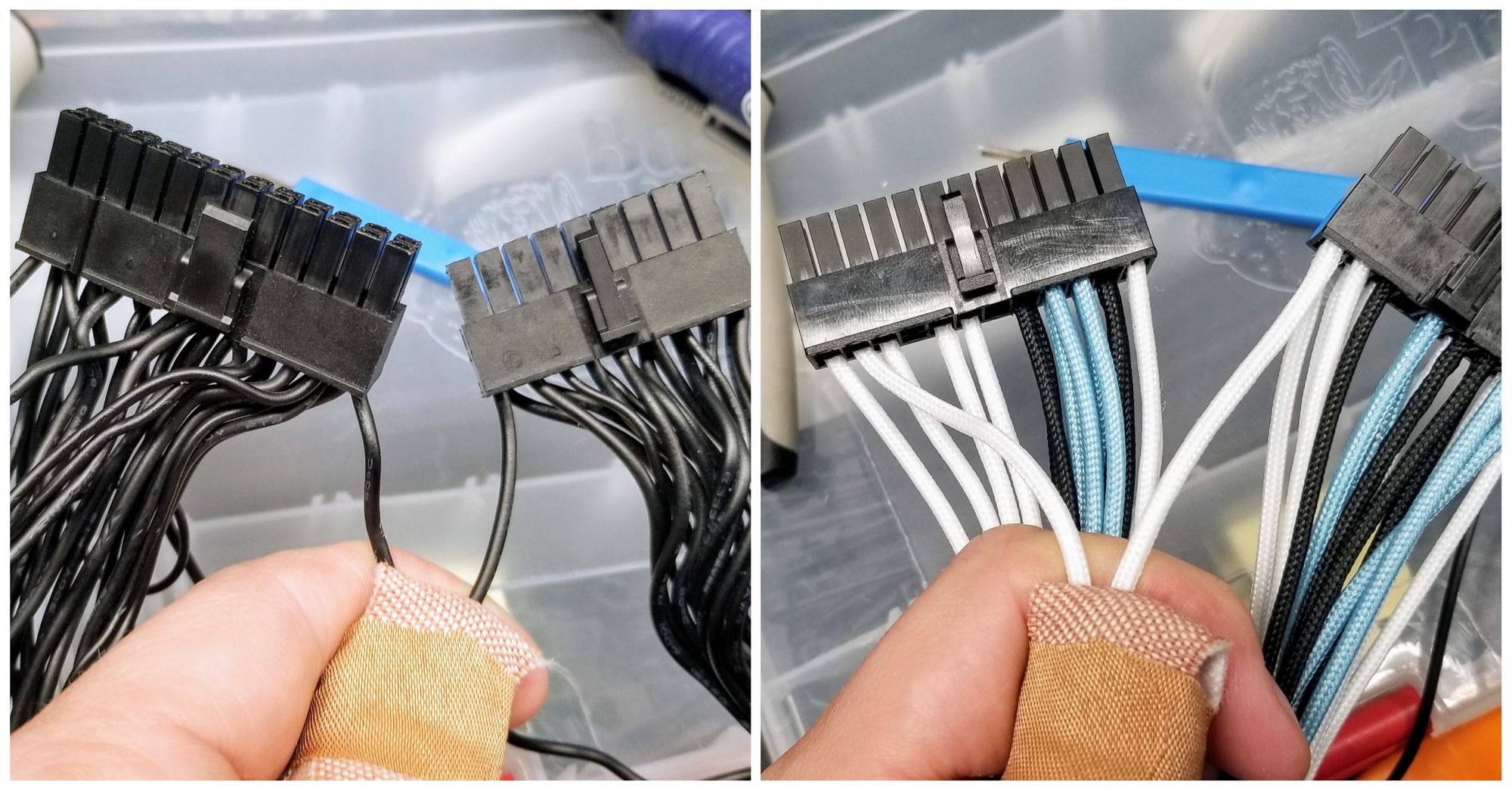

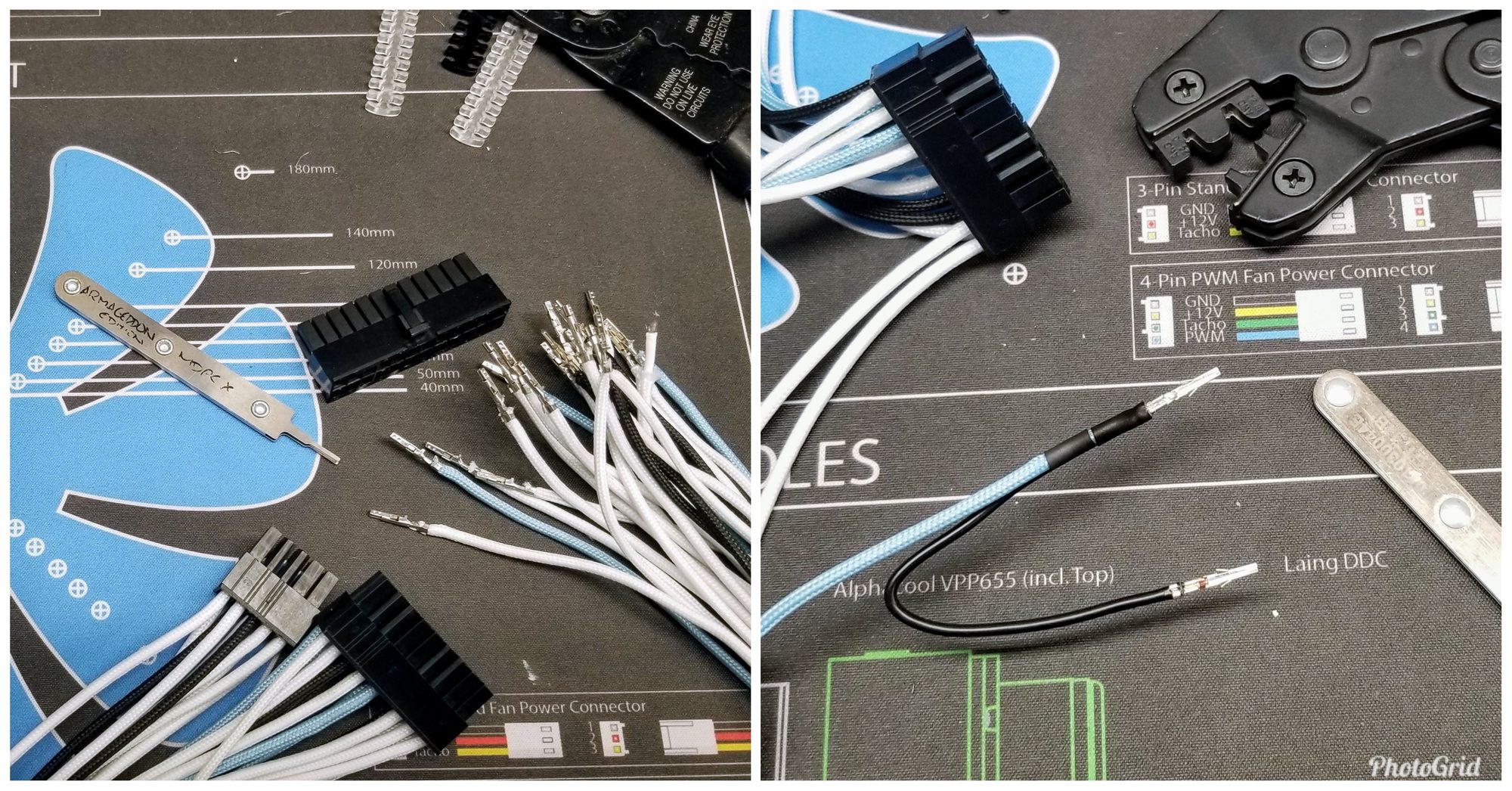

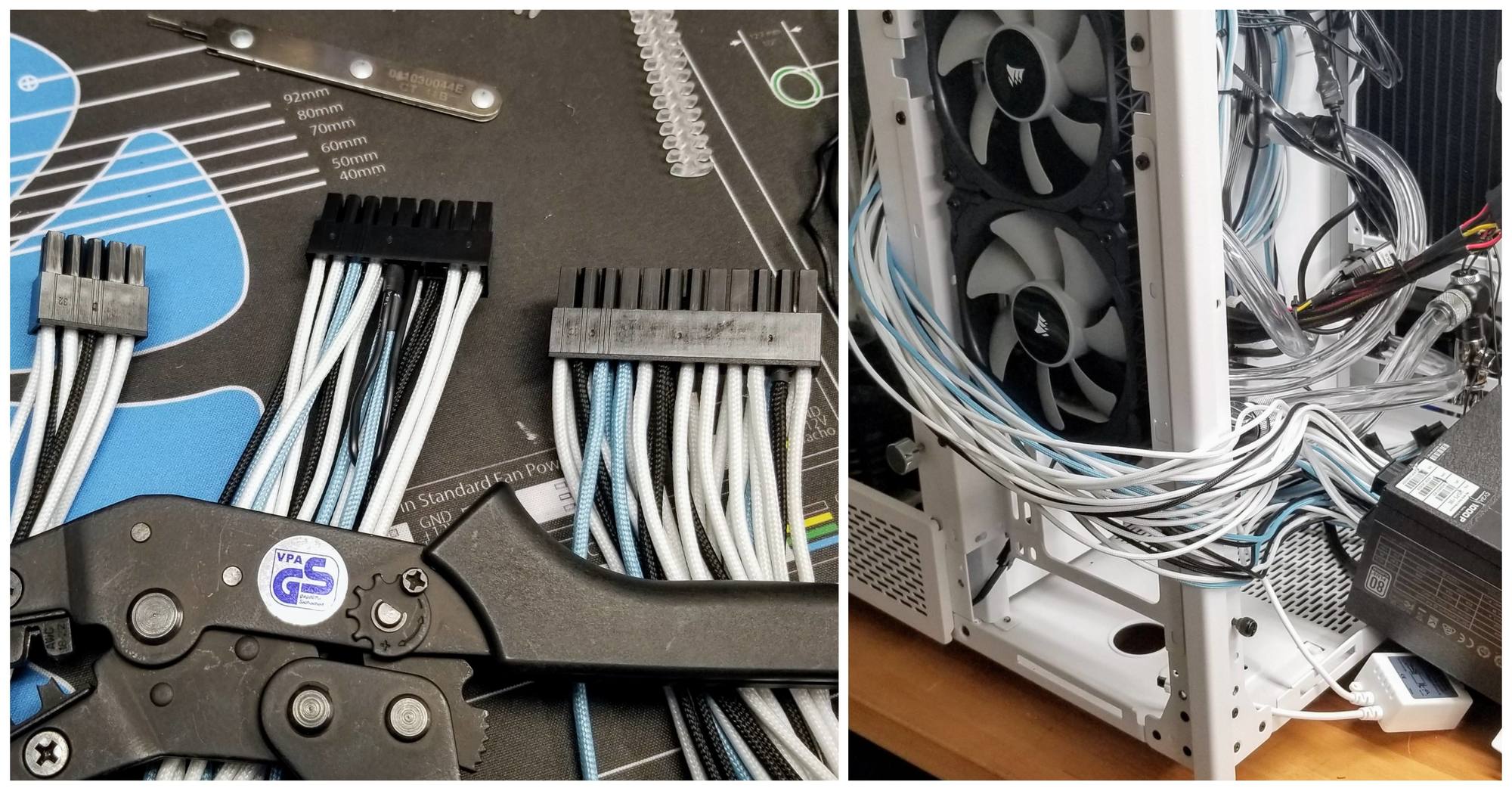

- Power Supply EVGA SuperNOVA 1000 P2 80+ PLATINUM, 1000W x1

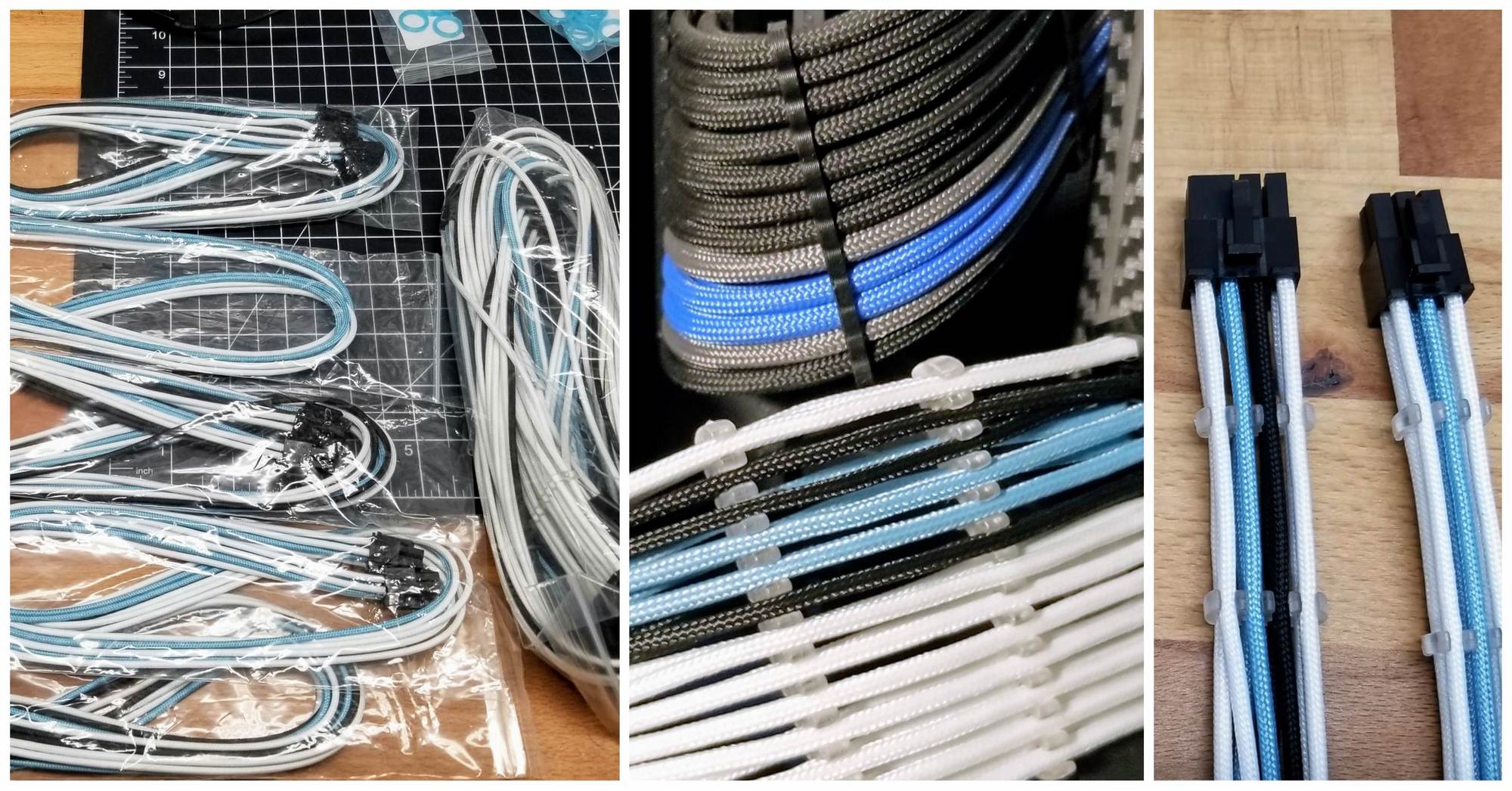

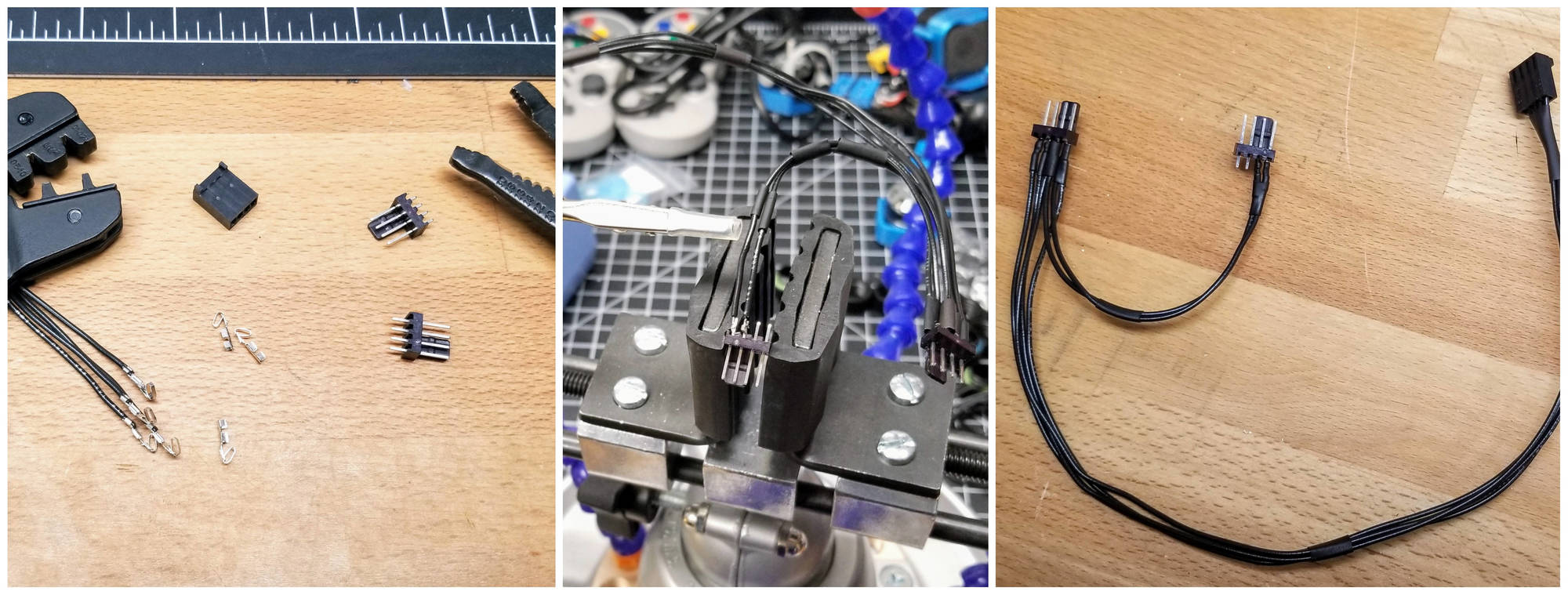

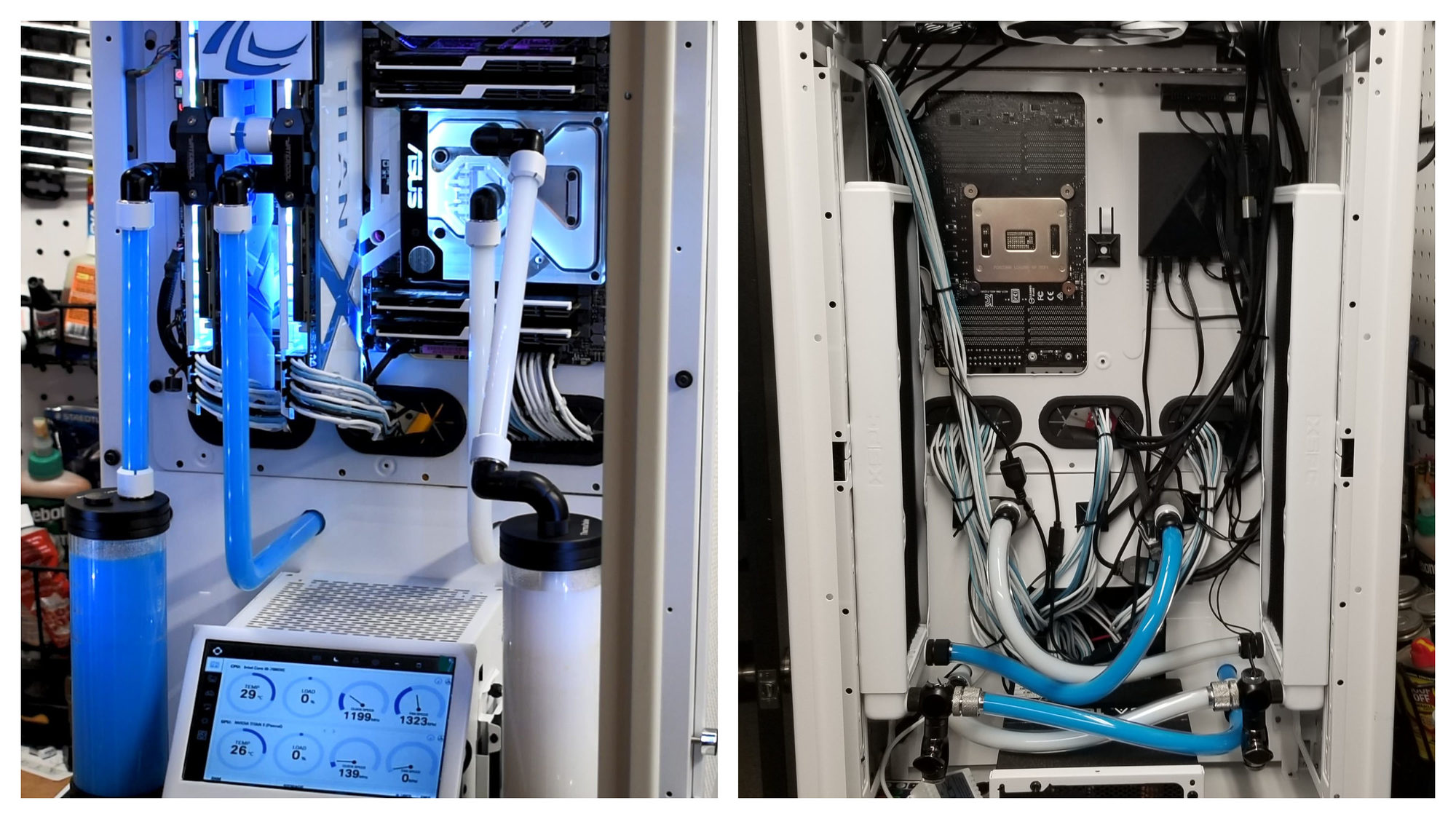

- Custom Cables Blue and Black sleeved x1

- OS (Dual Boot) Windows 10 x64 / OSX (HackinTosh)

- Fans / Lighting NZXT RF-AR140-C1 HUE+ & Aer RGB140 Fans Bundle Pack x1

- Lighting NZXT HUE+ Extension Kit LED Strips x2

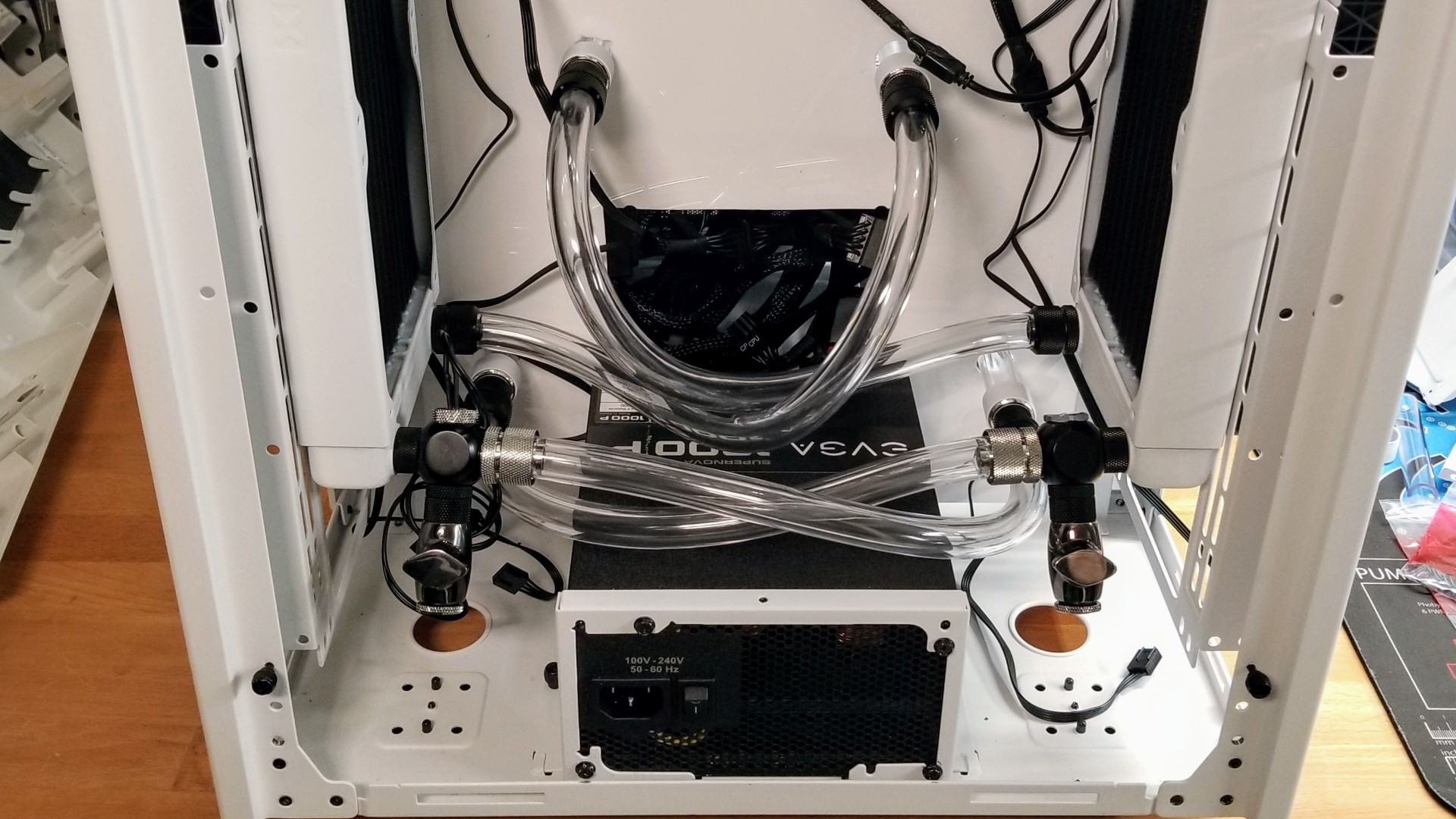

- Reservoir / Pump Thermaltake Pacific PR22-D5 Adjustable D5 Pump/Reservoir Combo x2

- Fans (Radiator) Corsair ML120, 120mm Magnetic Levitation SP Fan (2-Pack) x3

- Radiator XSPC EX360 High Performance Radiator x2

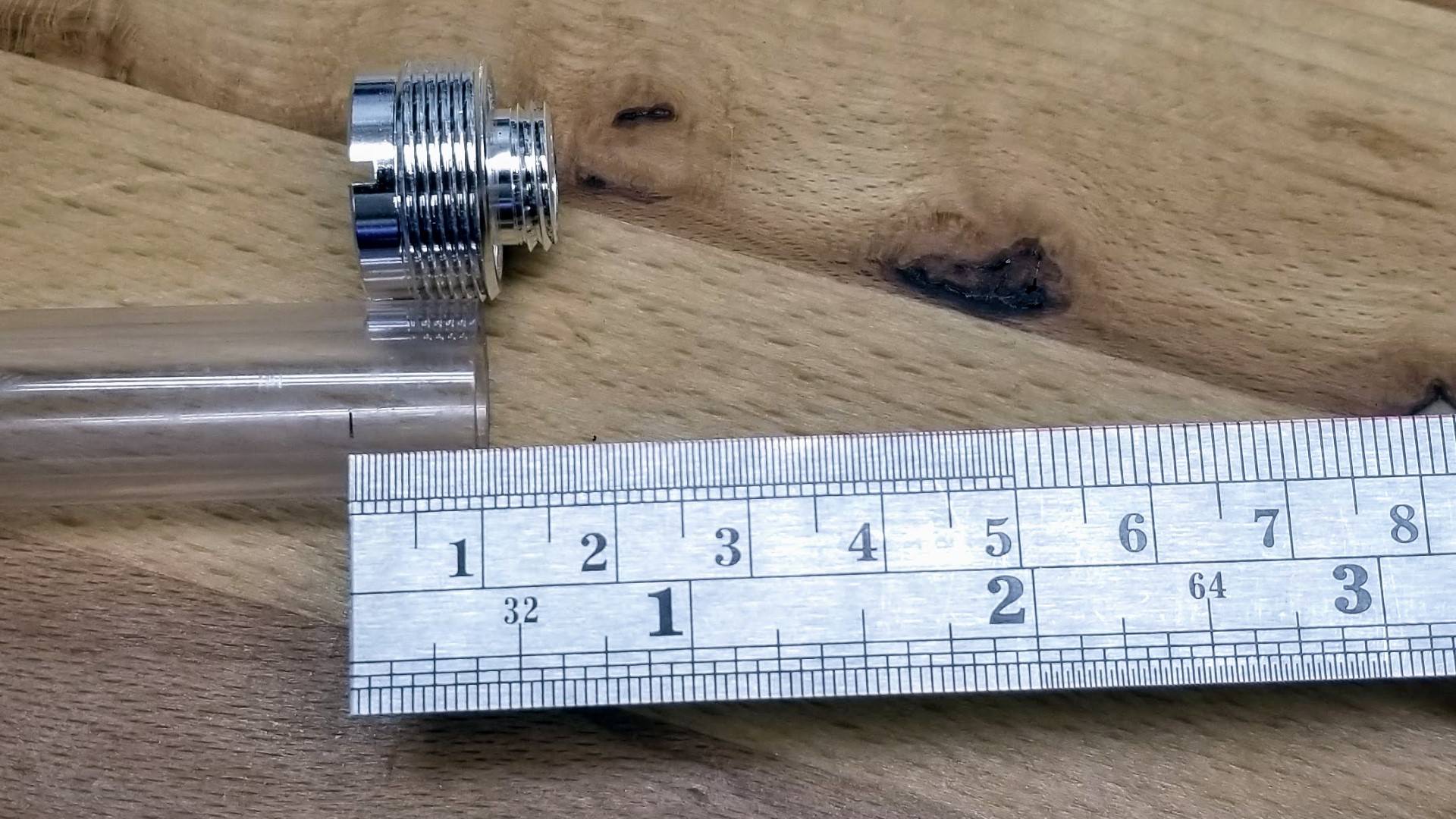

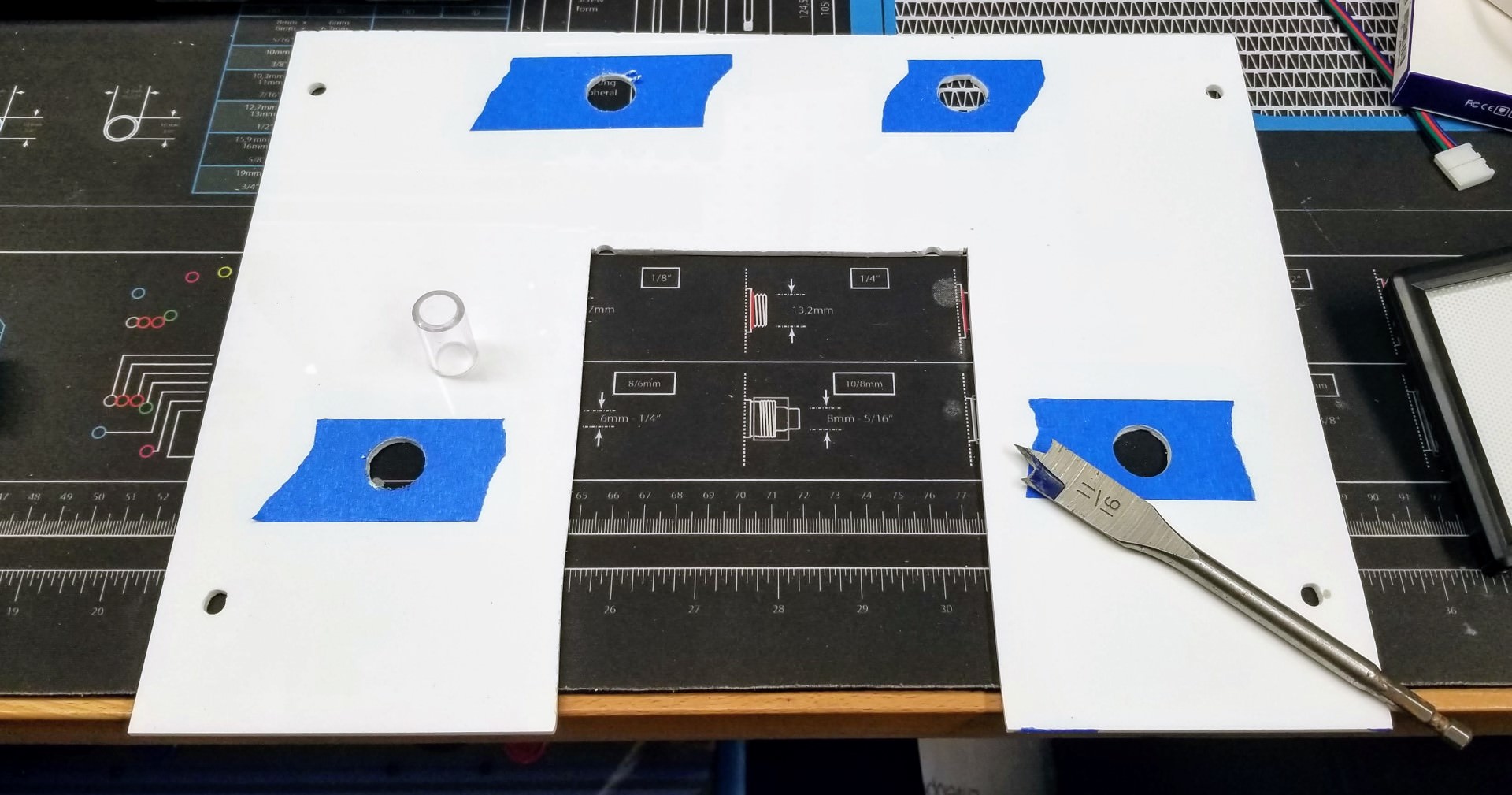

- Tubing (Hard) Monsoon Hardline PETG Tubing 1/2" ID, 5/8" OD (16mm) 36inx3 x1

- Tubing (Soft) PrimoFlex Advanced LRT 3/8in.ID x 5/8in.OD Tubing Bundle (10ft pack) x1

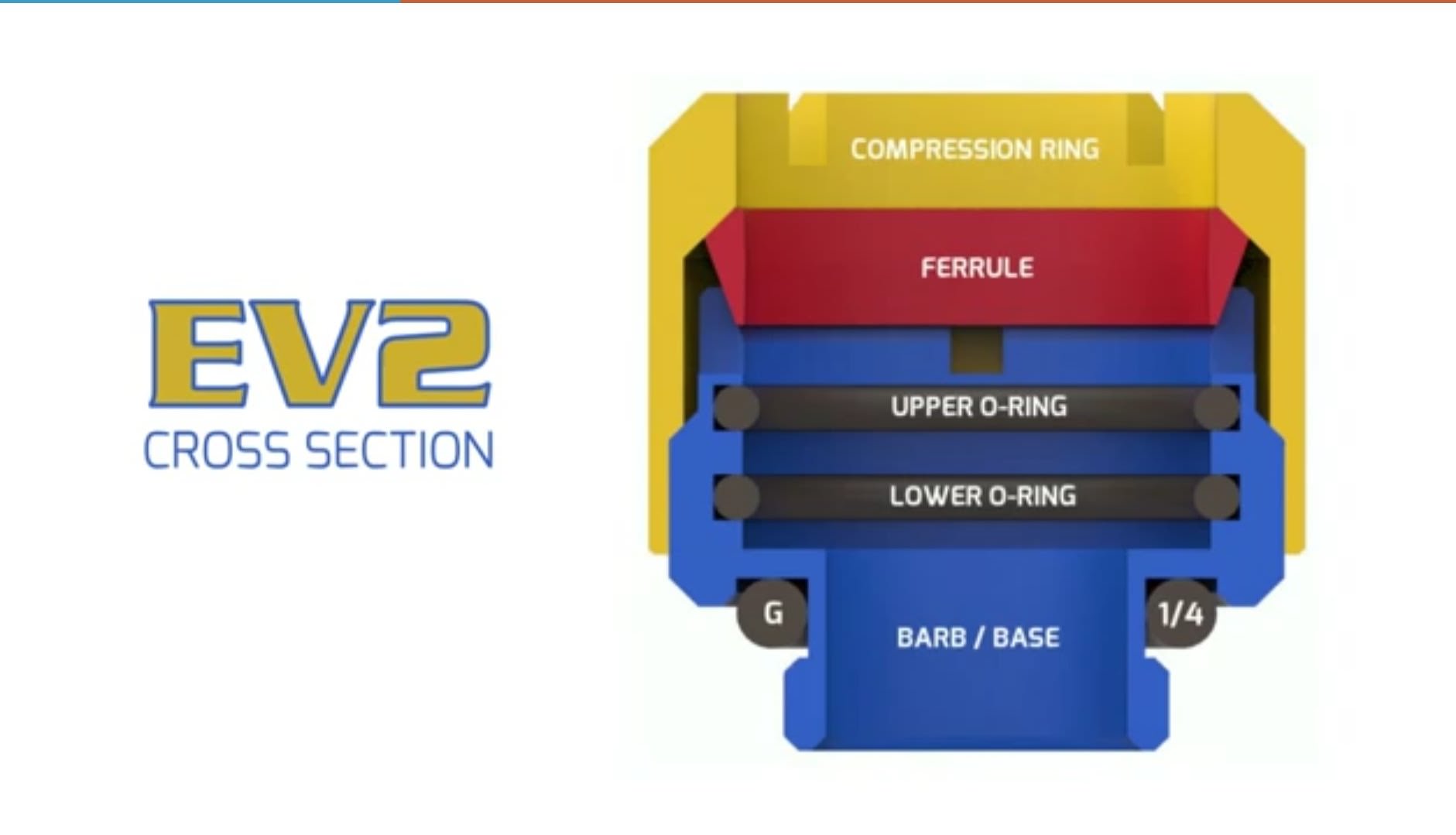

- Fittings Monsoon to 1/2" ID, 5/8" OD Hardline Eco V2 Compression Fittings x6 x3

- Fittings Barrow G1/4" Fittings (Various) x46

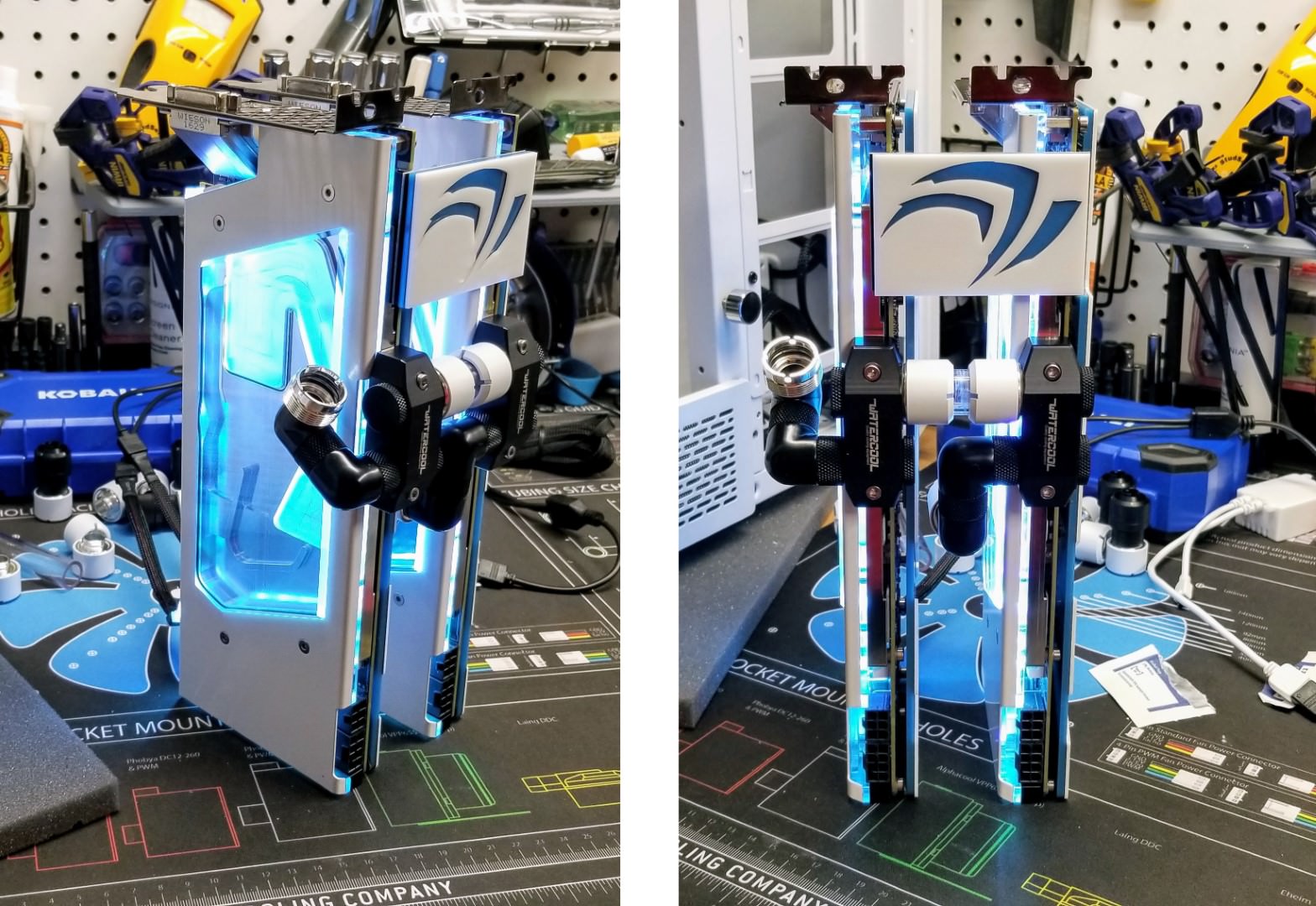

- Fittings XSPC G1/4" Ball Valve, Black Chrome x2

- Waterblock CPU EK X299 Monoblock x1

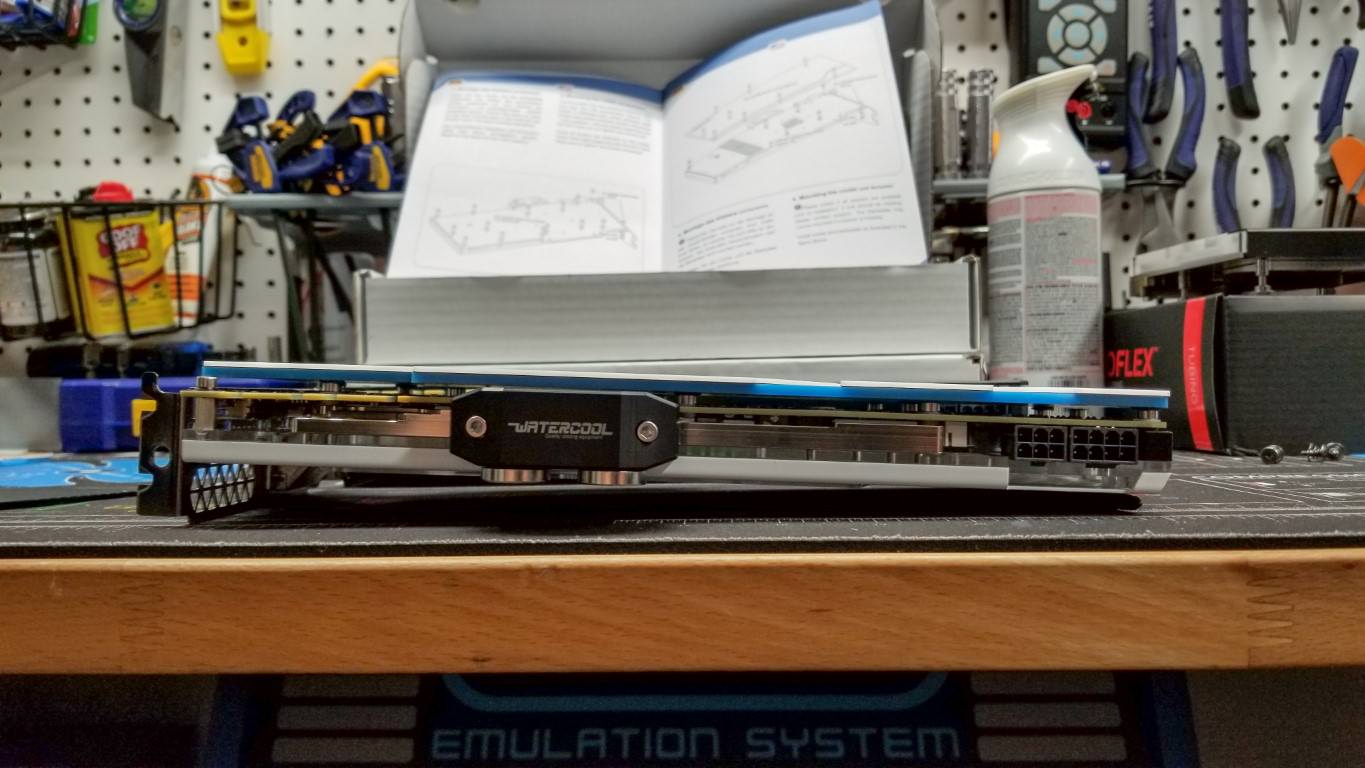

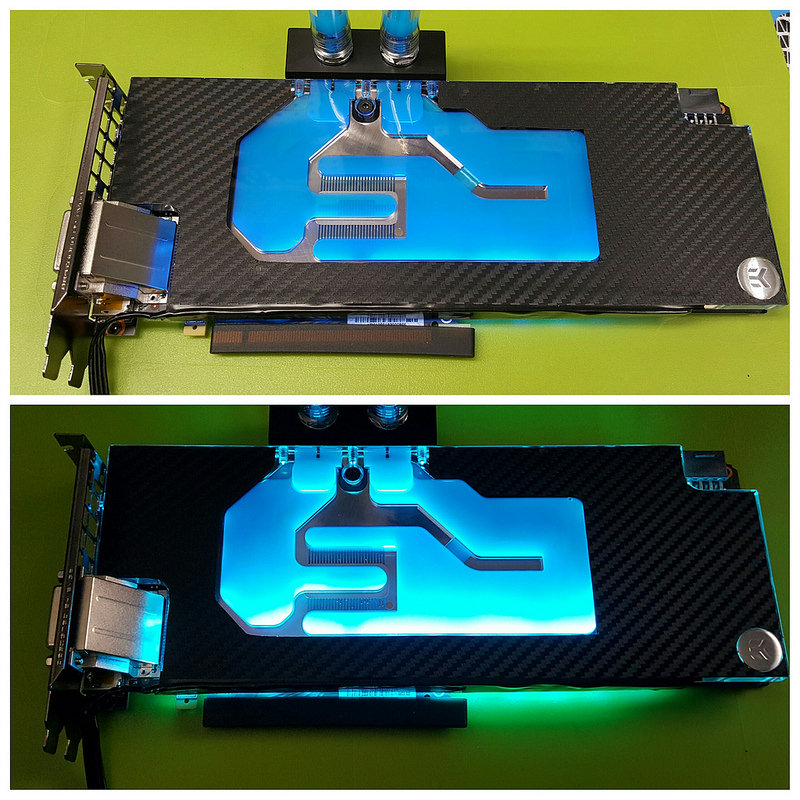

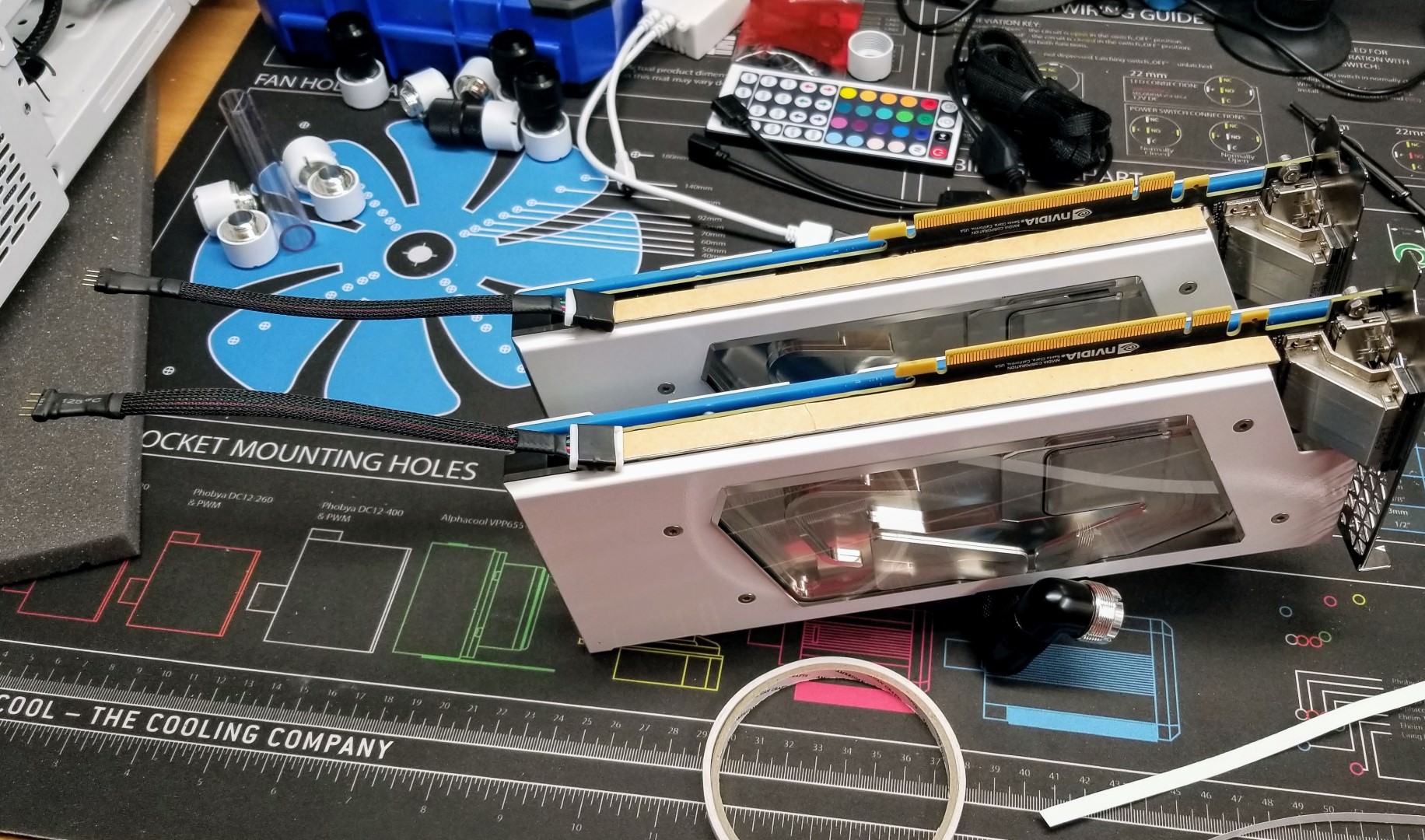

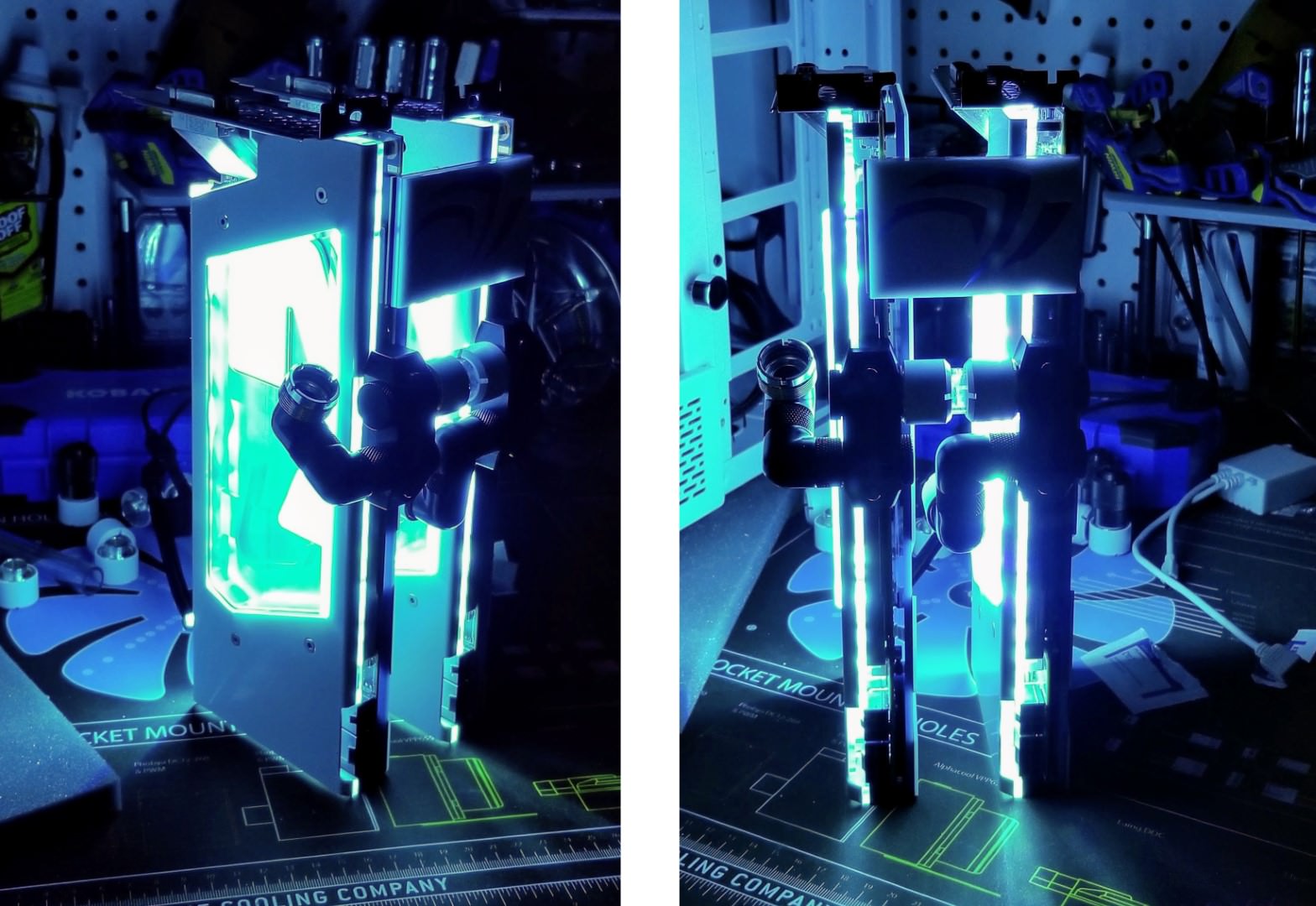

- GPU Waterblock Watercool HEATKILLER for Titan X Pascal - ACRYL Ni x2

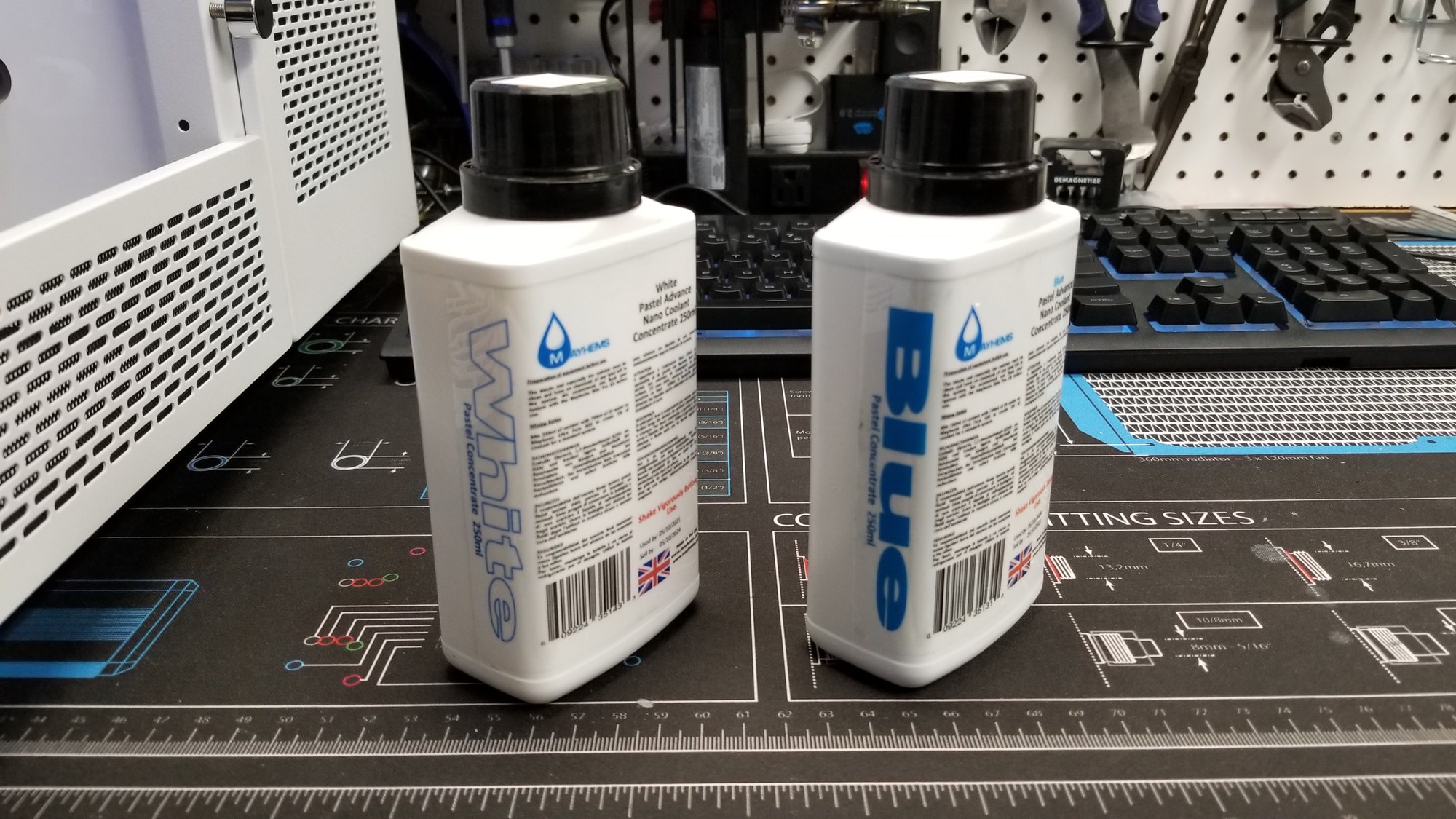

- Coolant Additive Mayhems Pastel Concentrate White - 250ml x1

- Coolant Additive Mayhems Pastel Concentrate Blue - 250ml x1

- Misc Barrow Replacement G1/4" O Ring - 10pcs - Blue x2

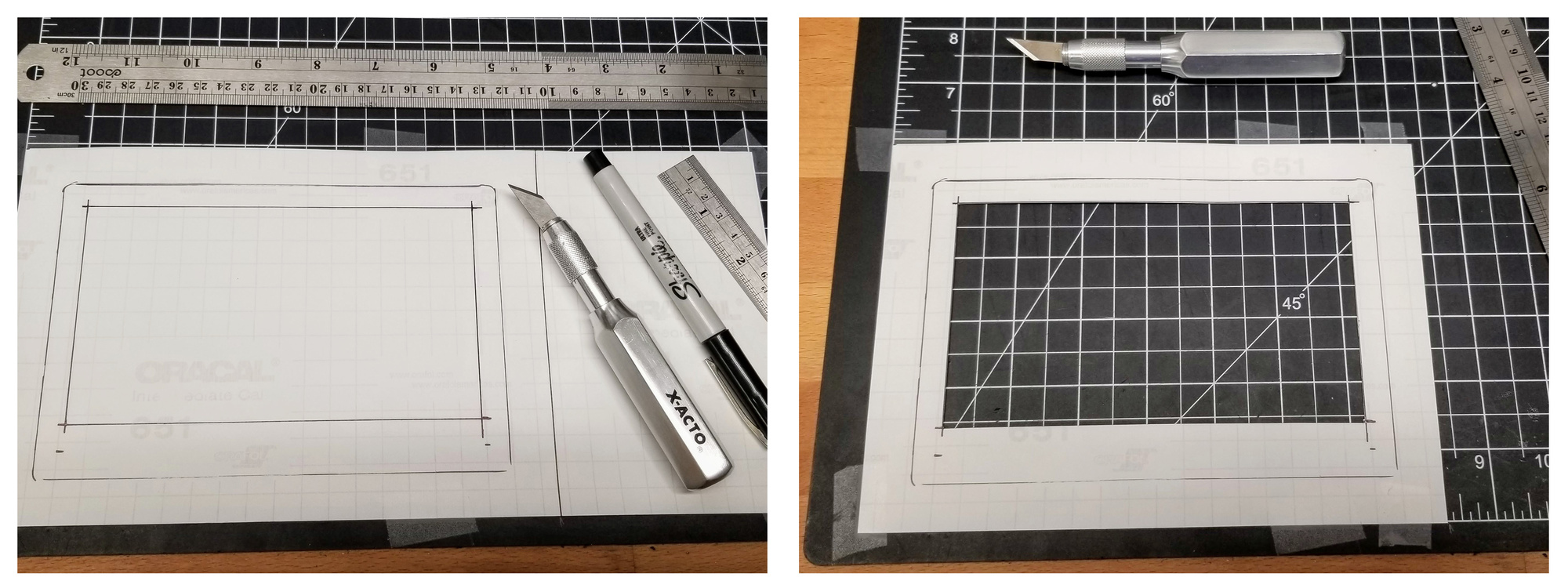

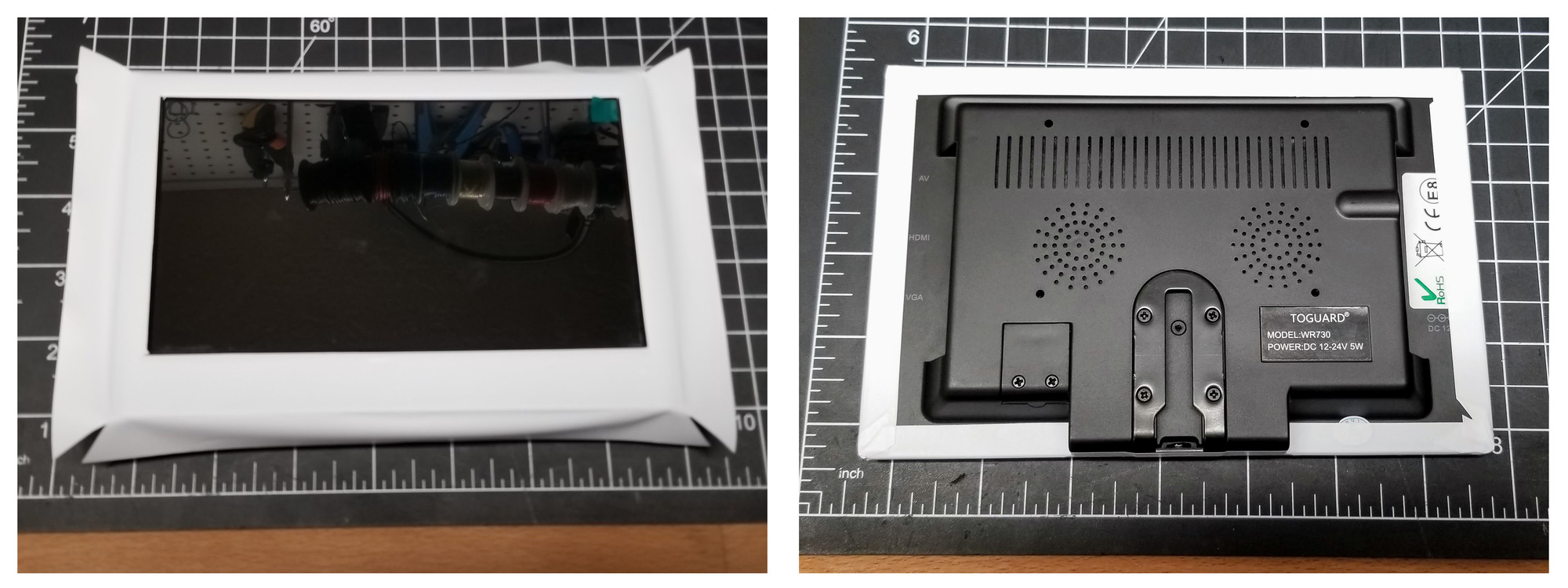

- Display Toguard 7 inch Ultra-Thin High-Res 1024x600 HDMI Monitor x1

- Misc Flat Slim High Speed HDMI Extension Cable x1

- Misc USB 2.0 Male to Micro USB 90 degree Angled Cable x1

- Misc DC Barrel Power Plug Pigtail Cable 12v x1

Build Log Project Index

- Intro / Component List

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)